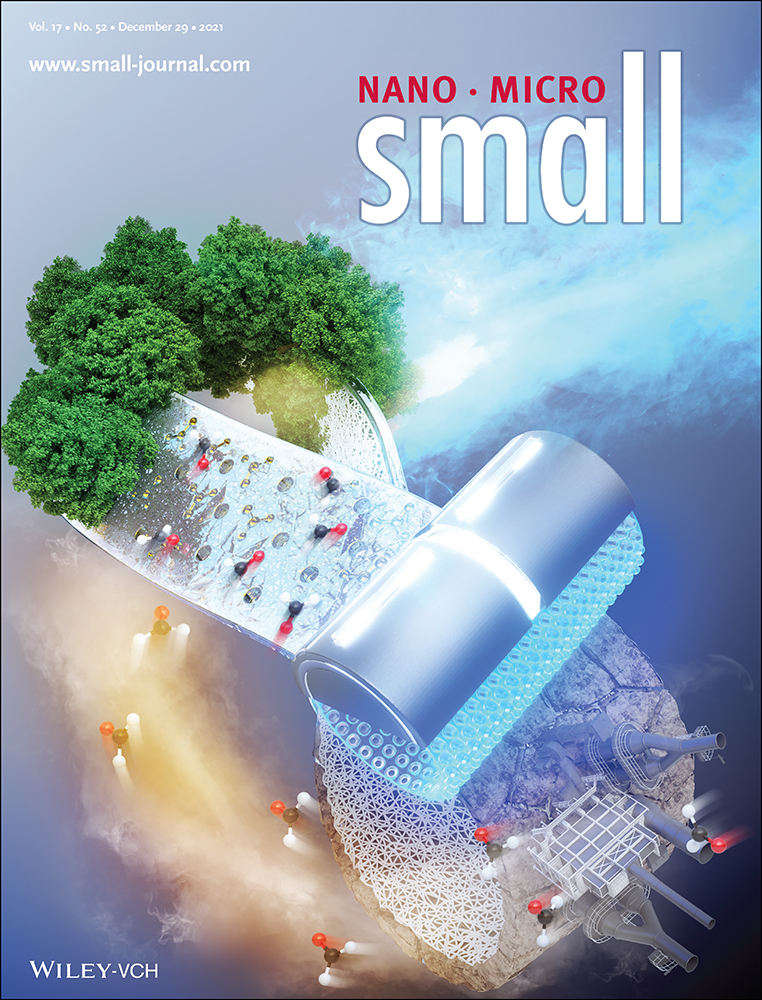

Rotating Cylinder-Assisted Nanoimprint Lithography for Enhanced Chemisorbable Filtration Complemented by Molecularly Imprinted Polymers

Sangheon Jeon

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorRowoon Park

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorJeonghwa Jeong

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorGyeonghwa Heo

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorJihye Lee

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorMin Chan Shin

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorYoung Woo Kwon

Department of Nano-fusion Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorJin Chul Yang

School of Applied Chemical Engineering, Kyungpook National University, Daegu, 41566 Republic of Korea

Search for more papers by this authorWoon Ik Park

Department of Materials Science and Engineering, College of Engineering, Pukyong National University, Busan, 48547 Republic of Korea

Search for more papers by this authorKi Su Kim

Department of Organic Materials Science and Engineering, College of Engineering, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorCorresponding Author

Jinyoung Park

School of Applied Chemical Engineering, Kyungpook National University, Daegu, 41566 Republic of Korea

E-mail: [email protected], [email protected]

Search for more papers by this authorCorresponding Author

Suck Won Hong

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

E-mail: [email protected], [email protected]

Search for more papers by this authorSangheon Jeon

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorRowoon Park

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorJeonghwa Jeong

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorGyeonghwa Heo

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorJihye Lee

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorMin Chan Shin

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorYoung Woo Kwon

Department of Nano-fusion Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorJin Chul Yang

School of Applied Chemical Engineering, Kyungpook National University, Daegu, 41566 Republic of Korea

Search for more papers by this authorWoon Ik Park

Department of Materials Science and Engineering, College of Engineering, Pukyong National University, Busan, 48547 Republic of Korea

Search for more papers by this authorKi Su Kim

Department of Organic Materials Science and Engineering, College of Engineering, Pusan National University, Busan, 46241 Republic of Korea

Search for more papers by this authorCorresponding Author

Jinyoung Park

School of Applied Chemical Engineering, Kyungpook National University, Daegu, 41566 Republic of Korea

E-mail: [email protected], [email protected]

Search for more papers by this authorCorresponding Author

Suck Won Hong

Department of Optics and Mechatronics Engineering, Department of Cogno-Mechatronics Engineering, College of Nanoscience and Nanotechnology, Pusan National University, Busan, 46241 Republic of Korea

E-mail: [email protected], [email protected]

Search for more papers by this authorAbstract

Rotating cylindrical stamp-based nanoimprint technique has many advantages, including the continuous fabrication of intriguing micro/nanostructures and rapid pattern transfer on a large scale. Despite these advantages, the previous nanoimprint lithography has rarely been used for producing sophisticated nanoscale patterns on a non-planar substrate that has many extended applications. Here, the simple integration of nanoimprinting process with a help of a transparent stamp wrapped on the cylindrical roll and UV optical source in the core to enable high-throughput pattern transfer, particularly on a fabric substrate is demonstrated. Moreover, as a functional resin material, this innovative strategy involves a synergistic approach on the synthesis of molecularly imprinted polymer, which are spatially organized free-standing perforated nanostructures such as nano/microscale lines, posts, and holes patterns on various woven or nonwoven blank substrates. The proposed materials can serve as a self-encoded filtration medium for selective separation of formaldehyde molecules. It is envisioned that the combinatorial fabrication process and attractive material paves the way for designing next-generation separation systems in use to capture industrial or household toxic substances.

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

Research data are not shared.

Supporting Information

| Filename | Description |

|---|---|

| smll202105733-sup-0001-SuppMat.pdf2.6 MB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1S. Zhang, J. Phys.: Conf. Ser. 2020, 1617, 012054.

- 2S. W. Hong, F. Du, W. Lan, S. Kim, H.-S. Kim, J. A. Rogers, Adv. Mater. 2011, 23, 3821.

- 3Y. Li, L. Huang, M. Zhong, Z. Wei, J. Li, Adv. Mater. Technol. 2016, 1, 1600001.

- 4Y. Wang, J.-A. Pan, H. Wu, D. V. Talapin, ACS Nano 2019, 13, 13917.

- 5M. Kim, D. K. Brown, O. Brand, Nat. Commun. 2020, 11, 1.

- 6A. Carlson, A. M. Bowen, Y. Huang, R. G. Nuzzo, J. A. Rogers, Adv. Mater. 2012, 24, 5284.

- 7T.-W. Lee, S. Jeon, J. Maria, J. Zaumseil, J. W. P. Hsu, J. A. Rogers, Adv. Funct. Mater. 2005, 15, 1435.

- 8U. Palfinger, C. Auner, H. Gold, A. Haase, J. Kraxner, T. Haber, M. Sezen, W. Grogger, G. Domann, G. Jakopic, J. R. Krenn, B. Stadlober, Adv. Mater. 2010, 22, 5115.

- 9N. A. Abu-Hatab, J. M. Oran, M. J. Sepaniak, ACS Nano 2008, 2, 377.

- 10S. Y. Chou, C. Keimel, J. Gu, Nature 2002, 417, 835.

- 11Y. W. Kwon, J. Park, T. Kim, S. H. Kang, H. Kim, J. Shin, S. Jeon, S. W. Hong, ACS Nano 2016, 10, 4609.

- 12S.-K. Lee, H. S. Park, G.-R. Yi, J. H. Moon, S.-M. Yang, Angew. Chem. 2009, 121, 7134.

10.1002/ange.200901166 Google Scholar

- 13K.-S. Han, S.-H. Hong, K.-I. Kim, J.-Y. Cho, K.-W. Choi, H. Lee, Nanotechnology 2013, 24, 045304.

- 14N. Kooy, K. Mohamed, L. T. Pim, O. S. Guan, Nanoscale Res. Lett. 2014, 9, 320.

- 15M. Leitgeb, D. Nees, S. Ruttloff, U. Palfinger, J. Götz, R. Liska, M. R. Belegratis, B. Stadlober, ACS Nano 2016, 10, 4926.

- 16B. D. Gates, Q. B. Xu, M. Stewart, D. Ryan, C. G. Willson, G. M. Whitesides, Chem. Rev. 2005, 105, 1171.

- 17A. R. Cardoso, M. H. de, M. G. F. Sales, Bioelectrochemistry 2019, 130, 107287.

- 18J. Erdőssy, V. Horváth, A. Yarman, F. W. Scheller, R. E. Gyurcsányi, TrAC, Trends Anal. Chem. 2016, 79, 179.

- 19A. Cutivet, C. Schembri, J. Kovensky, K. Haupt, J. Am. Chem. Soc. 2009, 131, 14699.

- 20D. Cai, L. Ren, H. Zhao, C. Xu, L. Zhang, Y. Yu, H. Wang, Y. Lan, M. F. Roberts, J. H. Chuang, M. J. Naughton, Z. Ren, T. C. Chiles, Nat. Nanotechnol. 2010, 5, 597.

- 21R. Schirhagl, Anal. Chem. 2014, 86, 250.

- 22Y. T. Wang, Z. Q. Zhang, V. Jain, J. J. Yi, S. Muellere, J. Sokolova, Z. X. Liu, K. Levong, B. Rigasb, M. H. Rafailovich, Sens. Actuators, B 2010, 146, 381.

- 23D. K. Oh, J. C. Yang, S. W. Hong, J. Park, Sens. Actuators, B 2020, 323, 128670.

- 24J. C. Yang, H.-K. Shin, S. W. Hong, J. Y. Park, Sens. Actuators, B 2015, 216, 476.

- 25W. Chen, X. Tian, W. He, J. Li, Y. Feng, G. Pan, BMC Mater. 2020, 2, 1.

10.1186/s42833-019-0007-1 Google Scholar

- 26W. Zhao, B. Li, S. Xu, X. Huang, J. Luo, Y. Zhu, X. Liu, J. Mater. Chem. B 2019, 7, 2311.

- 27E. Yilmaz, D. Majidi, E. Ozgur, A. Denizli, Sens. Actuators, B 2015, 209, 714.

- 28J. John, Y. Tang, J. P. Rothstein, J. J. Watkins, K. R. Carter, Nanotechnology 2013, 24, 505307.

- 29M. Lohse, M. W. Thesen, A. Haase, M. Smolka, N. B. Iceta, A. A. Izquierdo, I. Ramos, C. Salado, A. Schleunitz, Nanomaterials 2021, 11, 902.

- 30S. Photong, V. Boonamnuayvitaya, J. Environ. Sci. 2009, 21, 1741.

- 31S. Ahn, L. J. Guo, Adv. Mater. 2008, 20, 2044.

- 32J. G. Ok, M. K. Kwak, C. M. Huard, H. S. Youn, L. J. Guo, Adv. Mater. 2013, 25, 6554.

- 33H. Cho, J. Kim, H. Park, J. W. Bang, M. S. Hyun, Y. Bae, L. Ha, D. Y. Kim, S. M. Kang, T. J. Park, S. Seo, M. Choi, K. -Y. Suh, Nat. Commun. 2014, 5, 3137.

- 34H. E. Jeong, J. K. Lee, H. N. Kim, S. H. Moon, K. Y. Suh, Proc. Natl. Acad. Sci. U. S. A. 2009, 106, 5639.

- 35R. Kwak, H. E. Jeong, K. Y. Suh, Small 2009, 5, 790.

- 36S. Seo, T. -I. Kim, H. H. Lee, Microelectron. Eng. 2007, 84, 567.

- 37S. H. Ahn, L. J. Guo, ACS Nano 2009, 3, 2304.

- 38J. Lee, J. C. Yang, S. Lone, W. I. Park, Z. Lin, J. Park, S. W. Hong, Biomacromolecules 2021, 22, 1523.

- 39J. C. Yang, J. Lee, S. W. Hong, J. Park, Sens. Actuators, B 2020, 320, 128366.

- 40G. A. Aya, J. C. Yang, S. W. Hong, J. Y. Park, Polymers 2019, 11, 1332.

- 41J. C. Yang, S. W. Hong, S. Jeon, W. Park, M. Byun, J. Park, Appl. Surf. Sci. 2021, 570, 151161.

- 42J. Lee, J. Y. Kim, J. H. Choi, J. G. Ok, M. K. Kwak, ACS Omega 2017, 2, 1097.

- 43J. Kim, Y. Wang, H. Park, M. C. Park, S. E. Moon, S. M. Hong, C. M. Koo, K.-Y. Suh, S. Yang, H. Cho, Adv. Mater. 2017, 29, 1605078.

- 44Y. Yang, K. Lee, K. Mielczarek, W. Hu, A. Zakhidov, Nanotechnology 2011, 22, 485301.

- 45H. Yi, I. Hwang, J. H. Lee, D. Lee, H. Lim, D. Tahk, M. Sung, W.-B. Bae, S.-J. Choi, M. K. Kwak, H. E. Jeong, ACS Appl. Mater. Interfaces 2014, 6, 14590.

- 46S. Wu, Polymer Interface and Adhesion, Marcel Dekker, New York, 1982.

- 47Y. H. Choi, J. Lee, D.-Y. Khang, J. Membr. Sci. 2020, 612, 118474.

- 48P. S. Sharma, M. Dabrowski, F. D'Souza, W. Kutner, TrAC, Trends Anal. Chem. 2013, 51, 146.

- 49J. C. Yang, J. Y. Park, ACS Appl. Mater. Interfaces 2016, 8, 7381.

- 50B. D. Tiu, R. B. Pernites, S. B. Tiu, R. C. Advincula, Colloids Surf., A 2016, 495, 149.

- 51J. Y. Park, Analyst 2016, 141, 5709.

- 52J. Williams, H. Li, A. B. Ross, S. P. Hargreaves, Atmos. Environ. 2019, 218, 117019.

- 53S. Sai, H. Ho, J. Z. Yu, Environ. Sci. Technol. 2004, 38, 862.

- 54Y. Yang, Z. D. Deng, Appl. Phys. Rev. 2019, 6, 011309.

- 55H. Y. Y. Nyein, M. Bariya, L. Kivimäki, S. Uusitalo, T. S. Liaw, E. Jansson, C. H. Ahn, J. A. Hangasky, J. Zhao, Y. Lin, T. Happonen, M. Chao, C. Liedert, Y. Zhao, L.-C. Tai, J. Hiltunen, A. Javey, Sci. Adv. 2019, 5, eaaw9906.

- 56A. A. Malik, C. Nantasenamat, T. Piacham, Mater. Sci. Eng., C 2017, 77, 1341.

- 57T. W. Park, M. Byun, H. Jung, G. R. Lee, J. H. Park, H.-I. Jang, J. W. Lee, S. H. Kwon, S. Hong, J.-H. Lee, Y. S. Jung, K. H. Kim, W. I. Park, Sci. Adv. 2020, 6, eabb6462.