High-toughening modification of polylactic acid by long-chain hyperbranched polymers

Jianjian Sun

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorCorresponding Author

Yujuan Jin

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Correspondence

Yujuan Jin and Huafeng Tian, School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing 100048, China.

Email: [email protected] and [email protected]

Search for more papers by this authorBo Wang

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorCorresponding Author

Huafeng Tian

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Correspondence

Yujuan Jin and Huafeng Tian, School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing 100048, China.

Email: [email protected] and [email protected]

Search for more papers by this authorKaier Kang

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorShuang Men

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorYunxuan Weng

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorJianjian Sun

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorCorresponding Author

Yujuan Jin

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Correspondence

Yujuan Jin and Huafeng Tian, School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing 100048, China.

Email: [email protected] and [email protected]

Search for more papers by this authorBo Wang

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorCorresponding Author

Huafeng Tian

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Correspondence

Yujuan Jin and Huafeng Tian, School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing 100048, China.

Email: [email protected] and [email protected]

Search for more papers by this authorKaier Kang

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorShuang Men

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorYunxuan Weng

School of Chemistry and Materials Engineering, Beijing Technology and Business University, Beijing, China

Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Beijing Technology and Business University, Beijing, China

Search for more papers by this authorFunding information: Beijing Young Top-notch Personnel Foundation, Grant/Award Number: CIT&TCD201804030; National Natural Science Youth Foundation, Grant/Award Number: 51503007; Beijing Key Laboratory of Quality Evaluation Technology for Hygiene and Safety of Plastics, Grant/Award Number: QETHSP2020013

Abstract

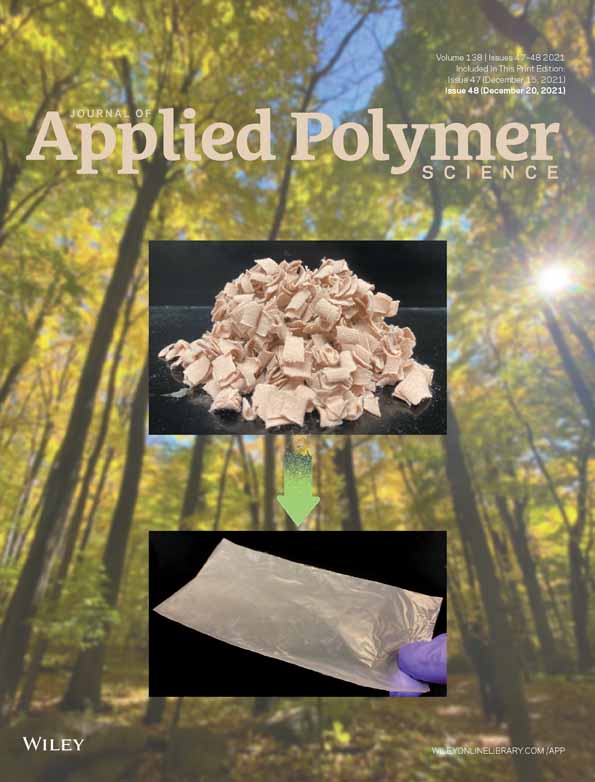

The hyperbranched polyester synthesized by “one-step method” was grafted with stearic acid to obtain long-chain hyperbranched polymers (LCHBPs) with a large number of long stearic acid chains at the end. By means of FTIR and 13C-NMR characterization, it was proved that stearic acids were grafted onto hyperbranched polyesters (HBPE) to yield LCHBPs successfully. It was determined by GPC and hydroxyl value titration that the number average molecular weight of HBPE was 4.86 × 103 and the grafting rate of stearic acid was 47%. Polylactic acid (PLA)/LCHBPs blends were prepared by melt processing method. The results showed that comparing with neat PLA, the tensile strength of PLA/LCHBPs blends decreased slightly with the increase of LCHBPs, but still maintained a high level, while the elongation at break and the impact strength of the PLA with 3.0 phr LCHBPs were greatly improved by 1360.0% and 119.8%, respectively. In addition, the impacted fracture characteristics of PLA changed significantly from brittle fracture to ductile fracture after LCHBPs incorporation, with the formation of a large number of filamentous structures. Thus, LCHBPs was an excellent toughening modifier for PLA and the resulting blends with improved performance possess wider applications.

REFERENCES

- 1P. T. Benavides, U. Lee, O. Zare-Mehrjerdi, J. Cleaner Prod. 2020, 277, 124010.

- 2Z. A. Raza, S. Abid, I. M. Banat, Biodegradation 2018, 126, 45.

- 3S. H. Diermann, M. Y. Lu, M. Dargusch, L. Grøndahl, H. Huang, J. Biomed. Mater. Res. Part B 2019, 107, 2596.

- 4J. W. Xu, P. H. Manepalli, L. J. Zhu, S. Narayan-Sarathy, S. Alavi, J. Polym. Res. 2019, 26, 1.

- 5F. Luzi, E. Fortunati, A. Jimenez, D. Puglia, D. Pezzolla, G. Gigliotti, J. M. Kenny, A. Chiralt, L. Torre, Ind. Crop. Prod. 2016, 93, 276.

- 6Y. J. Jin, Y. Y. Sima, Y. X. Weng, S. Men, Z. G. Huang, Polym. Bull. 2019, 76, 5733.

- 7M. A. Elsawy, K. H. Kim, J. W. Park, A. Deep, Renew. Sust. Energ. Rev. 2017, 79, 1346.

- 8J. M. Chacon, M. A. Caminero, E. Garcia-Plaza, P. J. Nunez, Mater. Des. 2017, 124, 143.

- 9Y. Ramot, M. Haim-Zada, A. J. Domb, A. Nyska, Adv. Drug Delivery Rev. 2016, 107, 153.

- 10Y. J. Jin, S. Men, Y. X. Weng, J. Polym. Eng. 2018, 38, 223.

- 11B. G. Wu, W. J. Yang, D. Y. Niu, W. F. Dong, M. Q. Chen, T. X. Liu, M. L. Du, P. M. Ma, Chin. J. Polym. Sci. 2020, 38, 73.

- 12B. Deeksha, V. Sadanand, N. Hariram, A. V. Rajulu, J. Bioresour. Bioprod. 2021, 6, 75.

- 13E. R. Radu, D. M. Panaitescu, C. A. Nicolae, R. A. Gabor, V. Raditoiu, S. Stoian, E. Alexandrescu, R. Fierascu, I. Chiulan, J. Polym. Environ. 2021, 15, 1.

- 14N. H. N. Do, V. T. Tran, Q. B. M. Tran, K. A. Le, Q. B. Thai, R. T. T. Nguyen, H. M. Duong, P. K. Le, J. Polym. Environ. 2021, 29, 1112.

- 15B. Ashok, N. Hariram, S. Siengchin, A. V. Rajulu, J. Bioresour. Bioprod. 2020, 5, 180.

- 16G. Ehrmann, A. Ehrmann, Polymer 2021, 13, 164.

- 17A. Pedna, L. Pinho, P. F. Andrea, M. J. Mosquera, Prog. Org. Coat 2016, 90, 91.

- 18X. Wang, S. X. Peng, H. Chen, X. L. Yu, X. P. Zhao, Compos. Pt. B-Eng. 2019, 173, 107028.

- 19N. Burgos, I. Armentano, E. Fortunati, F. Dominici, F. Luzi, S. Fiori, F. Cristofaro, L. Visai, A. Jimenez, J. M. Kenny, Food. Bioprocess. Technol. 2017, 10, 770.

- 20M. Aznar, S. Ubeda, N. Dreolin, C. Nerin, J. Chromatogr. A. 2019, 1583, 1.

- 21G. L. Gavril, M. Wrona, A. Bertella, M. Swieca, M. Rapa, J. Salafranca, C. Nerin, Food Chem. Toxicol. 2019, 132, 110662.

- 22S. Rani, K. D. Kumar, S. Mandal, R. Kumar, J. Polym. Res. 2020, 27, 312.

- 23R. Y. Tabasi, A. Ajji, Int. Polym. Process. 2017, 32, 606.

- 24X. C. Yin, L. Wang, S. Li, G. J. He, Z. T. Yang, Y. H. Feng, J. P. Qu, J. Polym. Eng. 2017, 37, 355.

- 25M. Decol, W. M. Pachekoski, D. Becker, Polym. Compos. 2019, 40, 3464.

- 26E. Brown, M. Abdelwahab, O. Valerio, M. Misra, A. K. Mohanty, ACS Omega 2018, 3, 3857.

- 27X. T. Shi, J. B. Qin, L. Wang, L. C. Ren, F. Rong, D. H. Li, R. Wang, G. C. Zhang, RSC Adv. 2018, 8, 11850.

- 28E. Garskaite, L. Alinauskas, M. Drienovsky, J. Krajcovic, R. Cicka, M. Palcut, L. Jonusauskas, M. Malinauskas, Z. Stankeviciute, A. Kareiva, RSC Adv. 2016, 6, 80462.

- 29S. Farah, D. G. Anderson, R. Langer, Adv. Drug Delivery Rev. 2016, 107, 367.

- 30S. Lee, M. Kim, H. Y. Song, K. Hyun, Macromolecules 2019, 52, 7904.

- 31R. Supthanyakul, N. Kaabbuathong, S. Chirachanchai, Polym. Degrad. Stab. 2017, 142, 160.

- 32R. Supthanyakul, N. Kaabbuathong, S. Chirachanchai, Polymer 2016, 105, 1.

- 33A. Carbonell-Verdu, J. M. Ferri, F. Dominici, T. Boronat, L. Sanchez-Nacher, R. Balart, L. Torre, Express. Polym. Lett. 2018, 12, 808.

- 34Y. Ding, W. T. Feng, B. Lu, P. L. Wang, G. X. Wang, J. H. Ji, Polymer 2018, 146, 179.

- 35X. M. Fei, W. Wei, Y. Y. Tang, Y. Zhu, J. Luo, M. Q. Chen, X. Y. Liu, Eur. Polym. J. 2017, 90, 431.

- 36C. Ma, S. L. Qiu, J. L. Wang, H. B. Sheng, Y. Zhang, W. Z. Hu, Y. Hu, Polym. Degrad. Stab. 2018, 154, 157.

- 37J. Chen, X. A. Nie, J. C. Jiang, ACS Omega 2020, 5, 5480.

- 38R. Bhardwaj, A. K. Mohanty, Biomacromolecules 2007, 8, 2476.

- 39Y. Lin, K. Y. Zhang, Z. M. Dong, L. S. Dong, Y. S. Li, Macromolecules 2007, 40, 6257.

- 40B. Mu, T. T. Liu, W. Tian, Macromol. Rapid Commun. 2018, 40, 1800471.

- 41S. Karpagam, S. Guhanathan, Asian J. Chem. 2010, 22, 5130.

- 42C. Kavitha, K. P. Dasan, Chim. Oggi. 2013, 31, 46.