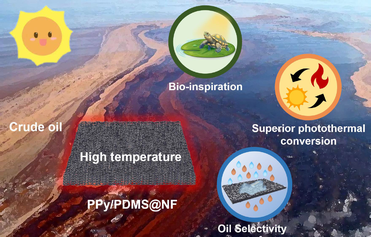

Lotus and Poikilotherm Inspired PPy/PDMS@Nonwoven Fabric Sorbent with Superior Photothermal Effects for the Cleanup of High-viscous Crude Oil†

Hiroshi Fu

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

Huafon Microfibre (Jiangsu) Co., Ltd., Nantong, Jiangsu, 226000 China

These authors contributed equally to this work.

Search for more papers by this authorYang Chen

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

These authors contributed equally to this work.

Search for more papers by this authorTong Zhang

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

These authors contributed equally to this work.

Search for more papers by this authorXi Wang

Jiangxi Center for Modern Apparel Engineering and Technology, Jiangxi Institute of Fashion Technology, Nanchang, Jiangxi, 330201 China

Search for more papers by this authorCorresponding Author

Songnan Zhang

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorJianying Huang

National Engineering Research Center of Chemical Fertilizer Catalyst (NERC-CFC), College of Chemical Engineering, Fuzhou University, Fuzhou, Fujian, 350116 China

Search for more papers by this authorCorresponding Author

Di Zhang

School of Chemical Engineering and Technology, Tiangong University, Tianjin, 300387 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorXiaoming Qian

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

Search for more papers by this authorCorresponding Author

Yuekun Lai

National Engineering Research Center of Chemical Fertilizer Catalyst (NERC-CFC), College of Chemical Engineering, Fuzhou University, Fuzhou, Fujian, 350116 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorHiroshi Fu

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

Huafon Microfibre (Jiangsu) Co., Ltd., Nantong, Jiangsu, 226000 China

These authors contributed equally to this work.

Search for more papers by this authorYang Chen

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

These authors contributed equally to this work.

Search for more papers by this authorTong Zhang

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

These authors contributed equally to this work.

Search for more papers by this authorXi Wang

Jiangxi Center for Modern Apparel Engineering and Technology, Jiangxi Institute of Fashion Technology, Nanchang, Jiangxi, 330201 China

Search for more papers by this authorCorresponding Author

Songnan Zhang

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorJianying Huang

National Engineering Research Center of Chemical Fertilizer Catalyst (NERC-CFC), College of Chemical Engineering, Fuzhou University, Fuzhou, Fujian, 350116 China

Search for more papers by this authorCorresponding Author

Di Zhang

School of Chemical Engineering and Technology, Tiangong University, Tianjin, 300387 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this authorXiaoming Qian

State Key Laboratory of Separation Membranes and Membrane Processes/National Center for International Joint Research on Separation Membranes/Key Laboratory of Advanced Textile Composites of Ministry of Education, School of Textile Science and Engineering, Tiangong University, Tianjin, 300387 China

Search for more papers by this authorCorresponding Author

Yuekun Lai

National Engineering Research Center of Chemical Fertilizer Catalyst (NERC-CFC), College of Chemical Engineering, Fuzhou University, Fuzhou, Fujian, 350116 China

E-mail: [email protected]; [email protected]; [email protected]Search for more papers by this author† Dedicated to the Special Issue of Biomimetic Materials.

Comprehensive Summary

The frequent occurrence of oil spills not only results in the waste of petroleum resources, but also poses a serious threat to the marine ecological environment. Considering the large amount of crude oils with high viscosity, it is urgent to develop a sorbent capable of efficiently reducing the viscosity for the cleanup of oil spills. Inspired by the “lotus effect” and “poikilotherm which utilize the solar energy for thermoregulation”, the low surface energy material polydimethylsiloxane (PDMS) and polypyrrole (PPy) were loaded over the island nonwoven fabric to fabricate a novel crude oil sorbent material. The nonwoven fabric achieved an efficient photothermal conversion. Wherein, the fluorine-free PDMS was used to hydrophobically modify the nonwoven fabric, endowing it with excellent oil-water separation performance, with a separation efficiency of up to 95%. After 10 cycles, the separation efficiency of PPy/PDMS modified nonwoven fabric (PPy/PDMS@NF) was still above 90%, demonstrating superior recyclability. In addition, the PPy/PDMS@NF possessed the self-cleaning capabilities. Under light conditions, the PPy/PDMS@NF was rapidly heated up, reducing the viscosity of crude oil and enabling the effective recovery of oil spills. Under one sun illumination (1.0 kW·m–2), the surface temperature of the PPy/PDMS@NF reached 60.7 °C, and its sorption capacity for high-viscosity crude oil reached 7 gcrude oil·gsorbent–1. Thanks to its environmental friendliness and excellent sorption capacity, this work provides a new option for dealing with the high-viscosity marine oil spills.

Supporting Information

| Filename | Description |

|---|---|

| cjoc202401014-sup-0001-supinfo.pdfPDF document, 1.6 MB |

Appendix S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1(a) Dong, J.; Zheng, W.; Yang, Y.; Dong, S.; Li, S.; Zhong, Y.; He, Y.; Cai, Z.; Lin, Z. Room-temperature synthesis of fluorinated covalent organic framework decorated superhydrophobic sponges for highly efficient crude oil spill cleanup. Sep. Purif. Technol. 2024, 344, 127314; (b) Wang, Z.; An, C.; Lee, K.; Owens, E.; Chen, Z.; Boufadel, M.; Taylor, E.; Feng, Q. Factors influencing the fate of oil spilled on shorelines: a review. Environ. Chem. Lett. 2021, 19, 1611–1628; (c) Wang, M.; Ma, C.; Zhang, G. Dynamic surface antifouling materials. Chin. J. Chem. 2023, 41, 2881–2888.

- 2 Husseneder, C.; Donaldson, J. R.; Foil, L. D. Impact of the 2010 deepwater horizon oil spill on population size and genetic structure of horse flies in Louisiana marshes. Sci. Rep. 2016, 6, 18968.

- 3(a) Huynh, B. Q.; Kwong, L. H.; Kiang, M. V.; Chin, E. T.; Mohareb, A. M.; Jumaan, A. O.; Basu, S.; Geldsetzer, P.; Karaki, F. M.; Rehkopf, D. H. Public health impacts of an imminent Red Sea oil spill. Nat. Sustain. 2021, 4, 1084–1091; (b) Dong, L.; Li, Y.; Li, J.; Guan, Y.; Chen, X.; Zhang, D.; Wang, Z. Mesoporous carbon hollow spheres encapsulated phase change material for efficient emulsification of high-viscosity oil. J. Hazard. Mater. 2023, 451, 131112; (c) Dong, T.; Liu, Y.; Tian, N.; Zhang, Y.; Han, G.; Peng, F.; Lou, C.-W.; Chi, S.; Liu, Y.; Liu, C.; et al. Photothermal and Concus Finn capillary assisted superhydrophobic fibrous network enabling instant viscous oil transport for crude oil cleanup. J. Hazard. Mater. 2023, 443, 130193.

- 4 Wang, C.; Lü, Y.; Qi, H.; Luo, X.; He, L. Flotation mechanism and performance of air/condensate bubbles for removing oil droplets in the presence of acetic acid. Sci. Total Environ. 2024, 927, 172311.

- 5 Faksness, L.-G.; Leirvik, F.; Taban, I. C.; Engen, F.; Jensen, H. V.; Holbu, J. W.; Dolva, H.; Bråtveit, M. Offshore field experiments with in-situ burning of oil: emissions and burn efficiency. Environ. Res. 2022, 205, 112419.

- 6 Wu, S.; Tian, S.; Jian, R.; Wu, T.-N.; Milazzo, T. D.; Luo, T.; Xiong, G. Graphene petal foams with hierarchical micro- and nano-channels for ultrafast spontaneous and continuous oil recovery. J. Mater. Chem. A 2022, 10, 11651–11658.

- 7 Yang, D.; Xia, S.; Bao, M.; Chen, X.; Kang, H.; Zhao, H.; Li, Y. A new class of amide-based organogels: from oil spill recovery to self-assembly structure analysis. J. Mater. Chem. A 2023, 11, 6181–6190.

- 8 Song, X.; Zhang, B.; Cao, Y.; Liu, B.; Chen, B. Shrimp-waste based dispersant as oil spill treating agent: Biodegradation of dispersant and dispersed oil. J. Hazard. Mater. 2022, 439, 129617.

- 9 Pete, A. J.; Bharti, B.; Benton, M. G. Nano-enhanced bioremediation for oil spills: a review. ACS ES&T Eng. 2021, 1, 928–946.

- 10(a) Li, R.; Geng, Y.; Wei, S.; Zhao, Z.; Zhang, H.; Chen, X.; Jiao, C.; Kuang, S. Magnetic, self-heating and superhydrophobic sponge decorated with BN and CoFe2O4 for high-efficient cleanup of crude oil spills using facile co-precipitation strategy. Sep. Purif. Technol. 2025, 354, 128952; (b) Qi, B.; Wang, N.; Cui, S.; Liu, H.; Hu, X.; Li, H.; Li, Y.; Li, Y.; Lu, J.; He, R.; et al. Bioinspired melt-blown fiber felt with flame retardancy for efficient oil spill remediation by solar-driven oil evaporation and adsorption. Sep. Purif. Technol. 2024, 348, 127625.

- 11(a) Yan, K.; Zhao, F.; Pan, L.; Jiang, Y.; Shi, Y.; Yu, G. High-throughput clean-up of viscous oil spills enabled by a gel-coated mesh filter. Nat. Sustain. 2023, 6, 1654–1662; (b) Hasan, S. W.; Ghannam, M. T.; Esmail, N. Heavy crude oil viscosity reduction and rheology for pipeline transportation. Fuel 2010, 89, 1095–1100.

- 12(a) He, X.; Lu, J.; Liu, J.; Wu, Z.; Li, B.; Chen, Z.; Tao, W.; Li, Z. Superhydrophobic Co-MOF-based sponge for efficient oil-water separation utilizing photothermal effect. J. Hazard. Mater. 2024, 469, 134090; (b) Guan, H.; Lian, R.; Li, R.; Zhu, J.; Zhao, Z.; Liu, L.; Chen, X.; Jiao, C.; Kuang, S. A low-temperature carbonization strategy for efficient viscous crude oil spill disposal without hydrophobic coating: CoFe-PBA- catalyzed carbonization of superhydrophobic flame retardant melamine sponge. Adv. Funct. Mater. 2024, 34, 2313224.

- 13(a) Yang, Y.; Guo, Y.; Guo, Z.; Liu, W. Multifunctional polypyrrole/ MXene-wrapped sponge with synergistic solar and joule-heating effect for efficient adsorption and all-weather recovery of crude oil. Chem. Eng. J. 2024, 485, 149927; (b) Chen, Z.; Wang, B.; Qi, J.; Liu, T.; Feng, Y.; Liu, C.; Shen, C. Eco-friendly bacterial cellulose/MXene aerogel with excellent photothermal and electrothermal conversion capabilities for efficient separation of crude oil/seawater mixture. Carbohydr. Polym. 2024, 336, 122140; (c) Wu, X.; Lei, Y.; Li, S.; Huang, J.; Teng, L.; Chen, Z.; Lai, Y. Photothermal and Joule heating-assisted thermal management sponge for efficient cleanup of highly viscous crude oil. J. Hazard. Mater. 2021, 403, 124090.

- 14(a) Song, Y.; Shi, L.-A.; Xing, H.; Jiang, K.; Ge, J.; Dong, L.; Lu, Y.; Yu, S.-H. A magneto-heated ferrimagnetic sponge for continuous recovery of viscous crude oil. Adv. Mater. 2021, 33, 2100074; (b) Zeng, X.; Xu, Z.; Mo, H.; Zhuang, J.; Xing, Z.; Xie, Y.; Qiu, J.; Yu, J.; Jiang, G.; Ye, X. Robust superhydrophobic Fe3O4/PAN/PBA nanofibrous aerogel with photo/magneto-thermal properties for efficient all-weather cleanup of viscous crude oil spills. Sep. Purif. Technol. 2025, 353, 128460.

- 15(a) Cui, X.; Ruan, Q.; Zhuo, X.; Xia, X.; Hu, J.; Fu, R.; Li, Y.; Wang, J.; Xu, H. Photothermal nanomaterials: a powerful light-to-heat converter. Chem. Rev. 2023, 123, 6891–6952; (b) Zhang, Z.; Wang, X.; Li, G.; Zhao, K.; Liu, G.; Wang, Y.; Li, Z.; Huang, J.; Xu, Z.; Lai, Y.; et al. Synergistic dual-mechanism raised structure and vertically aligned porous 3D hydrogel fabric for ultra-high salt-resistant water desalination. Chem. Eng. J. 2024, 480, 148006; (c) Zhang, Z.; Wang, X.; Li, H.; Liu, G.; Zhao, K.; Wang, Y.; Li, Z.; Huang, J.; Xu, Z.; Lai, Y.; et al. A humidity/thermal dual response 3D-fabric with porous poly(N-isopropyl acrylamide) hydrogel towards efficient atmospheric water harvesting. J. Colloid Interface Sci. 2024, 653, 1040–1051.

- 16 Guan, Y.; Wang, Z.; Bao, M.; Chen, X.; Dong, L.; Shen, Y.; Li, Y. Multi- energies assisted and all-weather recovery of crude oil by superhydrophobic melamine sponge. J. Hazard. Mater. 2023, 443, 130131.

- 17 Wu, N.; Yang, Y.; Wang, C.; Wu, Q.; Pan, F.; Zhang, R.; Liu, J.; Zeng, Z. Ultrathin cellulose nanofiber assisted ambient-pressure-dried, ultralight, mechanically robust, multifunctional MXene aerogels. Adv. Mater. 2023, 35, 2207969.

- 18 Sun, A.; Hou, X.; Hu, X. Super-performance photothermal conversion of 3D macrostructure graphene-CuFeSe2 aerogel contributes to durable and fast clean-up of highly viscous crude oil in seawater. Nano Energy 2020, 70, 104511.

- 19 Zhang, D.; Liang, Q.; Zhou, Z.; Jia, Y.; Chen, S.; Wang, H. Multifunctional bacterial cellulose photothermal aerogels with multi-bonded network assisted by carbon nanotube. Chem. Eng. J. 2023, 470, 144436.

- 20(a) Li, Z.-T.; Lin, B.; Jiang, L.-W.; Lin, E.-C.; Chen, J.; Zhang, S.-J.; Tang, Y.-W.; He, F.-A.; Li, D.-H. Effective preparation of magnetic superhydrophobic Fe3O4/PU sponge for oil-water separation. Appl. Surf. Sci. 2018, 427, 56–64; (b) Duman, O.; Cengiz, C.; Özcan Diker, C.; Cengiz, U.; Güreşir, S. M.; Tunç, S. Effect of alkoxysilane chain length on the surface, stability, sorption and oil–water separation properties of novel superhydrophobic porous sorbent materials produced using innovative drainage technique in scCO2 atmosphere. Sep. Purif. Technol. 2024, 345, 127354; (c) Duman, O.; Diker, C. Ö.; Güreşir, S. M.; Cengiz, U.; Tunç, S. Superhydrophobic melamine sponge-sorbent fabricated using WS2, halloysite nanotube, octyltriethoxysilane, tetraethoxysilane, and polydimethylsiloxane for the selective uptake of oil from water. J. Water Process Eng. 2023, 56, 104454.

- 21(a) Zhang, Z.-h.; Wang, H.-j.; Liang, Y.-h.; Li, X.-j.; Ren, L.-q.; Cui, Z.-q.; Luo, c. One-step fabrication of robust superhydrophobic and superoleophilic surfaces with self-cleaning and oil/water separation function. Sci. Rep. 2018, 8, 3869; (b) Liu, L.; Pan, Y.; Jiang, K.; Zhao, X. On-demand oil/water separation enabled by magnetic super-oleophobic/super-hydrophilic surfaces with solvent-responsive wettability transition. Appl. Surf. Sci. 2020, 533, 147092.

- 22(a) Li, Z.; Zhong, L.; Zhang, T.; Qiu, F.; Yue, X.; Yang, D. Sustainable, flexible, and superhydrophobic functionalized cellulose aerogel for selective and versatile oil/water separation. ACS Sustainable Chem. Eng. 2019, 7, 9984–9994; (b) Duman, O.; Diker, C. Ö.; Uğurlu, H.; Tunç, S. Highly hydrophobic and superoleophilic agar/PVA aerogels for selective removal of oily substances from water. Carbohydr. Polym. 2022, 286, 119275.

- 23(a) Cavalcante, J.; Szekely, G. Surface engineering of a superamphiphilic, self-growing fibrous Janus membrane prepared from mycelium. J. Mater. Chem. A 2023, 11, 24598–24607; (b) Yang, C.; Topuz, F.; Park, S.-H.; Szekely, G. Biobased thin-film composite membranes comprising priamine–genipin selective layer on nanofibrous biodegradable polylactic acid support for oil and solvent-resistant nanofiltration. Green Chem. 2022, 24, 5291–5303.

- 24(a) Duman, O.; Uğurlu, H.; Diker, C. Ö.; Tunç, S. Fabrication of highly hydrophobic or superhydrophobic electrospun PVA and agar/PVA membrane materials for efficient and selective oil/water separation. J. Environ. Chem. Eng. 2022, 10, 107405; (b) Jiang, S.; Meng, X.; Chen, B.; Wang, N.; Chen, G. Electrospinning superhydrophobic–superoleophilic PVDF-SiO2 nanofibers membrane for oil–water separation. J. Appl. Polym. Sci. 2020, 137, 49546; (c) Li, Z.; Dong, G.; Pan, J.; Chen, X.; Lou, X.; Huang, L.; Guo, K. Preparation and properties of bio-based PA56/SiO2–NH2 composite nanofiber membranes for high efficiency oil-water separation. J. Membr. Sci. 2025, 713, 123400.

- 25(a) Bu, Y.; Huang, J.; Zhang, S.; Wang, Y.; Gu, S.; Cao, G.; Yang, H.; Ye, D.; Zhou, Y.; Xu, W. Robust superhydrophobic surface by nature-inspired polyphenol chemistry for effective oil-water separation. Appl. Surf. Sci. 2018, 440, 535–546; (b) Liu, X.; Ni, S.; Chen, X.; Li, Z.; Fu, Y.; Qin, M.; Zhang, F. Green fabrication of fabric by ethanol/water solvent-mediated self-assembly of homogeneous lignin for oil–water separation. Green Chem. 2024, 26, 3418–3428.

- 26 Liu, M.; Wang, S.; Jiang, L. Nature-inspired superwettability systems. Nat. Rev. Mater. 2017, 2, 17036.

- 27 Chen, J.; Sun, M.; Ni, Y.; Zhu, T.; Huang, J.; Li, X.; Lai, Y. Superhydrophobic polyurethane sponge for efficient water-oil emulsion separation and rapid solar-assisted highly viscous crude oil adsorption and recovery. J. Hazard. Mater. 2023, 445, 130541.

- 28(a) Ku, B.-J.; Lee, B.-M.; Kim, D. H.; Mnoyan, A.; Hong, S. K.; Go, K. S.; Kwon, E. H.; Kim, S. H.; Choi, J. H.; Lee, K. Photothermal fabrics for efficient oil-spill remediation via solar-driven evaporation combined with adsorption. ACS Appl. Mater. Interfaces 2021, 13, 13106–13113; (b) Wen, H.; Liang, L.; Xu, N.; Liu, C. Multi-functional self-cleaning superhydrophobic cotton fabric as photothermal-reinforced crude oil separator, oil skimmer and underwater oil absorbent. Sep. Purif. Technol. 2024, 337, 126258.

- 29 Yu, Z.; Fan, T.; Liu, Y.; Li, L.; Liu, J.; Yang, B.; Ramakrishna, S.; Long, Y.-Z. Efficient air filtration through advanced electrospinning techniques in nanofibrous materials: a review. Sep. Purif. Technol. 2024, 349, 127773.

- 30 Lu, P.; Xu, J.; Wang, X.; Lian, W.; Li, C.; Guan, S. Gradient pore structured Ppy/PDMS conductive sponge for flexible pressure sensor. Chem. Eng. J. 2024, 488, 151049.

- 31 Omastová, M.; Trchová, M.; Kovářová, J.; Stejskal, J. Synthesis and structural study of polypyrroles prepared in the presence of surfactants. Synth. Met. 2003, 138, 447–455.

- 32 Wang, Y.; Zhang, Y.; Zhong, W.; Qing, X.; Zhou, Q.; Liu, Q.; Wang, W.; Liu, X.; Li, M.; Wang, D. Flexible supercapacitor with high energy density prepared by GO-induced porous coral-like polypyrrole (PPy)/PET non-woven fabrics. J. Mater. Sci. 2018, 53, 8409–8419.

- 33 Elavathingal Johny, J.; Jose, D.; Kochuveetil Vavachan, V.; Kachirayil Joseph, S.; John, H. Enhanced mechanical energy harvesting in triboelectric nanogenerator by the reinforcement of Polypyrrole-decorated rGO sheets in PDMS. Adv. Eng. Mater. 2023, 25, 2201789.

- 34 Cui, X.; Zhu, G.; Pan, Y.; Shao, Q.; Zhao, C.; Dong, M.; Zhang, Y.; Guo, Z. Polydimethylsiloxane-titania nanocomposite coating: Fabrication and corrosion resistance. Polymer 2018, 138, 203–210.

- 35 Zhai, S.; Zhai, B.; An, Q. Effect of preparation conditions on structural properties of PMHS-TEOS hybrid materials. J. Sol-Gel Sci. Technol. 2011, 59, 480–487.

- 36 Téllez, L.; Rubio, J.; Rubio, F.; Morales, E.; Oteo, J. L. FT-IR study of the hydrolysis and polymerization of tetraethyl orthosilicate and polydimethyl siloxane in the presence of tetrabutyl orthotitanate. Spectr. Lett. 2004, 37, 11–31.

- 37(a) Shu, H.; Yang, L.; Wang, C.; Song, C.; Chen, D.; Zhang, X.; Ma, Y.; Yang, W. Fabrication and properties of asymmetric PET fabrics with high-permeation flux for on-demand oil/water separation. J. Membr. Sci. 2024, 692, 122271; (b) Liu, X.; Liu, Z.; Wang, X.; Gao, Y.; Zhang, J.; Fan, T.; Ning, X.; Ramakrishna, S.; Long, Y.-Z. Superhydrophobic nanofibrous sponge with hierarchically layered structure for efficient harsh environmental oil-water separation. J. Hazard. Mater. 2022, 440, 129790; (c) Yang, X.; Tian, Y.; Zhou, R.; Xia, F.; Gong, Y.; Zhang, C.; Ji, F.; Liu, L.; Li, F.; Zhang, R.; et al. Bioinspired design of textile- based absorbers: photothermal and electrothermal synergistic conversion for efficient clean-up of heavy oil. Adv. Fiber Mater. 2024, 6, 1446–1455.

- 38(a) Xu, J.; Wang, N.; Xue, S.; Zhang, H.; Zhang, J.; Xia, S.; Han, Y. Insights into the mechanism during viscosity reduction process of heavy oil through molecule simulation. Fuel 2022, 310, 122270; (b) Li, B.; Guo, Z.; Du, M.; Han, D.; Han, J.; Zheng, L.; Yang, C. Research status and outlook of mechanism, characterization, performance evaluation, and type of pour point depressants in waxy crude oil: a review. Energy Fuels 2024, 38, 7480–7509.

- 39 Wang, K.; Peng, B.; Zhao, R.; Xu, H.; Yan, F. Molecular dynamics simulation of waxy deposition in crude oil system. Int. J. Mod. Phys. B 2021, 35, 2150246.