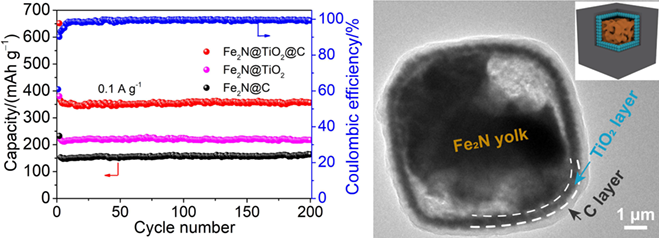

Double-Coated Fe2N@TiO2@C Yolk-Shell Submicrocubes as an Advanced Anode for Potassium-Ion Batteries†

Yichen Du

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

‡These authors contributed equally to this work.

†Dedicated to the Special Issue of Nanostructured Materials for Electrochemical Energy Conversion and Storage.

Search for more papers by this authorWangsuo Weng

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

‡These authors contributed equally to this work.

†Dedicated to the Special Issue of Nanostructured Materials for Electrochemical Energy Conversion and Storage.

Search for more papers by this authorZhuangzhuang Zhang

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorYanan He

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorJingyi Xu

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorTian Yang

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorCorresponding Author

Jianchun Bao

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

E-mail: [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Xiaosi Zhou

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

E-mail: [email protected]; [email protected]Search for more papers by this authorYichen Du

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

‡These authors contributed equally to this work.

†Dedicated to the Special Issue of Nanostructured Materials for Electrochemical Energy Conversion and Storage.

Search for more papers by this authorWangsuo Weng

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

‡These authors contributed equally to this work.

†Dedicated to the Special Issue of Nanostructured Materials for Electrochemical Energy Conversion and Storage.

Search for more papers by this authorZhuangzhuang Zhang

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorYanan He

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorJingyi Xu

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorTian Yang

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

Search for more papers by this authorCorresponding Author

Jianchun Bao

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

E-mail: [email protected]; [email protected]Search for more papers by this authorCorresponding Author

Xiaosi Zhou

Jiangsu Key Laboratory of New Power Batteries, Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 China

E-mail: [email protected]; [email protected]Search for more papers by this authorMain observation and conclusion

Rationally designing inexpensive iron nitrides that have large conductivity, high theoretical capacity, and rapid ionic diffusion kinetics is of great importance for realizing their practical application in potassium-ion batteries. In this work, we have constructed double-shelled Fe2N@TiO2@C yolk-shell submicrocubes with porous Fe2N yolk as an anode material for stable and high-rate capability potassium-ion batteries. This special structure can effectively buffer the large volume variation of electrode during cycling, supply abundant reaction sites to host potassium ions, and enhance electronic conductivity of the electrode material. Benefiting from these structural and compositional advantages, the Fe2N@TiO2@C yolk-shell submicrocube anode delivers high specific capacity, long-term cyclability, and remarkable rate property.

Supporting Information

| Filename | Description |

|---|---|

| cjoc202100065-sup-0001-Supinfo.pdfPDF document, 1.5 MB |

Appendix S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 Ko, M.; Chae, S.; Ma, J.; Kim, N.; Lee, H.-W.; Cui, Y.; Cho, J. Scalable Synthesis of Silicon-Nanolayer-Embedded Graphite for High-Energy Lithium-Ion Batteries. Nat. Energy 2016, 1, 16113.

- 2 Su, Y.; Chen, G.; Chen, L.; Li, Q.; Lu, Y.; Bao, L.; Li, N.; Chen, S.; Wu, F. Advances and Prospects of Surface Modification on Nickel-Rich Materials for Lithium-Ion Batteries. Chin. J. Chem. 2020, 38, 1817–1831.

- 3 Xu, T.; Zhou, C.; Zhou, H.; Wang, Z.; Ren, J. Synthesis of Alumina-Coated Natural Graphite for Highly Cycling Stability and Safety of Li-Ion Batteries. Chin. J. Chem. 2019, 37, 342–346.

- 4 Ge, X.; Liu, S.; Qiao, M.; Du, Y.; Li, Y.; Bao, J.; Zhou, X. Enabling Superior Electrochemical Properties for Highly Efficient Potassium Storage by Impregnating Ultrafine Sb Nanocrystals within Nanochannel-Containing Carbon Nanofibers. Angew. Chem. Int. Ed. 2019, 58, 14578–14583.

- 5 Griffith, K. J.; Wiaderek, K. M.; Cibin, G.; Marbella, L. E.; Grey, C. P. Niobium Tungsten Oxides for High-Rate Lithium-Ion Energy Storage. Nature 2018, 559, 556–563.

- 6 Liu, Q.; Hu, Z.; Liang, Y.; Li, L.; Zou, C.; Jin, H.; Wang, S.; Lu, H.; Gu, Q.; Chou, S. L.; Liu, Y.; Dou, S. X. Facile Synthesis of Hierarchical Hollow CoP@C Composites with Superior Performance for Sodium and Potassium Storage. Angew. Chem. Int. Ed. 2020, 59, 5159–5164.

- 7 Wu, T.; Wang, K.; Xiang, M.; Fu, Q. Progresses in Manufacturing Techniques of Lithium-Ion Battery Separators in China. Chin. J. Chem. 2019, 37, 1207–1215.

- 8 Zhang, Z.; Du, Y.; Wang, Q. C.; Xu, J.; Zhou, Y. N.; Bao, J.; Shen, J.; Zhou, X. A Yolk-Shell-Structured FePO4 Cathode for High-Rate and Long-Cycling Sodium-Ion Batteries. Angew. Chem. Int. Ed. 2020, 59, 17504–17510.

- 9 Ding, H.; Zhou, J.; Rao, A. M.; Lu, B. Cell-Like-Carbon-Micro-Spheres for Robust Potassium Anode. Natl. Sci. Rev. 2021, 8, nwaa276.

- 10 Feng, Y.; Chen, S.; Wang, J.; Lu, B. Carbon Foam with Microporous Structure for High Performance Symmetric Potassium Dual-Ion Capacitor. J. Energy Chem. 2020, 43, 129–138.

- 11 Yi, X.; Ge, J.; Zhou, J.; Zhou, J.; Lu, B. SbVO4 Based High Capacity Potassium Anode: A Combination of Conversion and Alloying Reactions. Sci. China Chem. 2021, 64, 238–244.

- 12 Pan, Q.; Gong, D.; Tang, Y. Recent Progress and Perspective on Electrolytes for Sodium/Potassium-Based Devices. Energy Storage Mater. 2020, 31, 328–343.

- 13 He, H.; Yao, W.; Tunmee, S.; Zhou, X.; Ji, B.; Wu, N.; Song, T.; Kidkhunthod, P.; Tang, Y. An Iron-Based Polyanionic Cathode for Potassium Storage with High Capacity and Excellent Cycling Stability. J. Mater. Chem. A 2020, 8, 9128–9136.

- 14 Li, X.; Ou, X.; Tang, Y. 6.0 V High-Voltage and Concentrated Electrolyte toward High Energy Density K-Based Dual-Graphite Battery. Adv. Energy Mater. 2020, 10, 2002567.

- 15 Chang, X.; Zhou, X.; Ou, X.; Lee, C.-S.; Zhou, J.; Tang, Y. Ultrahigh Nitrogen Doping of Carbon Nanosheets for Capacity and Long Cycling Potassium Ion Storage. Adv. Energy Mater. 2019, 9, 1902672.

- 16 Zhang, R.; Huang, J.; Deng, W.; Bao, J.; Pan, Y.; Huang, S.; Sun, C.-F. Safe, Low-Cost, Fast-Kinetics and Low-Strain Inorganic-Open Framework Anode for Potassium-Ion Batteries. Angew. Chem. Int. Ed. 2019, 58, 16474–16479.

- 17 Mao, M.; Cui, C.; Wu, M.; Zhang, M.; Gao, T.; Fan, X.; Chen, J.; Wang, T.; Ma, J.; Wang, C. Flexible ReS2 Nanosheets/N-Doped Carbon Nanofibers-Based Paper as a Universal Anode for Alkali (Li, Na, K) Ion Battery. Nano Energy 2018, 45, 346–352.

- 18 Ji, B.; Yao, W.; Zheng, Y.; Kidkhunthod, P.; Zhou, X.; Tunmee, S.; Sattayaporn, S.; Cheng, H. M.; He, H.; Tang, Y. A Fluoroxalate Cathode Material for Potassium-Ion Batteries with Ultra-Long Cyclability. Nat. Commun. 2020, 11, 1225.

- 19 Fujiwara, Y.-i.; Lee, J. S. M.; Tsujimoto, M.; Kongpatpanich, K.; Pila, T.; Iimura, K.-i.; Tobori, N.; Kitagawa, S.; Horike, S. Fabrication of ε-Fe2N Catalytic Sites in Porous Carbons Derived from an Iron-Triazolate Crystal. Chem. Mater. 2018, 30, 1830–1834.

- 20 Huang, H.; Gao, S.; Wu, A.-M.; Cheng, K.; Li, X.-N.; Gao, X.-X.; Zhao, J.-J.; Dong, X.-L.; Cao, G.-Z. Fe3N Constrained inside C Nanocages as an Anode for Li-Ion Batteries through Post-Synthesis Nitridation. Nano Energy 2017, 31, 74–83.

- 21 Li, Y.; Yan, Y.; Ming, H.; Zheng, J. One-Step Synthesis Fe3N Surface- Modified Fe3O4 Nanoparticles with Excellent Lithium Storage Ability. Appl. Surface Sci. 2014, 305, 683–688.

- 22 Li, Z.; Fang, Y.; Zhang, J.; Lou, X. W. Necklace-Like Structures Composed of Fe3N@C Yolk-Shell Particles as an Advanced Anode for Sodium-Ion Batteries. Adv. Mater. 2018, 30, 1800525.

- 23 Liang, D.; Zhang, H.; Ma, X.; Liu, S. Mao, J.; Fang, H.; Yu, J.; Guo, Z.; Huang, T. MOFs-Derived Core-Shell Co3Fe7@Fe2N Nanopaticles Supported on rGO as High-Performance Bifunctional Electrocatalyst for Oxygen Reduction and Oxygen Evolution Reactions. Mater. Today Energy 2020, 17, 100433.

- 24 Wu, Y.; Cai, J.; Xie, Y.; Niu, S.; Zang, Y.; Wu, S.; Liu, Y.; Lu, Z.; Fang, Y.; Guan, Y.; Zheng, X.; Zhu, J.; Liu, X.; Wang, G.; Qian, Y. Regulating the Interfacial Electronic Coupling of Fe2N via Orbital Steering for Hydrogen Evolution Catalysis. Adv. Mater. 2020, 32, 1904346.

- 25 Liu, D.; Xu, X.; Tan, J.; Zhu, J.; Li, Q.; Luo, Y.; Wu, P.; Zhang, X.; Han, C.; Mai, L. Micrometer-Sized Porous Fe2N/C Bulk for High-Areal-Capacity and Stable Lithium Storage. Small 2019, 15, 1803572.

- 26 Sun, W.; Liu, C.; Li, Y.; Luo, S.; Liu, S.; Hong, X.; Xie, K.; Liu, Y.; Tan, X.; Zheng, C. Rational Construction of Fe2N@C Yolk-Shell Nanoboxes as Multifunctional Hosts for Ultralong Lithium-Sulfur Batteries. ACS Nano 2019, 13, 12137–12147.

- 27 Zhang, N.; Xie, S.; Wang, W.; Xie, D.; Zhu, D.; Cheng, F. Ultra-Small Fe2N/N-CNTs as Efficient Bifunctional Catalysts for Rechargeable Zn-Air Batteries. J. Electrochem. Soc. 2020, 167, 020505.

- 28 Jiang, H.; Huang, L.; Wei, Y.; Wang, B.; Wu, H.; Zhang, Y.; Liu, H.; Dou, S. Bio-Derived Hierarchical Multicore-Shell Fe2N-Nanoparticle-Impregnated N-Doped Carbon Nanofiber Bundles: A Host Material for Lithium-/Potassium-Ion Storage. Nano-Micro Lett. 2019, 11, 56.

- 29 Ding, R.; Zhang, J.; Zhang, J.; Li, Z.; Wang, C.; Chen, M. Core-Shell Fe2N@Amorphous Carbon Nanocomposite-Filled 3D Graphene Framework: An Additive-Free Anode Material for Lithium-Ion Batteries. Chem. Eng. J. 2019, 360, 1063–1070.

- 30 Xie, S.; Lin, J.; Wang, S.; Xie, D. Liu, P.; Tan, G.; Zhang, M.; Ruan, D.; Zhen, C.; Cheng, F. Rational Design of Hybrid Fe7S8/Fe2N Nanoparticles as Effective and Durable Bifunctional Electrocatalysts for Rechargeable Zinc-Air Batteries. J. Power Sources 2020, 457, 228038.

- 31 Guo, Q.; Zhou, C.; Ma, Z.; Yang, X. Fundamentals of TiO2 Photocatalysis: Concepts, Mechanisms, and Challenges. Adv. Mater. 2019, 31, 1901997.

- 32 Li, H.; Wang, T.; Liu, S.; Luo, Z.; Li, L.; Wang, H.; Zhao, Z.-J.; Gong, J. Controllable Distribution of Oxygen Vacancies in Grain Boundaries of p-Si/TiO2 Heterojunction Photocathodes for Solar Water Splitting. Angew. Chem. Int. Ed. 2021, 60, 4034–4037.

- 33 Lu, Y.; Wang, J.; Chen, Y.; Zheng, X.; Yao, H.; Mathur, S.; Hong, Z. Spatially Controlled Lithium Deposition on Silver-Nanocrystals-Decorated TiO2 Nanotube Arrays Enabling Ultrastable Lithium Metal Anode. Adv. Funct. Mater. 2021, 31, 2009605.

- 34 Xu, X.; Chen, B.; Hu, J.; Sun, B.; Liang, X.; Li, N.; Yang, S. A.; Zhang, H.; Huang, W.; Yu, T. Heterostructured TiO2 Spheres with Tunable Interiors and Shells toward Improved Packing Density and Pseudocapacitive Sodium Storage. Adv. Mater. 2019, 31, 1904589.

- 35 Yu, X.-Y.; Hu, H.; Wang, Y.; Chen, H.; Lou, X. W. Ultrathin MoS2 Nanosheets Supported on N-doped Carbon Nanoboxes with Enhanced Lithium Storage and Electrocatalytic Properties. Angew. Chem. Int. Ed. 2015, 54, 7395–7398.

- 36 Yousaf, M.; Chen, Y.; Tabassum, H.; Wang, Z.; Wang, Y.; Abid, A. Y.; Mahmood, A.; Mahmood, N.; Guo, S.; Han, R. P. S.; Gao, P. A. Dual Protection System for Heterostructured 3D CNT/CoSe2/C as High Areal Capacity Anode for Sodium Storage. Adv. Sci. 2020, 7, 1902907.

- 37 Wang, S.; Guan, B. Y.; Yu, L.; Lou, X. W. Rational Design of Three- Layered TiO2@Carbon@MoS2 Hierarchical Nanotubes for Enhanced Lithium Storage. Adv. Mater. 2017, 29, 1702724.

- 38 Yuan, H.; Nai, J.; Fang, Y.; Lu, G.; Tao, X.; Lou, X. W. Double-Shelled C@MoS2 Structures Preloaded with Sulfur: An Additive Reservoir for Stable Lithium Metal Anodes. Angew. Chem. Int. Ed. 2020, 59, 15839–15843.

- 39 Zhou, X.; Yu, L.; Lou, X. W. Formation of Uniform N-Doped Carbon- Coated SnO2 Submicroboxes with Enhanced Lithium Storage Properties. Adv. Energy Mater. 2016, 6, 1600451.

- 40 Bourgeois, J.-P.; Vlad, A.; Melinte, S.; Gohy, J.-F. Design of Flexible and Self-Standing Electrodes for Li-Ion Batteries. Chin. J. Chem. 2017, 35, 41–47.

- 41 Zhang, Y.; Zhu, Y.; Fu, L.; Meng, J.; Yu, N.; Wang, J.; Wu, Y. Si/C Composites as Negative Electrode for High Energy Lithium Ion Batteries. Chin. J. Chem. 2017, 35, 21–29.

- 42 Wang, Q.; Zhu, X.; Liu, Y.; Fang, Y.; Zhou, X.; Bao, J. Rice Husk-Derived Hard Carbons as High-Performance Anode Materials for Sodium-Ion Batteries. Carbon 2018, 127, 658–666.

- 43 Wang, Q.; Ge, X.; Xu, J.; Du, Y.; Zhao, X.; Si, L.; Zhou, X. Fabrication of Microporous Sulfur-Doped Carbon Microtubes for High-Performance Sodium-Ion Batteries. ACS Appl. Energy Mater. 2018, 1, 6638–6645.

- 44 Li, Y.; Wang, H.; Wang, L.; Wang, R.; He, B.; Gong, Y.; Hu, X. Ultrafast Na+-Storage in TiO2-Coated MoS2@N-Doped Carbon for High-Energy Sodium-Ion Hybrid Capacitors. Energy Storage Mater. 2019, 23, 95–104.

- 45 Zhang, Q.; Cheng, X.; Wang, C.; Rao, A. M.; Lu, B. Sulfur-Assisted Large-Scale Synthesis of Graphene Microspheres for Superior Potassium-Ion Batteries. Energy Environ. Sci. 2021, 14, 965–974.

- 46 Liu, Q.; Rao, A. M.; Han, X.; Lu, B. Artificial SEI for Superhigh-Performance K-Graphite Anode. Adv. Sci. 2021, 8, 2003639.

- 47 Dong, Y.; Li, Y.; Shi, H.; Qin, J.; Zheng, S.; He, R.; Wu, Z.-S. Graphene Encapsulated Iron Nitrides Confined in 3D Carbon Nanosheet Frameworks for High-Rate Lithium Ion Batteries. Carbon 2020, 159, 213–220.

- 48 Dong, Y.; Wang, B.; Zhao, K.; Yu, Y.; Wang, X.; Mai, L.; Jin, S. Air-Stable Porous Fe2N Encapsulated in Carbon Microboxes with High Volumetric Lithium Storage Capacity and a Long Cycle Life. Nano Lett. 2017, 17, 5740–5746.

- 49 Fu, Y.; Wei, Q.; Wang, X.; Shu, H.; Yang, X.; Sun, S. Porous Hollow α-Fe2O3@TiO2 Core-Shell Nanospheres for Superior Lithium/Sodium Storage Capability. J. Mater. Chem. A 2015, 3, 13807–13818.

- 50 Lee, D. H.; Lee, B. H.; Sinha, A. K.; Park, J. H.; Kim, M. S.; Park, J.; Shin, H.; Lee, K. S.; Sung, Y. E.; Hyeon, T. Engineering Titanium Dioxide Nanostructures for Enhanced Lithium-Ion Storage. J. Am. Chem. Soc. 2018, 140, 16676–16684.

- 51 Cui, X.; Liang, X.; Chen, J.; Gu, W.; Ji, G.; Du, Y. Customized Unique Core-Shell Fe2N@N-Doped Carbon with Tunable Void Space for Microwave Response. Carbon 2020, 156, 49–57.

- 52 Hou, S.; Wang, P.; Li, Y.; Pang, F.; Liu, M.; Luo, Y.; Zhuang, L.; Zhao, L. Podocarpus-Like ɑ-Fe2O3/TiO2 Composite with Balsam Pear Texture for Enhanced Lithium Storage. Appl. Surface Sci. 2019, 476, 959–965.

- 53 Yu, P.; Wang, L.; Xie, Y.; Tian, C.; Sun, F.; Ma, J.; Tong, M.; Zhou, W.; Li, J.; Fu, H. High-Efficient, Stable Electrocatalytic Hydrogen Evolution in Acid Media by Amorphous FexP Coating Fe2N Supported on Reduced Graphene Oxide. Small 2018, 14, 1801717.

- 54 Zhang, M.; Wang, Y.; Zhang, Y.; Song, J.; Si, Y.; Yan, J.; Ma, C.; Liu, Y. T.; Yu, J.; Ding, B. Conductive and Elastic TiO2 Nanofibrous Aerogels: A New Concept toward Self-Supported Electrocatalysts with Superior Activity and Durability. Angew. Chem. Int. Ed. 2020, 59, 23252–23260.

- 55 Augustyn, V.; Simon, P.; Dunn, B. Pseudocapacitive Oxide Materials for High-Rate Electrochemical Energy Storage. Energy Environ. Sci. 2014, 7, 1597–1614.