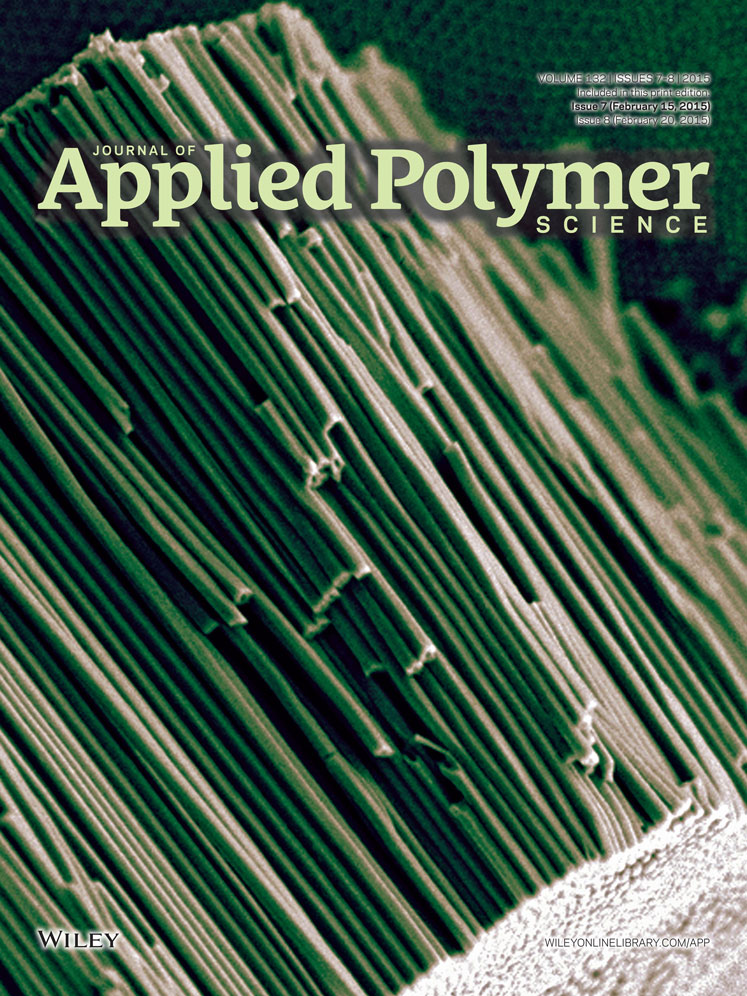

Effects of processing conditions on foaming behaviors of polyetherimide (PEI) and PEI/polypropylene blends in microcellular injection molding process

ABSTRACT

Foaming behaviors of both neat polyetherimide (PEI) and PEI/polypropylene (PP) blends were studied in this article in microcellular injection molding (Mucell) process. The study mainly focused on the comparison of two materials' foaming behaviors under different processing conditions which took a critical effect on the morphologies of foams. The results indicated that the different characteristics of PEI and PEI/PP blends, such as melt strength, gas dissolvability, and solubility, induced different nucleation ability of PEI and PEI/PP blends. The addition of PP could obviously improve the cell density and reduce the cell size. With the processing conditions changing, the morphologies of PEI/PP altered more variously, and their distribution of cell density was wider. This suggested that foaming behaviors of PEI/PP blends was more flexible to be controlled by the processing conditions than neat PEI. The effects of shot size, gas injection, and injection rate on foam morphologies were studied in detail. Shot size determined the weight reduction of samples and affected the cell density and size significantly. Gas dosing time and dosing rate determined the gas ratio which effected on foam morphologies of the PEI and PEI/PP foams. © 2014 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2015, 132, 41443.