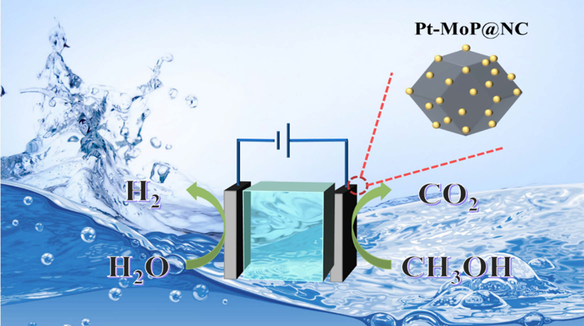

Energy-Saving Hydrogen Production from Methanol Electrocatalysis Catalyzed by Molybdenum Phosphide/Nitrogen-Doped Carbon Polyhedrons Supported Pt Nanoparticles

Jiaojiao Li

School of Chemistry and Chemical Engineering, Yangzhou University, Yangzhou, Jiangsu, 225002 China

Search for more papers by this authorMeng Li

School of Chemistry and Chemical Engineering, Yangzhou University, Yangzhou, Jiangsu, 225002 China

Search for more papers by this authorCorresponding Author

Fulin Yang

Faculty of Materials Science and Engineering, Kunming University of Science and Technology, Kunming, Yunnan, 650093 China

E-mail: [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Ligang Feng

School of Chemistry and Chemical Engineering, Yangzhou University, Yangzhou, Jiangsu, 225002 China

E-mail: [email protected]; [email protected]Search for more papers by this authorJiaojiao Li

School of Chemistry and Chemical Engineering, Yangzhou University, Yangzhou, Jiangsu, 225002 China

Search for more papers by this authorMeng Li

School of Chemistry and Chemical Engineering, Yangzhou University, Yangzhou, Jiangsu, 225002 China

Search for more papers by this authorCorresponding Author

Fulin Yang

Faculty of Materials Science and Engineering, Kunming University of Science and Technology, Kunming, Yunnan, 650093 China

E-mail: [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Ligang Feng

School of Chemistry and Chemical Engineering, Yangzhou University, Yangzhou, Jiangsu, 225002 China

E-mail: [email protected]; [email protected]Search for more papers by this authorComprehensive Summary

Improving the catalytic efficiency and anti-poisoning ability of Pt-based catalysts is very critical in methanol electrolysis technology for high-purity hydrogen generation. Herein, the nitrogen-doped carbon polyhedrons-encapsulated MoP (MoP@NC) supported Pt nanoparticles were demonstrated to be effective for methanol electrolysis resulting from the combined advantages. The nitrogen-doped carbon polyhedrons not only greatly enhanced the conductivity but also effectively prevented the aggregation of MoP to offer Pt anchoring sites. The electronic structure modification of Pt from their interaction reduced the adsorption energy of CO*, resulting in good CO-poisoning resistance and accelerated reaction kinetics. Specifically, Pt-MoP@NC exhibited the highest peak current density of 106.4 mA·cm–2 for methanol oxidation and a lower overpotential of 28 mV at 10 mA·cm–2 for hydrogen evolution. Energy-saving hydrogen production from methanol electrolysis was demonstrated in the two-electrode systems assembled by Pt-MoP@NC which required a low cell voltage of 0.65 V to reach a kinetic current density of 10 mA·cm–2 on the glass carbon system, about 1.02 V less than that of water electrolysis.

Supporting Information

| Filename | Description |

|---|---|

| cjoc202400523-sup-0001-supinfo.pdfPDF document, 2 MB |

Appendix S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 Liang, K.; Tabassum, A.; Kothakonda, M.; Zhang, X.; Zhang, R.; Kenney, B.; Koplitz, B. D.; Sun, J.; Naguib, M. Two-dimensional titanium carbonitride MXene as a highly efficient electrocatalyst for hydrogen evolution reaction. Mater. Rep.: Energy 2022, 2, 100075.

- 2 Chen, J.; Chen, C.; Qin, M.; Li, B.; Lin, B.; Mao, Q.; Yang, H.; Liu, B.; Wang, Y. Reversible hydrogen spillover in Ru-WO3-x enhances hydrogen evolution activity in neutral pH water splitting. Nat. Commun. 2022, 13, 5382.

- 3 Wang, C.; Yang, F.; Feng, L. An efficient bi-functional Ir-based catalyst for the acidic overall water splitting reaction. Chem. Commun. 2023, 59, 9984–9987.

- 4 Wang, C.; Yu, L.; Yang, F.; Feng, L. MoS2 nanoflowers coupled with ultrafine Ir nanoparticles for efficient acid overall water splitting reaction. J. Energy Chem. 2023, 87, 144–152.

- 5 Ding, J.; Jiang, X.; Wang, C.; Zhu, Z.; Xu, C.; Zhou, Y.; Wang, X.; Liu, Q.; Liu, Z.; Tang, Y.; Lin, J.; Fu, G. Epitaxial growth triggered core-shell Pd@RuP nanorods for high-efficiency electrocatalytic hydrogen evolution. J. Energy Chem. 2023, 86, 510–517.

- 6 Miao, Z.; Wu, G.; Wang, Q.; Yang, J.; Wang, Z.; Yan, P.; Sun, P.; Lei, Y.; Mo, Z.; Xu, H. Recent advances in graphitic carbon nitride-based photocatalysts for solar-driven hydrogen production. Mater. Rep.: Energy 2023, 3, 100235.

- 7 Hu, J.; Xu, B.; Xu, J.; Li, S.; Liu, Z.; Lu, C.; Feng, Y.; Feng, K.; Zhong, J. Electrocatalysis induced reconstruction of RuNiPO for highly efficient hydrogen evolution reaction. J. Energy Chem. 2023, 87, 24–31.

- 8

Zhang, K.; Liang, X.; Wang, L.; Sun, K.; Wang, Y.; Xie, Z.; Wu, Q.; Bai, X.; Hamdy, M. S.; Chen, H.; Zou, X. Status and perspectives of key materials for PEM electrolyzer. Nano Res. Energy 2022, 1, e9120032.

10.26599/NRE.2022.9120032 Google Scholar

- 9 Wu, M.; Zhang, Y.; Fu, Z.; Lyu, Z.; Li, Q.; Wang, J. Structure-Activity Relationship of Atomic-Scale Cobalt-Based N-C Catalysts in the Oxygen Evolution Reaction. Acta Phys.-Chim. Sin. 2023, 39, 2207007.

- 10 Sun, H.; Kim, H.; Song, S.; Jung, W. Copper foam-derived electrodes as efficient electrocatalysts for conventional and hybrid water electrolysis. Mater. Rep.: Energy 2022, 2, 100092.

- 11 Zhou, Y.; Kuang, Y.; Hu, G.; Wang, X.; Feng, L. An effective Pt–CoTe/NC catalyst of bifunctional methanol electrolysis for hydrogen generation. Mater. Today Phys. 2022, 27, 100831.

- 12 He, R.; Wang, C.; Feng, L. Amorphous FeCoNi-S as efficient bifunctional electrocatalysts for overall water splitting reaction. Chin. Chem. Lett. 2023, 34, 107241.

- 13 Yang, F.; Qiao, W.; Yu, L.; Wang, S.; Feng, L. Support engineering modulated Pt/hierarchical MoSe2@mesoporous hollow carbon spheres for efficient methanol-assisted water splitting. Chem. Eng. J. 2024, 483, 149055.

- 14 Muthumeenal, A.; Pethaiah, S. S.; Nagendran, A. Investigation of SPES as PEM for hydrogen production through electrochemical reforming of aqueous methanol. Renewable Energy 2016, 91, 75–82.

- 15 Qiao, W.; Yu, L.; Chang, J.; Yang, F.; Feng, L. Efficient bi-functional catalysis of coupled MoSe2 nanosheet/Pt nanoparticles for methanol-assisted water splitting. Chin. J. Catal. 2023, 51, 113–123.

- 16 Ding, M.; Chen, Z.; Liu, C.; Wang, Y.; Li, C.; Li, X.; Zheng, T.; Jiang, Q.; Xia, C. Electrochemical CO2 reduction: Progress and opportunity with alloying copper. Mater. Rep.: Energy 2023, 3, 100175.

- 17 Li, J.; Wang, C.; Zhang, Y.; Hata, S.; Zhang, K.; Ye, C.; Shiraishi, Y.; Du, Y. Advanced heterostructure of Pd nanosheets@Pt nanoparticles boosts methanol electrooxidation. J. Energy Chem. 2023, 85, 430–438.

- 18 Wang, Y.; Zheng, M.; Li, Y.; Ye, C.; Chen, J.; Ye, J.; Zhang, Q.; Li, J.; Zhou, Z.; Fu, X.-Z.; Wang, J.; Sun, S.-G.; Wang, D. p–d Orbital Hybridization Induced by a Monodispersed Ga Site on a Pt3Mn Nanocatalyst Boosts Ethanol Electrooxidation. Angew. Chem. Int. Ed. 2022, 61, e202115735.

- 19 Qiao, W.; Huang, X.; Feng, L. Advances of PtRu-based electrocatalysts for methanol oxidation. Chin. J. Struct. Chem. 2022, 41, 2207016–2207034.

- 20 Liu, C.; Feng, L. Advances in anode catalysts of methanol-assisted water-splitting reactions for hydrogen generation. Chin. J. Struct. Chem. 2023, 42, 100136.

- 21 Zheng, X.; Wang, Z.; Zhou, Q.; Wang, Q.; He, W.; Lu, S. Precision tuning of highly efficient Pt-based ternary alloys on nitrogen-doped multi-wall carbon nanotubes for methanol oxidation reaction. J. Energy Chem. 2024, 88, 242–251.

- 22 Lu, Q.; Gu, X.; Li, J.; Li, W.; Luque, R.; Eid, K. Unraveling ultrasonic assisted aqueous-phase one-step synthesis of porous PtPdCu nanodendrites for methanol oxidation with a CO-poisoning tolerance. Ultrason. Sonochem. 2023, 98, 106494.

- 23 Kuang, Y.; Qiao, W.; Wang, S.; Yang, F.; Feng, L. Doping and Interfacial Engineering of MoSe2 Nanosheets by NH3 Plasma Promoted Pt for Methanol Electrolysis. ACS Mater. Lett. 2024, 6, 1722–1731.

- 24 Chen, Q.; Du, C.; Yang, Y.; Shen, Q.; Qin, J.; Hong, M.; Zhang, X.; Chen, J. Two-dimensional siloxene as an advanced support of platinum for superior hydrogen evolution and methanol oxidation electrocatalysis. Mater. Today Phys. 2023, 30, 100931.

- 25 Ding, X.; Li, M.; Jin, J.; Huang, X.; Wu, X.; Feng, L. Graphene aerogel supported Pt-Ni alloy as efficient electrocatalysts for alcohol fuel oxidation. Chin. Chem. Lett. 2022, 33, 2687–2691.

- 26 Zhou, Y.; Wang, Q.; Tian, X.; Feng, L. Efficient bifunctional catalysts of CoSe/N-doped carbon nanospheres supported Pt nanoparticles for methanol electrolysis of hydrogen generation. Nano Res. 2022, 15, 8936–8945.

- 27 Kuang, P.; Ni, Z.; Yu, J.; Low, J. New progress on MXenes-based nanocomposite photocatalysts. Mater. Rep.: Energy 2022, 2, 100081.

- 28 Zhang, H.; Zhang, P.; Qiu, M.; Dong, J.; Zhang, Y.; Lou, X. W. Ultrasmall MoOx Clusters as a Novel Cocatalyst for Photocatalytic Hydrogen Evolution. Adv. Mater. 2019, 31, 1804883.

- 29 Yang, Z.; Li, M.; Cui, P.; Zhang, G.; Jiang, X.; Wang, Y. Designed Formation of Hollow Pt Nanocrystals Supported on MoOx-Modified Carbon for High-Performance Methanol Electro-Oxidation. ACS Sustainable Chem. Eng. 2018, 6, 14026–14032.

- 30 Wang, L.; Liu, Z.; Zhang, J. Ru anchored on Mo@MoOx nanowires as self-supported electrocatalysts for efficient hydrogen production in alkaline media. ChemNanoMat 2022, 8, e202200309.

- 31 Jiao, Y.; Yan, H.; Wang, R.; Wang, X.; Zhang, X.; Wu, A.; Tian, C.; Jiang, B.; Fu, H. Porous Plate-like MoP Assembly as an Efficient pH-Universal Hydrogen Evolution Electrocatalyst. ACS Appl. Mater. Interfaces 2020, 12, 49596–49606.

- 32 Zhu, J.; Huang, S.; Key, J.; Nie, S.; Ma, S.; Shen, P. K. Facile synthesis of a molybdenum phosphide (MoP) nanocomposite Pt support for high performance methanol oxidation. Catal. Sci. Technol. 2017, 7, 5974–5981.

- 33

Li, M.; Yang, F.; Chang, J.; Schechter, A.; Feng, L. MoP-NC nanosphere supported Pt nanoparticles for efficient methanol electrolysis. Acta Phys.-Chim. Sin. 2023, 39, 2301005.

10.3866/PKU.WHXB202301005 Google Scholar

- 34 Zhou, C.; Gan, M.; Xie, F.; Ma, L.; Ding, J.; Shen, J.; Han, S.; Wei, D.; Zhan, W. Pt nanoparticles coated on multiwalled carbon nanotubes by the modification of small-sized molybdenum phosphide for enhanced methanol electro-oxidation. Ionics 2020, 26, 6331–6340.

- 35 Li, J.-S.; Zhang, S.; Sha, J.-Q.; Wang, H.; Liu, M.-Z.; Kong, L.-X.; Liu, G.-D. Confined Molybdenum Phosphide in P-Doped Porous Carbon as Efficient Electrocatalysts for Hydrogen Evolution. ACS Appl. Mater. Interfaces 2018, 10, 17140–17146.

- 36 Yang, J.; Zhang, F.; Wang, X.; He, D.; Wu, G.; Yang, Q.; Hong, X.; Wu, Y.; Li, Y. Porous Molybdenum Phosphide Nano-Octahedrons Derived from Confined Phosphorization in UIO-66 for Efficient Hydrogen Evolution. Angew. Chem. Int. Ed. 2016, 55, 12854–12858.

- 37 Song, H.; Li, Y.; Shang, L.; Tang, Z.; Zhang, T.; Lu, S. Designed controllable nitrogen-doped carbon-dots-loaded MoP nanoparticles for boosting hydrogen evolution reaction in alkaline medium. Nano Energy 2020, 72, 104730.

- 38 Wu, Z.; Wang, J.; Liu, R.; Xia, K.; Xuan, C.; Guo, J.; Lei, W.; Wang, D. Facile preparation of carbon sphere supported molybdenum compounds (P, C and S) as hydrogen evolution electrocatalysts in acid and alkaline electrolytes. Nano Energy 2017, 32, 511–519.

- 39 Yang, G.; Jiao, Y.; Yan, H.; Xie, Y.; Wu, A.; Dong, X.; Guo, D.; Tian, C.; Fu, H. Interfacial Engineering of MoO2-FeP Heterojunction for Highly Efficient Hydrogen Evolution Coupled with Biomass Electrooxidation. Adv. Mater. 2020, 32, 2000455.

- 40 Liu, B.; Li, H.; Cao, B.; Jiang, J.; Gao, R.; Zhang, J. Few Layered N, P Dual-Doped Carbon-Encapsulated Ultrafine MoP Nanocrystal/MoP Cluster Hybrids on Carbon Cloth: An Ultrahigh Active and Durable 3D Self-Supported Integrated Electrode for Hydrogen Evolution Reaction in a Wide pH Range. Adv. Funct. Mater. 2018, 28, 1801527.

- 41

Wang, Z.-M.; Hong, Q.-L.; Wang, X.-H.; Huang, H.; Chen, Y.; Li, S.-N. RuP Nanoparticles Anchored on N-doped Graphene Aerogels for Hydrazine Oxidation-Boosted Hydrogen Production. Acta Phys.-Chim. Sin. 2023, 39, 2303028.

10.3866/PKU.WHXB202303028 Google Scholar

- 42 Cheng, C.; Zong, S.; Shi, J.; Xue, F.; Zhang, Y.; Guan, X.; Zheng, B.; Deng, J.; Guo, L. Facile preparation of nanosized MoP as cocatalyst coupled with g-C3N4 by surface bonding state for enhanced photocatalytic hydrogen production. Appl. Catal. B 2020, 265, 118620.

- 43 Ge, R.; Huo, J.; Liao, T.; Liu, Y.; Zhu, M.; Li, Y.; Zhang, J.; Li, W. Hierarchical molybdenum phosphide coupled with carbon as a whole pH-range electrocatalyst for hydrogen evolution reaction. Appl. Catal. B 2020, 260, 118196.

- 44

Zheng, S.; Wu, J.; Wang, K.; Hu, M.; Wen, H.; Yin, S. Electronic Modulation of Ni-Mo-O Porous Nanorods by Co Doping for Selective Oxidation of 5-Hydroxymethylfurfural Coupled with Hydrogen Evolution. Acta Phys.-Chim. Sin. 2023, 39, 2301032.

10.3866/PKU.WHXB202301032 Google Scholar

- 45 Xiao, P.; Sk, M. A.; Thia, L.; Ge, X.; Lim, R. J.; Wang, J.-Y.; Lim, K. H.; Wang, X. Molybdenum phosphide as an efficient electrocatalyst for the hydrogen evolution reaction. Energy Environ. Sci. 2014, 7, 2624–2629.

- 46 Huang, H.; Zhu, J.; Li, D.; Shen, C.; Li, M.; Zhang, X.; Jiang, Q.; Zhang, J.; Wu, Y. Pt nanoparticles grown on 3D RuO2-modified graphene architectures for highly efficient methanol oxidation. J. Mater. Chem. A 2017, 5, 4560–4567.

- 47 Zhou, Y.; Yu, L.; Chang, J.; Feng, L.; Zhang, J. Low carbon alcohol fuel electrolysis of hydrogen generation catalyzed by a novel and effective Pt–CoTe/C bifunctional catalyst system. Green Energy Environ. 2024, 9, 758–770.

- 48 Ding, J.; Jing, S.; Yin, C.; Ban, C.; Wang, K.; Liu, X.; Duan, Y.; Zhang, Y.; Han, G.; Gan, L.; Rao, J. A new insight into the promoting effects of transition metal phosphides in methanol electrooxidation. Chin. Chem. Lett. 2023, 34, 107899.

- 49 Ma, J.; Liu, B.; Wang, R.; Sun, Z.; Zhang, Y.; Sun, Y.; Cai, Z.; Li, Y.; Zou, J. Single-Cu-atoms anchored on 3D macro-porous carbon matrix as efficient catalyst for oxygen reduction and Pt co-catalyst for methanol oxidation. Chin. Chem. Lett. 2022, 33, 2585–2589.

- 50 Yu, L.; Pang, X.; Tian, Z.; Wang, S.; Feng, L. Fe-doped NiSe2 nanorods for enhanced urea electrolysis of hydrogen generation. Electrochim. Acta 2023, 440, 141724.

- 51 Kuang, Y.; He, R.; Gu, X.; Yang, F.; Tian, X.; Feng, L. High polarity catalyst of CoFe alloy/fluoride interconnected by bamboo-like nitrogen-doped carbon nanotubes for efficient oxygen evolution reaction. Chem. Eng. J. 2023, 456, 141055.

- 52 Li, M.; Zhang, D.; Yi, Y.; Xue, B.; Liu, B. Boosting anodic methanol upgrading over RuO2 through integration with CeO2 for energy- saving H2 generation in acidic environment. Electrochim. Acta 2022, 423, 140566.

- 53 Shen, Q.; Du, C.; Chen, Q.; Tang, J.; Wang, B.; Zhang, X.; Chen, J. In-situ formed Cu-doped RuS2 hollow polyhedrons integrated with simultaneously heterostructure engineering with metallic Ru for boosting hydrogen evolution in alkaline media. Mater. Today Phys. 2022, 23, 100625.

- 54 Hao, Y. F.; Wang, X. D.; Zheng, Y. Y.; Shen, J. F.; Yuan, J. H.; Wang, A. J.; Niu, L.;Huang, S. T. Uniform Pt Nanoparticles Incorporated into Reduced Graphene Oxides with MoO3 as Advanced Anode Catalysts for Methanol Electro-oxidation. Electrochim. Acta 2016, 198, 127–134.

- 55 Yan, W.; Ma, H.; Zhao, X.; Zhang, Y.; Vishniakov, P.; Wang, X.; Zhong, X.; Hong, Z.; Maximov, M. Y.; Song, L. P and Se binary vacancies and heterostructures modulated MoP/MoSe2 electrocatalysts for improving hydrogen evolution and coupling electricity generation. Small 2023, 19, 2208270.

- 56 Abdelghafar, F.; Xu, X.; Jiang, S. P.;Shao, Z. Designing single-atom catalysts toward improved alkaline hydrogen evolution reaction. Mater. Rep.: Energy 2022, 2, 100144.

- 57 Yang, F.; Wang, Q.; Li, J.; Feng, L. Structural evolution of Ru/Te interaction for hydrogen generation engineered by proof of concept via carbon doping. Mater. Today Phys. 2023, 38, 101262.

- 58

Liu, D.; Zeng, Q.; Hu, C.; Chen, D.; Liu, H.; Han, Y.; Xu, L.; Zhang, Q.; Yang, J. Light doping of tungsten into copper-platinum nanoalloys for boosting their electrocatalytic performance in methanol oxidation. Nano Res. Energy 2022, 1, e9120017.

10.26599/NRE.2022.9120017 Google Scholar

- 59

Zhang, Q.; Xia, T.; Huang, H.; Liu, J.; Zhu, M.; Yu, H.; Xu, W.; Huo, Y.; He, C.; Shen, S.; Lu, C.; Wang, R.; Wang, S. Autocatalytic reduction- assisted synthesis of segmented porous PtTe nanochains for enhancing methanol oxidation reaction. Nano Res. Energy 2023, 2, e9120041.

10.26599/NRE.2023.9120041 Google Scholar