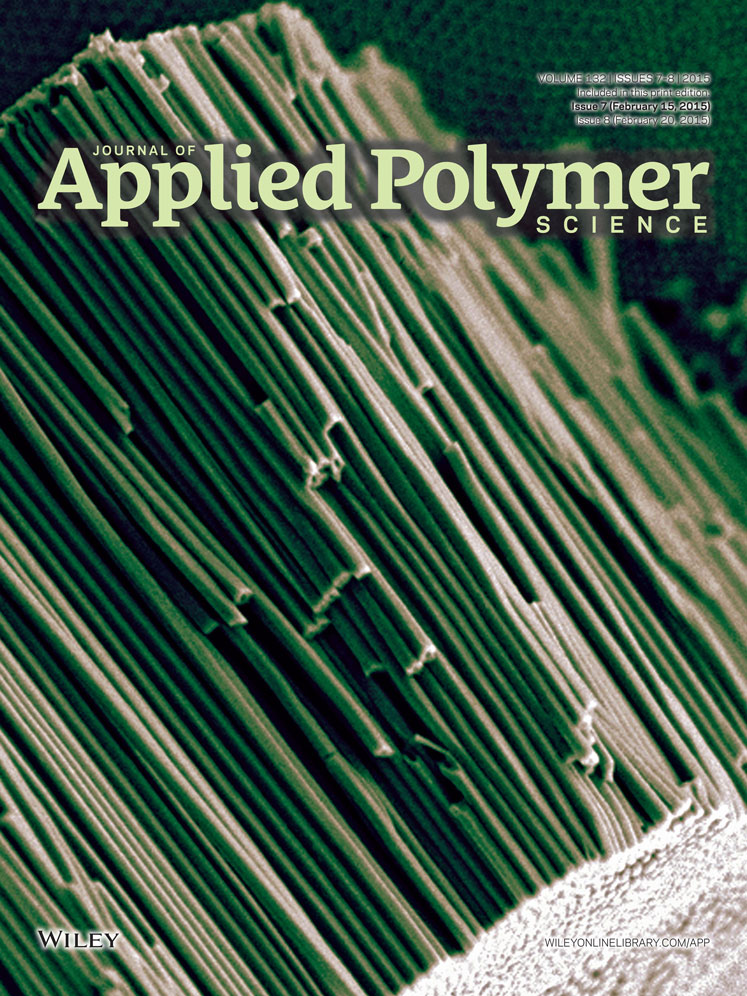

Effect of polymer structure on the morphologies and dielectric properties of nanoporous polyimide films

ABSTRACT

Low dielectric constant polyimide (PI) films have potential applications in integrated circuit. In this study, poly(methyl methacrylate), poly(ethylene oxide), and polystyrene as thermally labile materials were used as templates to generate PI films with nanopores by first mixing the polymer templates with the precursor of PI, poly(amic acid), followed by imidization of poly(amic acid) together with degradation of the polymer templates. The sizes of the formed pores, the thermal and dielectric constant of the nanofoamed PI films were studied and compared in detail. It is concluded that the dielectric constant of PI films using poly(ethylene oxide) as pore template is more stable because of the formation of uniform pores which is from the great accordance of imidization temperature of poly(amic acid) with the degradation temperature of poly(ethylene oxide). But that using poly(methyl methacrylate) as pore template is frequency dependent as the influence of inhomogeneous pores and PMMA residue from incompletely degradation of poly(methyl methacrylate). © 2014 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2015, 132, 41480.