Surface grafting stearic acid to the coupling agent on attapulgite: A reinforced filler in castor oil-based polyurethane coating

Shiping Wang

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Qingyuan Innovation Laboratory, Quanzhou, China

Contribution: Formal analysis (lead), Funding acquisition (lead), Investigation (lead), Writing - original draft (lead)

Search for more papers by this authorLushen Shen

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Contribution: Data curation (lead), Investigation (supporting)

Search for more papers by this authorHonglin Yang

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Contribution: Data curation (supporting), Investigation (supporting)

Search for more papers by this authorCorresponding Author

Guohui Cai

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Correspondence

Guohui Cai, Yingying Zhan, and Lilong Jiang, National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou 350002, China Email: [email protected], [email protected], and [email protected]

Contribution: Supervision (equal), Writing - review & editing (equal)

Search for more papers by this authorGanchang Lei

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Contribution: Validation (equal)

Search for more papers by this authorLijuan Shen

College of Environmental Science and Engineering, Fujian Normal University, Fuzhou, China

Contribution: Validation (equal)

Search for more papers by this authorCorresponding Author

Yingying Zhan

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Qingyuan Innovation Laboratory, Quanzhou, China

Correspondence

Guohui Cai, Yingying Zhan, and Lilong Jiang, National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou 350002, China Email: [email protected], [email protected], and [email protected]

Contribution: Funding acquisition (lead), Resources (supporting), Supervision (equal), Writing - review & editing (equal)

Search for more papers by this authorCorresponding Author

Lilong Jiang

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Qingyuan Innovation Laboratory, Quanzhou, China

Correspondence

Guohui Cai, Yingying Zhan, and Lilong Jiang, National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou 350002, China Email: [email protected], [email protected], and [email protected]

Contribution: Funding acquisition (lead), Resources (lead), Supervision (equal), Writing - review & editing (equal)

Search for more papers by this authorShiping Wang

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Qingyuan Innovation Laboratory, Quanzhou, China

Contribution: Formal analysis (lead), Funding acquisition (lead), Investigation (lead), Writing - original draft (lead)

Search for more papers by this authorLushen Shen

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Contribution: Data curation (lead), Investigation (supporting)

Search for more papers by this authorHonglin Yang

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Contribution: Data curation (supporting), Investigation (supporting)

Search for more papers by this authorCorresponding Author

Guohui Cai

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Correspondence

Guohui Cai, Yingying Zhan, and Lilong Jiang, National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou 350002, China Email: [email protected], [email protected], and [email protected]

Contribution: Supervision (equal), Writing - review & editing (equal)

Search for more papers by this authorGanchang Lei

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Contribution: Validation (equal)

Search for more papers by this authorLijuan Shen

College of Environmental Science and Engineering, Fujian Normal University, Fuzhou, China

Contribution: Validation (equal)

Search for more papers by this authorCorresponding Author

Yingying Zhan

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Qingyuan Innovation Laboratory, Quanzhou, China

Correspondence

Guohui Cai, Yingying Zhan, and Lilong Jiang, National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou 350002, China Email: [email protected], [email protected], and [email protected]

Contribution: Funding acquisition (lead), Resources (supporting), Supervision (equal), Writing - review & editing (equal)

Search for more papers by this authorCorresponding Author

Lilong Jiang

National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou, China

Qingyuan Innovation Laboratory, Quanzhou, China

Correspondence

Guohui Cai, Yingying Zhan, and Lilong Jiang, National Engineering Research Center of Chemical Fertilizer Catalyst, Fuzhou University, Fuzhou 350002, China Email: [email protected], [email protected], and [email protected]

Contribution: Funding acquisition (lead), Resources (lead), Supervision (equal), Writing - review & editing (equal)

Search for more papers by this authorAbstract

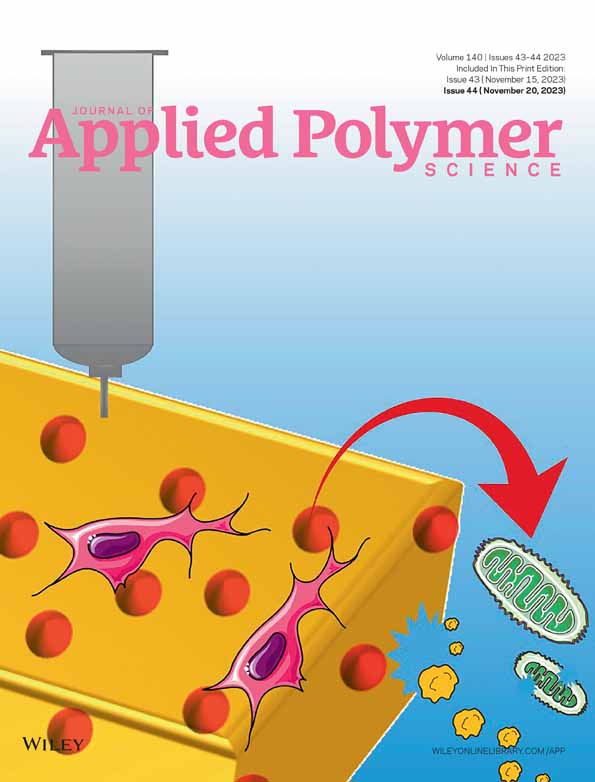

Developing economic controlled-release fertilizers (CRFs) with superior performance is an ongoing and important research area. This work investigated the co-modification of acid-activated attapulgite (ac-AT) to optimize its surface properties for polyurethane (PU) composite applications, specifically in the coatings of CRFs. The modified ac-AT (MAT) rods were obtained through treatment with 2.0 wt.% KH-560 coupling agent and in-situ grafting with stearic acid (SA). Varying the addition amount of SA resulted in the synthesis of different MAT fillers. Along with the adjustment of the filling amount, the properties of the MAT/PU composites were controlled. Notably, applying 1.5 wt.% SA onto the KH-560 treated ac-AT produced MAT with a contact angle of 100.8°, enhancing hydrophobicity and dispersion within the PU matrix. Furthermore, at a filling amount of 9.0 wt.%, the MAT/PU composite exhibited the most favorable properties with a tensile strength of 2.37 MPa, making it the optimal coating for CRFs with 75% nutrient release within 46 days while the coating efficiency was 3.0 wt.%. This co-modification approach shows great potential in enhancing filler properties and promoting their application in organic coatings.

CONFLICT OF INTEREST STATEMENT

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Supporting Information

| Filename | Description |

|---|---|

| app54624-sup-0001-Supinfo.docxWord 2007 document , 4.9 MB | Data S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

REFERENCES

- 1M. Y. Naz, S. A. Sulaiman, J. Controlled Release 2016, 225, 109.

- 2P. Vejan, T. Khadiran, R. Abdullah, N. Ahmad, J. Controlled Release 2021, 339, 321.

- 3R. Bortoletto-Santos, M. A. Cavigelli, S. E. Montes, H. H. Schomberg, A. Le, A. I. Thompson, M. Kramer, W. L. Polito, C. Ribeiro, J. Cleaner Prod. 2020, 249, 119329.

- 4B. Azeem, K. KuShaari, Z. B. Man, A. Basit, T. H. Thanh, J. Controlled Release 2014, 181, 11.

- 5Y. C. Yang, M. Zhang, Y. C. Li, X. H. Fan, Y. Q. Geng, J. Agric. Food Chem. 2012, 60, 11229.

- 6H. Y. Tian, Z. G. Liu, M. Zhang, Y. L. Guo, L. Zheng, Y. C. C. Li, ACS Appl. Mater. Interfaces 2019, 11, 5380.

- 7C. F. Uzoh, O. D. Onukwuli, I. H. Ozofor, R. S. Odera, Process Saf. Environ. Prot. 2019, 121, 133.

- 8J. Xie, Y. Yang, B. Gao, Y. Wan, Y. C. Li, J. Xu, Q. Zhao, ACS Appl. Mater. Interfaces 2017, 9, 15868.

- 9R. Bortoletto-Santos, C. Ribeiro, W. L. Polito, J. Appl. Polym. Sci. 2016, 133, 43790.

- 10G. D. Feng, Y. Ma, M. Zhang, P. Y. Jia, L. H. Hu, C. G. Liu, Y. H. Zhou, Prog. Org. Coat. 2019, 133, 267.

- 11M. M. E. Costa, E. C. M. Cabral-Albuquerque, T. L. M. Alves, J. C. Pinto, R. L. Fialho, J. Agric. Food Chem. 2013, 61, 9984.

- 12P. Rai, S. Mehrotra, S. Priya, E. Gnansounou, S. K. Sharma, Bioresour. Technol. 2021, 325, 124739.

- 13C. Zhang, S. A. Madbouly, M. R. Kessler, ACS Appl. Mater. Interfaces 2015, 7, 1226.

- 14S. Wang, R. Huang, K. Ren, L. Shen, X. Li, G. Lei, L. Shen, Y. Zhan, Y. Zheng, L. Jiang, Prog. Org. Coat. 2023, 178, 107499.

- 15H. Tian, Z. Li, P. Lu, Y. Wang, C. Jia, H. Wang, Z. Liu, M. Zhang, Carbohydr. Polym. 2021, 251, 117060.

- 16A. El Gharrak, Y. Essamlali, O. Amadine, S. Aboulhrouz, A. Hafnaoui, H. Ghalfi, M. Zahouily, Prog. Org. Coat. 2022, 170, 106982.

- 17X. Chen, T. Guo, H. Yang, L. Zhang, Y. Xue, R. Wang, X. Fan, S. Sun, Int. J. Biol. Macromol. 2022, 221, 1130.

- 18N. H. Tarte, L. Q. Cui, S. Woo, Adv. Polym. Sci. 2013, 258, 311.

- 19C. Wang, S. Song, Z. Yang, Y. Liu, Z. He, C. Zhou, L. Du, D. Sun, P. Li, Prog. Org. Coat. 2022, 165, 106756.

- 20S. Wang, X. Li, K. Ren, R. Huang, G. Lei, L. Shen, Y. Zhan, L. Jiang, Arab. J. Chem. 2023, 16, 104400.

- 21S. G. Zhang, Y. C. Yang, B. Gao, Y. C. Li, Z. G. Liu, J. Mater. Chem. A 2017, 5, 19943.

- 22D. Qi, C. Liu, Z. Chen, H. Chen, C. Huang, Z. Cao, Colloids Surf., A 2016, 489, 265.

- 23N. Stanley, B. Mahanty, Polym. Bull. 2020, 77, 529.

- 24M. Salimi, E. Motamedi, B. Motesharezedeh, H. M. Hosseini, H. A. Alikhani, J. Environ. Eng. 2020, 8, 103765.

- 25D. H. H. Sim, I. A. W. Tan, L. L. P. Lim, B. H. Hameed, J. Cleaner Prod. 2021, 303, 127018.

- 26S. K. Das, G. K. Ghosh, Energy 2022, 242, 122977.

- 27D. Liang, H. Shi, Q. Lu, R. L. Quirino, C. Zhang, J. Mater. Chem. A 2023, 11, 4527.

- 28W. Haden, I. A. Schwint, Ind. Eng. Chem. Res. 1967, 59, 58.

- 29J. H. Wang, D. J. Chen, J. Nanomater. 2013, 2013, 496584.

10.1155/2013/496584 Google Scholar

- 30A. S. Bhatt, P. L. Sakaria, M. Vasudevan, R. R. Pawar, N. Sudheesh, H. C. Bajaj, H. M. Mody, RSC Adv. 2012, 2, 8663.

- 31J. M. Xu, W. Li, Q. F. Yin, Y. L. Zhu, Electrochim. Acta 2007, 52, 3601.

- 32C. D. Delhom, L. A. White-Ghoorahoo, S. S. Pang, Composites, Part B 2010, 41, 475.

- 33A. Elkhaoulani, F. Z. Arrakhiz, K. Benmoussa, R. Bouhfid, A. Qaiss, Mater. Des. 2013, 49, 203.

- 34Y. Liu, S. Zhang, X. Wang, Y. Pan, F. Zhang, J. Huang, Composites Interfaces 2019, 27, 73.

- 35B. Pan, Q. Yue, J. Ren, H. Wang, L. Jian, J. Zhang, S. Yang, Polym. Test. 2006, 25, 384.

- 36K. Xu, C. Li, C. Wang, Y. Jiang, Y. Liu, H. Xie, J. Therm. Anal. Calorim. 2019, 137, 1189.

- 37J. C. Dai, J. T. Huang, Appl. Clay Sci. 1999, 15, 51.

- 38L. Wang, J. Sheng, Polymer 2005, 46, 6243.

- 39X. Wang, L. H. Wang, W. W. Ji, Q. L. Hao, G. H. Zhang, Q. K. Meng, Polymer 2019, 11, 769.

- 40Q. G. Tang, F. Wang, H. Guo, Y. Yang, Y. L. Du, J. S. Liang, F. Q. Zhang, Powder Technol. 2015, 270, 92.

- 41X. Li, R. Yang, D. T. Wang, G. Li, Conf. Ser.: Earth Environ. Sci. 2020, 545, 012031.

10.1088/1755-1315/594/1/012031 Google Scholar

- 42W. Liu, W. Liu, B. Wang, H. Duan, X. Peng, X. Chen, Q. Zhao, Miner. Eng. 2019, 142, 105894.

- 43D. Wang, W. Guo, G. Zhang, L. Zhou, M. Wang, Y. Lu, D. Cai, Z. Wu, ACS Sustainable Chem. Eng. 2017, 5, 2246.

- 44Q. Wu, D. Wang, J. Wen, C. Chen, J. Zhang, Z. Wu, D. Cai, Surf. Interfaces 2022, 32, 102117.

- 45W. Wang, J. Zhang, H. Chen, A. Wang, J. Appl. Polym. Sci. 2007, 103, 2419.

- 46W. Zhang, L. Qian, Y. Chen, D. Ouyang, L. Han, X. Shang, J. Li, M. Gu, M. Chen, Chemosphere 2021, 267, 129183.

- 47S. He, B. J. Xin, Z. M. Chen, Y. Liu, Text. Res. J. 2018, 0, 1.

- 48J. Rubio, M. A. Mazo, A. Martín-Ilana, A. Tamayo, Bol. Soc. Esp. Ceram. 2018, 57, 160.

- 49Z. C. Ge, H. H. Ren, S. Q. Fu, S. J. Chen, RSC Adv. 2017, 7, 42320.

- 50R. G. Sinclair, A. F. Mckay, K. Norman Jones, J. Am. Chem. Soc. 1952, 74, 2570.

- 51L. Chen, G. Ye, D. Xu, L. Zhu, Z. Lu, L. Dong, Y. Liu, Mater. Lett. 2012, 85, 91.

- 52M. Fröba, M. Joe Wong, G. E. B. Rowen Jr.., T. Tanaka, Z. Rek, Physica B Condens. Matter. 1995, 208-209, 555.

10.1016/0921-4526(94)00748-K Google Scholar

- 53J. Huang, A. Li, K. Li, Int. J. Adhes. Adhes. 2021, 105, 102763.

- 54N. H. Mudri, L. C. Abdullah, M. M. Aung, M. Z. Salleh, D. R. Awang Biak, M. Rayung, Polymers 2020, 12, 102763.

10.3390/polym12071494 Google Scholar

- 55M. Li, J. Xia, W. Mao, X. Yang, L. Xu, K. Huang, S. Li, ACS Sustainable Chem. Eng. 2017, 5, 6883.

- 56Y. Qin, J. R. Jia, Z. X. Huang, Adv. Mat. Res. 2011, 311-313, 1128.

- 57N. Teramoto, Y. Saitoh, A. Takahashi, M. Shibata, J. Appl. Polym. Sci. 2010, 115, 3199.