Materials and structures at cold-region and Arctic low temperatures: A state-of-the-art review

Abstract

Construction of infrastructures in cold regions and the Arctic has grown rapidly since the 2000s, including railways, platforms, bridges, roads, and pipelines. However, the harsh low temperatures significantly influence the mechanical behaviors of construction materials, and bring safety and durability challenges to these engineering structures. This study made a state-of-the-art review on materials and structures exposed to low temperatures. This review started from constructional-material mechanical properties, including concrete, steel reinforcement, mild/high-strength steel plate, and steel strand at low temperatures. It reflected that low temperatures improved the strength of construction materials. However, the freeze–thaw cycles (FTCs) had a detrimental effect on the modulus and strength of concrete. Furthermore, it was revealed that low temperatures increased the interfacial bonding strength between the steel reinforcements (or shear connectors) and concrete. Moreover, low temperatures improved the bending, shear, and compression resistances of reinforced concrete (RC) or prestressed concrete structures, but reduced the ductility of RC columns under lateral cyclic loads. Finally, reviews also found that low temperatures improved the compression resistance of concrete-filled steel tubes using mild, high-strength, and stainless steels, whereas FTCs and erosion reduced their compression capacity. In addition, low temperatures increased the bending resistance of steel–concrete composite structures, but the FTCs reduced it. The low temperatures bring challenges to the safety and resilience of engineering constructions, which requires careful further studies. Continuous further studies may focus on the durability of materials and the resilience of structures under diverse hazards, including earthquakes, impacts, and even blasts.

Abbreviations

-

- AC

-

- artificial corrosion

-

- CC

-

- concrete crushing

-

- CFRP

-

- carbon fiber reinforced polymer

-

- CFSTs

-

- concrete-filled steel tubes

-

- DI

-

- ductility ratio

-

- FE

-

- finite element

-

- FT

-

- freeze–thaw

-

- FTC

-

- freeze–thaw cycles

-

- HSRs

-

- high-speed railways

-

- HSS

-

- high-strength steel

-

- LNG

-

- liquid natural gas

-

- LT

-

- lowest temperatures

-

- LWC

-

- lightweight concrete

-

- NWC

-

- normal weight concrete

-

- OB

-

- outward buckling

-

- PC

-

- prestressed concrete

-

- PCB

-

- prestressed concrete beams

-

- RC

-

- reinforced concrete

-

- RCBs

-

- reinforced concrete beams

-

- SCC

-

- self-compacting concrete

-

- SCCSs

-

- steel–concrete composite structures

-

- SCSSC

-

- steel–concrete–steel sandwich composite

-

- SEM

-

- scanning electron microscopy

-

- SFRCC

-

- steel fiber reinforced cementitious composite

-

- SS

-

- stainless-steel

-

- TF

-

- tensile fracture

-

- UFHSSTs

-

- UHPC-filled HSS tubes

-

- UHPC

-

- ultrahigh performance concrete

1 INTRODUCTION

Recently, engineering constructions in cold and Arctic regions have increased rapidly due to the fast-developing economy and activities of human beings, for example, railways built in Tibet and Northern China (see Figure 1).1, 2 The Arctic and cold regions become essentially important due to their rich natural resources,3 for example, the Arctic stores about 13% (or 30%) undiscovered oil (or gas) in the world.4 The explorations of these oil (or gas) resources promoted the engineering constructions for their storage and transportation, for example, platforms, containers, and pipelines. Since these engineering structures were constructed in the harsh cold-region or Arctic environments, the construction materials and structures at low temperatures deserve in-depth investigations to make sure these infrastructures are safe and durable.

The Arctic experienced a wide temperature range, which varied from winter lows of −72°C to summer highs of +30°C.5-8 Meanwhile, in winter, the northern China experiences the minimum temperature of about −50°C.9 At low temperatures, waters in the concrete tend to be frozen, and the microstructures of steel also changes, which changes their mechanical properties at low temperatures. Moreover, structural behaviors of engineering constructions were also affected by the low temperatures. Therefore, investigating materials and structures at low temperatures is important and necessary.

2 ENGINEERING CONSTRUCTIONS AT LOW TEMPERATURES

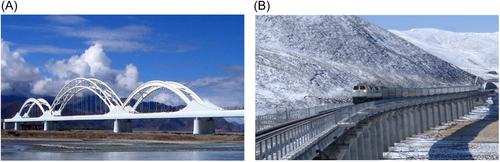

2.1 High-speed railway (HSR) bridges

In the new century, the railways in northern China achieved fast developments, for example, Qinghai–Tibet Railway (see Figure 2A). This railway, connecting Xining and Lasa, China, is about 2000 km long, and crosses the Qinghai–Tibet Plateau that was exposed to the low temperatures of about −50°C. After the new millennium 2000s, the HSRs of China were extensively built, and amounts of them were constructed in cold northern China, for example, Harbin-Dalian HSR in northern China (see Figure 2B), Mudanjiang-Jiamusi HSR in Figure 2C, Beijing-Harbin HSR in Figure 2D, Beijing-Zhangjiakou HSR in Figure 2E, and Lanzhou-Urumqi HSR in Figure 2F. These constructed HSRs in northern China were also exposed to the lowest temperature of about −50°C.

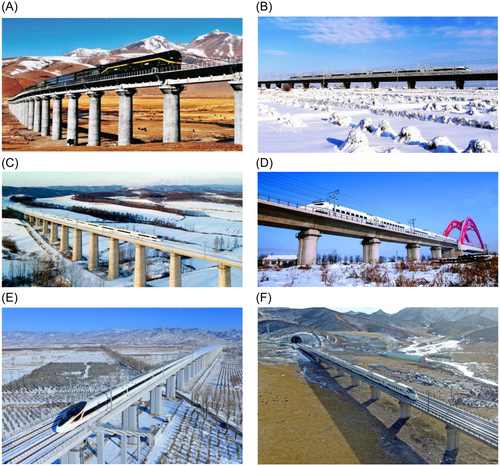

2.2 Bridges

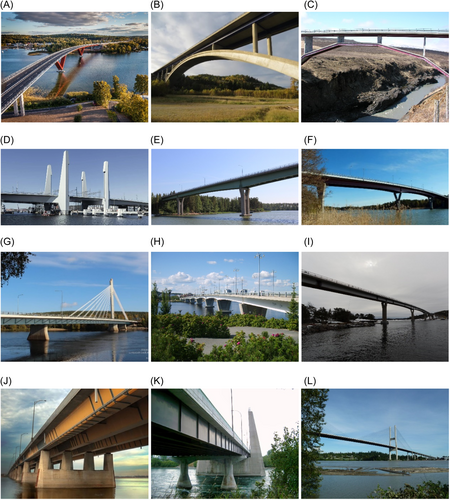

Bridges are important engineering structures for railway and road transportation systems. In the Arctic and cold regions, different kinds of bridges have been built. Figure 3A–D shows the highway–railway combined steel bridges built in China, Canada, and Russia.16-19 These constructed steel bridges in northern China and Canada were also exposed to the lowest temperature of about −50°C. Therefore, the steel materials and structural members in these bridges at low temperatures are reserved for in-depth investigations.

Including the steel bridges, numerous reinforced concrete (RC) or composite bridges have been built in the countries around the Arctic circle as listed in Figure 4, for example, Sweden, Finland, and Canada.20-31 These concrete or composite bridges were exposed to the Arctic low temperatures of −50°C to −60°C. Therefore, investigating behaviors of concrete materials and structures at low temperatures becomes necessary.

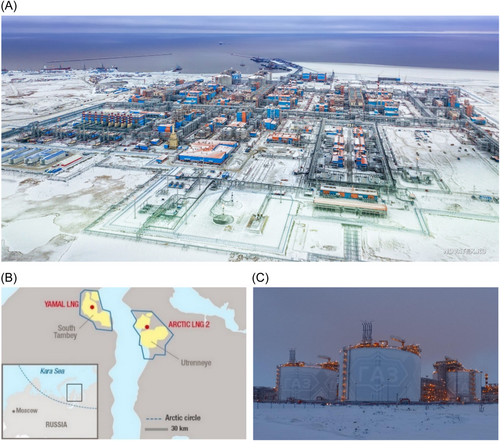

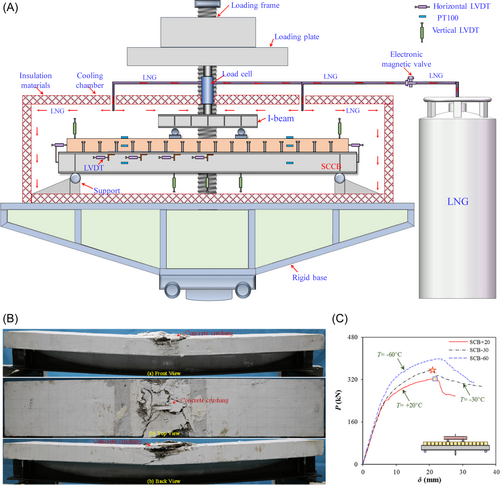

2.3 Liquid natural gas container

The liquefied natural gas (LNG) provides clean energies for the industry and daily life. The Arctic reserves about 1/3 undiscovered gas of the world, and the explorations in this region have been performed for many years. The Yamal project, locating in the Arctic, Russia, reserves about 1.3 trillion cubic meter LNG, and was started in December 2013. In 2018, the first ship of LNG produced by the Yamal project was transported to China. To assist in the storage and transportation of these LNG, several concrete LNG containers were constructed, as shown in Figure 5, which were exposed to the low temperature below −60°C.

Moreover, to reserve the LNG, amounts of RC containers have been built in different countries. At the end of year 2022, more than 40 LNG containers have been built in China. During the services, these RC containers were under a high risk of LNG leakage, which would expose them to the lowest temperature of about −160°C. Therefore, to ensure the safety of these LNG containers during service life, performing studies on the RC structures at extremely low temperatures above −160°C becomes necessary.

2.4 Platforms and pipelines

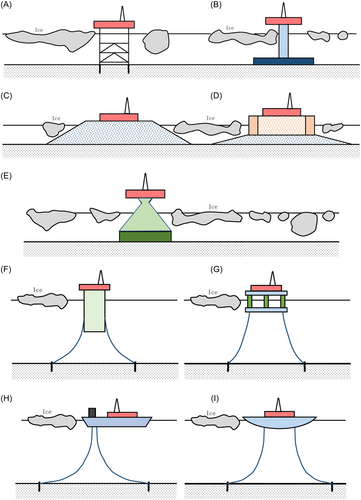

As revealed by the U.S. Geological Survey,4 the undiscovered oil (or gas) in the Arctic occupies about 13% (or 30%) of the world's reserve. Most of these reservations in the Arctic were distributed along the continental shelf within a seawater depth of 0–500 m. To make explorations of these oil (or gas), different types of platforms have been developed, as shown in Figure 6. Traditional jacket structure (see Figure 6A) has been used for oil exploration in Bohai Gulf, China, after the 1960s. The monopod tower provides another type of platform for oil exploration, as shown in Figure 6B, which has been already used in Southern Alaska. An artificial island, as shown in Figure 6C, provides economic solutions for oil explorations in shallow seawater, which has already been adopted for several projects on the North Alaska coast.3 As the depth of the sea increases, a caisson-retained island, as shown in Figure 6D, is an optional structural form, for example, the Molikpaq caisson in Beaufort Sea, USA. Gravity-based conical platform, as shown in Figure 6E, provides the solutions for oil explorations within a seawater depth of 0–100 m, which has already been used in on-site projects in the North Sea. For deep-sea oil explorations, the floating platform provides solutions, as shown in Figure 6F–I.

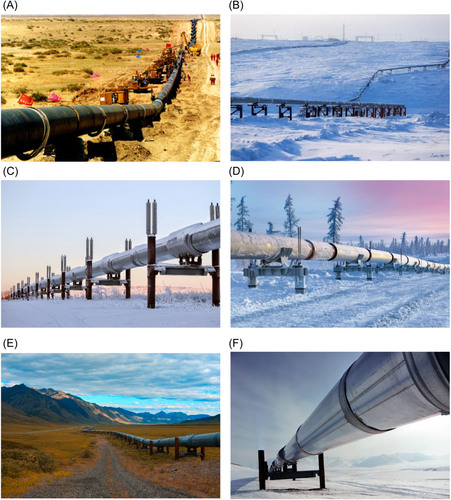

After the oil and gas explorations in cold regions, the pipelines act essentially on their transportations, for example, the national project of Natural Gas Transmission from the West–East of China (see Figure 7A), the Yamal–Europe pipelines transporting natural gas from Russia to Austria, as shown in Figure 7B, the Eastern Siberia to Pacific Ocean oil pipeline, as shown in Figure 7C, the Russia–Europe Druzhba pipeline, as shown in Figure 7D, Keystone Pipeline connecting Canada and USA, as shown in Figure 7E, and Mackenzie Valley LNG pipeline connecting Mackenzie and northern Alberta, Canada, as shown in Figure 7F. All these pipelines suffer the lowest temperature in winter within −50°C to −60°C, which critically changed their safety during the service.

The review revealed that amounts of engineering infrastructures, for example, bridges, railways, platforms, pipelines, and containers, have been constructed and put into service in the cold or Arctic regions. During their services, these engineering infrastructures face low temperatures dropping to about −80°C or even lower to about −160°C for LNG containers. The low temperatures challenge the mechanical properties of construction materials, and finally influence the mechanical behaviors of structures.

3 CONSTRUCTION MATERIALS AT LOW TEMPERATURES

3.1 Concrete at low temperatures

RC or prestressed concrete (PC) structures act essentially in the cold/Arctic-region infrastructures, LNG containers, and platforms. Mechanical properties of concrete provide the basis for analysis/design on RC/PC structures. Normal weight concrete (NWC), ultrahigh performance concrete (UHPC), and lightweight concrete (LWC) are included in this review.

3.1.1 Compressive behaviors

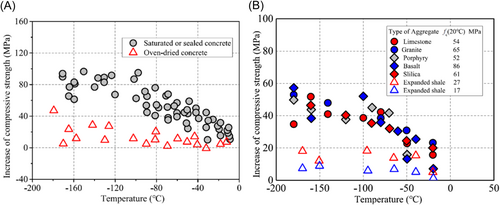

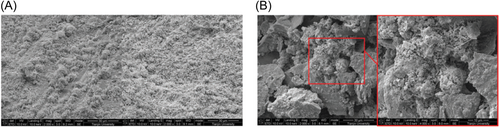

Amounts of research studies have been reported on mechanical properties of NWC at dropping low temperatures. Lee et al.39 and Yamane et al.40 both conducted research on the compressive/tensile strength of NWC at various low temperatures. Lee et al.39 focused on temperatures ranging from −70°C to 20°C and found that as T decreased from 20°C to −70°C, the compressive strength (fc) and splitting tensile strength (ft) of NWC increased by approximately 100%, with Poisson's ratio also increasing by 50%. Yamane et al.40 extended the low-temperature range from −10°C to −196°C and observed that the fc, ft, and modulus of elasticity (Ec) of NWC also increased within this range. Moreover, they found that the increments of fc, ft, and Ec were much larger for NWC with higher moisture. Tognon41 studied the mechanical behaviors of mortars/concretes at T = 20 to −196°C, and found that the concretes with different types of cements exhibited close improvements in fc as the temperature dropped to −196°C. Marechal42 studied the Ec at T = 500 to −160°C, and found that as the T decreased to −50°C, −100°C, and −160°C, the Ec of concrete was increased by about 35%, 20%, and 36%, respectively. Continuous works focused on the applications of NWC in LNG container. Krstulovic-Opara43 reviewed the previous studies on the concrete used in LNG storage. Continuous reviews on the concrete for LNG storage were made by Kogbar et al.,44 Jiang et al.,45 and Lin et al.46 Their works revealed that the Wc, w/c, and aggregate type greatly influenced the increasing rate of NWC fc, as shown in Figure 8. Further studies were extended to UHPC, Kim et al.47-49 researched the mechanical properties of UHPC at T = −170°C. They found that both compressive/tensile strengths of UHPC were significantly improved, but the tensile strength of NWC was not affected.

Filiatrault and Holleran50 studied the compression behaviors of NWC at −40°C at a strain rate of 0.1/s. Rostásy and Wiedemann51 researched compression behaviors of NWC at −170°C, which showed large increases in the modulus and strength under compression. Moreover, the water-saturated NWC exhibited larger increments in the elastic modulus/compression strength than those of normally-stored NWC. MacLean and Lloyd52 studied compression behaviors of C30 and C50 NWC at T = 20°C, −10°C, −40°C, and −70°C. They found that as T drops to −70°C, the compression strength and Ec of NWC receive their respective maximum increments of about 43% and 59%. Liu et al.53 also researched the low-temperature compressive behaviors of NWC, LWC, and ultralightweight concrete. They also found that the concretes with higher water content and larger w/c ratio received higher improvements in their compressive strength and modulus. Moreover, these improvements were also affected by the concrete type.

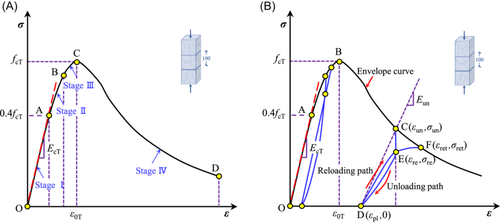

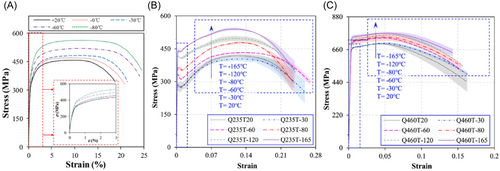

Recently, Xie et al.55 and Kang et al.56 studied behaviors of different grades of NWC under monotonic and cyclic compression loads at T = 20°C to −80°C. They found that as the T dropped from 20°C to −80°C, the NWC peak compression strain was not affected, but their fcu, fc, and Ec of C55 NWC were significantly increased by 47.3%, 69.0%, and 45.3%, respectively. Besides, it was revealed that the cyclic compressive stress–strain behaviors exhibit similar patterns to those observed under monotonic loading. In addition to the study on NWC, Kang et al.57 also investigated low-temperature monotonic/cyclic compression behaviors of UHPC. Finally, they proposed the monotonic/cyclic compression stress–strain models for NWC and UHPC at T = 20°C to −80°C, as shown in Figure 10.

3.1.2 Tensile behaviors

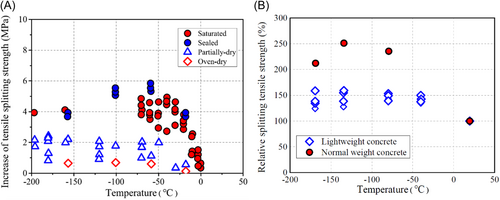

Previous studies pointed out that low temperatures generally improved the concrete tensile strength, and exhibited their maximum improvements at T = −30°C to −70°C.58, 59 Browne and Bamforth59 found that below −70°C, the increments in tensile strength due to the low temperature tended to remain unchanged. Meanwhile, Yamane et al.40 pointed out that as T dropped from 20°C to −50°C, the NWC tensile strength of wet and dry NWC was linearly increased by about 150% and 50%, respectively, and these increments tended to achieve their maximum values at −30°C to −50°C. Beyond that low-temperature range, the increments in tensile strength tended to be steady with slight reductions. This was mainly related to the frozen ice in pores. As the temperature decreased, the water in gel and capillary pores gradually froze and formed ice mesh inside, which acted similarly to the fibers and could support the load applied to the concrete. Meanwhile, the increased strength of ice at low temperatures improved the tensile strength of concrete. However, due to the different pore structures of various concrete, the ice mesh structure varied at low temperatures. The different freezing processes of pore water resulted in the maximum tensile strength of concrete varying in the range of −30°C to −70°C. Subsequently, as the temperature decreased further, the ice was subjected to increasing temperature stresses. When the ultimate tensile strain of ice was reached, the ice mesh began to collapse, which led to a slight decline in the tensile strength of the concrete. In summary, the increasing rate of tensile strength for NWC was affected by their Wc, aggregate type, and w/c.39, 40, 45, 60, 61 And the moisture content and aggregate type exhibited the most significant influences. Figure 11 shows that larger moisture-content concrete received larger strength improvements as T drops, and the tensile strength of LWC exhibits much smaller influences than that on NWC by the dropping T. The increased concrete tensile strength by reducing T due to the ice-net structure.62 In this theory,62 after the frozen of the capillary water, these frozen ices formed a structural net frame in NWC. Once the concrete is under tensile force, this formed ice-net frame partly shares the tensile force that acts the functions of steel or other types of fibers in concrete, which finally improves the concrete tensile stress. The ice-net tensile strength increased with the dropping T till to a specific value. Beyond this value, the concrete contraction tended to destroy this ice-net structure, and thus reduced its tensile resistances. Including these key influencing factors, Shi et al.63 found that higher-grade concrete showed a smaller increase in low-temperature tensile strength.

Including the splitting tensile strength, the first-mode fracture behavior of concrete was researched. NWC fracture behaviors at T = 20°C, −20°C, −70°C, −120°C, and −170°C were researched by Maturana et al.64 and Rocco et al.65 Continuous experimental studies on concrete fracture behaviors at 20°C, 0°C, −20°C, and −40°C have been reported by Hu and Fan66 and Fan et al.67 These studies showed that as T drooped the concrete fracture energy and toughness were improved, but its characteristic length was reduced.

In addition, low-temperature tensile behaviors of UHPC have been experimentally studied. Flexural tensile behaviors of UHPC at T = −20°C have been experimentally studied by Fang et al.68 Their studies showed that as the temperature dropped, the UHPC tensile strength was increased, but its ductility was reduced. Moreover, Kim et al.47, 48 found that at −165°C, the compressive/tensile strength of UHPC was improved. He et al.69 studied the influences of fibers on the flexural behaviors of UHPC after exposure to low temperatures. They found that UHPC adding steel fibers exhibited larger flexural tensile strength than those with PP and PVA fibers.

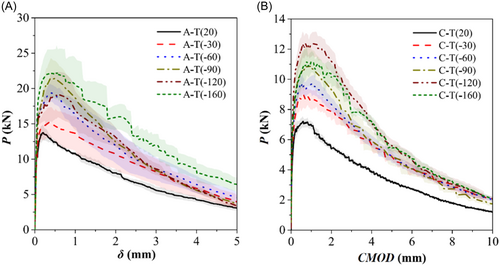

Xie et al.70 experimentally investigated the NWC fracture behaviors at T = 20°C to −80°C through 72 three-point notched NWC beams. They found that the low temperatures improved the cracking and ultimate resistances of NWC beams. As T dropped to −80°C, the NWC fracture toughness (or fracture energy) was significantly improved. This was mainly due to the increased tensile strength by low temperatures. Furthermore, Liu et al.71 researched fracture and flexural behaviors of UHPC at T = 20°C to −160°C (see Figure 12). Finally, models for fracture energy were developed for NWC and UHPC.

3.2 Steels at low temperatures

Steel materials are widely utilized in engineering constructions. Nevertheless, their mechanical properties are significantly affected by dropping temperatures.

3.2.1 Steel reinforcements

Extensive research works were made to investigate the low-temperature tensile behaviors of reinforcements. Elites et al.72 performed tensile tests on hot-rolled/cold-stretched reinforcing steels at 20°C to −180°C. Their tests revealed that the yield/ultimate (fy/fu) strength of these reinforcements was improved with the dropping T. The fy and fu of hot-rolled/cold-formed steel reinforcements were increased by 88%/42% and 94%/67% at −180°C, respectively. Sloan73 pointed out that the steel-reinforcement fy and fu were improved by 26% and 24% at about 40°C. Montejo et al.74 also performed tensile tests on reinforcing-steel coupons at T = 20°C to −40°C. They observed that the reinforcing-steel fy and fu were improved by about 10%–12% at −25°C to −40°C. Dahmani et al.75 reviewed previous studies and pointed out that reinforcing steel received a notable increase in the yield/ultimate strength as the temperature dropped to −196°C, but the elastic modulus was slightly increased. Filiatrault and Holleran50 performed tensile tests on steel reinforcements at combined T and varying strain rates. Their test results showed that strain rates below 0.1/s and low temperatures (−40°C) increased the steel-reinforcement fy (or fu) by about 20% (or 10%). Levings and Sritharan76 also carried out tension tests on ASTM 420 (60) steel reinforcements at T = 20–40°C and strain rates of 0.003–0.3/min. They observed that the yield (or ultimate) strength of ASTM 420 (60) was increased by 5.1% (or 6.3%) as T dropped from 20°C to −40°C.

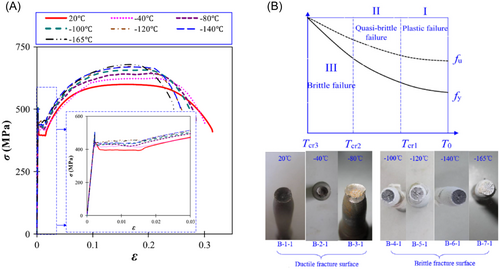

Yan and Xie77 investigated low-temperature mechanical properties of Chinese HRB335 and HRB400 reinforcing steel between 20°C and −165°C. As illustrated in Figure 13, the yield/ultimate strengths of HRB335 and HRB400 were significantly improved, but their ductility was compromised. Decreasing the T from 20°C to −165°C received a respective average increase of 23% (14%) and 17% (14%) for HRB335 and HRB400, but reduced the ultimate tensile strains of HRB335 and HRB400 reinforcements by 33% and 34%, respectively. Moreover, the increasing factors for those reinforcements due to low temperatures were also developed based on these test data.

3.2.2 Steel strands

Previous limited studies have been made on low-temperature mechanical properties of steel strands. Peng et al.78 studied the working mechanism of wire rope at T = −5°C, −10°C, and −15°C. Planas et al.79 researched low-temperature influence on tendon anchorages. Tensile behaviors of three-wire strands at 20°C to −165°C have been experimentally studied by Xie et al.80 They found that compared with strands at 20°C the steel strand's yield/ultimate strength at −165°C was increased by 13%/8% whilst the ultimate tensile strain was reduced by about 34%. Furthermore, Xie et al.81 conducted 21 tests on steel wire in strands at T = 20°C to −160°C, and obtained their stress–strain behaviors (see Figure 14). As shown in Figure 14, the yield and ultimate strengths of steel wires were increased by approximately 20% as T decreased from 20 to −160. Additionally, the figure further illustrated that as T dropped below −100°C, the failure mode of the steel wire changed from ductile to brittle mode. From these obtained low-temperature mechanical properties of steel wire, the constitutive stress–strain models of different multilayer strands can be obtained by theoretical and empirical models. In addition, the stress relaxation and thermal expansion behaviors of steel strands at T = 20°C to −165°C were also studied by Xie and Yan82 and Yan et al.83

3.2.3 Normal mild steel plate

Pisarenko et al.84 carried out tension tests on structural steels and alloys at T = −196°C and −270°C, and found that the decreasing T improved the strength of tested steels.

Polyzois et al.85 studied mechanical behaviors of cold-formed steel angles at T = 25°C to −45°C, and found that the fy (or fu) of steel angles at −40°C was increased by 8% than that at room temperatures. Abdel-Rahim and Polyzois86 investigated the low-temperature mechanical properties of A715 (60) and G40.21-300W steel. They pointed out that decreasing T to −50°C improved the strengths of these tested steel materials. Wang et al.87 performed extensive investigations on constructional steels at T = 20°C to −60°C, for example, Q235, 16Mn, 15MnV, 16Mnq, and 14MnNbq. They found that reducing T increased the fy and fu of constructional steels, but reduced their ductility indexes. Besides, Wang et al.88 investigated fracture behaviors of Q345B steels at 20°C to −60°C. They revealed that decreasing T reduced the fracture toughness of concrete. Hu et al.89 conducted tension tests on DH36 steel at 20°C, 0°C, −20°C, −40°C, and −60°C. As T reduced from 20°C to −60°C, the fy and fu of DH36 were increased by 15.7% and 14.9%, respectively. Moreover, studies90, 91 have been performed on fatigue performances of mild steels at decreasing T.

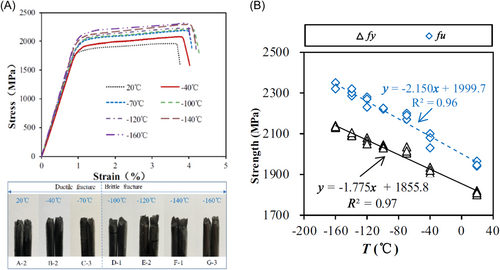

Mechanical behaviors of headed studs at T = 20°C to −80°C were studied by Xie et al.92 through 56 tension tests, and they pointed out that as T decreased to −80°C, the headed-stud yield strength was increased by about 10%, and its fracture strain was not reduced but even increased by about 20% (see Figure 15A). Besides, Xie et al.93 studied tensile stress–strain behaviors of China-standard Q235–Q460 steels at T = 20°C to −165°C and developed corresponding low-temperature stress versus strain models (see Figure 15B,C).

3.2.4 High-strength steels (HSSs)

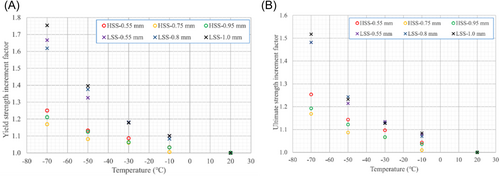

Low-temperature mechanical behaviors and fracture toughness of Q460C HSS and corresponding butt weld have been experimentally studied by Liu et al.94 They revealed that reducing T increased the fy and fu, but reduced the fracture toughness of Q460C HSS. Tong et al.95 studied the toughness of HSS under impact loads with yield strengths of 460–960 MPa at −40°C to 20°C. The test results showed that the impact toughness of HSS with the same nominal yield strength and plate thickness diminished as the temperature decreased. Additionally, the SEM micrographs confirmed that the Q690 and Q960 HSS exhibited ductile fracture at 20°C with more dimple structures, and brittle fracture at −40°C with more significant tongues or river patterns. Rokilan and Mahendran96 studied the mechanical behaviors of mild steel and HSS at T = 20°C to −70°C, and found that mechanical behaviors of mild steel were significantly increased by the reducing T (see Figure 16).

Perez-Martin et al.97 studied the impact toughness of HSS at T = 20°C to −90°C through Charpy V-notch tests. They found that the HSS impact energy slightly increased with the dropping T. Parkes et al.98 performed tensile tests on dual-phase steel and HSS and laser-welded joints at −40°C, 25°C, and 180°C. They pointed out that decreasing the T increased the Es, fy, and fu of HSS and joints. Moreover, Zhang et al.99 studied the influences of T = −30°C to 25°C and stress amplitudes (0.5, 0.7, 0.9fy) on fatigue performances of Q420B steel. They found that decreasing T improved the fatigue behaviors of Q420B steel. These previous reported investigations pointed out that the reducing T has positive effects on the Es and strength of steels, but reduced their ductility. However, these influences greatly depend on their containing elements and microstructures. Moreover, most of the previous investigations less focused on the tensile stress–strain behaviors of steels at reducing T.

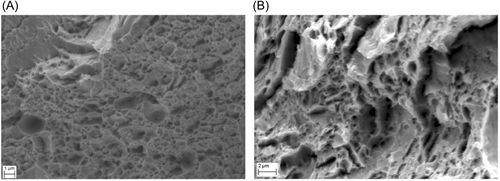

Yan et al.100-102 studied the influences of T = −165°C to 20°C on mechanical properties of HSS Q690/Q690E/Q960E/S690 and normal steels. They revealed that the fy and fu of normal steel or HSS were improved by the decreasing temperature. The full-range stress–strain models were finally developed for normal steel and HSS at low temperatures. These increments in the strength of steels at low temperatures can be attributed to several factors103: (1) Dislocation motion inhibition. At low temperatures, the reduced thermal energy within the steel lattice slows down atomic movements, which inhibits dislocation motion within the material. This makes the steel less prone to deformation and, consequently, exhibits higher strength. (2) Lattice structure changes. Low temperatures cause the lattice structure of steel to become more compact and stable, reducing the mobility of lattice defects. This closer packing results in greater resistance to deformation, and, therefore, enhanced strength of the steel. (3) Phase transformation. Certain steels undergo phase transformations at low temperatures, such as martensitic transformation. These transformations result in a more densely packed and complex crystal structure, with higher dislocation densities and grain boundary areas. These microstructural changes contribute significantly to the increased strength of steel at low temperatures. Figure 17A,B97 shows the microfracture surfaces of S960 HSS specimens after ambient temperature and −40°C tensile tests, respectively. A classic dimple structure was observed at both temperatures, which indicated ductile failure. Furthermore, these figures reveal that the dimples became shallower as T decreased, which implied a reduction in the ductility of S960 HSS at low temperatures.

The developments of LNG containers and cold-region infrastructures require investigations on corresponding steel at low temperatures. This section introduced five batches of low-temperature tensile tests on reinforcing steels for RC, HSS strands, mild steel, HSS, and headed studs in composite structures. These results revealed that the fy and fu of steel at low temperatures were obviously increased, which is mainly caused by the transmissions of steel microstructure at low temperatures, for example, lattice refinement and phase transformation. The dislocation movement is hindered. However, the ductility of steel materials did not necessarily decrease at low temperatures. By these test results, empirical formulae considering the key mechanical indexes of low temperature were proposed. Moreover, the stress–strain models of these steel at low temperatures were also proposed for the analysis/design of engineering structures exposed to low temperatures. However, quite limited studies have been reported on the cyclic stress–strain behaviors of steel at low temperatures, highlighting the need for further research in this area. Potential future research directions could include investigating the effects of low temperatures on the cyclic stress–strain response of different steel grades, and also exploring the potential for developing new materials or treatments to improve the cyclic performance of steel at low temperatures.

4 STEEL–CONCRETE INTERFACIAL BONDING (SCIB) AT LOW TEMPERATURES

4.1 SCIB in RC and PC structures

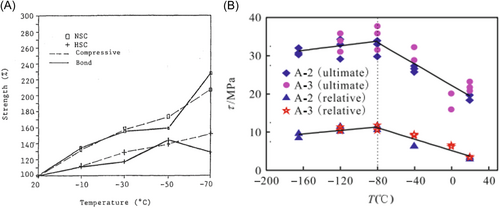

SCIB determines the stiffness, bending resistance and ductility of RC and PC members, which reserved in-depth investigations. Amounts of research works have been reported on low-temperature SCIBs. Shih et al.104, 105 experimentally studied the bar–concrete bonding behavior at T = 20°C to −70°C. They found that with the decreasing T from 20°C to −70°C, the ultimate bar–concrete bonding strength was improved by 28% and 127% for high-strength concrete and NWC, as depicted in Figure 18A. On the basis of their tests, Huang et al.106 proposed regression models to predict the low-temperature concrete–bar interfacial shear–slip relationships. Vandewalle107 investigated the steel bar–concrete bonding behaviors at T = 20°C to −165°C by the testing method. It showed that reducing T from 20°C to −120°C increased the bar–concrete bonding strength; however, this bonding strength reduced slightly at T = −120°C to −165°C. Jin et al.108 studied the low-temperature bar–concrete bonding behavior using numerical simulation methods.

Previous investigations on strand–concrete bonding (SCB) for PCs were mainly performed at room temperatures. Influences of anchorage length, concrete grade, and diameter of strand on the SCB have been reported in Salmons and McCrate109 and Cousins et al.110 (see Figure 18B). Figure 18 shows that the SCB strength increases linearly with the dropping T within 20°C to −80°C, and is maintained at T = −80°C to −165°C. Gustanvson111 carried out tests on the SCB behaviors, and found that the surficial roughness of steel strand significantly influenced interfacial bonding strength. Pozolo and Andrawes112 tested the bonding behaviors between prestressing strands and self-compacting concrete (SCC). They revealed that strands in SCC performed equally to those in NWC.

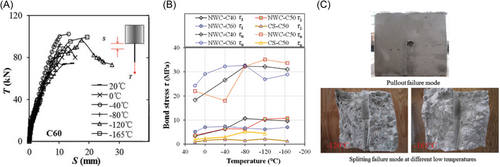

Xie et al.113 studied the steel bar–concrete bonding behaviors at T = 20°C to −80°C through 69 pulling-out tests. Their tests showed that this bonding strength increased linearly with the decreasing T. In addition, low-temperature SCB behaviors have also been studied. Xie et al.80, 114 performed pull-out tests on SCB behaviors at T = 20°C to −165°C. As shown in Figure 19, the typical load–slip curve associated with these tests could be characterized by three stages: initial elastic, slipping development, and recession stages. Furthermore, two typical failure modes were observed in the tests: pullout failure and splitting failure. Additionally, the figure showed that SCB stress at 1 mm slip and ultimate bond stress increased with reduced low temperatures. However, as T decreased from −80°C to −165°C, the bond stress exhibited limited increase. This is due to the fact that the water content has counteracting effects on concrete strength.

Since the temperature in cold regions tends to fluctuate around frozen point, the bond after freeze–thaw cycles (FTCs) has been investigated. Deng et al.115 studied the BFRP bar–concrete bonding under FTCs, and observed that the FTCs significantly affected the bonding strength. Li et al.116 studied the recycled concrete-steel bar bonding behaviors after −17°C to 5°C cycles through 36 pull-out tests. They found that the bonding strength was reduced as the freeze–thaw (FT) damage and anchorage length increased. Berto et al.117 developed the bonding models of NWC structures after FT damages. Wang et al.118 investigated the bonding behaviors of glass aggregated-concrete after FTCs. They also proposed new bond-slip constitutive models considering different FTCs and the content of glass aggregate.

These studies showed that the decreasing low temperature tended to increase the bonding strength at reinforcement/strand–concrete interface, which depended on the low temperature level and concrete grades. However, the FTCs tended to reduce the reinforcement/SCB strength.

4.2 SCIB in composite structures at low temperatures

At the steel–concrete interface in composite structures, headed studs are common measures to connect the concrete and steel I-beam or plate. The interfacial shear behaviors of studs affect the composite actions of steel–concrete composite structures (SCCSs), and finally influence the structural behaviors of SCCSs at low temperatures.

Amounts of researches have been performed on interfacial shear behaviors of headed studs at room or high temperatures.119-125 Dalen126 performed pioneer push-out tests on studs at −10°C and −20°C. They found that dropping the T to −20°C improved shear resistances (SRs) of studs (diameter = 13 mm), but reduced SR of studs (diameter = 19 mm). Xie127 found that the SR and stiffness of studs increased linearly with the dropping T till −40°C. But, the plasticity and ductility deterioration of stud decreased with the reduced low temperature. Hou and Ye128 and Hou et al.129 studied fatigue behaviors of 14MnNbq headed studs at T = 20°C to −50°C. Research results show that fatigue resistances of headed studs were improved as temperature reduced.

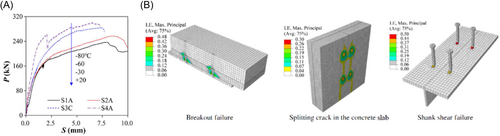

Yan and Xie130 made efforts to experimentally investigate the shear behaviors of studs at T = 20°C to −80°C. Figure 20A revealed that reducing the T from 20°C to −80°C increased the headed-stud SR by about 25%, but reduced their slip capacity by about 30%. These effects occurred because the reducing T improved the NWC elastic modulus and strength, and the strength of studs, but reduced the ductility of studs. The increased NWC strength also resulted in the enhanced confinement on the head studs, which in turn deterred the NWC splitting and improved studs' SR. Yan et al.131 also investigated shear behaviors of studs by finite element (FE) approach (see Figure 20B). This FE model adopted low-temperature mechanical properties of concrete and steel, and made an in-depth parametric study.

In addition, SRs of studs in concrete after FTCs have also been investigated. Li et al.132 and Xiao et al.133 investigated the SR prediction model and shear mechanism of studs in SCCSs suffering FTCs and artificial corrosion (AC). They found that shear stiffness and resistances of studs were significantly compromised after the FTCs or AC.

Thus, these studies revealed that the low temperatures improved ultimate and fatigue SRs of studs in SCCSs. However, the FTCs were harmful to the shear capacities of studs.

5 RC AND PC MEMBERS AT LOW TEMPERATURES

Extensive studies have been reported on the structural behaviors of RCs and PCs at low temperatures, for example, RC beam (RCB)/PC beam (PCB) and columns. Ohlsson et al.134 studied fatigue and fracture behaviors of pure concrete beams at T = 20°C to −35°C. They found that fracture energy and fatigue resistances of pure concrete beams were improved as T dropped from 20°C to −35°C. Liu et al.135 performed bending tests on six RC beams (RCBs) at T = 0°C to −180°C. They revealed that the ultimate strength of RCBs was improved as T dropped. DeRosa et al.136 performed bending tests on four RCBs at T = 20°C and −20°C. They found that cracking width reduced with the reducing T. Mirzazadeh et al.137 studied ultimate strength behaviors of RCBs at −25°C and 20°C. They revealed that at −25°C the strength/ductility of RCBs was improved by 13%/34%. Moreover, Mirzazadeh et al.138 proposed numerical models for simulating the low-temperature ultimate strength behaviors of RCBs. Mirzazadeh et al.139 also investigated fatigue behaviors of RCBs at −25°C and 20°C. They observed that at T = −25°C the fatigue lives for RCBs with/without shear reinforcements were increased by 11%/51%. Li et al.140 finished two-point loading tests on three RCBs at T = 0°C to −165°C. Berry et al.141 experimentally studied the flexural behaviors of glass fiber reinforced ploymer–reinforced concrete beams at low temperatures. They pointed out that the bending resistances of these beams were improved by 17.5% as T dropped from 20°C to −40°C.

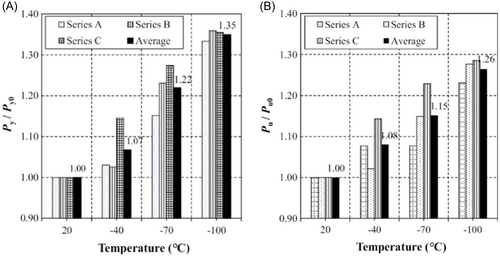

Yan and Xie142 performed two-point loading tests on 12 RCBs at T = 20°C to −100°C. Figure 21 plots the effects of T on bending resistances of RCBs at low temperatures. As T reduces from 20°C to −40°C, −70°C, and −100°C, the yield (or ultimate) resistance of RCBs exhibits average increments of 7% (8%), 22% (15%), and 35% (26%), respectively. Furthermore, Xie et al.143, 144 performed two-point loading tests on PCBs at low temperatures. They found that decreasing T from 20°C to −100°C increased the ultimate resistance of bonded PCBs by 33% whilst the ultimate resistance of unbonded PCBs was improved by 12%.

Studies on the behaviors of RC columns at low temperatures have also been reported. Sloan73 and Montejo et al.74, 145, 146 performed cyclic tests on RC columns at T = −40°C to 20°C. These studies show that reducing T improved flexural/shear strengths and initial stiffness of the RC column, and also slowed down its spreading of plasticity and reduced the drifting capacity. On the basis of these reported tested results,74, 145, 146 Montejo et al.147 also proposed theoretical models for simulating RC columns under cyclic loading at T = −40°C to 20°C. Ma and Lu148 studied the effects of reducing T on the ultimate strength behaviors of carbon fiber reinforced polymer–RC columns.

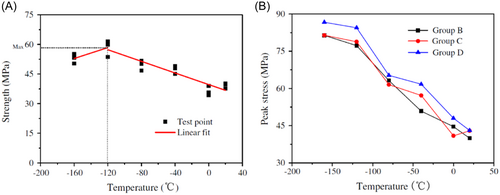

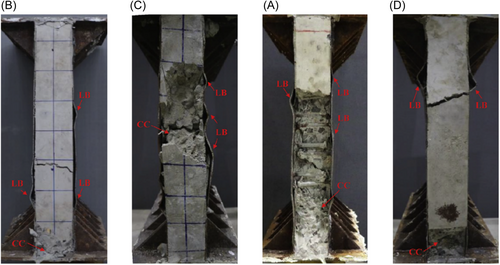

Xie et al.149 performed compression tests on RC columns at T = 20°C to −160°C. Figure 22 plots the effects of T on compression resistances of RC columns. It shows that the compression resistance of RC columns increases linearly with the dropping T from 20°C to −120°C, and then maintained at T = −120°C to −160°C. Moreover, the peak stress of RC columns was largely improved as T drops from 20°C to −165°C. Xie et al.150 also studied compression behaviors of steel UHPC-jacketed concrete columns at low temperatures. They found that introducing the steel fiber reinforced cementitious composite jackets greatly improved the compression resistance of RC columns.

6 STEEL–CONCRETE COMPOSITE STRUCTURES AT LOW TEMPERATURES

SCCS, combining the advantages of steel tension and concrete compression, acts essentially in engineering constructions, for example, the concrete-filled steel tubes (CFSTs), steel–concrete composite beams (SCCBs), walls, and slabs.

6.1 CFSTs at low temperatures

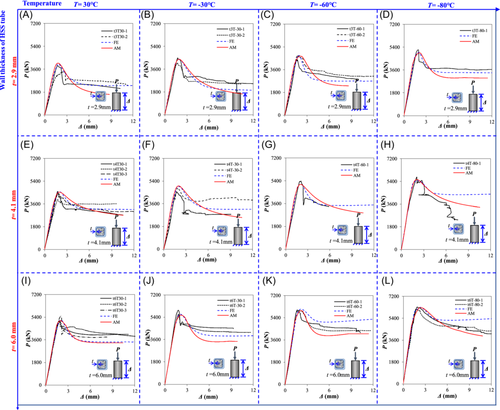

Numerous investigations have been performed to explore compression behaviors of CFSTs at low temperatures or after FTCs. Jin et al.151 carried numerical mesoscale numerical simulations on the CFSTs at dropping temperatures. Yang et al.152 studied compression behaviors of stub CFSTs after FTCs. They found that the compression resistance of those stub CFSTs decreased with the increasing FTCs. Gao et al.153 performed compression tests on 24 circular CFSTs after FTCs. They found that the axial compression capacity of CFSTs with different grades of concrete all reduced as FTCs increased, and their deterioration in strength became more serious for CFSTs with lower-strength concrete. Gao et al.154 also performed further studies on the compression behaviors of CFSTs after combined chloride erosion and FTCs. The ultimate compression capacity of CFSTs decreased almost linearly with the increasing erosion velocity and FTCs. In addition, the erosion velocity, FTCs, and grades of steel tubes exhibited marginal influences on the failure modes of CFSTs. Zhang et al.155 studied axial-compression-capacity degradation of 40 square CFSTs exposed to FTCs and acid rain erosion. They observed that after exposed to acid rain and FTCs, all the CFSTs failed in steel-tube local buckling and tube-corner vertical fracture. As the FTCs increased to 240, the stiffness and ultimate compression capacity of CFSTs were reduced by 4% and 2%–3%, respectively. Meanwhile, the acid corrosion exhibited much larger reductions than the FTCs on the compression behaviors of CFSTs. Lyu et al.156 also obtained the same findings as Zhang et al.155 Continuous works by Song et al.157 and Zhang et al.158, 159 revealed that FTCs compromised the compression or lateral share capacities of CFSTs.

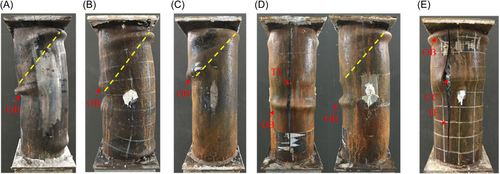

Yan et al.160-163 performed compression tests on stub CFSTs made of square or circular mild steel tubes and NWC. Figure 23 shows that the steel-tube local buckling and concrete crushing were the major failure modes of those CFSTs, and the only different failure modes from those CFSTs subjected to ambient-temperature compression was the vertical fracture of mild steel tubes due to its brittleness at low temperatures. Moreover, the dropping T increased the stiffness/compression resistances of CFSTs, which were due to the increased steel-tube yield strength, increased compressive strength of concrete, improved tube–concrete bonding strength, and increased confinement at low temperatures. Following this, the low-temperature compression behavior of stub CFSTs adopting Q690 and Q960 HSS tubes was experimentally studied through 30 compression tests.164-166 These compression tests showed that the CFST with HSS tubes failed in concrete compression, HSS-tube outward buckling, and welding fracture at HSS-tube corners. Further extended experimental studies by Yan et al.165, 167, 168 focused on the compression behaviors of CFSTs with UHPC and Q690/Q960 HSS tubes. Their experimental studies revealed that the UHPC crushing, HSS-tube outward local buckling, and weld fracture were the three main failure modes of UFHSSTs (UHPC-filled HSS tubes) after low-temperature compression. Moreover, as shown in Figure 24, the low temperatures actually improve the compressive behaviors of UFHSSTs, for example, increased compression resistance, elastic stiffness, and ductility ratio (DI). More recently, Chen and Yan169 and Yan et al.170 studied compressive behaviors of CFST using stainless-steel (SS) tubes. Due to the good ductility of SS S30408, the CFST with circular SS tubes shows a ductile behavior with a long strength hardening in their load-shortening curves.170 Their main failure modes occurred were concrete crushing and elephant local buckles of SS tube. Different from those CFST with circular SS tube, the CFST with square SS tubes exhibited vertical fracture at the SS-tube corner,169 which is due to the stress concentration at SS-tube corners.

In summary, these pilot research works studied the compression performances of CFSTs with mild steel, HSS, and SS tubes and different types of cores (NWC and UHPC), but these researches mainly concentrate on stub CFSTs under low-temperature compression or compression after CF cycles. The information on the slender CFSTs is still limited.

6.2 SCCSs at low temperatures

In the 1970s, Long et al.171 studied fatigue behaviors of SCCSs by performing fatigue tests on three continuous SCCSs at room (21°C) and low (−29°C) temperatures. They found that at −29°C the flexural behaviors of continuous SCCSs were not compromised after 500,000 fatigue loading cycles. Zhu et al.172 performed fatigue tests on SCCBs after FT (the low temperature was −20°C) cycles and chloride erosion. Due to the frost heave damage in concrete due to the FTCs, the strength and stiffness of SCCBs were compromised. Xu et al.173 investigated flexural resistances of SCCBs that suffer negative moments after FTCs. They found that after 150 salt FTCs, the flexural bending resistances of SCCB with NWC and UHPC were reduced by 62% and 18%, respectively. These previous studies on the SCCSs confirmed that low temperatures increased the flexural bending resistances of SCC or steel–concrete–steel sandwich composite (SCSSC) beams, but the FTCs reduced the ultimate bending resistance of these SCC beams.

Moreover, the low-temperature compression performances of SCSSC walls were investigated. The reported test results159, 171 reflected that as T reduced from 20°C to −30°C, −60°C, and −80°C, the compression resistances of SCSSC walls were significantly increased by 15%, 62%, and 113%, respectively. These improved compression resistances were mainly caused by improved compressive strength of concrete, compressive buckling resistance of faceplates, and improved confinements provided by the faceplate to the concrete core. In addition, Wang et al.174 developed detailed 3D numerical models to simulate compression behaviors of SCSSC walls by the ABAQUS.

Yan et al.175 performed bending tests on 3 large-scale SCCBs at T = 20°C, −30°C, and −60°C (see Figure 25). They found that reducing T from 20°C to −60°C improved the ultimate bending resistance of SCCB by 24% and the elastic stiffness of SCCB by 16%. Then, prediction models were developed to calculate the bending resistance of SCCBs. Besides, Yan et al.176 also performed four-point bending tests on 12 large-scale SCSSC beams at T = −70°C to 20°C. They found that: (1) Flexure failure occurred to SCSSC beams even to those beams with a small shear span of about 3.0; (2) as T reduces from 20°C to −30°C, −50°C, and −70°C, the ultimate bending resistance of SCSSC beams was increased by 8%, 14%, and 16% whilst the elastic stiffness was increased by 5%, 29%, and 33%, respectively. All these increments were mainly due to the improved concrete modulus and compressive strength, steel-plate yield/ultimate strength, and steel–concrete bonding strength. Moreover, comprehensive theoretical and numerical models have also been proposed for simulating low-temperature structural behaviors of SCSSC beams by Yan et al.177

Including the SCC beams, Yan et al.178, 179 also performed compression tests on SCSSC walls at T = 20°C to −80°C. These SCSSC walls exhibited close load-shortening behaviors to those CFSTs that included elastic, nonlinear, and recession stages. The main failure modes that occurred to these SCSSC walls include concrete crushing and faceplate local buckling (see Figure 26).

In summary, these limited experimental and numerical studies confirmed that the low temperatures improved the bending resistance and compression capacity of SCC structural members. However, the FTCs compromised their flexural bending resistances of SCC structures. To further explore the influence mechanism of low temperatures and FTCs on SCC structural members, a comprehensive experimental design along with mesoscopic numerical simulations that encompass a wider range of low temperature and FTC parameters is needed.

7 SEISMIC BEHAVIORS OF ENGINEERING CONSTRUCTIONS AT LOW TEMPERATURES

Earthquakes are a common type of natural hazard in cold regions and the Arctic. On December 26, 1920 (T = − 10°C), an Ml7.5 earthquake occurred in Gansu, China, which caused 288,200 deaths. On November 4, 1954 (T is about −22°C), an Ml9.0 earthquake occurred in Kamchatka Peninsula, Russia.180 On March 28, 1964 (T is about −8°C), an Ml9.2 earthquake occurred in Alaska, USA, which caused 125 deaths and Tsunami.180 On December 21, 2021 (T = −31°C), an Ml6.1 earthquake took place in Southern Alaska, USA. On November 30, 2021 (T = −15°C), an Ml5.8 earthquake occurred in Naqu, Tibet, China. On January 8 (T = −16°C), an Ml6.9 earthquake occurred in Menyuan, Qinghai, China. It can be found that there is a very high possibility for the occurrence of earthquakes at low temperatures. Therefore, the engineering infrastructures in the cold regions are probably subjected to combinations of earthquakes and low temperatures.

Yin et al.181 studied the cyclic models for cast steel at T = 20°C to −60°C. Kang et al.56, 57 proposed the cyclic compressive models for NWC and UHPC. At the structural member level, Montejo et al.74, 145-147 performed a series of experimental studies on RC columns under cyclic bending and shear forces. They found that the low temperatures increased the stiffness and flexural bending resistance of RC columns, but the decreasing T also delayed the plasticity spreading and deformation capacity, which means the reduced energy dissipation capacity of RC columns.

However, the information on the seismic behaviors of engineering constructions at low temperatures is still limited, which has been not fully investigated and deserves for further studies. Future research suggests that, based on in-depth studies of the low-temperature seismic performance of construction materials and components, the seismic behavior of joints and engineering structures in cold and Arctic regions can be comprehensively assessed through a combination of targeted experimental tests and refined numerical simulations.

8 CONCLUSIONS

- 1.

A wide range of engineering constructions have been constructed in cold regions and the Arctic. These engineering structures usually suffered low temperatures within −80°C to 0°C, and the LNG containers were probably exposed to the lowest temperature of about −165°C during their service.

- 2.

The below-zero temperatures improved the Ec, fc, and ft of concrete. The increasing amplitudes of the strength or modulus due to the low temperature significantly depended on their water content, water-to-cement ratio, and types of aggregate. Furthermore, low-temperature constitutive compressive stress–strain models of NWC and UHPC have also been developed.

- 3.

Low temperatures increased the fy and fu of steel reinforcements, mild and HSS steel plates, and HSS strands, but exhibited ignorable influences on the Es of these steel. Empirical stress–strain constitutive models have been developed for analytical and design purposes. However, limited studies have been reported on the cyclic stress–strain behaviors of steel at low temperatures, which need further research.

- 4.

As the temperature decreased, both the steel–concrete bond in RC/PC structures and the shear strength of headed-stud connectors in composite structures were significantly improved. As the T reduced from 20°C to about −70°C, the steel–concrete bonding strength was nearly doubled, and the shear strength of studs increased by about 30%. However, exposure to the FTCs significantly reduced the steel–concrete bonding strength.

- 5.

Low temperatures improved the flexural bending and SRs of RCB and PCB. As T reduced from 0°C to −100°C, the yielding/ultimate bending resistances of RCBs were improved by 35%/26%. Additionally, the low-temperature fatigue lives of RCBs were also improved. Furthermore, low temperatures also improved the compression or later SRs of RC columns, but reduced their spread of plasticity and deformation capacity, which means reduced energy dissipation capacity.

- 6.

Low temperatures improved the compression capacity of CFSTs using mild steel, HSS, and SS tubes. However, both FTCs and erosions reduced their compression resistances. Notably, erosions exhibited a more pronounced detrimental effect compared to FTCs. Similarly, low temperatures increased the bending resistance of SCC beams. Nevertheless, the FTCs reduced the ultimate bending resistance of these beams.

- 7.

Current literatures mainly focused on the monotonic stress–strain models of steel and concrete materials at low temperatures. Nonetheless, in the seismic design of engineering structures at low temperatures, it is necessary to develop cyclic models for steel. Since most current studies have been limited to stub columns, more comprehensive studies on the intermediate and long RC or composite CFST columns are still necessary, which are more useful for engineering applications.

- 8.

Preliminary studies on the cyclic tests on the RC columns at low temperatures showed that low temperatures increased the stiffness and flexural bending resistance of the RC column, but the decreasing T delayed the plasticity spreading and deformation capacity.

- 9.

The cold-region low temperatures bring safety and resilience challenges to the engineering structures, which requires more extensive further investigations. Continuous further studies may focus on the durability of materials and the resilience of structures under diverse hazards, including earthquakes, impacts, and even blasts.

ACKNOWLEDGMENTS

The work presented in this paper was supported by the Key Project of Natural Science Foundation of Heilongjiang (No. ZD2022E009) and National Natural Science Foundation of China (Nos. 52478195 and 52178494). The authors gratefully express their gratitude for the financial support.

CONFLICTS OF INTEREST

The author declares no conflicts of interest.