The influence of fatty alcohol ether phosphate salt on carbon fiber's dispersion property

ABSTRACT

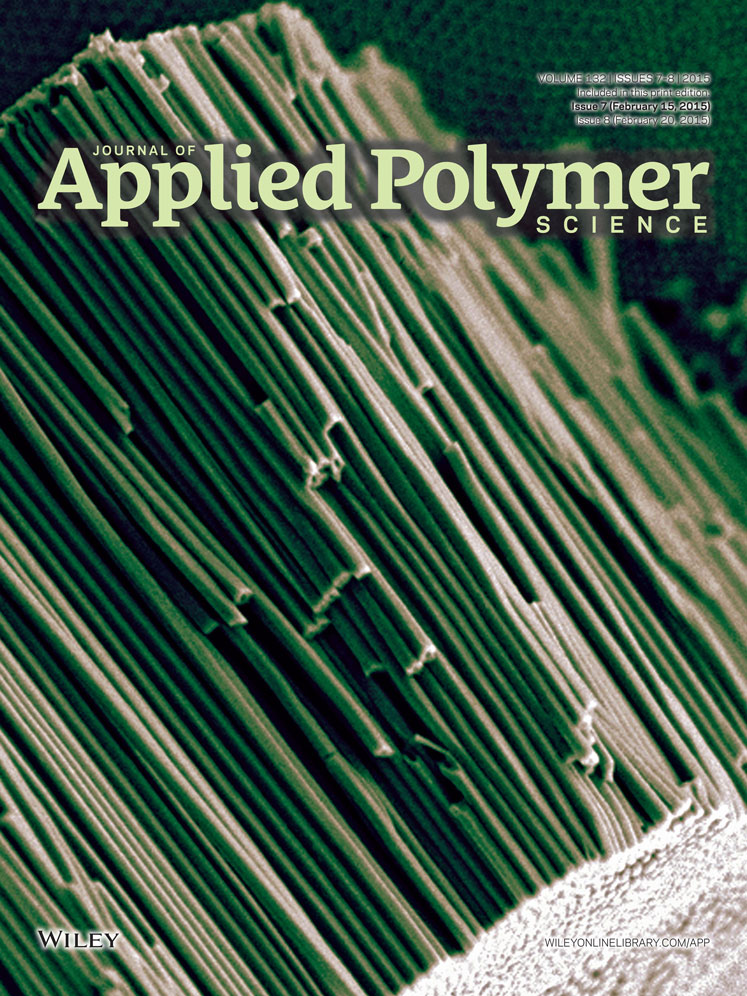

The influence of fatty alcohol ether phosphate salt on the dispersion property of carbon fiber in oil material is assessed by the settling time, the turbidity and the dispersant condition of carbon fiber in oil material, and the surface morphologic structure and chemical composition of carbon fiber before and after leaching silk are characterized by field emission scanning electron microscope, scanning tunneling microscope, and X-ray photoelectron spectroscopy. Experiments show that fatty alcohol ether phosphate salt can improve the dispersion of carbon fiber in oil material significantly, and the optimum leaching silk concentration of fatty alcohol ether phosphate salt is 0.3%, while dispersants would spread over on the surface of carbon fiber evenly and the maximum turbidity value and the longest settlement time is 1.081 NTU and 28 min, respectively. © 2014 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2015, 132, 41470.