Facile control of high temperature shape memory polymers

Xueying Qiu

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorCorresponding Author

Xinli Xiao

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Correspondence to: X. Xiao (E-mail: [email protected])Search for more papers by this authorDeyan Kong

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorWenbo Zhang

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorZhuo Ma

School of Life Science and Technology, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorXueying Qiu

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorCorresponding Author

Xinli Xiao

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Correspondence to: X. Xiao (E-mail: [email protected])Search for more papers by this authorDeyan Kong

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorWenbo Zhang

MIIT Key Laboratory of Critical Materials Technology for New Energy Conversion and Storage, School of Chemistry and Chemical Engineering, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorZhuo Ma

School of Life Science and Technology, Harbin Institute of Technology, No. 92 West Dazhi Street, Harbin, 150001 People's Republic of China

Search for more papers by this authorABSTRACT

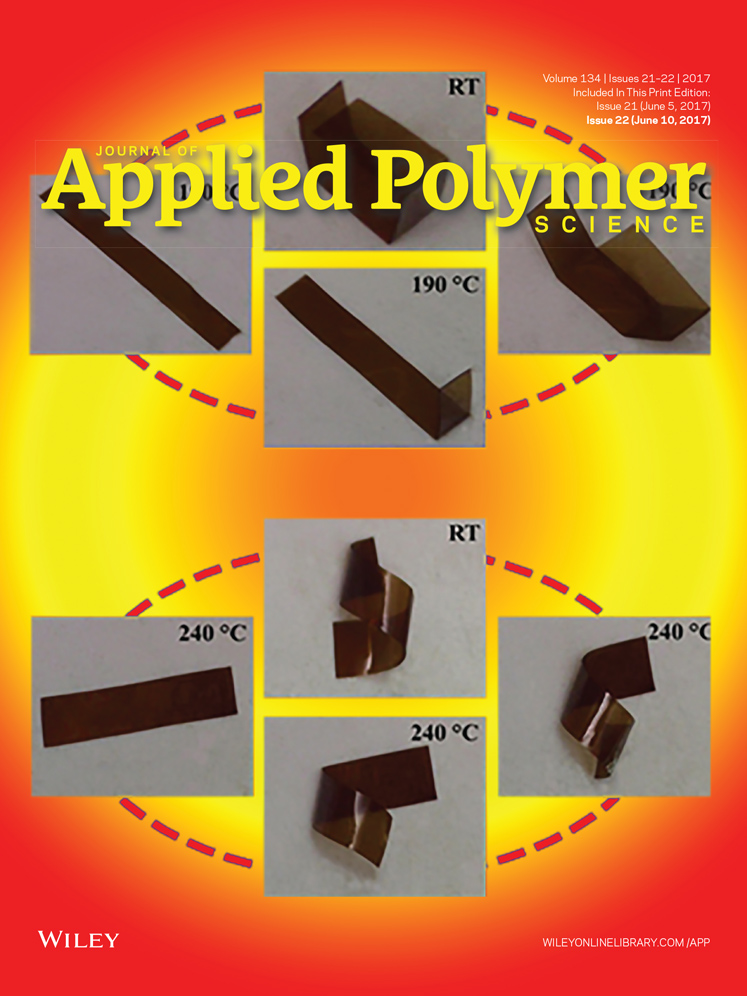

Glass transition temperature (Tg) is crucial in determining application areas of high temperature shape memory polymers (SMPs), but some Tgs are difficult or uneconomic to be obtained. Here we introduce a facile way to prepare high temperature SMPs with controllable Tgs from 183 to 230 °C by copolymerization of polyimides, and relationships between Tgs and diamine components of the shape memory copolyimides agree with Fox Equation. These copolyimides can fix temporary shape and return to original shape nicely, and the possible mechanisms of their high shape fixity and shape recovery are analyzed on the basis of thermomechanical properties and molecular structures. The copolymerization of shape memory polyimides has offered an effective way to obtain high temperature SMPs with desired properties. © 2017 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2017, 134, 44902.

Supporting Information

Additional Supporting Information may be found in the online version of this article.

| Filename | Description |

|---|---|

| app44902-sup-0001-suppvideo1.avi1.9 MB | Supporting Information Video 1. |

| app44902-sup-0002-suppinfo.pdf89.4 KB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

REFERENCES

- 1 Liu, F.; Urban, M. W. Prog. Polym. Sci. 2010, 35, 3.

- 2 Meng, H.; Li, G. Q. Polymer 2013, 54, 2199.

- 3 Xiao, X.; Hu, J. Sci. Rep. 2016, 6, 26393.

- 4 Jin, X. D.; Ni, Q. Q.; Natsuki, T. J. Comp. Mater. 2011, 45, 2547.

- 5 Behl, M.; Razzaq, M. Y.; Lendlein, A. Adv. Mater. 2010, 22, 3388.

- 6 Chen, H.; Li, Y.; Liu, Y.; Gong, T.; Wang, L.; Zhou, S. Polym. Chem. 2014, 5, 5168.

- 7 Khaldi, A.; Elliott, J. A.; Smoukov, S. K. J. Mater. Chem. C 2014, 2, 8029.

- 8 Haberl, J. M.; Sánchez-Ferrer, A.; Mihut, A. M.; Dietsch, H.; Hirt, A. M.; Mezzenga, R. Adv. Funct. Mater. 2014, 24, 3179.

- 9 Nagahama, K.; Ueda, Y.; Ouchi, T.; Ohya, Y. Biomacromolecules 2009, 10, 1789.

- 10 Hu, J.; Zhu, Y.; Huang, H.; Lu, J. Prog. Polym. Sci. 2012, 37, 1720.

- 11 Yu, K.; Ge, Q.; Qi, H. J. Nat. Commun. 2014, 5, 3066.

- 12 Zhang, Y. Y.; Li, Y. M.; Liu, W. G. Adv. Funct. Mater. 2015, 25, 471.

- 13 Xu, H. X.; Yu, C. J.; Wang, S. D.; Malyarchuk, V.; Xie, T.; Rogers, J. A. Adv. Funct. Mater. 2013, 23, 3299.

- 14 Jeon, H. G.; Mather, P. T.; Haddad, T. S. Polym. Int. 2000, 49, 453.

- 15 Song, J. J.; Chang, H. H.; Naguib, H. E. Polymer 2015, 56, 82.

- 16 Sokolowski, W. M.; Tan, S. C. J. Spacecraft Rockets 2007, 44, 750.

- 17 Shumaker, J. A.; McClung, A. J. W.; Baur, J. W. Polymer 2012, 53, 4637.

- 18 Shi, Y.; Weiss, R. A. Macromolecules 2014, 47, 1732.

- 19 Xiao, X. L.; Kong, D. Y.; Qiu, X. Y.; Zhang, W. B.; Zhang, F. H.; Liu, L. W.; Liu, Y. J.; Zhang, S.; Hu, Y.; Leng, J. S. Macromolecules 2015, 48, 3582.

- 20 Xie, F.; Huang, L. N.; Liu, Y. J.; Leng, J. S. Polymer 2014, 55, 5873.

- 21 Yoonessi, M.; Shi, Y.; Scheiman, D. A.; Lebron-Colon, M.; Tigelaar, D. M.; Weiss, R. A.; Meador, M. A. ACS Nano 2012, 6, 7644.

- 22 Shi, Y.; Yoonessi, M.; Weiss, R. A. Macromolecules 2013, 46, 4160. −

- 23 Wang, Q. H.; Bai, Y. K.; Chen, Y.; Ju, J. P.; Zheng, F.; Wang, T. M. J. Mater. Chem. A 2015, 3, 352.

- 24 Xiao, X. L.; Kong, D. Y.; Qiu, X. Y.; Zhang, W. B.; Liu, Y. J.; Zhang, S.; Zhang, F. H.; Hu, Y.; Leng, J. S. Sci. Rep. 2015, 5, 14137.

- 25 Koerner, H.; Strong, R. J.; Smith, M. L.; Wang, D. H.; Tan, L. S.; Lee, K. M.; White, T. J.; Vaia, R. A. Polymer 2013, 54, 391.

- 26 Chung, H.; Jang, W.; Hwang, J.; Han, H. J. Polym. Sci. Part B: Polym. Phys. 2001, 39, 796.

- 27 Chung, I. S.; Park, C. E.; Ree, M.; Kim, S. Y. Chem. Mater. 2001, 13, 2801.

- 28 Han, Y.; Fang, X. Z.; Zuo, X. X. eXPRESS Polym. Lett. 2010, 4, 712.

- 29 Kurosawa, T.; Lai, Y. C.; Higashihara, T.; Ueda, M.; Liu, C. L.; Chen, W. C. Macromolecules 2012, 45, 4556.

- 30 Chen, L.; Jiang, S.; Chen, J.; Chen, F.; He, Y.; Zhu, Y.; Hou, H. New J. Chem. 2015, 39, 8956.

- 31 Cao, L.; Zhang, M. Y.; Niu, H. Q.; Chang, J. J.; Liu, W. W.; Yang, H. C.; Cao, W. Y.; Wu, D. Z. J. Mater. Sci. 2017, 52, 1883.

- 32 Pryde, C. A. J. Polym. Sci. Part A: Polym. Chem. 1989, 27, 711.

- 33 Xiao, X. L. et al. Soft Matter 2016, 12, 2894.

- 34 Kwei, T. K. J. Polym. Sci. Lett. 1984, 22, 307.

- 35 Brostow, W.; Chiu, R.; Kalogeras, I. M.; Vassilikou–Dova, A. Mater. Lett. 2008, 62, 3152.

- 36 Page, K. A.; Cable, K. M.; Moore, R. B. Macromolecules 2005, 38, 6472.

- 37 Xie, T. Nature 2010, 464, 267.

- 38 Kalogeras, I. M.; Hagg Lobland, H. E. J. Mater. Ed. 2012, 34, 69.

Citing Literature

10 June 2017