Properties of polyamide 6/multiwalled carbon nanotubes composites: The influence of processing methods

Xue Lei

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Contribution: Data curation (lead), Formal analysis (lead), Investigation (lead), Validation (lead), Visualization (lead), Writing - original draft (lead)

Search for more papers by this authorMei Liang

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Contribution: Project administration (lead)

Search for more papers by this authorCorresponding Author

Huawei Zou

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Correspondence

Huawei Zou and Shengtai Zhou, The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu 610065, China.

Email: [email protected] and [email protected]

Contribution: Resources (lead), Funding acquisition (lead)

Search for more papers by this authorCorresponding Author

Shengtai Zhou

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Correspondence

Huawei Zou and Shengtai Zhou, The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu 610065, China.

Email: [email protected] and [email protected]

Contribution: Conceptualization (supporting), Funding acquisition (supporting), Writing - original draft (supporting), Writing - review & editing (supporting)

Search for more papers by this authorXue Lei

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Contribution: Data curation (lead), Formal analysis (lead), Investigation (lead), Validation (lead), Visualization (lead), Writing - original draft (lead)

Search for more papers by this authorMei Liang

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Contribution: Project administration (lead)

Search for more papers by this authorCorresponding Author

Huawei Zou

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Correspondence

Huawei Zou and Shengtai Zhou, The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu 610065, China.

Email: [email protected] and [email protected]

Contribution: Resources (lead), Funding acquisition (lead)

Search for more papers by this authorCorresponding Author

Shengtai Zhou

The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu, China

Correspondence

Huawei Zou and Shengtai Zhou, The State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute, Sichuan University, Chengdu 610065, China.

Email: [email protected] and [email protected]

Contribution: Conceptualization (supporting), Funding acquisition (supporting), Writing - original draft (supporting), Writing - review & editing (supporting)

Search for more papers by this authorFunding information: National Natural Science Foundation of China, Grant/Award Number: 52103040; Postdoctoral Research Foundation of China, Grant/Award Number: 2020M673217

Abstract

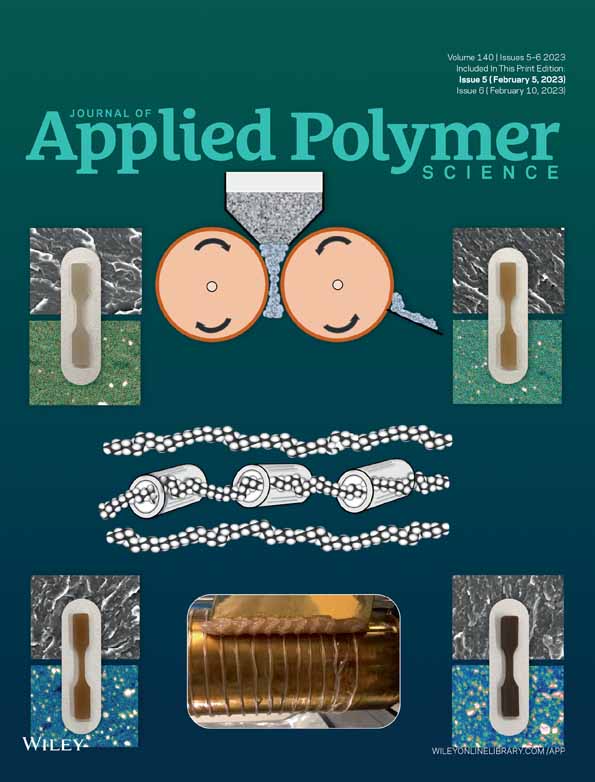

The objective of this work was to elucidate the influence of shear rates on the properties of polyamide 6/multiwalled carbon nanotube (PA6/CNT) composites which was realized by adopting different types of processing methods that feature different orders of magnitude in shear rates, such as compression molding (CM, ~0 s−1), conventional injection molding (CIM, ~102 s−1) and microinjection molding (μIM, ~105 s−1). Electrical conductivity (σ) results indicated that the prevailing high shearing conditions in injection molding was unfavorable for the formation of intact filler network, thereby resulting in a much lower σ than CM counterparts. Moreover, the σ of PA6/CNT microparts was higher than that of CIM macroparts when the filler content was less than 5 wt%, otherwise the σ of CIM macroparts prevailed over that of μIM counterparts. A better filler distribution was observed when PA6/CNT composites were processed under higher shearing conditions, as corroborated by SEM. In addition, CNTs were preferentially aligned along flow direction and a higher degree of CNT orientation was expected with increasing shear rates, as confirmed by Raman spectral analysis. The tensile strength of injection molded PA6/CNT samples increased with increasing filler concentrations, and the more preferential orientation and better distribution of CNT were considered to be the contributing factors. The comparative study of the properties of PA6/CNT composites that processed using different methods was important for their practical applications in industrial sectors.

CONFLICT OF INTEREST

The authors declare no conflicts of interest.

Open Research

DATA AVAILABILITY STATEMENT

Research data are not shared.

Supporting Information

| Filename | Description |

|---|---|

| app53424-sup-0001-FigureS1.docxWord 2007 document , 1.4 MB | Figure S1. Optical images of PA6/CNT samples that prepared by different processing methods: (a, b) CM; (c, d) CIM and (e) μIM. |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

REFERENCES

- 1S. Zhou, Y. Chen, H. Zou, M. Liang, Thermochim. Acta 2013, 566, 84.

- 2Y. Shi, Y. Bai, Y. Lei, H. Zhang, S. Zhou, H. Zou, M. Liang, Y. Chen, J. Mater. Sci. Technol. 2022, 99, 239.

- 3S. Zhou, Y. Wu, H. Zou, M. Liang, Y. Chen, Compos. Commun. 2021, 28, 100918.

- 4W. Bauhofer, J. Z. Kovacs, Compos. Sci. Technol. 2009, 69, 1486.

- 5T. Kuilla, S. Bhadra, D. Yao, N. H. Kim, S. Bose, J. H. Lee, Prog. Polym. Sci. 2010, 35, 1350.

- 6P. Brigandi, J. Cogen, R. Pearson, Polym. Eng. Sci. 2014, 54, 23530.

- 7M. H. Al-Saleh, U. Sundararaj, Carbon 2009, 47, 2.

- 8M. Baniassadi, A. Laachachi, A. Makradi, S. Belouettar, D. Ruch, R. Muller, H. Garmestani, V. Toniazzo, S. Ahzi, Thermochim. Acta 2011, 520, 33.

- 9S. Zhou, Electronic Thesis and Dissertation Repository 2018, 5579.

- 10M. H. Al-Saleh, W. H. Saadeh, U. Sundararaj, Carbon 2013, 60, 146.

- 11Y. Luo, G. Wang, B. Zhang, Z. Zhang, Eur. Polym. J. 1998, 34, 1221.

- 12J. Wang, Y. Kazemi, S. Wang, M. Hamidinejad, M. B. Mahmud, P. Pötschke, C. B. Park, Compos. Part B Eng. 2020, 183, 107663.

- 13S. Abbasi, P. J. Carreau, A. Derdouri, Polymer 2010, 51, 922.

- 14J. Mei, X. Lei, M. Liang, H. Wu, S. Zhou, H. Zou, Y. Chen, J. Appl. Polym. Sci. 2020, 138, 49984.

- 15S. Zhou, A. N. Hrymak, M. R. Kamal, Compos. Part A 2017, 103, 84.

- 16A. H. A. Hoseini, M. Arjmand, U. Sundararaj, M. Trifkovic, Mater. Des. 2017, 125, 126.

- 17H. Deng, L. Lin, M. Ji, S. Zhang, M. Yang, Q. Fu, Prog. Polym. Sci. 2014, 39, 627.

- 18A. E. Eken, E. J. Tozzi, D. J. Klingenberg, W. Bauhofer, Polymer 2011, 52, 5178.

- 19I. Alig, P. Pötschke, D. Lellinger, T. Skipa, S. Pegel, G. R. Kasaliwal, T. Villmow, Polymer 2012, 53, 4.

- 20S. Zhou, A. N. Hrymak, M. R. Kamal, Nano 2018, 8, 779.

- 21J. O. Aguilar, J. R. Bautista-Quijano, F. Aviles, Express Polym Lett 2010, 4, 292.

- 22L. Gao, T.-W. Chou, E. T. Thostenson, A. Godara, Z. Zhang, L. Mezzo, Carbon 2010, 48, 2649.

- 23S. Tamayo-Vegas, A. Muhsan, C. Liu, M. Tarfaoui, K. Lafdi, Polymers 2022, 14, 1842.

- 24G. S. Ezat, A. L. Kelly, M. Youseffi, P. D. Coates, Int. Polym. Process. 2022, 37, 45.

- 25S. Zhou, X. Lei, J. Mei, A. N. Hrymak, M. R. Kamal, H. Zou, J. Appl. Polym. Sci. 2020, 138, 49817.

- 26M. M. L. Arras, C. Schillai, T. F. Keller, R. Schulze, K. D. Jandt, Carbon 2013, 60, 366.

- 27A. A. Vasileiou, M. Kontopoulou, H. Gui, A. Docoslis, ACS Appl. Mater. Interfaces 2015, 7, 1624.

- 28P. Potschke, F. Mothes, B. Krause, B. Voit, Polymers 2019, 11, 189.

- 29X. Yan, H. Dong, Z. Xiao, Y. Liu, T. Liu, H. G. Chae, S. Kumar, Polym. Compos. 2015, 38, 719.

- 30X. Zhao, L. Tao, Y. Lu, Z. Jiang, Y. Men, Macromolecules 2021, 54, 1c00077.

- 31S. Zhou, A. N. Hrymak, M. R. Kamal, Polym. Adv. Technol. 2018, 29, 1753.

- 32Z. Jiang, Y. Chen, Z. Liu, J. Polym. Res. 2014, 21, 451.

- 33N. Zhang, S. Y. Choi, M. D. Gilchrist, Macromol. Mater. Eng. 2014, 299, 1362.

- 34S. Zhou, A. N. Hrymak, M. R. Kamal, Polym. Eng. Sci. 2016, 56, 1182.

- 35Z. Liu, Y. Chen, W. Ding, C. Zhang, Compos. Part A Appl. Sci. Manuf. 2015, 72, 85.

- 36X. Peng, M. Zhang, Z. Guo, L. Sang, W. Hou, Compos. Commun. 2020, 22, 100478.

- 37M. Abdelwahab, A. Codou, A. Anstey, A. K. Mohanty, M. Misra, Compos. Part A Appl. Sci. Manuf. 2020, 129, 105695.

- 38T. S. Ghanta, S. Aparna, N. Verma, D. Purnima, Polym. Eng. Sci. 2020, 60, 1717.

- 39R. Liu, Q. S. Liu, Phys. Rev. E 2012, 85, 066318.

- 40N. Zhang, M. D. Gilchrist, Polym. Test. 2012, 31, 48.

- 41A. Motaghi, A. Hrymak, G. H. Motlagh, J. Appl. Polym. Sci. 2015, 132, 41744.

- 42N. Anicet, F. Ebanda, L.-M. Ohandja, A. Ateba, Model. Simul. Mater. Sci. Eng. 2021, 11, 19.

- 43G.-X. Chen, Y. Li, H. Shimizu, Carbon 2007, 45, 2334.

- 44I. Alig, T. Skipa, D. Lellinger, P. Pötschke, Polymer 2008, 49, 3524.

- 45Y. Li, H. Shimizu, Polymer 2007, 48, 2203.

- 46M. Martyn, P. Coates, R. Joseph, K. Tanner, W. Bonfield, Plast. Rubber Compos. 2001, 30, 205.

- 47C.-M. Hong, J. Kim, S. C. Jana, Polym. Eng. Sci. 2004, 44, 2101.

- 48P. Pötschke, M. Abdel-Goad, I. Alig, S. Dudkin, D. Lellinger, Polymer 2004, 45, 8863.

- 49Y. Bai, Y. Shi, S. Zhou, H. Zou, M. Liang, Macromol. Mater. Eng. 2021, 306, 2100267.

- 50P. Lima, S. P. Magalhães da Silva, J. Oliveira, V. Costa, Polym. Test. 2015, 45, 58.

- 51K. Hamad, M. Kaseem, F. Deri, J. Mater. Sci. 2011, 46, 3013.

- 52E. Dal Lago, E. Cagnin, C. Boaretti, M. Roso, A. Lorenzetti, M. Modesti, Polymer 2020, 12, 29.

- 53T. Liu, I. Y. Phang, L. Shen, S. Y. Chow, W.-D. Zhang, Macromolecules 2007, 40, 8812.

- 54I. Y. Phang, J. Ma, L. Shen, T. Liu, W.-D. Zhang, Polym. Int. 2006, 55, 71.

- 55B. Krause, P. Pötschke, L. Häußler, Compos. Sci. Technol. 2009, 69, 1505.

- 56E. Logakis, C. Pandis, V. Peoglos, P. Pissis, C. Stergiou, J. Pionteck, P. Pötschke, M. Mičušík, M. Omastová, J. Polym. Sci. B Polym. Phys. 2009, 47, 764.

- 57A.-C. Brosse, S. Tencé-Girault, P. M. Piccione, L. Leibler, Polymer 2008, 49, 4680.

- 58A. M. Gohn, J. Seo, T. Ferris, P. Venkatraman, E. J. Foster, A. M. Rhoades, Thermochim. Acta 2019, 677, 99.

- 59D. Zou, T. Yu, C. Duan, Thermochim. Acta 2022, 711, 179197.

- 60S. Zhou, L. Yu, X. Song, J. Chang, H. Zou, M. Liang, J. Appl. Polym. Sci. 2014, 131, 39596.

- 61K. Ebner, J. L. White, Int. Polym. Process. 1994, 9, 233.

- 62P. Pötschke, H. Brünig, A. Janke, D. Fischer, D. Jehnichen, Polymer 2005, 46, 10355.

- 63R. Ramlee, M. Mariatti, Z. A. M. Ishak, A. R. Mohamed, J. Polym. Mater. 2013, 30, 103.

- 64Y. Kanbur, Z. Küçükyavuz, J. Reinf. Plast. Compos. 2008, 28, 2251.

- 65G. R. Kasaliwal, T. Villmow, S. Pegel, P. Pötschke, Polymer–Carbon Nanotube Composites, Woodhead Publishing, Sawton, UK 2011, p. 92.

10.1533/9780857091390.1.92 Google Scholar

- 66M. H. Al-Saleh, Mater. Des. 2015, 85, 76.

- 67Z. Dekel, S. Kenig, Int. Polym. Process. 2021, 36, 276.