Effect of synergy between pyrolysis carbon black and carbon nanofibers on composite properties

Funding information: National Natural Science Foundation of China, Grant/Award Number: 51345006

Abstract

Carbon nanofibers (CNFs) as new materials have been the focus of materials research, while being widely used in the processing of rubber composites. To solve the problem that CNFs are easy to agglomerate, the existing methods are mainly chemical modification of CNFs (complicated processing process), blending with fillers such as carbon nanotube (expensive material and high production cost ratio). In this study, we integrated the economics and processing methods, and used pyrolysis carbon black (CBp) and CNFs for blending to prepare rubber composites to solve the filler agglomeration problem. It was found that CBp and CNFs produce a synergistic effect, and the two are isolated from each other and in contact with each other, forming a more complete filler network inside the composite. Through the synergistic effect, the filler dispersion in the rubber becomes better and the performance of the composite is greatly improved. Compared with traditional filler blending, it is more economical and can save production costs to a great extent; compared with chemical modification, the process is simple and saves production time. The recycling of rubber products can be promoted through the mass use of CBp, which has a certain environmental protection effect. This study provides new ideas for polymer composite processing, and more experiments are needed later to verify the feasibility of this method.

1 INTRODUCTION

With the continuous development of the rubber industry and the expansion of rubber application fields, people have put forward higher requirements for the performance of rubber products, while giving new properties to prepare rubber composites.1-5 Mainly, filler particles with special functions are added to achieve rubber reinforcement and functionalization modification.6, 7 Carbon materials are widely used as rubber fillers, especially carbon nanofibers (CNFs), because of their good reinforcing effect and excellent thermoelectric properties.8-10 However, CNFs as fillers are prone to agglomeration when blended with rubber, resulting in uneven dispersion of fillers, and the excellent properties of CNFs cannot be maximized, while the performance of rubber composites is difficult to achieve the expected results.11-13

Researchers have solved the problem of filler agglomeration by modifying CNFs with certain results.14-18 Researchers modified different fillers through different processes to verify the effect of filler modification on polymer properties. For example, FeCu-montmorillonite,19 CuAl layered double hydroxide (CuAl-LDH),20 iron phenyl phosphonate (FePP) nanosheets21 and Fe-CNTs22 are added to epoxy resin (EP) after different modification processes. Studies have shown that different modification methods can well promote the dispersion effect of fillers in EP, which has a great contribution to improving the mechanical properties and fire resistance of composites. Zheng et al23 first obtained helical carbon nanofibers (HCNFs) by modifying CNFs and then used HCNFs as fillers to reinforce NR. The results showed that HCNFs were well dispersed and formed a good interfacial bond with the rubber, and the composite had the best overall properties when the HCNF filler was 5 Phr. Park et al24 added aminated CNFs to ethylene-propylene-diene monomer (EPDM)and analyzed the effect of CNFs content on EPDM performance, and the study results showed that the physical properties of the composite were best when 5–7 Phr CNFs were added as well as the best thermal properties. Sinclair et al25 studied the effect of different modifiers on CNFs-reinforced styrene-butadiene rubber (SBR) by adding modified and unmodified CNFs to SBR using different modifiers. It was found that the modified CNFs had better dispersion as well as interfacial bonding ability, and had a better reinforcement effect on SBR. From the above, it can be found that the problem of CNFs agglomeration can be solved to some extent by different modification means, and a better reinforcement effect can be achieved. There exists a complicated modification process, a long modification period, and the chemicals used for modification will have implicit effects on the properties of the composites. The modification means are very helpful for experimental research, but not suitable for generalized application in actual production.

The reinforcing effect has also been achieved by filler blending while promoting the dispersion of the filler.26-29 For example, Pingot et al30 added different dispersants to CNFs/NBR composites to analyze the reinforcing effect of CNFs on NBR, and the results showed that the addition of dispersants was beneficial to improving the mechanical properties and electrical conductivity of the composites. Shi et al31 prepared composites by blending CNTs/CNFs together and found that the blending of carbon materials could mutually promote the dispersion of fillers, which was very helpful in the strengthening the composites. Mianehrow et al32 prepared CNF/GO composites and found that all the properties of the composites were improved to different degrees. Ramanujam et al33 prepared composites by mixing carbon black (CB), CNF and expanded graphite (ExGr). The composites were found to have greatly improved electrical and thermal conductivity. The performance of the composites can be maximized by blending fillers with the same properties, especially in the preparation of highly thermally and electrically conductive composites, but this method still has some disadvantages. These carbon materials with excellent properties (carbon nanotubes, graphene, acetylene CB, etc.) are costly and increase manufacturing costs when used in large quantities.

Pyrolysis CB is a product recovered from rubber products through the cracking process, which has a slight difference in various properties compared with ordinary CB, but has a great price advantage and can be used to a certain extent instead of ordinary CB, which has a greater prospect of application in the field of composite processing.34-40 In this experiment, the rubber composites were prepared by blending pyrolysis carbon black (CBp) with CNFs, focusing first on the effect of CBp in solving the filler agglomeration and promoting the dispersion of CNFs. The effects of different contents of CNFs on the properties of the composites under the conditions of quantitative CBp were also investigated. To explore the potential of CBp in promoting filler dispersion and reinforcing material properties during the production of composites. It has some reference value in expanding the application scope of CBp and reducing the production cost of composite materials.

2 EXPERIMENTS

2.1 Materials

Natural rubber (NR) 100 Phr was used as the matrix material; antioxidant (4020) 2 Phr was used to resist the effect of aging on the composite properties; zinc oxide (ZnO) 2 Phr, stearic acid (SAD) 2 Phr, and accelerator (CZ) 1 Phr were used as vulcanization activators to promote the vulcanization reaction; sulfur (S) 2 Phr was used to carry out the rubber molecular vulcanization crosslinking reaction. CNFs and thermally cracked CB (CBp) were used as reinforcing fillers, mainly to enhance the properties of the composites. The CBp/CNFs ratios and sample numbers are shown in Table 1.

| Samples | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| CBp | 0 | 40 | 40 | 40 | 40 |

| CNFs | 2 | 0 | 2 | 4 | 6 |

- Abbreviations: CBp, pyrolysis carbon black; CNFs, carbon nanofibers.

The specifications of CNFs and CBp are as follows: CNFs, JCGCF (OD: 20–30 nm, Length: 3–12 um, SSA: 180–230 m2/g), Jia Cai Technology; CBp, N990 (DBP: 44 ± 10 ml/100 g, PH: 8.0–10, Ash: ≤0.5), Tianjin Yiborui Chemical Co.

2.2 Sample preparation

Cut the NR into small pieces to facilitate feeding. Set the speed of the internal mixer (XSM-500 type, Shanghai Kechuang Rubber & Plastic Machinery Equipment Co., Ltd.) to 80 r/min and the initial temperature to 40°C. Put the cutting NR into the mixer, add 1/2CBp for mixing at 1:20, add other fillers except for CZ and S for mixing at 2:00, and discharge the rubber at 5:00. Continue to mix and add CZ and S on the open mixer (BL-6157 type, Baolun Precision Testing Instruments Co., Ltd.), and then drop the sheet after sufficient mixing, and leave the mixed rubber for 8 h. Vulcanize the compound using a plate vulcanizing machine (QLB-400X400X2 type, Shanghai No.1 Rubber Machinery Factory), place the quantitative mixed rubber in the vulcanizing mold, the vulcanizing temperature is 150°C, and the vulcanizing time is T90 × 1.3 (T90 is obtained by vulcanizing characteristics).

2.3 Performance test

Vulcanized rubber samples were impregnated in liquid nitrogen, removed and subjected to brittle fracture to obtain cross-sections. A field emission scanning electron microscope (SEM, SU8000, Hitachi Group) was used to characterize the cross-sections and to analyze the dispersion of the filler in the rubber. 3D laser measuring microscope (LEXT OLS5000, Olympus, Japan) was used to watch the 3D morphology of the brittle fracture surface of samples. The analysis of the fracture surface can reflect the size of the filler agglomerates within the rubber collective to a certain extent, and the greater the roughness of the fracture surface indicates the more serious filler agglomeration.

No rotor vulcanizing instrument (M-2000-AN, Taiwan High-Tech Testing Instruments Co., Ltd.) was set to 150°C, pressure 0.6 MPa, and test time 60 min. A total of 5.8 g of mixed rubber was weighed and tested on no rotor vulcanizing instrument to obtain the vulcanization characteristics data.

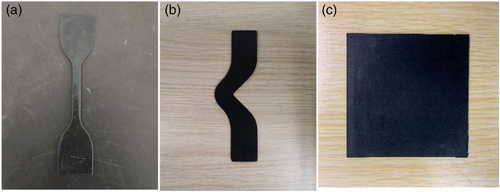

The vulcanized rubber was cut into standard samples for physical and mechanical property testing, and the thickness of each sample was measured before testing. The tensile samples are shown in Figure 1a and the tear samples are shown in Figure 1b. Set the tensile rate of Tensile testing machine (TS 2005b type, Taiwan Ucan Technology Co., Ltd.) to 500 mm/min for the physical and mechanical property test of vulcanized samples, and measure three samples in each group and take the average value. The hardness of the vulcanized samples was measured by using Shore A hardness tester (LX-A type, Shanghai Liuling Instrument Factory), and three standard specimens were superimposed for hardness measurement.

A conductivity instrument (JSM-2100, Japan Electronics Corporation) and a high resistance meter (ST2254) were used to build a test platform for sample volume resistivity measurements, and the sample surface was cleaned and the sample thickness was measured before testing. The conductive samples are shown in Figure 1c.

3 DISTRIBUTION STATE OF FILLER PARTICLES

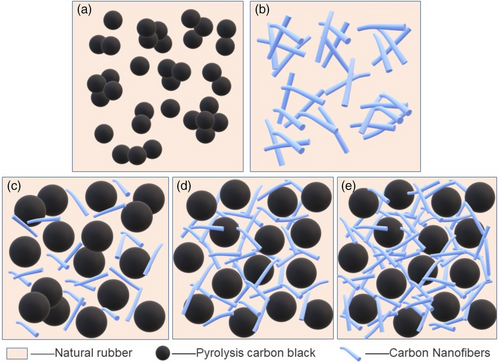

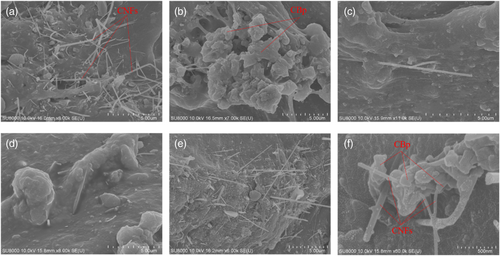

The distribution states of filler particles at different additions are shown in Figure 2. Figure 2a,b show that a certain degree of agglomeration occurs in the matrix when a single filler is added, which affects the dispersion condition of the filler and thus cannot form a perfect filler network. Compared with CBp, CNFs are more likely to form agglomerates. One of the reasons may be that the surface energy of CNFs is extremely unstable, which makes them more reactive with stronger particle-to-particle binding ability.

When CNFs and CBp are blended together the filler will be combined in the matrix (physically combined and chemically combined), creating a synergistic effect to promote the dispersion of the filler particles. Since the particle size of CBp is larger than that of CNFs. CNFs mainly exists between the CBp particles, preventing the agglomeration of CBp and CNF itself. The two are isolated from each other and connected to each other, forming a filler network in the rubber. The filler morphology at different levels of CNFs is shown in Figure 2c–e. It can be seen that when the content of CNFs is small, the CBp can completely isolate the CNFs and prevent the CNFs from agglomerating themselves. However, due to a little bit CNFs, it cannot fully isolate the CBp, and a little bit CBp agglomerates still exist in the matrix, while the CNFs in the matrix have not yet formed a complete filler network. The synergistic effect of the two reaches the best when the CNFs reach a certain content. The agglomerates in the rubber matrix basically disappear, while the formed filler network is more complete. Continuing to increase the content of CNFs, CNF agglomerates start to appear in the matrix. The possible causes for this are that the existing CBp is already sufficiently bound to the CNFs and there is not enough CBp to isolate the excess CNFs.

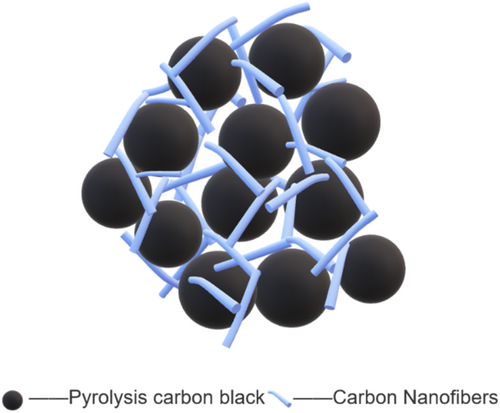

The filler network in the rubber matrix is shown in Figure 3. The CNFs are completely dispersed among the CBp, forming a complete filler network. The excellent properties of the filler are maximized and all the properties of the composite are improved.

4 RESULTS AND DISCUSSIONS

4.1 Cross-sectional SEM characterization

The SEM characterization of the sample sections is shown in Figure 4. From Figures 4a,b, it can be seen that there will be an obvious filler agglomeration phenomenon inside the composites when CNFs are added alone, which is not conducive to the dispersion of fillers and the improvement of composite properties. The agglomeration phenomenon also exists when CBp is added, which has an impact on the reinforcement of the rubber material. As can be seen from Figures 4c–e, the filler agglomeration problem is obviously improved when CBp and CNFs are added to the rubber matrix as fillers, and the CNFs are interspersed between the CBp particles to prevent the agglomeration of CBp particles. CBp and CNFs are isolated from each other and connected to each other, which solves the filler agglomeration and establishes a continuous filler network inside the compound, so that the filler reinforcement can be maximized. With the increase of CNFs content, CNFs aggregation will start to appear inside the composites again, indicating the saturation phenomenon of filler synergy. Only when the ratio of CBp and CNF is optimal, the synergistic effect will show the best effect.

Figure 4f can characterize the specific states of CBp and CNFs inside the composite. The CNFs are present between the CBp particles and interconnected at the larger gaps, forming a continuous network of CNFs. This continuous network isolates the CBp particles from each other and prevents the agglomeration of CBp. At the same time, this network has better reinforcement and conductivity, which is helpful for the enhancement of the basic characteristics and conductivity of the composites. SEM characterization of the composite sections is consistent with the analysis of the filler particle distribution state above.

4.2 Rubber processing properties

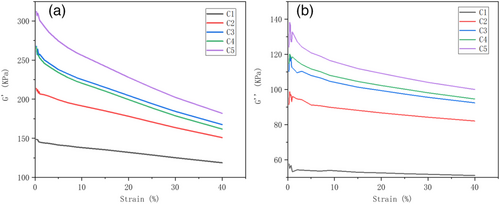

Figure 5 shows the change graphs of energy storage modulus and loss modulus . It can be seen that the energy storage modulus and loss modulus of the composite when CBp and CNFs are blended are significantly higher than that of the single filler. The possible reasons are in two aspects, firstly, the CNFs have strong activity on the surface and can physically/chemically bond with the CBp, and the synergistic effect of the two promotes the dispersion of the fillers in the matrix and increases the bonding point inside the composite. Second, the number of filler particles in the rubber increases after the blending of the two, and the number of filler binding points inside the composite is naturally added. With the increase of CNFs content, the filler binding points in the matrix keep increasing, and the energy storage modulus and loss modulus show an increasing trend.

Compared to large strains, at small strains, the energy storage modulus and loss modulus vary more with the filler. This is mainly because at low strains the external force first destroys the filler network in the rubber matrix, while causing some degree of damage to the bond between the matrix and the filler. At higher strains, the energy storage modulus and loss modulus change less because the filler network inside the composite has been destroyed, and mainly the rubber macromolecular chains inside the composite play a dominant role.

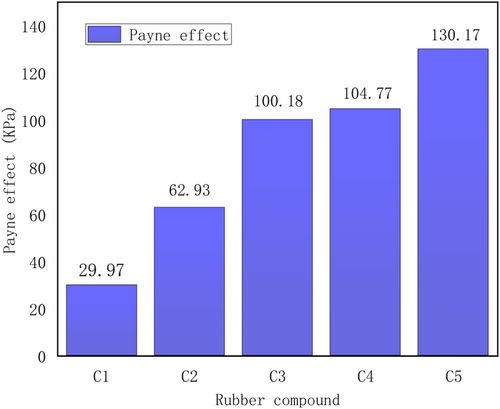

Figure 6 shows Payne effect. Compare and Contrast C1, C2, and C3, it was shown that Payne effect increased significantly when 2 Phr CNFs and 40 Phr CBp were blended together, increasing by 230% compared to when 2 Phr CNFs have added alone and by 59% compared to when 40 Phr CBp has added alone. It indicates that the synergistic effect of CBp/CNFs increased the Payne effect of the composites.

The Payne effect changed less when the CNFS content was increased from 2 to 4 Phr while the CBp was kept constant. The rubber matrix contains a large amount of CBp particles, which is sufficient to segregate the 4 Phr CNFs, and the CNFs are better dispersed inside the rubber matrix to prevent agglomeration among CNFs, when the synergistic effect reaches its best. Continuing to increase the content of CNFs, the Payne effect started to appear more substantially. The main reason is that the CBp content inside the rubber matrix is limited, and the agglomeration phenomenon occurs when the CNFs exceed a certain amount, which causes a significant increase in the bonding point inside the composite.

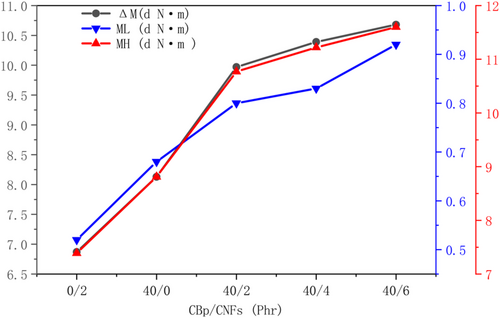

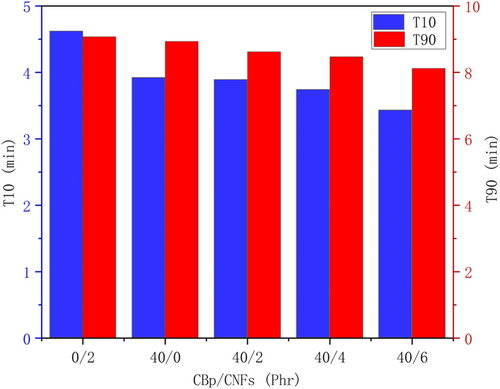

4.3 Vulcanization properties

Figure 7 shows the ML, MH, and ΔM variation curves of the mixed rubber, and the T10 and T90 variations of the mixed rubber are shown in Figure 8, and the corresponding values are shown in Table 2. It is obvious from the figure that the torque of CBp/CNFs/NR blends is significantly higher than that of CNFs/NR and CBp/NR blends, indicating a significant increase in the crosslink density within the rubber compound. The vulcanization time was reduced. The first reason, the increase in the number of filler particles inside the compound during filler blending, contributed to the increase in crosslink density and faster vulcanization rate. The second reason is that the physical and chemical combination of CBp/CNFs by the synergistic effect creates a complete filler network inside the rubber composite, which multiplies the number of filler-rubber bonding points and increases the crosslink density due to the combination between the fillers and the combination between the filler network and the rubber molecules. The complete filler network provides more pathways for heat transfer during the vulcanization process and increases the thermal conductivity of the compound, thus promoting vulcanization. The second reason is more important and plays a major role in the change of vulcanization properties.

| Samples | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| ML/d N m | 0.52 | 0.63 | 0.59 | 0.53 | 0.66 |

| MH/d N m | 11.25 | 12.51 | 12.03 | 13.74 | 12.72 |

| ΔM/d N m | 10.73 | 11.88 | 11.44 | 13.21 | 12.06 |

| T10/min | 3.66 | 4.59 | 5.12 | 4.94 | 5.89 |

| T90/min | 8.10 | 10.13 | 12.04 | 11.48 | 16.31 |

With the increase of CNFs content, the ML, MH, and ΔM curves of the compound tend to be smooth and the variation of the vulcanization time decreases, indicating that the influence of CNFs on the vulcanization properties of the compound decreases. The possible reason is that the filler network inside the compound is gradually improved, and the continuous increase of CNFs has little effect on the filler network, so the variation of the vulcanization properties is reduced.

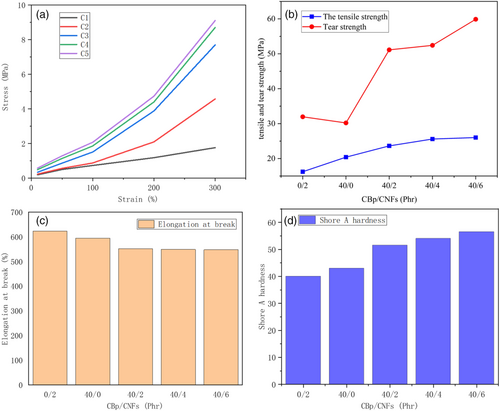

4.4 Physical and mechanical characteristics

The physical and mechanical characteristics of the vulcanized rubber were tested experimentally as shown in Table 3, and Figure 9 shows the variation curves of the data. The CBp/CNFs/NR composites were compared with CBp/NR and CNFs/NR. CBp/CNFs/NR showed a significant increase in tensile strength, tear strength and hardness, and a certain degree of decrease in elongation at break. At lower strains, there was little difference in the stress required to produce the same strain. However, as the strain increases, the stress required to produce the same deformation gradually increases. The possible reason for this is that at low strains the damage to the filler network and rubber macromolecular chains inside the composite is small and does not require much stress. In the case of large tensile strains, the stresses required to break the filler network and the rubber molecular chains inside the composite increase.

| Samples | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| Shore A hardness | 40 | 43 | 51.5 | 54 | 56.5 |

| 100% fixed elongation modulus/MPa | 0.72 | 0.87 | 1.5 | 1.85 | 2.06 |

| 300% fixed elongation modulus/MPa | 1.75 | 4.57 | 7.69 | 8.70 | 9.10 |

| The tensile strength/MPa | 16.23 | 20.40 | 23.63 | 25.69 | 26.02 |

| Tear strength/MPa | 31.97 | 30.21 | 51.14 | 52.42 | 59.89 |

| Elongation at break/% | 621.95 | 593.97 | 550.92 | 548.34 | 547.00 |

And with the increase of CNFs content, the physical and mechanical properties of CBp/CNFs/NR composites gradually stabilized. It is mainly because the filler network is gradually improved, the crosslink density inside the material changes less, and the resistance of the composite to damage is basically unchanged.

4.5 Resistance characteristics

The resistivities of the vulcanized rubber are shown in Table 4. The analysis shows that the volume resistivity of the composites was 4.33E13 and 4.03E14 when CNFs and CBp were added alone, and 1.25E12 when CBp/CNFs have blended, which respectively decreased by 1 and 2 orders of magnitude. The volume resistivity stabilized with increasing CNFs content. The surface resistivity of the composites reflected the same trend. The CBp/CNFs blending promoted the dispersion of the filler inside the composites and established a more complete filler network. The improved filler network has better electrical conductivity, which has a significant promotion on raising the electrical conductivity of the composites. The experimental results are consistent with the analysis of filler dispersion effect, which indicates that the above analysis has some accuracy.

| Samples | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| Volume resistivity/Ω cm | 4.33E13 | 4.03E14 | 1.25E12 | 8.96E11 | 5.96E11 |

| Surface resistivity/Ω cm | 4.93E14 | 2.25E15 | 1.58E13 | 7.23E12 | 4.54E12 |

5 CONCLUSIONS

The above analysis shows that the synergistic effect of CBp and CNFs has three main benefits: the number of filler binding sites inside the NR composite increases, the dispersion of CBp and CNFs in the rubber matrix increases, and CBp and CNFs can build a more complete filler network inside the composite. CBp/CNFs produce synergistic effect through physical and chemical combination, establish a perfect filler network and promote the dispersion of the filler, which can better play the excellent performance of the filler itself and maximize the performance of the composite. The CBp/CNFs blend increases the bonding point inside the rubber composite, improves the crosslink density and Payne effect of the vulcanizing rubber, and promotes the vulcanization performance and physical and mechanical properties of the composite. The resistivity of the rubber composites was largely reduced by the complete filler network with excellent electrical conductivity at the same time. Therefore, CBp/CNFs blends as fillers applied in the production and processing of polymer composites can solve the problem of easy agglomeration of single fillers, thus promoting the dispersion effect of fillers in the composites. Compared with the traditional CNFs composite preparation, the processing process is more convenient and the production cost is lower in promoting filler dispersion.

AUTHOR CONTRIBUTIONS

Deshang Han: Data curation (supporting).

ACKNOWLEDGMENT

Thanks to the National Natural Science Foundation of China (Grant no. 51345006) for supporting this study.

Biographies

Dr. Gang Yan, studying at Qingdao University of science and technology, is engaged in the research of polymer material processing and molding and processing machinery.

Dr. Deshang Han is creative and imaginative, pioneering the combination of rubber field and wear field, opening up a new area of rubber-metal friction and wear during compounding. Dr. Han is an editorial board member and guest editor of the journal polymers.

Professor Li Li, working in Qingdao University of science and technology, is engaged in the research of polymer material processing machinery.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available in the supplementary material of this article.