Recent advances in mechanism, influencing parameters, and dopants of electrospun EMI shielding composites: A review

Abstract

The rapid development and popularization of smart and portable electronic devices have led to increasingly related electromagnetic pollution affecting human health and equipment safety. Thus, designing high-performance electromagnetic interference (EMI) shielding materials with lightweight, flexible, and easy preparation is urgent. The intrinsic physiochemical properties of electrospun micro/nanofibers provide an attractive potential to ease and accelerate the next-generation EMI shielding materials. Here, a detailed review of the electrospun EMI shielding materials is established. First, this article outlines the shielding mechanism of EMI shielding materials obtained via electrospinning. Then, the affecting factors of electrospinning process conditions on the resulting EMI shielding micro/nanofibers are discussed. Next, diverse fillers that contribute to the EMI shielding efficiency of electrospun materials are demonstrated. Finally, the conclusion and prospects are introduced, hopefully contributing to assisting with more comprehensive and rational designs of high-performance electrospun fiber-based EMI shielding for various applications. Priority measures and future directions are suggested for the future development of electrospun EMI shielding materials.

1 INTRODUCTION

With the popularization of 5G technology and the widespread use of high-power electronic devices, electromagnetic pollution threatens people's physical and mental health and information security. It causes environmental and social problems.1, 2 To alleviate the adverse effects of electromagnetic waves (EMWs) radiation, EMI shielding materials have been widely applied in many fields, such as electronic equipment, aerospace, medicine, and the military. However, the rapid development of information technology leads to high-level requirements for EMI shielding materials.3 It is urgent to exploit more efficient EMI shielding materials to inhibit or lighten EMW radiation. Although traditional metal-based materials are common EMI shielding materials, such as silver, copper, and stainless steel, which can effectively prevent the leakage of EMWs, they are very heavy, easily corrosive, and difficult to process, limiting their large-scale applications in the field of EMI shielding.4, 5 Therefore, it is the imminent step to develop fascinating EMI shielding materials with good flexibility, lightweight, and high electromagnetic interference shielding effectiveness (EMI SE).

Nanofibers, as a typical one-dimensional material, possess the advantages of lightweight, high flexibility, and a large aspect ratio (the ratio of length to diameter),6, 7 which have been widely used in numerous areas.8-15 Due to nanofibers' remarkable physical and chemical properties, they have been gradually explored in the field of EMI shielding recently. The preparation methods of nanofibers mainly include the self-assembly method,16 template polymerization,17 chemical and mechanical separation,18 stretch method,19 and electrospinning.20, 21 Electrospinning is a promising technique for developing novel materials with specific morphologies for various applications.22-24 The nanofibers produced by electrospinning have several remarkable advantages, including small diameter, high aspect ratio, large specific surface area (surface area to volume ratio), and diverse composition.25, 26 In addition, the surface properties and structures of electrospun nanofibers can be modified by adjusting the electrospun parameters, resulting in controlling physical and chemical features. Thus, incorporating electrospun nanofibers with regulating characteristics for EMI shielding materials can meet the constantly growing performance requirements of EMI shielding on various occasions.27

Although electrospun nanofibers are one of the most commonly used materials for EMI shielding, they are generally insulated polymer-based materials.28 Nevertheless, high EMI shielding applications need shielding materials endowed with superior electrical, magnetic, or dielectric properties.29 Introducing various conductive and magnetic fillers into electrospun nanofibers is an alternative for preparing high-performance EMI shielding materials. Generally, the EMI shielding effectiveness strongly depends on the conductivity and dielectric properties of the materials.28 The higher the conductivity of the material, the larger the permittivity and the lower the impedance it exhibits. Thus, such materials would achieve effective reflections of the EMWs, resulting in a superior EMI shielding performance.30, 31

Meanwhile, the introduction of flexible and lightweight conductive materials can be utilized to circumvent physical rigidity.32, 33 This can maintain the lightweight and flexible characteristics of electrospun nanofibers while realizing the EMI shielding performance. In addition, the incorporation of fillers in fiber materials can form a continuous network structure, which enhances the ability to block EMWs and leads to fascinating EMI shielding performance. Furthermore, adding fillers also allows for adjusting the physical properties of fibers, such as tensile strength, bending resistance, and so forth, thus achieving optimized control over key factors affecting EMI shielding performance. Consequently, electrospinning is expected to be one of the most promising approaches to preparing valid EMI shielding materials for various intelligent electronic devices.34, 35

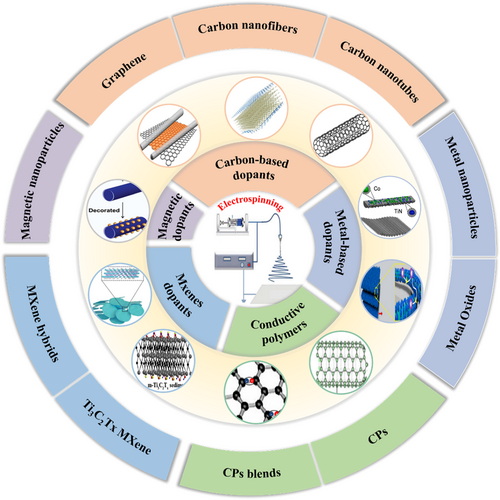

The existing literature review articles on electrospinning EMI shielding materials focus on discussing the shielding performance and mechanism of the materials. This article aims to analyze the influence of the preparation process and the type of fillers on EMI shielding performance. In this review, we briefly introduce the effect of electrospinning process parameters and environmental factors on the morphological structure of electrospun fibers, as well as on the EMI shielding performance. In addition, the recent research developments of electrospun EMI shielding materials doped with different fillers are summarized. The EMI shielding performance of the materials is analyzed mainly from the aspects of the experimental preparation process, processing technology, and the type of filler shown in Figure 1. Finally, we provide a summary of the issue related to the preparation of EMI shielding materials by electrospinning and an outlook on the future research directions of electrospun fibers within the field of EMI shielding.

2 EMI SHIELDING PRINCIPLE OF ELECTROSPUN MICRO/NANOFIBERS

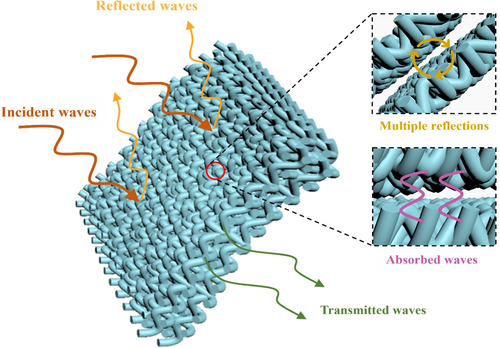

Electrospun micro/nanofibers can effectively dissipate EMWs due to their distinct advantage of high porosity, high specific surface area, good mechanical properties, outstanding physical properties and interface interactions27, 36-38—especially the last one. When EMWs pass through electrospun fibers, their energy is absorbed or reflected, and multiple diffraction, refraction, and scattering occur at the fiber surface. These processes gradually weaken or disperse the EMW energy until the shielding effect is achieved. Therefore, many studies today are focused on exploring high-performance electrospun micro/nanofibers to improve the shielding performance of electrospun materials for EMW shielding applications. Usually, the EMI shielding effects of electrospun micro/nanofibers can be adjusted by the physiochemical properties of the electrospun polymer jet, electrospun processing factors, and environmental parameters. The electromagnetic shielding form of electrospun micro/nanofibers mainly includes electrical loss, magnetic loss, and dielectric loss.39 Due to the interaction between incident EMWs and charge carriers on the surface of materials, the excessive electrical conductivity causes EMWs to be reflected. However, its main attenuation method for the penetrated wave depends on the absorption loss, which requires the material to have a matched dielectric and magnetic constant.40 The conductivity and the dielectric constant are positively correlated,41 so the EMI shielding material with high conductivity will exhibit a large dielectric constant, resulting in low impedance matching and thus reflecting most of the incident EMW.30 On the other hand, poor conductivity will produce a low dielectric constant, which leads to a decrease in attenuation ability and a weakening of the absorption loss of the shielding material—balancing impedance matching and attenuation ability to achieve excellent electromagnetic shielding performance. An optimal combination of the electrospinning process conditions can result in superior electrospun EMI shielding materials.

The primary shielding mechanisms of electrospun micro/nanofibers involve the reflection and absorption of electromagnetic radiation, as shown in Figure 2. Although the EMW absorption is the primary shielding mechanism of electrospun composite materials, the EMW reflection also plays a paramount role in their EMI shielding. When incident EMWs hit the electrospun composite materials, they will be reflected on the surface of the fiber membrane, resulting in a partial loss of the EMW energy. When the remaining EMWs get into the interior of these materials, multiple reflections of the EMW will occur within, generating lots of heat absorbed and dissipated by the electrospun materials.42, 43 In addition, the EMW will continue attenuating during the transmission inside the electrospun micro/nanofibers.44

3 INFLUENCE PARAMETERS OF ELECTROSPUN EMI SHIELDING PERFORMANCE CAPABILITY

Compared with conventional metal-based shielding materials, electrospun micro/nanofibers have become one of the most promising EMI shielding materials due to their advantages of superior flexibility, lightweight, porous, and high specific surface area. However, extensive research has revealed that complex and interdependent parameters can significantly impact the EMI shielding performance of electrospun micro/nanofibers. Their EMI shielding effects mainly depend on absorption and reflection, which is determined by the physical and chemical features of the resulting electrospun micro/nanofibers. Commonly, the physicochemical characteristics of the obtained electrospun micro/nanofibers can be adjusted by the electrospun processing conditions, including physiochemical properties of the polymer jet, processing factors, and environmental parameters. The combined effects of these three factors determine the electrospun fiber morphologies and properties, including diameter, surface roughness, porosity, and stress, as summarized in Table 1.23, 45-47 The electrospinning process cannot directly affect the EMI shielding performance of electrospun fibers. However, the physiochemical properties and morphologic structures of electrospun micro/nanofibers would have certain impacts on their EMI shielding capabilities. For example, electrospun fibers with a high specific surface area and a low porosity would contribute to the reflections of EMWs on the surface of electrospun fibers and the absorption inside them.42 Additionally, many reflecting surfaces between the electrospun fiber-based mats would make them multilevel shielding materials.22

| Influence factors | Physiochemical properties | EMI shielding performance | |

|---|---|---|---|

| Polymer jet | Concentration (↑) | Rough and folded structures (↑) | Absorption (↓) and reflection (↑) of EMW |

| Surface tension (↑) | Diameter (↓), neat and tight fibers | ||

| Volatility (↑) | Appropriate volatility is important for obtaining fibers | ||

| Conductivity (↑) | Diameter of electrospun micro/nanofibers (↓) | Absorption (↑) and reflection (↑) of EMW | |

| Processing factors | Static voltage (↑) | Specific surface area (↑) | Absorption (↓) and reflection (↑) of EMW |

| Feed velocity (↑) | Diameter (↑), inhomogeneous structures | ||

| Collection distance (↑) | Aspect ratio (↑), tensile strength (↑) | Absorption (↑) and reflection (↑) of EMW | |

| Environmental parameters | Humidity (↓) | Diameter (↓), morphology becomes uniform | Absorption (↑) and reflection (↑) of EMW |

| Temperature (↑) | Uniform and delicate fibers, physical property (↑) |

Polymer jet, electrospinning processing factors, and electrospinning environmental parameters are the three key factors affecting the physiochemical properties of electrospun micro/nanofibers. Among them, the features of the polymer jet are significant to obtain electrospun fibers with excellent properties, closely related to the polymer molecular structure and molecular weight. They are directly affecting the shape and size of the electrospun fibers. Subsequently, the electrospinning process factors regulate the morphology, diameter, distribution, and other characteristics of the obtained fiber to a certain extent, thereby affecting the mechanical and morphological properties of the electrospun fibers. An appropriate concentration is required to obtain good spin ability, which is the relative molecular weight of the electrospun polymer. Generally, polymers with high molecular weight are needed to prepare low-concentration electrospun solutions. The concentration of the polymer solution has a certain influence on the electrospun micro/nanofiber.48 Low solution concentration can reduce the intermolecular forces between micro/nanofibers, thereby promoting the formation and stretching of fibers.

Conversely, a higher concentration solution will increase the intermolecular interaction forces, making it difficult for molecules to separate and form independent fibers. Plus, the conductivity of the electrospun polymer solution also affects the morphology of the electrospun fibers. As the dielectric constant of the solution increases, more charge accumulates on the surface area of the jet, leading to a large electrostatic force applied to the polymer jet. Consequently, the diameter of the obtained fiber would become smaller.49 In contrast, the surface tension of the polymer jet would impact the electrospinning process to some extent, which is usually determined by the characteristics of the polymer solution and environmental parameters, including temperature and humidity.50 The volatility of the polymer solution will affect the stability during the electrospinning process and the formation and stretching of the micro/nanofibers, resulting in problems, such as the diameter and the morphology of the electrospun fibers.

Additionally, the processing factors are also significant for determining the physiochemical properties of the electrospun micro/nanofibers. Static voltage, collection distance, and feed velocity are crucial for electrospinning. Among them, the applied electrostatic voltage is essential to ensure successful electrospinning, which must be higher than a certain threshold level.51 Increasing the voltage will increase the charge density on the polymer jet surface, resulting in finer fiber diameters. The propulsion speed of the injection pump is another critical factor impacting electrospinning results. If the speed fluctuates continuously, it can destabilize the Taylor cone, resulting in non-uniform fibers. Additionally, the ideal collection distance for electrospinning is essential to obtain desirable fiber morphology, as solvent evaporation occurs after the fibers are spun out and solidified on a collector. Therefore, it is important to consider the solvent evaporation rate when setting an appropriate collection distance, which is key to enhancing EMW dissipation within the fibers.

Finally, the electrospinning environmental parameters affect the fiber stretching and solidification during the fiber formation process, which influences the surface properties and physiochemical properties of the electrospun micro/nanofibers. Commonly, reducing environmental humidity benefits the diffusion and release of solvents, thereby obtaining more uniform fiber morphologies and finer fiber diameters. Correspondingly, a better EMI shielding performance of the prepared fiber materials is obtained. Simultaneously, the environmental temperature directly impacts the electrospinning process, wherein elevated temperature elicits uneven polymer melting and hinders air convection, which impedes the stability of the electric field and the fiber morphology. This engenders irregular fiber shapes, nonuniform diameters, and other defects, consequently reducing the EMI shielding effectiveness.

In the electrospinning process, these three factors work together to decide the microstructures and physicochemical properties of the electrospun micro/nanofibers. Optimizing these conditions can lead to the obtainment of electrospun micro/nanofibers with improved performance. Based on the above discussion, the optimal synergistic interplay of these factors would provide electrospun micro/nanofibers with superior diverse physiochemical properties, resulting in fascinating EMI shielding capabilities.

3.1 Thickness and density

It is known that increasing the thickness and density of the electrospun micro/nanofiber membrane is an efficient method to improve the absorption and reflection of EMWs in electrospun EMI shielding materials.52 Generally speaking, thicker electrospun micro/nanofiber membranes can show a higher energy dissipation of the EMW within them. Similarly, electrospun micro/nanofibers with larger densities would exhibit a greater reflection of the EMW. Both of them, with higher values, can effectively improve the EMI shielding performance of electrospun materials.

Yuan et al.53 compared the EMI shielding performance of Fe3O4@SiO2@polypyrrole (FSPG) electrospun composite fiber membranes with different thicknesses and found that raising the electrospun membrane thickness can increase EMWs loss, thereby improving the EMI shielding effectiveness. Afterward, Jiang et al.54 prepared electrospun polyacrylonitrile/polyaniline-hydrochloric acid/multi-walled carbon nanotubes (PAN/PANI-HCl/MWNTs) for EMW shielding. They discovered that a higher PANI-HCl content can produce electrospun nanofibers with a higher thickness and density. The experimental results indicate that the greater the thickness and the density are, the better the EMI shielding ability of the obtained electrospun membrane. Ju et al.55 applied an auxiliary electrode to get oriented electrospun micro/nanofibers, significantly increasing fiber density from 2 to 4.2 fibers/cm. Plus, the porosity of the materials is lower than that of the traditional electrospun micro/nanofibers. As atomic layers continually deposit on the fiber surface with increasing fiber density, the fiber morphology improves, and defects are filled, resulting in enhanced conductivity and improved electromagnetic shielding performance of the fiber membrane.56 Table 2 summarizes relevant research on the EMI shielding performance of electrospun-based materials.

| Materials | Thickness (mm) | Conductivity (S/m) | EMI SE (dB) | Absorption frequency(GHz) | References | |

|---|---|---|---|---|---|---|

| Carbon-based dopants | AMS films | 0.6 | – | ~100 | 8.2 ~ 12.4 | 57 |

| CNF/Co3SnC0.7 | 2.3 | – | 51.2 | 7.44 | 58 | |

| CNF/GN/CNF | 0.22 ~ 0.27 | 0.8 | 25 ~ 28 | 8.2 ~ 12.4 | 59 | |

HAMS films Ni@G-P films |

0.5 0.7 |

0.0768 – |

43.3 51.4 |

18 ~ 26.5 8.2 ~ 12.4 |

60 | |

| MWCNT/PVA | 3 | – | 40.5 | 12 | 61 | |

| MWCNT/SiO2/PVDF | 0.4 ± 0.005 | – | ~20 | 8.2 ~ 12.4 | 62 | |

MWCNTs COOH/Fe3O4-TPU/PDA/Ag |

– | 361 | 85.4 | 8.2 ~ 12.4 | 63 | |

| MWCNT/PAN(BP/NF-130) | 0.1 | 6.17 | 23.3 | – | 64 | |

| CNT-PHEMA | 2 | – | 20.42 | 8.2 ~ 12.4 | 65 | |

| Metal-based dopants | PDA/(Ag, Cu) | 1.2 ~ 5×10−3 | – | 44.7 ~ 76.8 | 8 ~ 200 | 66 |

| PVA/(Cu, Ag, Ni) | – | – | 30 | 0.5 ~ 18 | 67 | |

| PVA/Fe2O3/Ag | 0.2 | – | 23.2 | 10 | 68 | |

| PVA/Fe3O4 | 0.075 | – | 40 | / | 69 | |

| PVA/AgNT | ~1 | – | ~35 | 8.2 ~ 12.4 | 70 | |

PAN@SiO2-Ag-PEDT PAN@ SiO2-Ag |

0.05 0.05 |

177.88 – |

81.01 22.68 |

8 ~ 12 8 ~ 12 |

71 | |

| PAN/W18O49/Ag | 0.11 | 304 | 100.9 | 8 ~ 26.5 | 72 | |

| CPAN/Ag | 0.053 | – | ~90 | 8.2 ~ 12.4 | 42 | |

| APAN-Ag-SA | 0.031 | 57.319 | 90.14 | 8.2 ~ 12.4 | 73 | |

| TCCNFs | – | – | 93 | 8.2 ~ 12.4 | 74 | |

| TPU/Fe3O4@MWCNT | – | 2.2 × 105 | 78.48 | 8.2 ~ 12.4 | 75 | |

| PAN/CNT-CoFe2O4 | – | – | 3.9 | 12 | 76 | |

| CF-ZONF | 2 | 0.0201 | 58.6 | 8.2 ~ 12.4 | 77 | |

| Conductive polymer | PANI/PEO/MWCNT | – | 4.8 | 42 | 0.8 ~ 8.5 | 78 |

| PANI/CF (CPF) | 2.5 (3.6) | – | 58.5 (68.6) | 6.9 (3.8) | 79 | |

| CPCs | – | 245.7 ± 30.6 | 96.9 | 12.4 | 80 | |

| TPU/PDA/AgNP/MXene | 0.015 | 952.38 | 108.8 | – | 81 | |

| TPU/PDA/Ag | 0.045 | 173.06 | 109 | 12.1 | 82 | |

| TPU/PDA/Fe3O4 (TPFM) | ~0.45 | – | 32.5 | 8 ~ 12 | 83 | |

| ZrC/SiC | 1.8 | 0.13 | 20.1 | 8.2 ~ 12 | 84 | |

| Janus Ti3C2Tx-(Fe3O4/PI) | 0.075 | – | 66 | 8 ~ 12 | 85 | |

| PPy/TiO2/SiO2/ rGO | / | – | 38 | 8 ~ 12 | 86 | |

| PPy/ZnFe2O4/C/ | 1.93 | – | 66.34 | 13.8 | 87 | |

| PVDF/PEDOT | 0.014 | – | ~40 | 8 ~ 12 | 88 | |

| Mxenes dopants | M@GAMS | 1.2 | – | 49.1 | 14.2 | 89 |

| TaC/C | 0.2 | 10.4 | 37.7 | 8.2 ~ 12.4 | 90 | |

| TaC/Fe3C-Fe | 0.18 | 15.4 | 46.4 | 8.2 ~ 12.4 | 91 | |

| Magnetic dopants | Fe3O4/PVP (FCNF) | 1 | – | 22 | 8.2 ~ 12.4 | 92 |

| Fe3O4/REPT NFs | – | – | 28.3 | 11.5 | 93 | |

| BMFO-PVDF | 3 | – | 28 | 2 ~ 3 | 94 | |

3.2 Porosity and specific surface area

Generally speaking, more multiple internal reflections happen for electrospun membranes with finer fiber diameters, smaller pore sizes, and larger specific surface areas, offering better EMI shielding effectiveness.

Nasouri et al.95 investigated the link between the diameter and the porosity of electrospun multi-walled carbon nanotubes (MWCNTs)/polyvinylpyrrolidone (PVP) fibers and their EMI shielding efficiency. In their study, electrospun membranes with various fiber diameters and porosities were obtained by adjusting the electrospinning process parameters and solution concentrations. The experimental results show that higher solution concentrations would produce electrospun films with thicker fibers, a lower porosity, and a poorer conductivity, which induces relatively lower EMI shielding effectiveness. Similarly, Yang et al.82 prepared composite thermoplastic polyurethane/polydopamine/silver (TPU/PDA/Ag) micro/nanofibers using electrospinning, which were heat-pressed into thin films. They found that the EMI shielding performance of the heat-pressed film is superior to that of the electrospun film. Although this compact membrane shows a smaller surface area, which is unfavorable for thermal losses of EMWs, the synergistic effects of their smaller porosity and a continuous conductive layer formed by the hot-pressing process endows them with a fascinating EMI shielding capability.

3.3 Conductivity and magnetic permeability

In general, adding conductive and magnetic fillers into the electrospun precursor solution can improve the overall conductivity and magnetic permeability of electrospun micro/nanofibers. Accordingly, the resulting electrospun membrane would display a better EMI shielding effect than the pure electrospun film because more free electrons exist in the electrospun composite materials. When the EMW comes into contact with the surface of the material, it will be easily reflected. In addition, the obtained material with a higher magnetic property owns a larger magnetization, allowing it to tend to dissipate and absorb more EMWs.

Bayat et al.96 utilized an electrospinning technique to prepare multifunctional composite carbon nanofibers embedded with Fe3O4. They investigated the effects of the contents of the Fe3O4 on their SE on the X-band (8.2–12.4 GHz). The experimental results indicated that a larger Fe3O4 content in the composites would enhance their magnetic and dielectric losses, improving EMI shielding performance. They also demonstrated that the composite materials with a thickness of approximately 0.7 mm show the highest EMI shielding effectiveness of 67 dB. Similarly, Nosouri et al.92 fabricated a high EMI shielding efficiency membrane by incorporating Fe3O4 into electrospun PVP. They found the magnetic properties of the composite material improved with increasing Fe3O4 content. The obtained product with a thickness of 0.7 mm owns a SE of nearly 22 dB. Additionally, Im et al.97 prepared EMI shielding micro/nanofibers containing FBC (Fe2O3, BaTiO3, MWCNTs) or FB (Fe2O3, BaTiO3) by electrospinning and heat treatment, whose EMI shielding efficiencies reach 40 and 36 dB, respectively. They studied their conductivity and permeability and found that the resulting sample with FBC possesses a higher conductivity than that with FB due to the dielectric properties and permeability of carbon nanotubes in the FBC.

4 ELECTROSPUN EMI SHIELDING DOPANTS

As mentioned before, the SE of electrospun micro/nanofiber members largely depends on the synergistic effects of their physiochemical properties, including thickness, density, porosity, specific surface area, conductivity, and magnetic permeability. To achieve better absorption for EMWs, multiple loss mechanisms must be built into the electromagnetic absorbing materials to fulfill the demands of high absorption and wide effective absorption bandwidth (EAB), such as electric loss and magnetic loss.39 Generally, the forms of the EMW shielding by electrospun composites are determined by the amounts of reflection and absorption. When EMWs hit the surface of the EMI shielding materials, the EMW would be reflected because of the high electrical conductivity arising from the interaction between the incident EMWs and charge carriers on the surface of the material.98 Absorption loss is the main form for attenuating the entering EMWs, which would be improved if the materials owned a matching dielectric and magnetic constant. Because appropriate electromagnetic parameters can enhance the impedance matching and attenuation capability of the EMI shielding materials,40 EMI shielding materials with high conductivity will exhibit low dielectric constants,30 which is a benefit for increasing the reflection of EMWs. Therefore, enhancing the reflection and absorption of the EMW for the materials are two key factors in achieving an excellent EMI shielding performance. Electrospun membranes possess several advantages of high surface area-to-volume ratio and high porosity, resulting in numerous interfaces between micro/nanofibers.99 The interfacial actions of composite micro/nanofibers promote multiple reflections of EMWs within the electrospun materials, leading to absorption losses of the EMW in them. As a result, the EMW entering them would be reflected back and forth inside until they were entirely absorbed. Therefore, incorporating high-performance EMI shielding fillers into the electrospun mats is one widely adopted approach to increase their EMI shielding ability, which may assist in avoiding secondary electromagnetic pollution to some extent.

These include carbon, metal-based fillers, conductive polymers, transition metal carbides/nitrides, and magnetic fillers. Each type of filler possesses distinct characteristics, rendering them suitable for specific applications. For example, carbon-based fillers are known for their exceptional conductivity and stability, making them attractive options for EMI. Similarly, Conductive polymers are favored due to their ease of preparation and excellent physicochemical properties. Transition metal carbides/nitrides exhibit good electrical conductivity and a strong affinity toward polymer micro/nanofibers, making them promising EMI materials. Magnetic fillers show fascinating permeability, which would dissipate the EMW hysteresis and eddy current losses, making them popular in fields of EMI shielding.101, 102

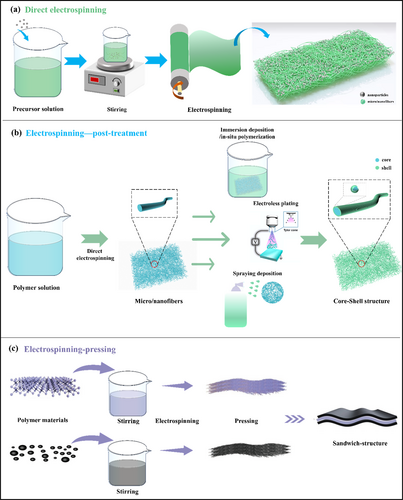

The EMI shielding performances of composite electrospun micro/nanofibers typically depend on the types and proportions of introduced fillers.103 The composite micro/nanofibers acting on EMWs' mechanisms vary according to the type of dropping filler within. In addition, the incorporating method of the fillers can also significantly affect their shielding mechanism against EMWs. Commonly, three main methods exist to load the filler into the composite electrospun micro/nanofibers. The first mean is direct electrospinning, which directly electrospun the polymer solution containing polymers and fillers to obtain composite EMI shielding materials (Figure 3a). The second way is electrospinning-post-treatment, which prepares electrospun EMI shielding films with core-shell structures by electrospinning and post-treatment. The post-treatment technique loads the fillers into the electrospun membrane, mainly including immersion deposition, in-situ polymerization, electroless plating and spraying deposition61, 81, 100 (Figure 3b). The last is electrospinning-pressing to get the EMI shielding films with the sandwich-structure (Figure 3c). Among them, the loaded nanoparticles are uniformly deposited on the surface of the fiber by mixing the nanoparticles into the electrospinning solution and electrospun with the micro/nanofiber. Similarly, the core-shell structure encapsulates the nanoparticles outside the electrospun micro/nanofiber to form a shell covering the surface of the fiber.

4.1 Carbon-based dopants

Metallic fillers such as silver, copper, and iron are commonly used as EMI shielding dopants due to their effective reflections of EMWs. However, reflected EMWs inevitably lead to secondary pollution. Furthermore, their inherent properties containing a high mass, poor flexibility, and low processability further limit the applications in EMI shielding. Compared to traditional metal-based fillers, carbon-based filler embedding electrospun composite materials generally exhibit lightweight, strong stability, and easy processability. Thus, electrospun polymer composite materials with carbon-based filler are ideal substitutes for high-performance EMI shielding applications.52, 104-107 Abdalla et al.108 prepared a porous fibrous CNFs/rGO film via electrospinning and a followed carbonization treatment. The results demonstrate that the carbon-based composite film with a thickness of 5 mm shows a minimum reflection loss of −43.60 dB. This indicates the carbonized polymer nanofibers can dissipate the incident EMW. Ramlow et al.109 obtained lightweight and flexible C/SiCN nonwovens through electrospinning and polymer-derived ceramic route. The experimental result shows that the C/SiCN exhibits a reflection loss of < −10 dB in the 5G C-band (90% of EM shielding). Yan et al.110 prepared porous GN/PS composites by high-pressure compression molding and a salt-leaching method. The porous functionalized graphene sheets (FGS)/PS composite at a relatively low density displays an average EMI SE of approximately 29 dB, which shows potential as a lightweight shielding material against electromagnetic radiation. Many studies have mentioned that carbon-based electrospun materials can be employed as EMI shielding applications.22, 111 The most used carbon-based fillers can be classified into carbon nanofibers (CNFs),111 graphene (GN),112 and carbon nanotubes (CNTs),113, 114 which have been extensively studied for the preparation of electrospun EMI shielding materials.

4.1.1 CNFs

Carbon nanofibers have attracted widespread attention in EMI shielding due to their excellent electrical properties, environmental friendliness, chemical inertness, and ease of preparation.111 PAN is a commonly adopted precursor for preparing carbon micro/nanofibers due to its high carbon formation rate. Electrospun PAN micro/nanofibers display a high specific surface area and excellent conductivity, making them one of the preferred materials for EMI shielding. Xu et al.115 prepared high-performance copolymerized PAN (coPAN) nanofibers using copolymerization and electrospinning techniques, increasing tensile strength from 304 to 595 MPa. Subsequently, Ma et al.116 obtained CNF by high-temperature carbonization of PAN and introduced it into the upper and lower layers of carbon fiber reinforced composites (CFRCs). Incorporating CNF does not affect the composite material's interlaminar shear strength (ILSS) and significantly improves its shielding performance by 35%. Im et al.117 fabricated a carbon-based EMI shielding material via the same approaches. They found that the material's dielectric constant increases with increasing carbonization temperature, resulting in a high EMI shielding performance.

Additionally, the experimental analysis shows that the EMI shielding effectiveness of this material could reach an average value of 31.79 dB in the frequency range of 800–8500 MHz. Bayat et al.96 used the same process to prepare multifunctional Fe3O4/carbon nanofiber composites and analyzed their corresponding EMI shielding performance. The results show that the electrical conductivity of the nanofibers increased from 0.05 ± 0.004 S/cm to 2.6 ± 0.9 S/cm as the carbonization temperature increased from 700 to 900°C. Accordingly, the nanofibers' shielding effectiveness (SE) increases from 0 to 15 dB. All these studies indicate that electrospun CNFs can be widely applied in the EMI shielding field.

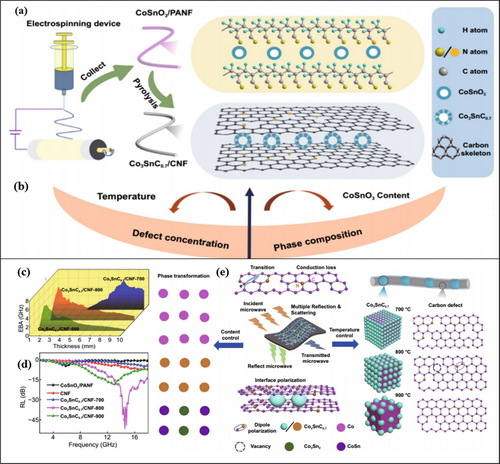

The aforementioned studies have all obtained carbon micro/nanofibers for EMI by carbonization of electrospun pure polymers. However, the EMI capabilities of those materials cannot meet the requirements of modern society. People started to add diverse fillers to enhance their EMI shielding effectiveness. Kang et al.118 prepared a carbon composite nanofiber web containing BaTiO3 and Fe3O4 using electrospinning and carbonization, achieving a maximum SE of 23 dB. Deeraj et al.119 also prepared composite nanofiber materials doped with ZrO2 via electrospinning, which exhibits an excellent EMI shielding ability in the Ku band (12–18 GHz). Additionally, the composites own an SE exceeding 90 dB by stacking this composite fibrous pad up to the 8th layer (thickness less than 0.8 mm). Li et al.57 also prepared a composite film by coating a large area of electrospun CNF and silicone resin on the surface of an alternating multi-layer structure (AMS) for EMI application. The test results show that the SE of this AMS film with a thickness of about 0.6 mm is approximately 100 dB, displaying a fascinating EMI shielding performance. Subsequently, Wang et al.58 reported a one-dimensional N-doped carbon nanofiber (Figure 4a,b), which encapsulated hollow Co3SnC0.7 nanocubes in the electrospun fibrous cavities. A strong impedance matching is achieved through the synergistic effect Co3SnC0.7 in conjunction with the carbon webs. At 800°C, this material with a thickness of 2.3 mm shows a necklace-like Co3SnC0.7/CNF with a low loading of 5%. It exhibits a strong absorption capability of −51.2 dB in the frequency of 14.56 GHz and an effective absorption bandwidth of 7.44 GHz with a matching thickness of 2.5 mm (Figure 4c,d). The multiple EMW reflections and interfacial polarization between the fibers and the fibers internally contribute to attenuating the EMW, as shown in Figure 4e.

4.1.2 GN

Graphene not only possesses comparable stability and physicochemical properties similar to CNF but also shows a unique feature of repairing these defects of EMWs transmission and absorption, making it one of the most attractive candidates for designing EMI shielding materials. In addition, GN can significantly enhance the electrical conductivity of electrospun micro/nanofibers without affecting their mechanical flexibility and structure integrity.120 Graphene has a higher tensile strength than CNTs and a more significant thermal conductivity than any other carbon-based fillers. Meanwhile, the design and production of innovative, flexible, lightweight, and robust materials having outstanding EMI sheltering characteristics is now an imperative mission.121, 122 It is a good choice as a filler for electrospun polymer nanocomposites for EMI shielding applications. GN, a wonder material, exhibits great promise in various fields with its unique electronic structure and excellent physical, chemical, electrochemical, thermal, and mechanical properties.123, 124

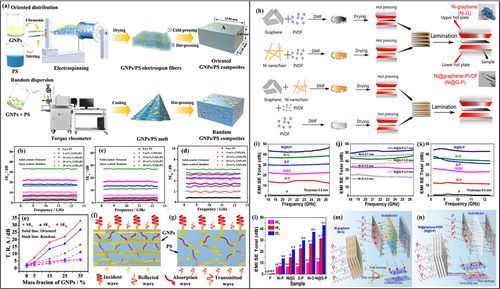

Many studies have explored an optimal preparation strategy to preserve GN's inherent physicochemical characteristics and create high-performance EMI shielding materials. Guo et al.125 prepared polystyrenes (PS) based composites containing interconnected and oriented graphite nanoplatelets (GNPs) via electrospinning, cold-pressing, and hot-pressing. As shown in Figure 5a, the obtained composite materials endow with oriented distribution and random dispersion of GNPs/PS, which display an excellent EMI shielding effectiveness due to the formation of thermally and electrically conductive networks. Figure. 5b–d presents the EMI SE values of the random and oriented GNPs/ PS composites at 8.2–12.4 GHz (X-band) frequency. From Figure. 5e, the SET, SEA, and SER all enhance with the increasing addition of GNPs and the SET, SEA, and SER of the oriented GNPs/PS composites are all higher than that of random GNPs/PS composites, and the SEA of all the GNPs/PS composites is higher than SER. Besides, the oriented GNPs/PS composites have stratified structures. The EMWs will have multi-reflection and absorption during transferring multi-layer GNPs (Figure. 5f). Moreover, the multi-reflection and absorption effects of the EMWs inner random GNPs/PS composites are also reduced due to poor conductive networks (Figure. 5g). And the SE of composite materials with 35 wt% GNPs and a thickness of 3 mm are found to be 33 dB. Subsequently, Liang et al.60 used electrospinning to prepare flexible PVDF membranes with alternating GN/Ni nanochain orientations for EMI shielding and heat dissipation applications, as shown in Figure 5h. The heterogeneous alternating multilayer structure (HAMS) of the flexible PVDF membrane can form a practical electron-conducting pathway, resulting in an optimal electrical conductivity of 76.8 S/m. In particular, the unique structure can simultaneously enable coordinated electromagnetic losses and multi-stage electromagnetic reflections of EMWs, as shown in Figure 5m,n. The results show that HAMS membrane with a thickness of 0.5 mm can exhibit a high EMI SE of 43.3 dB (Figure 5i,k), which can be further improved to 51.4 dB when the thickness increases to 0.7 mm (Figure 5j,l). reveals the specific ratio of SEA in SET of more than 50%. These results suggest the absorption dominant shielding mechanism for HAMS films. Both oriented distribution and HAMS could interconnect with each other to form effective conductive networks, thereby significantly enhancing the shielding performance of EMI materials.

Subsequently, Song et al.59 prepared a new flexible all-carbon network by electrospinning a blend of PAN and graphene, followed by high-temperature carbonization to eliminate the insulating framework of the composite material and form a CNF-GN-CNF heterostructure. These heterostructures are important interface modifiers that can significantly improve the conductivity of the obtained matrix, thus highly enhancing its EMI SE, and the composite networks with 31.9 wt% GN, this material with a thickness of about 0.22–0.27 mm show a relatively superior SE of 25–28 dB. Afterward, Bian et al.126 introduced the reduced graphene oxide (rGO) into electrospun CF networks via a similar method to prepare a novel graded carbon fiber/reduced graphene oxide/nickel (CF/rGO/Ni) composite textile. The EMI shielding performance indicated that the graded composite textile possesses a strong shielding effect greater than 61 dB, demonstrating a fabulous advantage over a conventional polymer shielding composite film. Similarly, Huang et al.86 electrospun a multi-scale double-continue conductive network (TiO2/SiO2@PPy@rGO). The sandwich structure works as an effective dissipative medium, leading to a high SE of approximately 30 dB in the X band.

4.1.3 CNTs

Carbon nanotubes can be classified into single-walled carbon nanotubes (SWCNTs) and MWCNTs.127 SWCNTs are more difficult and expensive to prepare compared to MWCNTs. Therefore, MWCNTs are usually chosen as conductive reinforcing fillers. Additionally, the excellent electrical conductivity (104 S/cm) and thermal conductivity (over 200 W/mK) of MWCNTs make them one of the most promising fillers in EMI shielding applications.128 In terms of electrospun MWCNT/polymer composites, several studies have shown that they exhibit excellent physicochemical properties, including lightweight, high porosity, large surface area, and strong stability.29 Especially those composed materials with low MWCNT loadings also own outstanding conductivities and high EMW absorption capabilities.129, 130 Those facts addressed that electrospun MWCNT/polymer membranes are preferred for constructing high-performance EMI shielding materials.

Commonly, the interconnection between MWCNTs can form a relatively complete conductive network, resulting in a high enhancement of EMI shielding abilities for electrospun micro/nanofibers embedded with them. For instance, Im et al.78 prepared PANI-based fibers with MWCNT and polyethylene oxide (PEO) by electrospinning and employed them as EMI shielding materials. To improve the EMI shielding performance of the material, their surfaces were modified by fluorination treatment, leading to the dispersion and adhesion of MWCNT in PANI/PEO fiber. The test results established that the composite fibers with the MWCNT load of 82 wt% display an excellent conductivity (4.8 × 103 S/m) and superior SE of about 42 dB. In contrast, Quanamnia et al.131 fabricated polystyrene (PS) nanofibers incorporated MWCNTs at varying concentrations ranging from 0 to 10 wt% via electrospinning. They found an opposite result: the addition of MWCNTs induces a decrease in the material's electrical conductivity due to the disorientations of MWCNT with increasing concentrations. Subsequently, Nasouri et al.61 fabricated electrospun lightweight conductive MWCNT/polyvinyl alcohol (PVA) composite nanofibers and studied the effects of several factors, including MWCNT contents, composite fiber thickness, and EMW frequency on their EMI shielding performance. They found that the composites with a thickness of 3 mm and MWCNT loading of 7.7 wt% show a low reflection loss of 8.8 dB and a maximum absorption loss of 31.5 dB at 12GHz frequency. Shoushtari et al.132, 133 prepared MWCNT/PVP composite nanofibers with different contents of MWCNT via electrospinning and measured their EMI shielding performance in the X-band (8.2–12.4 GHz) frequency range. They found that their SE can be as high as 42 dB. Chen et al.134 fabricated CNT/PAN composite nanofibers with uniform sizes through electrospinning and carbonization. Subsequently, they tested the EMI shielding performance of the obtained materials in the frequency range of 300 MHz to 3GHz. The results present that the thin carbon fiber sheets can even achieve more than 15 dB. When its thickness increases to 150 μm, the SE of the composite material can reach more than 30 dB. Similarly, Jiang et al.135 prepared PAN/MWCNT composite nanofibers via electrospinning and the test showed that the EMI shielding efficiency reached over 90% in the frequency range of 1–15 MHz when the MWCNT content was above 10%.

As mentioned, MWCNT shows a high porosity and specific surface area, which can offer a good shielding effect on EMWs in the lower frequency band. For example, through electrospinning, Salimbeygi et al.136 prepared PVA sodium dodecyl sulphate (SDS)/MWCNT composite nanofibers. It was found the 1 mm thick PVA/SDS/MWCNT nanofibrous film with 10 wt% MWCNT loading exhibits a maximum reflection loss of 15 dB at 8 GHz, wherein the average diameter of the nanofibers is 224 ± 30 nm. Soon afterward, Chen et al.65 applied magnetic-assisted electrospinning to produce CNT-poly(2-hydroxyethyl methacrylate) (CNT-PHEMA) composite material with arranged CNTs. The obtained materials present an awesome EMI shielding absorption performance and self-healing ability. Uniquely, the effective EWM absorption of the material is also largely due to the ordered CNT arrangements and high porosity. The SE of the 2 mm thick textile with very low CNT loading (0.17 wt%) is even 20.42 dB at a frequency of 11.3 GHz. Kim et al.64 prepared an ultrathin and lightweight MWCNT buckypaper/electrospun PAN nanofiber (BP/NF) film by electrospinning, thermal-rolling, and vacuum filtration. The BP/NF-130 (thermal-press at 130°C) composite film with a thickness of 100 μm possesses a good conductivity (6.177 S/cm) and an EMI SE of 23.3 dB. Ramírez-Herrera et al.137 developed interlayered composites consisting of MWCNT-filled polypropylene (PP) composite and carbon nanofiber mats to improve the conductivity and EMI shielding efficiency. The SE of assembled materials increases from 17 to 52 dB as the layer number changes from signal-layer to eight-layer at a frequency of 900 MHz. Sung et al.138 electrospun MWCNT and polyurethane (PU) to prepare (MWCNT-PU) nets, which show a remarkable SE up to 25 dB in the frequency range of 50 MHz–10 GHz.

4.2 Metal-based dopants

The fundamental requirements of shielding materials are the presence of electric dipoles and magnetic dipoles capable of interacting with the EMI field, such as high dielectric constant materials (BaTiO3) and high magnetic permeability materials (Fe2O3, Fe3O4, etc.).65, 97, 139 Traditional metal-based materials containing silver, copper, iron, and other highly conductive metals possess freely moving charge carriers that can interact effectively with electric fields and reflect EMWs. However, their employment in EMI shielding is limited by high cost, facile corrosion, and challenging processing. Consequently, incorporating metal-based fillers (e.g., metal nanoparticles, metal oxides) into electrospun composite fibers is an efficient way to realize high-performance electromagnetic shielding.42, 140, 141

4.2.1 Metal nanoparticles

Metal nanoparticles with nanoscale structures and excellent conductivities are effective fillers for preparing high-performance EMI shielding materials.75 Goude et al.142 synthesized carboxymethyl cellulose nanofibers (CMC-NFs) doped with different metal nanoparticles (Cu, Fe, Zn, Cd, and Co) via electrospinning. They evaluated their EMI shielding properties and found that the types of loading metals significantly influence the conductivity and EMI shielding performance of the resulting fibrous mats. Building upon this work, Kim et al.68 prepared PVA composite nanofiber webs decorated with Fe2O3 and Ag nanoparticles using a combination of electrospinning and metal deposition. They studied the EMI shielding performance of various composite nanofiber webs with different thicknesses. Experimental results indicate that Ag-coated nanofibers with 10% Fe2O3 show an exceptional SE of up to 45.2 dB at a frequency of 10 GHz. Wei et al.143 prepared polyethersulfone PES/PDA/Ag nanofibers with good electric conductivity by electrospinning and in situ polymerization.

In contrast to regular PES micro/nanofibers with 2.1 × 109 Ω/cm, the electrical resistivity of PES/PDA/Ag decreased to only 202 Ω/cm via the optimized AgNPs preparation process. Furthermore, the EMI shielding efficiency of metal-deposited nanofiber mats rises proportionally with the thickness of the deposited layer, which is also true in both bi-metallic and multi-metallic deposition systems.67 Zeng et al.66 designed a novel cell membrane structure based on a facile PDA-assisted metal (copper or silver) deposition on electrospun polymer nanofibers, which exhibits superior electrical conductivity, mechanical flexibility, and an ultrahigh EMI shielding performance. The analysis of their EMI performance unveils that the prepared membrane, merely 2.5 μm thick at a density of 1.6 g/cm3, shows an EMI SE exceeding 53 dB across a broad frequency range. Additionally, the corresponding EMI SE of this film remains high at 44.7 dB as its thickness decreased to 1.2 um.

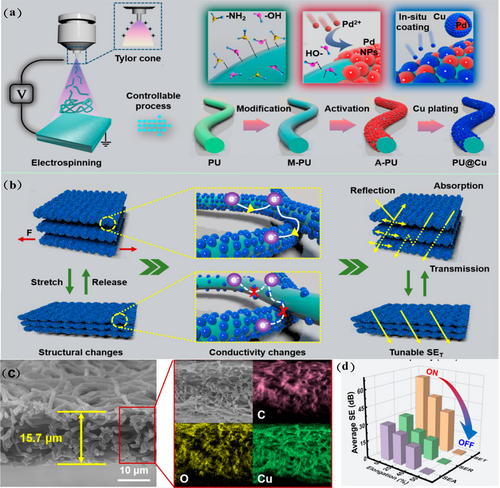

The EMI shielding effectiveness of metal-based shielding materials tends to increase with the amount of loading fillers.144 Chiscan et al.145 reported polyvinyl chloride (PVC)/Fe composite nanofibers via depositing Fe nanoparticles with varying concentrations onto the surfaces of PVC nanofibers with sizes ranging from 100 to 500 nm. The EMI shielding performance of the resulting composite fibers in the X-band is evaluated, and the results demonstrate that their EMI shielding effectiveness can be effectively tuned by controlling the concentrations of Fe nanoparticles. Ji et al.42 synthesized highly efficient cross-linked polyacrylonitrile (CPAN) composite films incorporating Ag, Cu, and Ni via electrospinning and chemical deposition. Experimental analyses show that the CPAN/Ag hybrid membrane (with a thickness of 53 μm) displays an excellent SE up to 90 dB, significantly higher than that of the hybrid films made of the other two metal nanoparticles. Li et al.71 used a similar technique to deposit Ag onto an electrospun fiber membrane. Then, they endowed a core-shell structure to the nanofiber via a simple wet-chemical deposition process. The research showed that this material exhibits a high electrical conductivity (approximately 17,788 S/m) and a strong EMI SE (approximately 82 dB). Plus, the composite film has a certain hydrophobicity and acid-alkali resistance properties. Yang et al.73 also chemically deposited Ag on electrospun polymer nanofibers, which are then modified with stearic acid (SA) to obtain a porous blend film with spatially distributed Ag coating. This composed film achieves an excellent conductivity of 57,319 S/cm and an EMI SE up to 90.14 dB in the ultra-wideband frequency range. Subsequently, Xia et al.100 chemically plated Cu on electrospun polyurethane (PU) nanofibers (Figure 6a), which can change from conducting to insulating when the stretch deformation reaches 50% and then back to conducting as the stress is released. The deformation causes repeated separation and contact of Cu nanoparticles on the surfaces of PU, thereby realizing effective shielding of EMWs (Figure 6b). This conductive fabric PU@Cu with stretching ability can dissipate EMWs by changing its structural properties. When the thickness of the materials is approximately 15.7 μm (Figure 6c), its EMI SE can be experimentally varied from 0 to 52.31 dB in real-time (Figure 6d).

Electrospun TPU usually exhibits remarkable properties, such as high tensile strength, good flexibility, and so forth, so it is often selected as the polymer substrate. Zhai et al.81 prepared multifunctional and highly stretchable EMI shielding fiber membranes using electrospun thermoplastic TPU fiber membranes, PDA, Ag nanoparticles (AgNPs), and MXene nanosheets. The TPU/PDA/Ag/MXene (TAMF) fiber membrane with a thickness of 150 nm has an ultra-high conductivity of 95,238 S/m and excellent EMI SE of 108.8 dB in the X-band. Subsequently, Yang et al.82 prepared a TPU/PDA/Ag composite material with superior EMI shielding capabilities by combining electrospinning, chemical deposition, and pressing techniques. When the thickness of the composite film is 45 μm, its SE is 109 dB in the X-band. This study proposed a unique fibers-induced segregated-like structure strategy for preparing EMI shielding materials, where a continuous Ag layer composed of a distinct quasi-segregation structure endows the composite film with a successive thermal conduction path. When such materials are applied in high-power LED modules, they can ensure a certain level of EMI SE and present a good thermal management ability. This study is significant for developing high thermally conductive and EMI shielding composite materials.

Similarly, Yang et al.75 introduced the AgNWs layer into the electrospun TPU fibrous film decorated by Fe3O4@MWCNT. The unique asymmetric conductive network with an interconnected thermally conductive path was successfully constructed, composed of the bottom TPU/Fe3O4@MWCNT fibrous film for the EMW absorption and the upper AgNWs layer for the EMI shielding. The resultant film showed remarkable conductivity (2.22 × 105 S/m), excellent SE (up to 78.48 dB), and super-high in-plane thermal conductivity (7.83 Wm−1 K−1).

In other studies, Huang et al.146 fabricated a multifunctional electrospun PU fiber with a unique multidimensional conductive network structure. Then, they deposited Ag onto its surface using an Ag adsorptive reduction process to achieve high-performance EMI shielding. Jiang et al.70 also prepared a fibrous membrane with a silver-carbon nanotube (AgNT) network structure by electrospinning and physical deposition techniques, as shown in Figure 7d, which also exhibits an excellent EMI shielding effectiveness and achieved thin-layer Rs of 1.0 Ω/sq and an EMI SE of 35 dB (Figure 7c,d). Figure 7b shows the shielding mechanism of AgNTs. Subsequently, Zhang et al.80 proposed a method to get highly conductive and durable nanofiber composites assisted with PVP. PVP-assisted preparation of the PVP/Ag@PU is schematically described in Figure 7e, which acted as an interface adhesive to significantly improve the interface interactions between Ag and the electrospun base material. It can be seen from Figure 7g,h that the SEA, SER, and SET all increase with the increase of the PVP concentration.

Furthermore, the PVP can form a protective layer to prevent oxidation of the Ag and enhance the mechanical properties of the polymer nanofibers. The prepared nanofiber composites have excellent EMI shielding performance (a conductivity of 245.7 ± 30.6 S/cm and an EMI SE of up to 96.9 dB). The EMI shielding mechanism is in Figure 7f. The facile fabrication approach for core-shell structures enables the preservation of multi-functionality to a significant extent for EMI materials, thereby endowing them with substantial potential in industrial applications. Wang et al.72 constructed a ternary PAN/W18O49/Ag composite nanofiber membrane through electrospinning and post-treatment. The conductivity of this membrane is as high as 30,400 S/cm−1. When the thickness of the membrane is 0.11 mm, its highest EMI SE in the frequency range of 8–26.5 GHz can reach 100.9 dB. Zhang et al.147 used electrospinning technology to obtain thermally stable and highly ductile EMI shielding membranes with sandwich structures. Their interlayers consist of two identical layers of Ag/polyimide (PI) nanofiber mats and the signal layer of very conductive MXene nanosheets. After hot pressing, the obtained membrane is endowed with excellent mechanical properties and EMI shielding performance (the highest SE in the X-band is 40.73 dB). Ju et al.74 obtained TCCNF by embedding TiN and Co in CNF through electrospinning and annealing. The EMI shielding test results show that TCCNF demonstrates an ultra-high SE of 93 dB in the 8.2–12.4 GHz frequency range. Kazushige et al.148 reported that Cu was deposited on the electrospun PVA composite nanofibers using the metal deposition technique. The Cu-deposited composite nanofibers showed a maximum EMI SE of about 25.1 dB at the frequency range from 0.5 to 18 GHz.

4.2.2 Metal oxide

Metal oxide is another powerful dopant in metal-based fillers for preparing EMI shielding materials.96 Much research has been conducted on combining metal oxide NPs, including iron, copper, and other metal oxides, with electrospun polymers for high EMI shielding fields.

Fe3O4 is a great filler for EMI shielding owing to its advantages of a great filler with low toxicity and a small permeability threshold. And Fe3O4-based composite materials with a certain loading content can also achieve high EMI shielding performance, thus attracting lots of attention in recent years.96, 149 Chiscan et al.150 deposited Fe3O4 nanoparticles on electrospun PVC to obtain a PVC/Fe3O4 composite nanofiber. They found that its EMI absorption property in the X-band can be turned by adjusting the loading amount of Fe3O4 in composite materials. Specifically, the composite nanofibers exhibit a transmission loss below −16 dB in the microwave frequency range of the X-band. Kim et al.68 incorporated Fe2O3 and Ag into electrospun PVA nanofiber webs through the same method. The experimental results show that the EMI shielding effectiveness of the composite fiber correspondingly increases with increasing the thickness of the metal layer on the fiber surface. The SE of the obtained material with 10% Fe2O3 content could reach 45.2 dB in the frequency range of 10 GHz. Bayat et al.151 developed an EMI shielding composite nanofibers using electrospinning and heat treatment. They investigated the effect of Fe3O4 nanoparticle size and content on the microstructure and electromagnetic properties of the composite. The diameter and conductivity of the composite nanofiber become larger with bigger Fe3O4 nanoparticles, leading to a high EMI shielding. Bayat et al.96 electrospun multifunctional Fe3O4/carbon nanofiber composite materials and tested their EMI shielding effectiveness in the X-band by examining Fe3O4 loading amount, carbonization temperature, and fiber thickness.

The test results indicate that a composite fiber with a 5 wt% Fe3O4 loading and a thickness of 0.7 mm exhibits the highest EMI shielding effectiveness (67 dB). Subsequently, Im et al.97 prepared Fe3O4/BaTiO3/MWCNT composite materials with the highest SE of 37 dB by electrospinning and heat treatment. The metal oxide additives preserve their original characteristics during the heat treatment process, and the introduction of MWCNTs increased the conductivity of the composite material. Building on this work, Chen et al.83 prepared TPU/PAN/Fe3O4 composite nanofiber membranes by depositing Fe3O4 onto a unique self-supporting electrospun TPU/PAN film via electrospinning and dip-coating processes. The obtained film shows a high magnetization intensity of 18.9 emu/g, and its SE in the X-band exceeds 30 dB. Nasouri et al.92 prepared a sandwich-structured composite nanofiber for EMI shielding by dispersing Fe3O4 nanoparticles in electrospun PVP fiber using ultrasonic technology. The resulting materials with a 4 wt% Fe3O4 loading realize an SE of approximately 22 dB in the X-band.

ZrO2 is also a popular additive in EMI shielding applications due to its high dielectric constant, low thermal conductivity, chemical inertness, and high hardness.65 Deeraj et al.119 fabricated a ZrO2-doped PAN film via electrospinning and carbonization. Then, they impregnated it with epoxy resin to form ZrO2/CNF-epoxy laminates. The EMI shielding testing revealed that the eight-layer epoxy laminate displays a great reflection performance over −90 dB at the Ku frequency range. Lee et al.152 demonstrated a ZnO nanorod (NR)-decorated PVDF-MXene composite nanofibers for the EMI shielding application. The electrospun PVDF-MXene composite provided superb flexibility, while MXene encapsulated in PVDF and hydrothermally decorated ZnO NRs around the nanofibers offered multiple internal absorption sites. The experiments suggested that the obtained materials demonstrated a high EMI SE of 61 dB in the X-band. Cheng et al.84 utilized polysilazane (PCS) and zirconium acetylacetonate (Zr(acac)3) as precursors to successfully prepare lightweight and flexible ZrC/SiC composite nanofiber mats through electrospinning and high-temperature pyrolysis. The study demonstrated that a three-layer ZrC/SiC nanofiber mat with a thickness of 1.8 mm could achieve an SE of 18.9 dB. When the density of the materials is lower than 0.06 g/cm3, its SSE is up to 315 dB/cm3/g. Notably, the SE of the lightweight EMI shielding material using ZrC/SiC nanofiber mats at 600°C could be elevated to 20.1 dB. This indicates that those materials show considerable potential for applications in high-temperature environments.

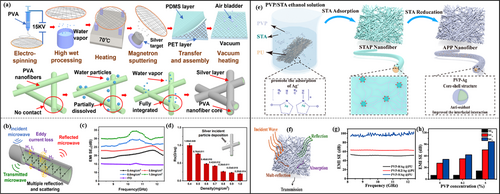

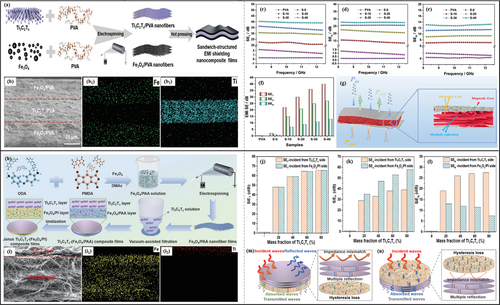

Besides specific metal oxide fillers incorporated with electrospun micro/nanofiber can improve the EMI shielding performance, altering the structure of electrospun composite materials with metal oxide filler can also enhance the absorption and reflection of EMWs. Zhang et al.69 employed an electrospinning-layering-hot pressing technique to prepare sandwich-structured EMI shielding nanocomposite films with PVA as a polymer matrix (Figure 8a). Fe3O4/PVA composite fibers are located on the top and bottom layers. In contrast, Ti3C2Tx/PVA composite fibers are positioned in the middle layer (Figure 8b), as indicated by the Fe and Ti elements shown in EDS images (Figure 8b1,b2). Figure 8c–f shows the EMI shielding performance of the sandwich-structure EMI shielding nanocomposite film. When the contents of Ti3C2Tx and Fe3O4 are 13.3 and 26.7 wt%, respectively, the SE of the 75 μm-thick fiber film is about 40 dB. Where after, Wu et al.63 fabricated a composite film using a mixture of polydimethylsiloxane (PDMS)/carboxyl-functionalized MWCNTs and magnetic iron oxide nanoparticles (MWCNTs-COOH/Fe3O4 MFs), which is employed as the top and bottom layers of a sandwich structure with Ag-deposited electrospun TPU fiber membrane as the middle layer to achieve an excellent low reflection and good durability. It exhibits outstanding EMI shielding properties (electrical conductivity of 361 S/cm and EMI SE of 85.4 dB). This obtained film can effectively function as an absorber layer and act as a micro-nano scale superhydrophobic surface. Zhang et al.85 prepared Fe3O4/polyamic acid (PAA) nanofiber membranes by in-situ polymerization and electrospinning (Figure 8h). Then, they obtained a Janus Ti3C2TX-(Fe3O4/PI) film by depositing Ti3C2Tx nanosheets on the surface of the fiber membrane, followed by thermal imidization (Figure 8i). The two sides of this film present completely different properties. The Fe3O4/PI side exhibits excellent hydrophobicity and insulation.

In comparison, the Ti3C2Tx side displays outstanding hydrophilicity and electrical conductivity (Figure 8m,n). When the mass fraction of Ti3C2Tx reaches 80 wt%, the Janus Ti3C2Tx-(Fe3O4/PI) composite shows remarkable EMI shielding properties (SE of approximately 66 dB), and mechanical features (tensile strength of 114.5 MPa, Young's modulus of 5.8 GPa). Figure 8j–l shows the EMI shielding performances of Ti3C2Tx-(Fe3O4/PI) composite films in the X-band. As the EMWs are incident from both sides of the Janus film, the two sides of the film present different EMI shielding effects. Compared to the EMI shielding composite film prepared via a blending-electrospinning-hot pressing process, the sandwich-structured EMI shielding membrane is more conducive to forming magnetic, electrical, and thermal conduction paths, thereby improving their loss absorption toward EMWs.

In other works, Jin et al.76 utilized electrospinning to fabricate CoFe2O4-containing PAN composite fiber membranes, which exhibit a SE of about 3.9 dB and a magnetization intensity of 4.7 emu/g. Nakhaei et al.153 prepared novel TiO2/SiO2 (TS) composite nanofibers using electrospinning. The XRD spectrum of the TS sample displayed both hexagonal SiO2 and rutile TiO2 structures within the polymer matrix. The EMI shielding testing demonstrated that the TS core-shell nanofibers possess excellent microwave absorption properties. Li et al.93 prepared recycled polyethylene terephthalate nanofiber web (RPET NFs) embedded using electrospinning from a bath-sonication solution. Compared with pure RPET NFs, the EMW reflection coefficient, absorption coefficient, and EMI shielding performance of the nanofiber web were significantly enhanced owing to the addition of Fe3O4 nanoparticles. Sharma et al.77 developed a novel lightweight carbon foam (CF) decorated with zinc chloride nanofibers (ZONF) for high-performance EMI shielding via electrospinning. The impedance matching and interface polarization provided by ZONF can effectively improve the CF's ability to absorb EMWs. The experimental results showed that the composite material with a thickness of 2 mm exhibits a great shielding performance in the X-band (SE up to 58.6 dB). Notably, the density of the composite is only 0.28 g/cm3, making it an ideal material for aerospace and next-generation smart electronic devices.

Wang et al.72 constructed PAN/W18O49/Ag composite nanofiber membranes through electrospinning and post-treatment methods, which show outstanding EMI shielding effectiveness against multi-band EMWs. In the infrared band (15–150 THz), the fiber membrane with a thickness of 0.11 mm exhibits a low infrared emissivity (0.26–0.6). It also presents a 99% attenuation rate for 30 keV x-rays as its thickness increases to 1.92 mm. Some studies have focused on the impact of metal oxide types and electrospun polymer solution concentrations on the EMI shielding effectiveness. For example, Jamil et al.154 prepared PVA/Bi2O3 and PVA/WO3 nanofiber mats with various Bi2O3/WO3 loading contents (0–40 wt%) and diverse PVA concentrations (10 or 15 wt%). The results show that the obtained materials with 35 wt% Bi2O3 loading or 35 wt% WO3 loading in 15 wt% PVA indicate great shielding effectiveness against x-rays, respectively.

4.3 Conductive polymers

Typical conductive polymers include polyacetylene (PA), PANI, polypyrrole (PPy), polythiophene (PT), and poly(3,4-ethylene dioxythiophene) (PEDOT), among others.155, 156 Those materials have gained lots of interest in fields of electrostatic protection, electromagnetic interface shielding, energy harvesting, and storage due to their superior characteristics of adjustable electrochemical properties, low density, low cost, favorable biocompatibility, and excellent electrical conductivity (10−11–105 S/cm).157, 158

To prevent agglomerations of functional groups in conductive polymers, they are often added as dopants to electrospun polymers, generating stable composite fibers with a higher charge density and viscosity of composite fibers.159 For example, Lee et al.78 manufactured PANI-based fibers with MWCNTs and PEO via electrospinning. Subsequently, fluorination treatment was directly conducted on the surface of the PANI-based fibers to enhance the dispersion and adhesion of CNTs within to obtain a higher EMI shielding materials with electrical conductivity of 4.8 × 103 S/m and SE of 42 dB. Yanan et al.160 synthesized hydrochloric acid doped with conductive PANI by chemical method and then prepared PANI-HCl/PAN nano-flexible EMI shielding composites by electrospinning technology. The results indicated that the EMI shielding performance of PANI-HCl/PAN increases correspondingly with film thickness. In particular, the EMI shielding film demonstrated excellent shielding effectiveness at low frequencies (1–9 MHz).

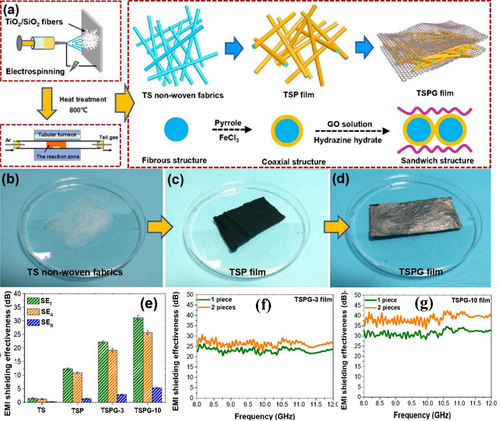

Moreover, Shoushtari et al.161 blended PVA, PANI, camphor sulfonic acid (CSA), and MWCNT to produce the composite material (PVA/PANI-CSA/MWCNT) through electrospinning. The optimal ratio of PVA, PANI, CSA, and MWCNT was obtained by comparing the absorption loss of the resulting composite fibers in the microwave. They found that this material exhibits a maximum reflection performance of −230 dB/mm in the low-frequency range (8.6 GHz), which is about eight times higher than that of PVA/PANI-CSA/MWCNT at a frequency of 8.4 GHz with −28 dB/mm. Li et al.86 fabricated a TiO2/SiO2/PPy/rGO (TSPG) composite film with a sandwich structure through electrospinning (Figure 9a–d). As an efficient dissipative medium, this film demonstrated a remarkable EMI shielding performance in the X-band resulting from the dopant of rGO sheets and TiO2/SiO2 nanoparticles. Figure 9f shows EMI SE for one piece of TSPG-3 (TSPG-3 represents TSPG film with an initial GO solution concentration of 3.0 mg/mL) is measured to be 24.3 dB in the X-band, the SE can be as high as 27.6 dB after stacking two pieces together. Nah et al.88 obtained a highly conductive PVDF nanofiber membrane through electrospinning, which exhibits outstanding flexibility due to the nanofibrous structure. The porous nature of the electrospun nanofibers also facilitates enhanced absorption and multiple reflections of EMWs in composite materials. When the thickness of the composite is 14 μm, the SE and SSE in the X band are 40 and 16,230 dB cm2/g, respectively.

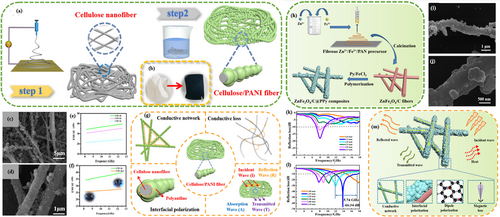

Besides directly electrospinning blends with conductive polymers to achieve high-performance EMI shielding materials, the other approach employs in-situ polymerization to introduce conductive polymers into pure electrospun micro/nanofibers. Zhang et al.79 utilized electrospinning to fabricate cellulose nanofibers, which were then subjected to in situ polymerization of PANI to generate interwoven cellulose/polyaniline nanofibers (CPF) (Figure 10a,b). The material displays excellent conductivity, which could be regulated by altering the polymerization time. The SEM images of the CPF fabrics are presented in Figure 10c,d. The fiber-like structure is maintained after polymerization for 1–3 h. As shown in Figure 10e, the total EMI SE value of the CPFs increases with the reaction time.

Additionally, CPF demonstrates exceptional capacitive behavior, including optimal impedance matching, interface polarization, and strong conductive loss, leading to superior EMW absorption properties (Figure 10g). The experimental results indicate that the average SE of CPF in the X-band is around 34 dB. After bending and twisting 1000 times, the CPF performs EMI SE over 25 dB in the X-band (Figure 10f). Ma et al.87 employed oxidative polymerization to coat PPy onto ZnFeO4/C obtained through electrospinning and calcination, forming ZnFeO4/C@PPy composite fibers (Figure 10h). The 1.93 mm thick composite material with a PPy loading of 25 wt% shows a reflection loss of −66.34 dB and effective absorption bandwidth (EAB) of 5.74 GHz (11.78–17.52 GHz) at 13.8 GHz (Figure 10k,l). The polymerization process offers a uniform coating of fillers on the electrospun fibers to form a continuous conductive network, resulting in a high-efficient EMI shielding and EMW absorption simultaneously.

4.4 MXene dopants

As one of the typical 2D materials, MXene is a type of transition metal carbide/nitride with the general formula Mn+1XnTx (n = 1, 2, or 3), where M, X, and T represent the transition metal, carbon or nitrogen, and functional groups related to the synthesis process.162 Due to its exceptional properties such as high conductivity, high surface area, lightweight, and ease of processing, MXene exhibits obvious advantages as a dopant for EMI shielding applications.163-166 Currently, 2D layered nanocrystals of MXene demonstrate high conductivity and strong mechanical properties similar to graphene.167, 168 Moreover, their remarkable surface chemical activity enables them to attach efficiently to the surface of polymer fibers, leading to the obtained composite with relatively superior EMI shielding performance.169

4.4.1 MXene laminates

The MXene layered films, including single-metal Ti3C2Tx, ordered dual-metal MoTiC2Tx, and Mo2Ti2C3Tx MXene, have been extensively studied for years.163 The excellent EMI shielding performances of Ti3C2Tx MXene films are mainly attributed to their outstanding electrical conductivity and the layer thickness and uniform arrangements of their microstructures. Many efforts have been made to obtain a high EMI performance material.

A recent study investigated the effect of MXene layered film thickness on its EMI shielding capability. For instance, Yun et al.170 assembled single-layer MXene films by interface self-assembling MXene flakes and then prepared multi-layer films by repeat stacking single-layer films. They investigated the influence of MXene layered film thickness on the material's shielding ability. They found that a single-layer Ti3C2Tx MXene film with an average thickness of 2.3 nm exhibited outstanding flexibility, over 90% transmission rate, and a thin-layer resistance of 1056 Ω/cm2. As the number of Ti3C2Tx MXene layers increased, the thin-layer resistance correspondingly decreased, and the corresponding EMI shielding performance increased. Test results showed that the SE of the assembled single-layer Ti3C2Tx MXene film was 1 dB. In comparison, the SE of the multilayer film with a thickness of 55 nm was 20 dB, effectively shielding 99% of electromagnetic radiation.

Generally, the mechanical properties of MXene layered films are poor, which has led to an increasing popularity in developing robust and durable MXene-based composite materials. Ye et al.43 first reported a highly flexible and stretchable electrospun PU nanofiber covered with Ti3C2Tx MXene. The sandwich-structured MXene/PU material is wrinkled and exhibits stable mechanical properties, demonstrating a high EMI shielding effectiveness (SE > 20 dB) within a deformation range of 30%. Subsequently, Guo et al.171 prepared a flexible composite film (d-Ti3C2Tx/r-CNFs) via electrospinning and vacuum-assisted filtration. The 15 μm thick composite film exhibits excellent EMI shielding performance (SE up to 42.7 dB) in the 2–18 GHz frequency range. Wei et al.146 used a weight ratio 1:2 for CNT and MXene and twice Ag absorption reduction processes. 0D silver nanoparticles are designed to be loaded on 2D MXene sheets and combined with 1D CNT in the ternary conductive matrix. This material possesses remarkable strain sensitivity and stability and demonstrates outstanding EMI shielding performance. Wang et al.81 prepared a TPU/PDA/Ag composite fibrous membrane by spray coating and electrospinning techniques, which was then laminated with Ti3C2Tx MXene nanosheets to obtain a multifunctional ultra-drawing TPU/PDA/Ag/MXene. MXene enhances the composite film's EMI shielding performance and strain ability among them. The experimental results revealed that the composite material with a thickness of 150 μm displays excellent EMI shielding effectiveness (SE of ~108.8 dB) and ultra-high conductivity (95,238 S/m) in the X-band. Wu et al.147 fabricated a highly thermally stable and tough Ag NW-PI/MXene/AgNW-PI composite with a sandwich structure via electrospinning, where its interlayer consisted of one layer of AgNW PI and one layer of highly conductive MXene nanosheets. The resulting membrane possesses outstanding mechanical properties and EMI shielding performance. Yu et al.172 successfully embedded MXene into electrospun poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) nanofibers to form a composite fabric that demonstrated both superhydrophobicity and outstanding EMI SE of up to 160 dB/mm.

4.4.2 MXene hybrids

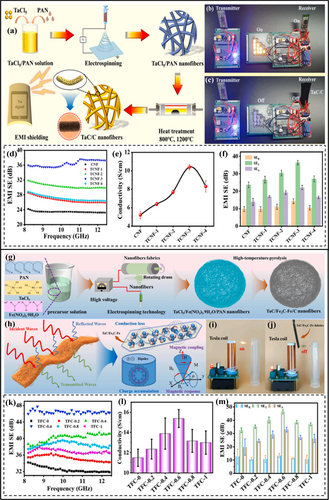

Exception of Mxene, MXene hybrids also contain other conductive and magnetic components, which can not only improve the stability and mechanical properties of the material itself but also lead to multiphase synergistic effects to enhance the EMW absorption inside the material, thereby further enhancing its shielding effectiveness. Many studies have demonstrated that constructing Mxene hybrids from different two-dimensional nanostructures is an effective way to achieve high-performance materials for microwave absorption. Meng et al.89 prepared a mixed aerogel microsphere of graphene oxide (GO) and MXene by rapid freezing-assisted electrospinning. Due to differences in conductivity between MXene and GO and the newly generated heterogeneous interface and enriched surface groups, MXene@GO mixed aerogel microspheres (M@GAMS) exhibit a remarkable impedance matching and microwave absorption property. The 1.2 mm thick M@GAMS with a loading of 10% presents a reflection loss of 49.1 dB at a frequency of 14.2 GHz and also shows a high EMI shielding effectiveness in the microwave band. Jiang et al.90 designed a multi-dimensional conductive framework loaded with TaC nanoparticles via electrospinning and high-temperature pyrolysis. The preparation process is shown in Figure 11a. The experimental results reported that the TaC nanoparticles can interconnect at a fixed concentration, resulting in a conductivity of up to 10.4 S/cm (Figure 11e).

Furthermore, they found that the X-band EMI SE of the composite fabric with a thickness of 0.2 mm is 37.7 dB, as shown in Figure 11d, and the SET, SER, and SEA of fabrics were displayed in Figure 11f. They also performed an experimental demonstration to illustrate the EMI shielding properties of these flexible TaC/C composite fabrics in the practical application (Figure 11b,c). Subsequently, Guo et al.91 reported a TaC/Fe3C-Fe-loaded composite using a similar method, as depicted in Figure 11g, which possesses superior features of a low density (0.34 g/cm3), excellent conductivity (approximately 15.4 S/cm) (Figure 11l), and saturated magnetization (13.3 emu/g). The experimental measurements addressed that the SE of the obtained material with a thickness of 0.18 mm reaches 46.4 dB (Figure 11k). The EMI shielding performance of electrospun composite fabrics with different weight ratios of TaC/Fe3C–Fe at a frequency range of X-band is shown in Figure 11m, and the shielding mechanism is shown in Figure 11h. Overall, incorporating multiple spatial-scale conductive frameworks containing tantalum carbide (TaC) nanoparticles provides a simplified and highly effective means for fabricating lightweight and thin composite textiles with intricate conductive networks. At the same time, they show a high EMI shielding performance. Mi et al.173 obtained a multilayer MXene/PLA film by alternatingly assembling MXene and electrospun poly(lactic acid) (PLA) nanofiber mats, wherein the MXene helped to retain the electromagnetic transmission pathway. Due to the effective conductivity of the MXene layer and the multiple reflection and absorption effects, the composite film realizes an optimal SE of 55 dB. Gu et al.85 deposited MXene nanosheets onto electrospun Fe3O4/PAA nanofibers to produce Janus Ti3C2Tx (Fe3O4/PI) composite films. When the mass fraction of Ti3C2Tx was 80 wt%, the resulting composite film performed excellent EMI shielding abilities (the SE up to 66 dB) and mechanical properties (tensile strength of 114.5 MPa and Young's modulus of 5.8 GPa). Wang et al.174 reported a bifunctional electrospun nanofiber membrane decorated with MXene nanosheets and Fe3O4 nanoparticles. The porous structure of the fiber, the magnetic loss effect of Fe3O4, and the dielectric loss effect of MXene result in outstanding EMI shielding performance of the composite fiber membrane with a thickness of 33 μm (SSEt = 9212.1 dB cm2/g). Chen et al.83 produced a unique TPU/ PAN self-supporting film via electrospinning and dipping processes. Subsequently, Fe3O4 nanoparticles and MXene were deposited onto its surface to form a hybrid membrane. Due to the hydrogen bond interaction between the PAN macromolecular chain and the surface functional group (Tx) of MXene, the interfacial attraction between MXene and TPU/PAN/Fe3O4 is enhanced, endowing the composite with a high stability and excellent EMI SE of over 30 dB in the X-band.

4.5 Magnetic dopants