Reversible Structural Oscillation Mediates Stable Oxygen Evolution Reaction

Dr. Qunlei Wen

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

These authors contributed equally to this work.

Search for more papers by this authorDr. Tianyang Liu

Jiangsu Co-Innovation Centre of Efficient Processing and Utilization of Forest Resources, College of Chemical Engineering, Nanjing Forestry University, Nanjing, Jiangsu, 210037 P.R. China

These authors contributed equally to this work.

Search for more papers by this authorDr. Danji Huang

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

PetroChina ShenZhen New Energy Research Institute Co., Ltd., Shenzhen, Guangdong, 518000 P.R. China

These authors contributed equally to this work.

Search for more papers by this authorDr. Yu Lin

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorZhenhong Yang

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorDr. Ruoou Yang

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorCorresponding Author

Prof. Youwen Liu

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

E-mail: [email protected]; [email protected]; [email protected]

Search for more papers by this authorProf. Xiaomeng Ai

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorCorresponding Author

Prof. Jiakun Fang

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

E-mail: [email protected]; [email protected]; [email protected]

Search for more papers by this authorProf. Yafei Li

Jiangsu Collaborative Innovation Centre of Biomedical Functional Materials, Jiangsu Key Laboratory of New Power Batteries, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 P.R. China

Search for more papers by this authorProf. Bao Yu Xia

Key Laboratory of Material Chemistry for Energy Conversion and Storage (Ministry of Education), Hubei Key Laboratory of Material Chemistry and Service Failure, Wuhan National Laboratory for Optoelectronics, School of Chemistry and Chemical Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorProf. Shijie Cheng

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorCorresponding Author

Prof. Tianyou Zhai

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

E-mail: [email protected]; [email protected]; [email protected]

Search for more papers by this authorDr. Qunlei Wen

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

These authors contributed equally to this work.

Search for more papers by this authorDr. Tianyang Liu

Jiangsu Co-Innovation Centre of Efficient Processing and Utilization of Forest Resources, College of Chemical Engineering, Nanjing Forestry University, Nanjing, Jiangsu, 210037 P.R. China

These authors contributed equally to this work.

Search for more papers by this authorDr. Danji Huang

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

PetroChina ShenZhen New Energy Research Institute Co., Ltd., Shenzhen, Guangdong, 518000 P.R. China

These authors contributed equally to this work.

Search for more papers by this authorDr. Yu Lin

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorZhenhong Yang

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorDr. Ruoou Yang

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorCorresponding Author

Prof. Youwen Liu

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

E-mail: [email protected]; [email protected]; [email protected]

Search for more papers by this authorProf. Xiaomeng Ai

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorCorresponding Author

Prof. Jiakun Fang

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

E-mail: [email protected]; [email protected]; [email protected]

Search for more papers by this authorProf. Yafei Li

Jiangsu Collaborative Innovation Centre of Biomedical Functional Materials, Jiangsu Key Laboratory of New Power Batteries, School of Chemistry and Materials Science, Nanjing Normal University, Nanjing, Jiangsu, 210023 P.R. China

Search for more papers by this authorProf. Bao Yu Xia

Key Laboratory of Material Chemistry for Energy Conversion and Storage (Ministry of Education), Hubei Key Laboratory of Material Chemistry and Service Failure, Wuhan National Laboratory for Optoelectronics, School of Chemistry and Chemical Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorProf. Shijie Cheng

State Key Laboratory of Advanced Electromagnetic Engineering and Technology, and School of Electrical and Electronic Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

Search for more papers by this authorCorresponding Author

Prof. Tianyou Zhai

State Key Laboratory of Materials Processing and Die & Mould Technology, and School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 P.R. China

E-mail: [email protected]; [email protected]; [email protected]

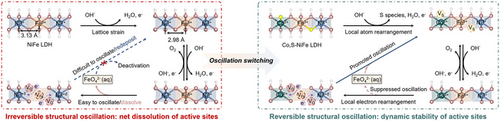

Search for more papers by this authorGraphical Abstract

This study reveals that dynamic structural oscillations within the [Ni–O2–Fe] units of NiFe LDHs identified a strong dependence on the alternating active Fe dissolution and redeposition, thus mediating the dynamic stability. Further, engineering the oscillation manners via the in situ sulfur leaching and cobalt-induced electron-withdrawing effects achieves unprecedented industrial-scale durability (>800 h @ 8000 mA) and a record energy efficiency (4.05 kWh Nm−3 H2 at 4000 A m−2).

Abstract

The dynamic dissolution of active species of electrocatalysts suffers severe durability issues, thus limiting practical sustainable electrochemical application despite the enormous strides in the activity. An atomistic understanding of the dynamic pattern is a fundamental prerequisite for realizing prolonged stability. Herein, modeling on NiFe LDHs, multiple operando spectroscopies revealed the structural oscillation of the local [Ni–O2–Fe] unit identified a strong dependence on the alternant Fe dissolution and redeposition during the oxygen evolution reaction (OER) process, thus mediating the dynamic stability. At this point, a proof-of-concept strategy with S, Co co-doping was demonstrated to tune structural oscillations. In situ S leaching that alleviates the lattice mismatch suppresses Fe dissolution, while the electron-withdrawing Co as a deposition site promotes Fe redeposition, thus achieving the reversible oscillation of local [Ni/Co–O2–Fe] units and dynamic stability. The implementation of the modified NiFe LDH in industrial water electrolysis equipment operated steadily over 800 h (5000-h lifetime obtained by epitaxial method with 10% attenuation) with an energy consumption of 4.05 kWh Nm−3 H2 @ 4000 A m−2. The levelized cost of hydrogen of US$ 2.315 per kgH2 overmatches the European Commission's target for the coming decade (<US$ 2.5 per kgH2).

Conflict of Interests

The authors declare no conflict of interest.

Open Research

Data Availability Statement

Research data are not shared.

Supporting Information

| Filename | Description |

|---|---|

| anie202509915-sup-0001-SuppMat.pdf4.6 MB | Supporting information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1N. S. Lewis, D. G. Nocera, Proc. Natl. Acad. Sci. USA 2006, 103, 15729–15735.

- 2S. Chu, A. Majumdar, Nature 2012, 488, 294–303.

- 3S. Z. Oener, M. J. Foster, S. W. Boettcher, Science 2020, 369, 1099–1103.

- 4W. J. Jiang, T. Tang, Y. Zhang, J. S. Hu, Acc. Chem. Res. 2020, 53, 1111–1123.

- 5Z. Y. Yu, Y. Duan, X. Y. Feng, X. Yu, M. R. Gao, S. H. Yu, Adv. Mater. 2021, 33, e2007100.

- 6D. Li, E. J. Park, W. Zhu, Q. Shi, Y. Zhou, H. Tian, Y. Lin, A. Serov, B. Zulevi, E. D. Baca, C. Fujimoto, H. T. Chung, Y. S. Kim, Nat. Energy 2020, 5, 378–385.

- 7J. Song, C. Wei, Z. F. Huang, C. Liu, L. Zeng, X. Wang, Z. J. Xu, Chem. Soc. Rev. 2020, 49, 2196–2214.

- 8L. C. Seitz, C. F. Dickens, K. Nishio, Y. Hikita, J. Montoya, A. Doyle, C. Kirk, A. Vojvodic, H. Y. Hwang, J. K. Norskov, T. F. Jaramillo, Science 2016, 353, 1011–1014.

- 9J. Rossmeisl, Z. W. Qu, H. Zhu, G. J. Kroes, J. K. Nørskov, J. Electroanal. Chem. 2007, 607, 83–89.

- 10J. Suntivich, K. J. May, H. A. Gasteiger, J. B. Goodenough, Y. Shao-Horn, Science 2011, 334, 1383–1385.

- 11E. Fabbri, M. Nachtegaal, T. Binninger, X. Cheng, B. J. Kim, J. Durst, F. Bozza, T. Graule, R. Schaublin, L. Wiles, M. Pertoso, N. Danilovic, K. E. Ayers, T. J. Schmidt, Nat. Mater. 2017, 16, 925–931.

- 12Y. Lin, B. Chen, D. Huang, Z. Yang, A. Lu, Z. Shi, Y. Liu, J. Fang, H. Li, T. Zhai, Angew. Chem. Int. Ed. 2025, 64, e202502151.

- 13C. Roy, B. Sebok, S. B. Scott, E. M. Fiordaliso, J. E. Sørensen, A. Bodin, D. B. Trimarco, C. D. Damsgaard, P. C. K. Vesborg, O. Hansen, I. E. L. Stephens, J. Kibsgaard, I. Chorkendorff, Nat. Catal. 2018, 1, 820–829.

- 14B. Zhang, X. Zheng, O. Voznyy, R. Comin, M. Bajdich, M. García-Melchor, L. Han, J. Xu, M. Liu, L. Zheng, F. Pelayo García de Arquer, C. Dinh, F. Fan, M. Yuan, E. Yassitepe, N. Chen, T. Regier, P. Liu, Y. Li, P. Luna, A. Janmohamed, H. L. Xin, H. Yang, A. Vojvodic, E. H. Sargent, Science 2016, 352, 333–337.

- 15B. Zhang, L. Wang, Z. Cao, S. M. Kozlov, F. P. García de Arquer, C. T. Dinh, J. Li, Z. Wang, X. Zheng, L. Zhang, Y. Wen, O. Voznyy, R. Comin, P. De Luna, T. Regier, W. Bi, E. E. Alp, C.-W. Pao, L. Zheng, Y. Hu, Y. Ji, Y. Li, Y. Zhang, L. Cavallo, H. Peng, E. H. Sargent, Nat. Catal. 2020, 3, 985–992.

- 16M. Gong, Y. Li, H. Wang, Y. Liang, J. Z. Wu, J. Zhou, J. Wang, T. Regier, F. Wei, H. Dai, J. Am. Chem. Soc. 2013, 135, 8452–8455.

- 17Q. Wen, K. Yang, D. Huang, G. Cheng, X. Ai, Y. Liu, J. Fang, H. Li, L. Yu, T. Zhai, Adv. Energy Mater. 2021, 11, 2102353.

- 18W. Feng, B. Chang, Y. Ren, D. Kong, H. B. Tao, L. Zhi, M. A. Khan, R. Aleisa, M. Rueping, H. Zhang, Adv. Mater. 2025, 37, e2416012.

- 19D. Y. Chung, P. P. Lopes, P. Farinazzo Bergamo Dias Martins, H. He, T. Kawaguchi, P. Zapol, H. You, D. Tripkovic, D. Strmcnik, Y. Zhu, S. Seifert, S. Lee, V. R. Stamenkovic, N. M. Markovic, Nat. Energy 2020, 5, 222–230.

- 20K. Du, L. Zhang, J. Shan, J. Guo, J. Mao, C. C. Yang, C. H. Wang, Z. Hu, T. Ling, Nat. Commun. 2022, 13, 5448.

- 21K. Obata, K. Takanabe, Angew. Chem. Int. Ed. 2018, 57, 1616–1620.

- 22L. Peng, N. Yang, Y. Yang, Q. Wang, X. Xie, D. Sun-Waterhouse, L. Shang, T. Zhang, G. I. N. Waterhouse, Angew. Chem. Int. Ed. 2021, 60, 24612–24619.

- 23Y. Lin, D. Huang, Q. Wen, R. Yang, B. Chen, Y. Shen, Y. Liu, J. Fang, H. Li, T. Zhai, Proc. Natl. Acad. Sci. USA 2024, 121, e2407350121.

- 24C. Feng, F. Wang, Z. Liu, M. Nakabayashi, Y. Xiao, Q. Zeng, J. Fu, Q. Wu, C. Cui, Y. Han, N. Shibata, K. Domen, I. D. Sharp, Y. Li, Nat. Commun. 2021, 12, 5980.

- 25Y. Lin, J. Fang, W. Wang, Q. Wen, D. Huang, D. Ding, Z. Li, Y. Liu, Y. Shen, T. Zhai, Adv. Energy Mater. 2023, 13, 2300604.

- 26P. P. Lopes, D. Strmcnik, D. Tripkovic, J. G. Connell, V. R. Stamenkovic, N. M. Markovic, ACS Catal. 2016, 6, 2536–2544.

- 27F. Polo-Garzon, Z. Bao, X. Zhang, W. Huang, Z. Wu, ACS Catal. 2019, 9, 5692–5707.

- 28S. H. Chang, J. G. Connell, N. Danilovic, R. Subbaraman, K. C. Chang, V. R. Stamenkovic, N. M. Markovic, Faraday Discuss. 2014, 176, 125–133.

- 29W. Wang, J. Duan, Y. Liu, T. Zhai, Adv. Mater. 2022, 34, e2110699.

- 30S. Zuo, Z. P. Wu, G. Zhang, C. Chen, Y. Ren, Q. Liu, L. Zheng, J. Zhang, Y. Han, H. Zhang, Angew. Chem. Int. Ed. 2024, 63.

- 31M. B. Stevens, L. J. Enman, A. S. Batchellor, M. R. Cosby, A. E. Vise, C. D. M. Trang, S. W. Boettcher, Chem. Mater. 2017, 29, 120–140.

- 32Y. Kuang, M. J. Kenney, Y. Meng, W. H. Hung, Y. Liu, J. E. Huang, R. Prasanna, P. Li, Y. Li, L. Wang, M. C. Lin, M. D. McGehee, X. Sun, H. Dai, Proc. Natl. Acad. Sci. USA 2019, 116, 6624–6629.

- 33C. Kuai, Z. Xu, C. Xi, A. Hu, Z. Yang, Y. Zhang, C.-J. Sun, L. Li, D. Sokaras, C. Dong, S.-Z. Qiao, X.-W. Du, F. Lin, Nat. Catal. 2020, 3, 743–753.

- 34Y. Shi, W. Du, W. Zhou, C. Wang, S. Lu, S. Lu, B. Zhang, Angew. Chem. Int. Ed. 2020, 59, 22470–22474.

- 35N. Zhang, Y. Hu, L. An, Q. Li, J. Yin, J. Li, R. Yang, M. Lu, S. Zhang, P. Xi, C. H. Yan, Angew. Chem. Int. Ed. 2022, 61, e202207217.

- 36S. Lee, L. Bai, X. Hu, Angew. Chem. Int. Ed. 2020, 59, 8072–8077.

- 37J. Kang, X. Qiu, Q. Hu, J. Zhong, X. Gao, R. Huang, C. Wan, L. Liu, X. Duan, L. Guo, Nat. Catal. 2021, 4, 1050–1058.

- 38Y. J. Wu, J. Yang, T. X. Tu, W. Q. Li, P. F. Zhang, Y. Zhou, J. F. Li, J. T. Li, S. G. Sun, Angew. Chem. Int. Ed. 2021, 60, 26829–26836.

- 39Y. Bai, Y. Wu, X. Zhou, Y. Ye, K. Nie, J. Wang, M. Xie, Z. Zhang, Z. Liu, T. Cheng, C. Gao, Nat. Commun. 2022, 13, 6094.

- 40Y. Sun, Y. Xie, X. Chen, J. Wu, P. Liu, X. Wang, Z. Tian, W. Zheng, Z. Jiang, Z. Kang, Y. Zhang, Nat. Commun. 2025, 16, 3073.

- 41Z. Wu, S. Zuo, Z. Pei, J. Zhang, L. Zheng, D. Luan, H. Zhang, X. Lou, Sci. Adv. 2025, 11, eadu5370.

- 42L. Wei, K. Zhang, R. Zhao, L. Zhang, Y. Zhang, S. Yang, J. Su, Nano Res. 2024, 17, 4720–4728.

- 43S. Zuo, Z. P. Wu, D. Xu, R. Ahmad, L. Zheng, J. Zhang, L. Zhao, W. Huang, H. Al Qahtani, Y. Han, L. Cavallo, H. Zhang, Nat. Commun. 2024, 15, 9514.

- 44F. Liu, Z. Gao, J. Su, L. Guo, Electrochim. Acta 2023, 468, 143193.

- 45Q. Wen, Y. Lin, Y. Yang, R. Gao, N. Ouyang, D. Ding, Y. Liu, T. Zhai, ACS Nano 2022, 16, 9572–9582.

- 46W. Yan, Q. Liu, C. Wang, X. Yang, T. Yao, J. He, Z. Sun, Z. Pan, F. Hu, Z. Wu, Z. Xie, S. Wei, J. Am. Chem. Soc. 2014, 136, 1150–1155.

- 47J. Huang, H. Sheng, R. D. Ross, J. Han, X. Wang, B. Song, S. Jin, Nat. Commun. 2021, 12, 3036.

- 48A. C. Garcia, T. Touzalin, C. Nieuwland, N. Perini, M. T. M. Koper, Angew. Chem. Int. Ed. 2019, 58, 12999–13003.

- 49J. D. Michael, E. L. Demeter, S. M. Illes, Q. Fan, J. R. Boes, J. R. Kitchin, J. Phys. Chem. C 2015, 119, 11475–11481.

- 50Q. Wen, J. Duan, W. Wang, D. Huang, Y. Liu, Y. Shi, J. Fang, A. Nie, H. Li, T. Zhai, Angew. Chem. Int. Ed. 2022, 61, e202206077.

- 51Y. Zuo, S. Bellani, M. Ferri, G. Saleh, D. V. Shinde, M. I. Zappia, R. Brescia, M. Prato, L. De Trizio, I. Infante, F. Bonaccorso, L. Manna, Nat. Commun. 2023, 14, 4680.

- 52R. Wiser, J. Rand, J. Seel, P. Beiter, E. Baker, E. Lantz, P. Gilman, Nat. Energy 2021, 6, 555–565.

- 53 IRENA, Green hydrogen cost reduction: Scaling up electrolysers to meet the 1.5 °C climate goal can be found under https://www.irena.org/publications/2020/Dec/Green-hydrogen-cost-reduction, 2020.

Online Version of Record before inclusion in an issue

e202509915