Flame retarding effect of graphite in rotationally molded polyethylene/graphite composites

Washington Mhike

Institute for Applied Materials, Department of Chemical Engineering, University of Pretoria, Private Bag X20, Hatfield, Pretoria, 0028 South Africa

Search for more papers by this authorIgnatius V. W. Ferreira

Institute for Applied Materials, Department of Chemical Engineering, University of Pretoria, Private Bag X20, Hatfield, Pretoria, 0028 South Africa

Search for more papers by this authorJing Li

Department of Fire Protection Engineering, University of Maryland, College Park, Maryland, 20742

Department of Mechanical Engineering, University of Maryland, College Park, Maryland, 20742

Search for more papers by this authorStanislav I. Stoliarov

Department of Fire Protection Engineering, University of Maryland, College Park, Maryland, 20742

Department of Mechanical Engineering, University of Maryland, College Park, Maryland, 20742

Search for more papers by this authorCorresponding Author

Walter W. Focke

Institute for Applied Materials, Department of Chemical Engineering, University of Pretoria, Private Bag X20, Hatfield, Pretoria, 0028 South Africa

Correspondence to: W. W. Focke (E-mail: [email protected])Search for more papers by this authorWashington Mhike

Institute for Applied Materials, Department of Chemical Engineering, University of Pretoria, Private Bag X20, Hatfield, Pretoria, 0028 South Africa

Search for more papers by this authorIgnatius V. W. Ferreira

Institute for Applied Materials, Department of Chemical Engineering, University of Pretoria, Private Bag X20, Hatfield, Pretoria, 0028 South Africa

Search for more papers by this authorJing Li

Department of Fire Protection Engineering, University of Maryland, College Park, Maryland, 20742

Department of Mechanical Engineering, University of Maryland, College Park, Maryland, 20742

Search for more papers by this authorStanislav I. Stoliarov

Department of Fire Protection Engineering, University of Maryland, College Park, Maryland, 20742

Department of Mechanical Engineering, University of Maryland, College Park, Maryland, 20742

Search for more papers by this authorCorresponding Author

Walter W. Focke

Institute for Applied Materials, Department of Chemical Engineering, University of Pretoria, Private Bag X20, Hatfield, Pretoria, 0028 South Africa

Correspondence to: W. W. Focke (E-mail: [email protected])Search for more papers by this authorABSTRACT

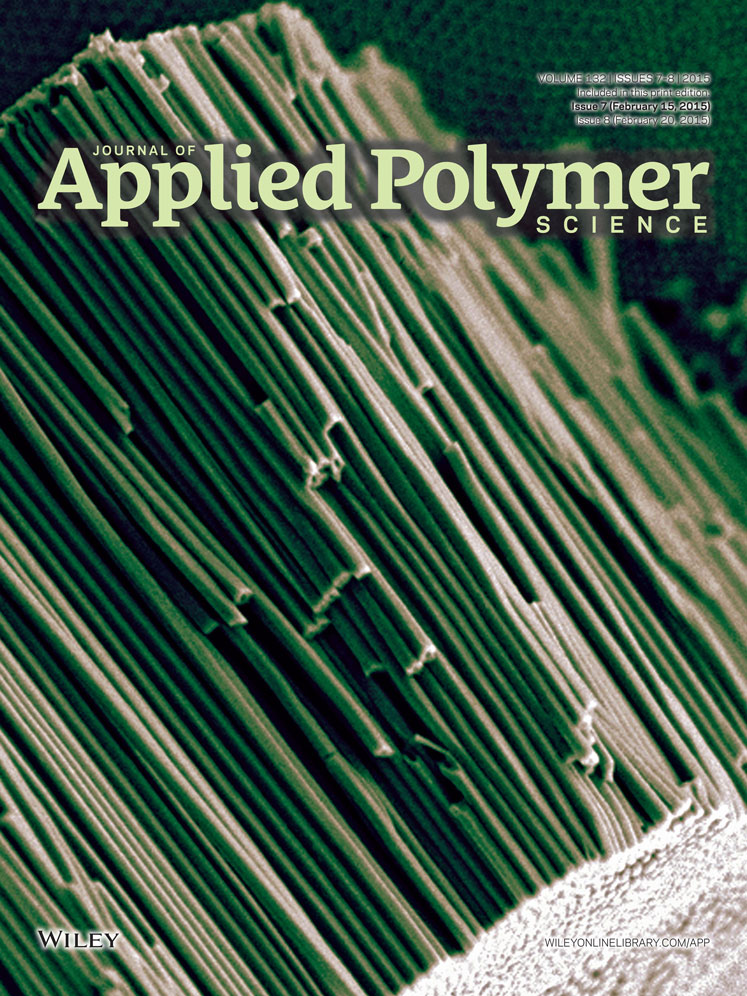

Linear low-density polyethylene (LLDPE) compounds containing 10 wt % graphite fillers were rotationally molded into flat sheets. Flame retardancy was studied using cone calorimeter tests conducted at a radiative heat flux of 35 kW/m2. Only the expandable graphite, an established flame retardant for polyethylene, significantly reduced the peak heat release rate. Compared with the neat polyethylene, it was easier to ignite the LLDPE composites containing carbon black, expandable graphite, and exfoliated graphite. However, rather unexpectedly, the inclusion of flake graphite increased the time to ignition by up to 80%. Simulations conducted with the ThermaKin numerical pyrolysis software suggest that increased reflectivity was mainly responsible for this effect. © 2014 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2015, 132, 41472.

REFERENCES

- 1 Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J. M.; Dubois, P. Mater. Sci. Eng. R: Rep. 2009, 63, 100.

- 2 Weil, E. D.; Levchik, S. V. J. Fire Sci. 2008, 26, 5.

- 3 Hull, T. R.; Witkowski, A.; Hollingbery, L. Polym. Degrad. Stabil. 2011, 96, 1462.

- 4 Qu, B.; Xie, R. Polym. Int. 2003, 52, 1415.

- 5 Xie, R.; Qu, B. J. Appl. Polym. Sci. 2001, 80, 1181.

- 6 Xie, R.; Qu, B. J. Appl. Polym. Sci. 2001, 80, 1190.

- 7 Pang, X. Y.; Song, M. Adv. Mater. Res. 2012, 560, 779.

- 8 Sun, Z.; Ma, Y.; Xu, Y.; Chen, X.; Chen, M.; Yu, J.; Hu, S.; Zhang, Z. Polym. Eng. Sci. 2014, 54, 1162.

- 9 Han, Z.; Dong, L.; Li, Y.; Zhao, H. J. Fire Sci. 2007, 25, 79.

- 10 Camino, G.; Costa, L.; Martinasso, G. Polym. Degrad. Stabil. 1989, 23, 359.

- 11 Wang, J. Q.; Chow, W. K. J. Appl. Polym. Sci. 2005, 97, 366.

- 12 Lewin, M. J. Fire Sci. 1999, 17, 3.

- 13 Dasari, A.; Yu, Z. Z.; Cai, G. P.; Mai, Y. W. Prog. Polym. Sci. 2013, 38, 1357.

- 14 Chen, G.; Weng, W.; Wu, D.; Wu, C. Eur. Polym. J. 2003, 39, 2329.

- 15 Chung, D. J. Mater. Sci. 2002, 37, 1475.

- 16 Wissler, M. J. Power Sources 2006, 156, 142.

- 17 Xie, R.; Qu, B. Polym. Degrad. Stabil. 2001, 71, 375.

- 18 Mhike, W.; Focke, W. W. J. Vinyl Addit. Techn. 2013, 19, 258.

- 19 Agari, Y.; Ueda, A.; Nagai, S. J. Appl. Polym. Sci. 1991, 42, 1665.

- 20 Osman, A. F.; Johar, B.; Adam, S. N. F. S.; Amin, S. A. M.; Osman, A. International Conference on Sustainable Materials Engineering (ICoSM 2007), Penang, Malaysia, 2007.

- 21 Sumirat, I.; Ando, Y.; Shimamura, S. J. Porous Mat. 2006, 13, 439.

- 22 Goldberg, V. M.; Kolesnikova, N. N.; Paverman, N. G.; Kavun, S. M.; Stott, P. E.; Gelbin, M. E. Polym. Degrad. Stabil. 2001, 74, 371.

- 23 Gilroy, H. M.; Chan, M. G. Polym. Sci. Technol. 1984, 26, 273.

- 24 Peña, J. M.; Allen, N. S.; Edge, M.; Liauw, C. M.; Valange, B. Polym. Degrad. Stabil. 2001, 72, 163.

- 25 Hawkins, W. L.; Hansen, R. H.; Matreyek, W.; Winslow, F. H. J. Appl. Polym. Sci. 1959, 1, 37.

- 26 Schartel, B.; Hull, T. R. Fire Mater. 2007, 31, 327.

- 27 Sacristán, M.; Hull, T. R.; Stec, A. A.; Ronda, J. C.; Galià, M.; Cádiz, V. Polym. Degrad. Stabil. 2010, 95, 1269.

- 28 Petrella, R. V. J. Fire Sci. 1994, 12, 14.

- 29 Stoliarov, S.; Lyon, R. DOT/FAA/AR-TN08/17 2008.

- 30 Stoliarov, S. I.; Crowley, S.; Lyon, R. E.; Linteris, G. T. Combust. Flame 2009, 156, 1068.

- 31 Stoliarov, S. I.; Safronava, N.; Lyon, R. E. Fire Mater. 2009, 33, 257.

- 32 Stoliarov, S. I.; Crowley, S.; Walters, R. N.; Lyon, R. E. Combust. Flame 2010, 157, 2024.

- 33 Linteris, G.; Zammarano, M.; Wilthan, B.; Hanssen, L. Fire Mater. 2012, 36, 537.

- 34 Lyon, R. E.; Safronava, N.; Quintiere, J. G.; Stoliarov, S. I.; Walters, R. N.; Crowley, S. Fire Mater. 2014, 38, 264.

- 35 Patel, P.; Hull, T. R.; Stec, A. A.; Lyon, R. E. Polym. Adv. Technol. 2011, 22, 1100.

- 36 Linteris, G. T. Fire Mater. 2011, 35, 463.

- 37

Higham, N. J. Accuracy and stability of numerical algorithms; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2002.

10.1137/1.9780898718027 Google Scholar

- 38 Kuan, C. F.; Tsai, K. C.; Chen, C. H.; Kuan, H. C.; Liu, T. Y.; Chiang, C. L. Polym. Composite. 2012, 33, 872.

- 39 Pang, X. Y.; Duan, M. W.; Tian, Y.; Zhai, M. Asian J. Chem. 2013, 25, 5390.

- 40 Fina, A.; Camino, G. Polym. Adv. Technol. 2011, 22, 1147.

- 41 Schartel, B.; Beck, U.; Bahr, H.; Hertwig, A.; Knoll, U.; Weise, M. Fire Mater. 2012, 36, 671.

- 42

Lyon, R.;

Walters, R.;

Stoliarov, S. J. ASTM Int. 2006, 3, 1.

10.1520/JAI13895 Google Scholar

- 43 Holman, J. P. Heat Transfer; McGraw-Hill: New York, 1986.

- 44 Lyon, R. E.; Janssens, M. L.; Flammability. Encyclopedia of Polymer Science and Technology. John Wiley & Sons, Inc. 2005.

Citing Literature

February 15, 2015