Effect of Curcumin Cross-Linked Epoxy Soybean Oil on Mechanical Properties and UV Resistance of Polylactic Acid

Zixuan Zou

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Data curation (lead), Investigation (lead), Writing - original draft (lead)

Search for more papers by this authorXuejing Wei

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Investigation (supporting), Methodology (supporting)

Search for more papers by this authorJiayi Yao

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Investigation (supporting), Methodology (supporting)

Search for more papers by this authorLi Sun

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Investigation (supporting), Methodology (supporting)

Search for more papers by this authorHua Wang

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Conceptualization (supporting), Funding acquisition (supporting), Project administration (supporting), Visualization (supporting), Writing - review & editing (supporting)

Search for more papers by this authorCorresponding Author

Shaohua Chen

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Correspondence:

Shaohua Chen ([email protected])

Luoxin Wang ([email protected])

Contribution: Conceptualization (lead), Funding acquisition (lead), Project administration (lead), Visualization (lead), Writing - review & editing (lead)

Search for more papers by this authorCorresponding Author

Luoxin Wang

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Correspondence:

Shaohua Chen ([email protected])

Luoxin Wang ([email protected])

Contribution: Formal analysis (equal), Project administration (equal), Resources (equal), Visualization (equal)

Search for more papers by this authorZixuan Zou

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Data curation (lead), Investigation (lead), Writing - original draft (lead)

Search for more papers by this authorXuejing Wei

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Investigation (supporting), Methodology (supporting)

Search for more papers by this authorJiayi Yao

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Investigation (supporting), Methodology (supporting)

Search for more papers by this authorLi Sun

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Investigation (supporting), Methodology (supporting)

Search for more papers by this authorHua Wang

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Contribution: Conceptualization (supporting), Funding acquisition (supporting), Project administration (supporting), Visualization (supporting), Writing - review & editing (supporting)

Search for more papers by this authorCorresponding Author

Shaohua Chen

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Correspondence:

Shaohua Chen ([email protected])

Luoxin Wang ([email protected])

Contribution: Conceptualization (lead), Funding acquisition (lead), Project administration (lead), Visualization (lead), Writing - review & editing (lead)

Search for more papers by this authorCorresponding Author

Luoxin Wang

College of Materials Science and Engineering, Hubei Provincial Engineering Research Center of Industrial Fiber Preparation and Application, Wuhan Textile University, Wuhan, Hubei, China

Correspondence:

Shaohua Chen ([email protected])

Luoxin Wang ([email protected])

Contribution: Formal analysis (equal), Project administration (equal), Resources (equal), Visualization (equal)

Search for more papers by this authorFunding: This study was supported by the Hubei Provincial Department of Education key project, D20221706.

ABSTRACT

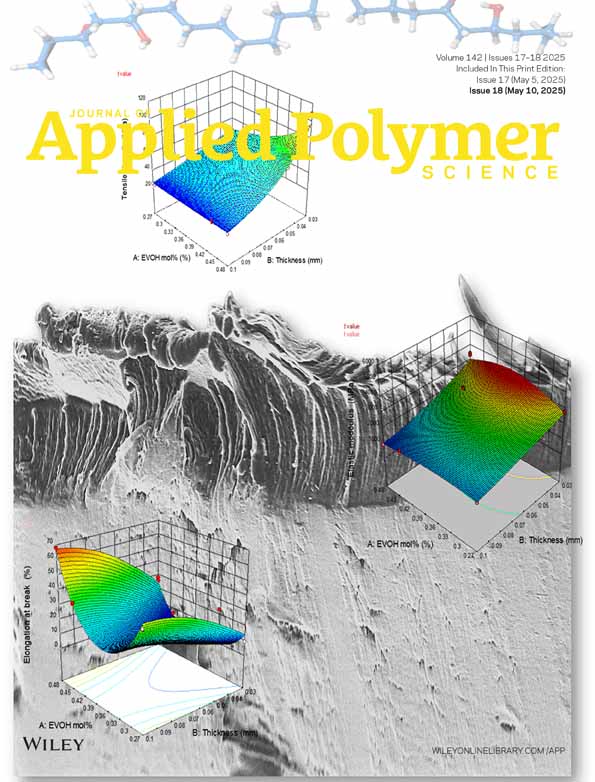

In order to improve the mechanical properties and UV resistance of polylactic acid (PLA) composites, a bio-based additive (ESO-CUR) was synthesized by one-pot method. A new environment-friendly toughening agent was synthesized by using epoxy soybean oil (ESO) as the core material and curcumin (CUR) as the curing agent. PLA composite material with toughening and UV resistance was prepared by melt blending process. Among them, the elongation at break of 6%ESO-CUR/PLA reached 20.26% in the tensile test, which was 11.8 times higher than that of pure PLA. In addition, 6%ESO-CUR/PLA has excellent UV resistance, and the UV protection factor (UPF) is increased from 3.1 to 15,485 of pure PLA. The results show that the new environmental protection toughening agent has a significant synergistic effect on improving the mechanical properties and UV protection properties of PLA. In order to reduce the white pollution caused by traditional plastics, it provides a new way to prepare biodegradable materials with excellent properties.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

Data will be made available on request.

Supporting Information

| Filename | Description |

|---|---|

| app56812-sup-0001-Supinfo.docxWord 2007 document , 315 KB |

Data S1. |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1L. Y. Liang and H. Y. Chen, “Development and Characterization of Biodegradable Ultraviolet Protective and Antibacterial Polylactic Acid-Cellulose Acetate Film Modified by Phenyl Salicylate,” International Journal of Biological Macromolecules 211 (2022): 85–93.

- 2P. M. Ma, P. Lv, P. W. Xu, et al., “Design of Bio-Based Conductive and Fast Crystallizing Nanocomposites With Controllable Distribution of Multiwalled Carbon Nanotubes via Interfacial Stereocomplexation,” Chemical Engineering Journal 336 (2018): 223–232.

- 3W. W. Jia, R. H. Gong, and P. J. Hogg, “Poly (Lactic Acid) Fibre Reinforced Biodegradable Composites,” Composites, Part B: Engineering 62 (2014): 104–112.

- 4M. Liao, X. Zhou, L. Fu, et al., “Flame Retardant and Antibacterial Properties of PLA/PHMG-P/APP Composites,” Journal of Vinyl and Additive Technology 29 (2023): 188–201.

- 5X. Wang, H. X. Niu, W. W. Guo, et al., “Renewable Isosorbide-Derived Poly (Phosphoester) for Simultaneously Enhanced Flame-Retardancy and Mechanical Property of Polylactide,” Progress in Natural Science: Materials International 31 (2021): 546–556.

- 6K. Zhang, H. O. Yu, K. X. Yu, et al., “A Facile Approach to Constructing Efficiently Segregated Conductive Networks in Poly (Lactic Acid)/Silver Nanocomposites via Silver Plating on Microfibers for Electromagnetic Interference Shielding,” Composites Science and Technology 156 (2018): 136–143.

- 7H. Y. Yin, X. F. Wei, R. Y. Bao, et al., “Enhancing Thermomechanical Properties and Heat Distortion Resistance of Poly (l-Lactide) With High Crystallinity Under High Cooling Rate,” ACS Sustainable Chemistry & Engineering 3 (2015): 654–661.

- 8M. Liao, H. J. Chen, L. M. Deng, et al., “Tannic Acid-Polyethyleneimine Modified Ammonium Polyphosphate: For Efficient Flame Retardant and UV Resistant of Polylactic Acid,” Reactive and Functional Polymers 192 (2023): 105735.

- 9H. Z. Liu and J. W. Zhang, “Research Progress in Toughening Modification of Poly (Lactic Acid),” Journal of Polymer Science Part B: Polymer Physics 49 (2011): 1051–1083.

- 10Z. X. Zou, X. Wei, M. Liao, et al., “Effect of Polycarbodiimide, Epoxy Chain Extenders and Tannic Acid on the Hydrolysis and UV Resistance of Polylactic Acid,” Reactive and Functional Polymers 199 (2024): 105894.

- 11W. M. Gramlich, M. L. Robertson, and M. A. Hillmyer, “Reactive Compatibilization of Poly (l-Lactide) and Conjugated Soybean Oil,” Macromolecules 43 (2010): 2313–2321.

- 12T. H. Zhao, Y. Wu, Y. D. Li, et al., “High Performance and Thermal Processable Dicarboxylic Acid Cured Epoxidized Plant Oil Resins Through Dynamic Vulcanization With Poly (Lactic Acid),” ACS Sustainable Chemistry & Engineering 5 (2017): 1938–1947.

- 13L. Quiles Carrillo, S. Duart, N. Montanes, et al., “Enhancement of the Mechanical and Thermal Properties of Injection-Molded Polylactide Parts by the Addition of Acrylated Epoxidized Soybean Oil,” Materials and Design 140 (2018): 54–63.

- 14X. Fang, N. G. Tian, W. Y. Hu, et al., “Dynamically Cross-Linking Soybean Oil and Low-Molecular-Weight Polylactic Acid Toward Mechanically Robust, Degradable, and Recyclable Supramolecular Plastics,” Advanced Functional Materials 32 (2022): 2208623.

- 15M. L. Robertson, J. M. Paxton, and M. A. Hillmyer, “Tough Blends of Polylactide and Castor Oil,” ACS Applied Materials & Interfaces 3 (2011): 3402–3410.

- 16M. Y. Hao, H. W. Wu, F. Qiu, et al., “Interface Bond Improvement of Sisal Fibre Reinforced Polylactide Composites With Added Epoxy Oligomer,” Materials 11 (2018): 398.

- 17W. D. Liu, T. S. Xie, and R. H. Qiu, “Bamboo Fibers Grafted With a Soybean-Oil-Based Monomer for Its Unsaturated Polyester Composites,” Cellulose 23 (2016): 2501–2513.

- 18T. H. Zhao, W. Q. Yuan, Y. D. Li, et al., “Relating Chemical Structure to Toughness via Morphology Control in Fully Sustainable Sebacic Acid Cured Epoxidized Soybean Oil Toughened Polylactide Blends,” Macromolecules 51 (2018): 2027–2037.

- 19W. D. Liu, J. H. Qiu, L. X. Zhu, et al., “Tannic Acid-Induced Crosslinking of Epoxidized Soybean Oil for Toughening Poly (Lactic Acid) via Dynamic Vulcanization,” Polymer 148 (2018): 109–118.

- 20D. Rosu, R. Bodrlu, C. A. Teac, et al., “Epoxy and Succinic Anhydride Functionalized Soybean Oil for Wood Protection Against UV Light Action,” Journal of Cleaner Production 112 (2016): 1175–1183.

- 21S. K. Olsson, M. Johansson, M. Westin, et al., “Reactive UV-Absorber and Epoxy Functionalized Soybean Oil for Enhanced UV-Protection of Clear Coated Wood,” Polymer Degradation and Stability 110 (2014): 405–414.

- 22S. Chauhan, M. Bansal, G. Khan, et al., “Development, Optimization and Evaluation of Curcumin Loaded Biodegradable Crosslinked Gelatin Film for the Effective Treatment of Periodontitis,” Drug Development and Industrial Pharmacy 44 (2018): 1212–1221.

- 23A. Etxabide, V. Coma, P. Guerrero, et al., “Effect of Cross-Linking in Surface Properties and Antioxidant Activity of Gelatin Films Incorporated With a Curcumin Derivative,” Food Hydrocolloids 66 (2017): 168–175.

- 24Y. C. Qiao and L. J. Duan, “Curcumin-Loaded Polyvinyl Butyral Film With Antibacterial Activity,” E-Polymers 20 (2020): 673–681.

- 25J. C. Dinardo and C. A. Downs, “Dermatological and Environmental Toxicological Impact of the Sunscreen Ingredient Oxybenzone/Benzophenone-3,” Journal of Cosmetic Dermatology 17 (2018): 15–19.

- 26R. K. Maheshwari, A. K. Singh, J. Gaddipati, et al., “Multiple Biological Activities of Curcumin: A Short Review,” Life Sciences 78 (2006): 2081–2087.

- 27B. H. Lee, H. A. Choi, M. R. Kim, et al., “Changes in Chemical Stability and Bioactivities of Curcumin by Ultraviolet Radiation,” Food Science and Biotechnology 22 (2013): 279–282.

- 28D. J. Mendoza, L. M. Mouterde, C. Browne, et al., “Grafting Nature-Inspired and Bio-Based Phenolic Esters Onto Cellulose Nanocrystals Gives Biomaterials With Photostable Anti-UV Properties,” ChemSusChem 13 (2020): 6552–6561.

- 29H. N. Redfearn and J. M. Goddard, “Reactive Extrusion of Poly(Lactic Acid)-Graft-Curcumin Antioxidant and Intelligent Packaging,” ACS Applied Polymer Materials 6 (2024): 192–206.

- 30T. Zhang, W. Zhang, Y. Deng, et al., “Curcumin-Based Waterborne Polyurethane-Gelatin Composite Bioactive Films for Effective UV Shielding and Inhibition of Oil Oxidation,” Food Control 141 (2022): 109199.

- 31S. Roy and J. W. Rhim, “Preparation of Bioactive Functional Poly(Lactic Acid)/Curcumin Composite Film for Food Packaging Application - ScienceDirect,” International Journal of Biological Macromolecules 162 (2020): 1780–1789.

- 32S. Mohan and K. Panneerselvam, “Development of Polylactic Acid Based Functional Films Reinforced With Ginger Essential Oil and Curcumin for Food Packaging Applications,” Journal of Food Measurement and Characterization 16 (2022): 4703–4715.

- 33N. D. Mao, H. Jeong, T. K. N. Nguyen, et al., “Polyethylene Glycol Functionalized Graphene Oxide and Its Influences on Properties of Poly (Lactic Acid) Biohybrid Materials,” Composites, Part B: Engineering 161 (2019): 651–658.

- 34L. Shechter and J. Wynstra, “Glycidyl Ether Reactions With Alcohols, Phenols, Carboxylic Acids, and Acid Anhydrides,” Industrial and Engineering Chemistry 48 (1956): 86–93.

- 35T. Zhang, Y. J. Deng, W. S. Zhang, et al., “A Self-Colored Waterborne Polyurethane Film With Natural Curcumin as a Chain Extender and Excellent UV-Absorbing Properties,” Polymer 239 (2022): 124465.

- 36M. Shibata, N. Teramoto, and K. Makino, “Preparation and Properties of Biocomposites Composed of Epoxidized Soybean Oil, Tannic Acid, and Microfibrillated Cellulose,” Journal of Applied Polymer Science 120 (2011): 273–278.

- 37J. Ferri, D. Garciagarcia, L. Sáncheznacher, et al., “The Effect of Maleinized Linseed Oil (MLO) on Mechanical Performance of Poly (Lactic Acid)-Thermoplastic Starch (PLA-TPS) Blends,” Carbohydrate Polymers 147 (2016): 60–68.

- 38A. Carbonellverdu, D. Garciagarcia, F. Dominici, et al., “PLA Films With Improved Flexibility Properties by Using Maleinized Cottonseed Oil,” European Polymer Journal 91 (2017): 248–259.

- 39R. H. Boyd, “Relaxation Processes in Crystalline Polymers: Experimental Behaviour—A Review,” Polymer 26 (1985): 323–347.

- 40F. S. Mohammed, M. Conley, S. R. Saunders, et al., “Epoxidized Linolenic Acid Salts as Multifunctional Additives for the Thermal Stability of Plasticized PVC,” Journal of Applied Polymer Science 132, no. 13 (2015): app.41736, https://doi.org/10.1002/app.41736.

- 41V. Ojijo and S. S. Ray, “Super Toughened Biodegradable Polylactide Blends With Non-Linear Copolymer Interfacial Architecture Obtained via Facile In-Situ Reactive Compatibilization,” Polymer 80 (2015): 1–17.

- 42L. Y. Wang, X. B. Jing, H. B. Cheng, et al., “Rheology and Crystallization of Long-Chain Branched Poly (L-Lactide)s With Controlled Branch Length,” Industrial & Engineering Chemistry Research 51 (2012): 10731–10741.

- 43W. D. Liu, J. H. Qiu, T. T. Chen, et al., “Regulating Tannic Acid-Crosslinked Epoxidized Soybean Oil Oligomers for Strengthening and Toughening Bamboo Fibers-Reinforced Poly (Lactic Acid) Biocomposites,” Composites Science and Technology 181 (2019): 107709.

- 44T. H. Zhao, Y. He, Y. D. Li, et al., “Dynamic Vulcanization of Castor Oil in a Polylactide Matrix for Toughening,” RSC Advances 6 (2016): 79542–79553.

- 45Y. S. Musso, P. R. Salgado, and A. N. Mauri, “Smart Edible Films Based on Gelatin and Curcumin,” Food Hydrocolloids 66 (2017): 8–15.

- 46K. Mahmood, K. M. Zia, M. Zuber, et al., “Morphological and Thermal Studies of Chitin-Curcumin Blends Derived Polyurethanes,” International Journal of Biological Macromolecules 105 (2017): 1180–1191.