A Review of IoT Applications in Food Processing and Related Fields

Abstract

The application of the Internet of Things (IoT) in food processing and related fields is reviewed in this paper. This review is aimed at identifying and elucidating IoT application areas, trends, architectures, and challenges in these fields. The essential survey was conducted following a systematic literature review (SLR) using academic documents written in English and published in peer-reviewed journals from 2011 to 2024. Selected references based on the application domains corresponding to food processing and related fields were clustered into food safety and quality, packaging and traceability, supply chain, waste, and contamination. A database that summarized and reviewed selected articles on the implementation of IoT solutions for monitoring variables and communication technologies in different food sectors was developed. Based on this study, we proposed an IoT architecture based on our findings that can be used for the application of IoT in food processing and related fields.

1. Introduction

Food and agriculture have significantly evolved over the last hundred years. We produce more food than ever before, but one of the current issues that needs to be addressed is the sustainability of the earth’s resources as we engage in the provision of sufficient food for all. We are gradually depleting some of the most important resources needed for agricultural production and food processing, such as arable land, water, and energy. With the global population expected to surpass 8 billion soon, the use of modern food production methods and tools to improve efficiency has become increasingly important [1]. There are various new technologies that have become prominent in human activities over the last two and a half decades, which could potentially address some of the major issues related to food security. Ensuring that no individual faces hunger on our increasingly populated planet is imperative. Food is a fundamental requirement for life, and access to it should be straightforward and affordable. When considering health, food plays a crucial role. So, there is nothing more important than constructing an information infrastructure that makes access to food possible for all, and this is viable through the Internet of Things (IoT) for food.

The Internet is a worldwide system of interconnected computer networks that use the web protocol suite (TCP/IP) to interface billions of gadgets around the world. The IoT provides a network of interrelated digital devices, mechanical and computing machines, objects, or individuals that are equipped with unique identifiers and the ability to transfer data over the network without requiring human-to-human or human-to-computer interaction. IoT devices share the sensor information they gather by interfacing with an IoT gateway or other edge devices where data is either sent to the cloud to be analyzed or interpreted locally. Sometimes, these devices share information with other related gadgets and act on the data they get from each other. The IoT can improve traceability and food safety in the food industry, as well as help reduce waste, expenses, and risks. Sensors can collect data on precipitation, humidity, temperature, and soil parameters, as well as other factors, that would help intelligent farming techniques.

In the food industries, the diverse range of processes, physical objects, and partners results in a wide variety of IoT applications, which hinders the widespread adoption of IoT in the agri-food domain. IoT-based systems are often fragmented, and the use of various information platforms with limited interoperability and significantly more advanced applications is still in an early stage of development [2]. To overcome this situation, autonomous IoT systems should act as interoperable nodes within a well-aligned software ecosystem that maximizes reuse and synergies across multiple IoT systems [3]. In such an ecosystem, technology companies can concentrate on the development of components that best fit their core competencies [4]. The food industry has experienced substantial advancements through the integration of the IoT across various sectors. For instance, IoT facilitates food companies to ensure superior levels of traceability, food safety, and accountability throughout the farm-to-plate supply chain operations. The list of advantages offered by IoT technology within the food industry is long; consequently, the impact is additionally impressive. Food safety, supply chain management, traceability, production efficiency, storage solutions, and waste reduction are key areas influenced by the implementation of IoT in the food industry.

From a global standpoint, the number of connected IoT devices has steadily increased from 13.8 billion in 2022 to 17.7 billion in 2024 and is projected to reach approximately 40.6 billion by 2034, reflecting the rapid digital transformation across industries [5]. The deployment of IoT solutions to agro-food industrial fields is essential because they cover broad areas of the food sector and must be continuously monitored and controlled. IoT technology can support the food industry in four key areas: enhancing food safety efficiency, reducing waste, maintaining coherent records, and facilitating interconnected data analysis [6]. That means that with IoT, opportunities are created for the physical world to be further integrated into a computer-based system by using the existing network infrastructure to collect real-time data in the cloud through the wireless sensor network (WSN) for further analysis.

This review seeks to examine the current landscape of IoT applications within the agro-food industry. It aims to identify existing solutions, emerging trends, relevant architectures, technologies, and associated challenges in this domain. This paper uses the conduction method developed by Kitchenham and Charters [7], systematic literature review (SLR), to ensure unbiased data selection, processing, and presentation of results. The outlines of this study are as follows: Section 2 describes the literature search and bibliometric networks, and the results of the SLR methodology are brought in Section 3. Section 4 includes a discussion of the obtained result, and based on the research performed, Section 5 provides concluding remarks. A graphical abstract illustrating the overall review workflow and methodology is available as supporting information (Figure S1).

2. Document Search and Bibliometric Networks

At the first step of SLR, a strategy was outlined. This included research questions, search strategies, selection criteria, and synthesis methodologies. For this step, the following questions were considered: What are the leading technical solutions of the IoT in agro-food and related fields? What are the methods or tools of IoT used in agro-food and related fields? The start of our search was performed by selecting the sources of the available databases. For this matter, two library searches (IEEE and Science Direct), three engine searches (Scopus, Google Scholar, and Web of Science), and one network site (ResearchGate) were searched based on the availability of access to the full article. The articles with the phrases “Food” and “Internet of Things” inclusively in the title of papers published in peer-reviewed conferences and journals between the inclusive years of 2011–2024 were searched. This decision of searching in the titles was made to reach directly to our objectives and make it unbiased in terms of information selection, processing, and presentation of results. The obtained results were manually compiled to select the best papers. More than 116 papers were found from the above academic sources.

From these 116 papers, 33 papers were withdrawn for the following reasons: (1) similarity in title and authors, (2) not providing a comprehensive solution for IoT in agro-food and related fields, (3) lack of details on infrastructure and/or technologies, and (4) irrelevance or poor quality. The remaining number (83) of high-quality papers was studied in detail and summarized. A sample of the summarized paper is exposed in Table 1. From these summarized tables, we extract relevant information to address the questions that arise from the statistical analysis process. As shown in Table 1, the information fields extracted for each study are authors, year of publication, title of article, subdomain, communication technology, IoT platforms, monitoring variables, methodology, and future challenge presented in different tables and held in our archive for taking the next step of the SLR which is data mining and synthesis. The aim was to gather the information needed to answer the research questions objectively.

| Authors/year | Vladimir Vujovic and Mirjana Maksimovic (2015) |

| Title of article | Application of Internet of Things in food packing and transportation |

| Subdomain | Food safety management, food packing, transportation, and food traceability |

| Communication technology | RFID, near-field communication (NFC), Bluetooth, GPS/GPRS, and Wi-Fi |

| IoT platforms | Raspberry Pi (RPi) board with RESTful web service |

| Monitoring variables | Freshness, pathogens, leakage, carbon dioxide, oxygen, pH, time, and temperature |

| Methodology | They proposed a hardware implementation system based on a low-cost computer board, card-sized Raspberry Pi (RPi), with a powerful and lightweight ARM-based computer board. RPi runs on Linux or Windows 10. Internet connectivity is via an Ethernet/LAN cable or via a USB, Wi-Fi, and Bluetooth to measure food properties |

| Future challenge | Future research will be focused on interconnecting vehicles, sensors, and mobile devices into a global IoV network, which should enable various services to be delivered to vehicular and transportation systems, as well as people within and around vehicles |

The publication statistics by continent provide a good overview of the study related to IoT in the food sectors worldwide. As shown in Figure 1, most of the papers were published between the years 2017 and 2024. The number of countries that had contributed to publishing papers was 25. It is worth mentioning that China, with 23 articles, and India, with 18 articles, had the most contributions, respectively. Within this period (2011–2024), from the standpoint of continents, Asia published 58 papers, Europe 18 papers, North America 3 papers, Africa 2 papers, and Oceania with just 1 paper has the least contribution. Notably, Africa and Oceania began contributing in 2021 and 2024, respectively, highlighting their emerging interest in this field. In contrast, Asia consistently contributed across the entire period, except in 2012, indicating sustained research activity. In general, Asia had more than 70%, and Europe had a share of over 21% of contributions. However, North America, Africa, and Oceania, with less than eight overall percent, showed massive potential for these continents. South America made no contribution.

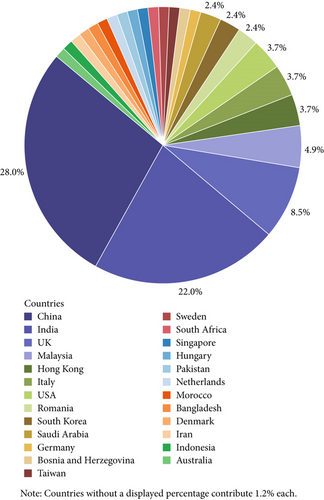

Figure 2 compares the percentages of published papers in IoT related to food sectors contributed by 25 countries worldwide from 2011 to 2024. China holds the largest share of published papers in IoT research for food processing, contributing 28%, followed by India with a 22% share; both are leading Asian countries in this field. The United Kingdom and Malaysia also make significant contributions, with 8.5% and 4.9%, respectively. All other participating countries contributed less than 4% to the research efforts.

3. Specific Applications of IoT in the Food Industry

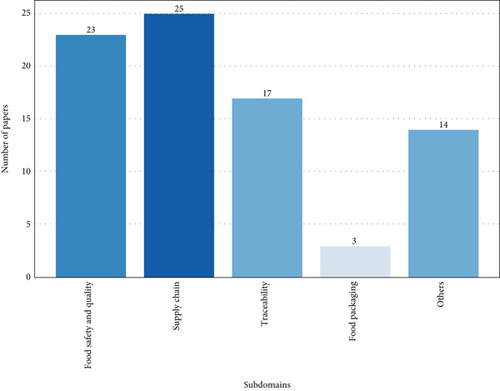

In this section, we present the answer to the questions raised in Section 2 based on our studies made through the reviewed papers in seven categories of (1) monitoring, (2) communication technology, (3) food safety and quality, (4) supply chain, (5) traceability, (6) food packaging, and (7) food perishable, waste, and contamination.

3.1. Monitoring

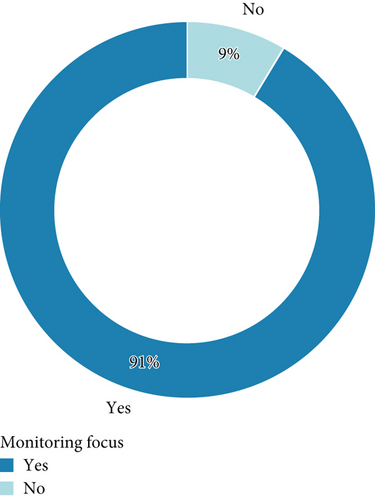

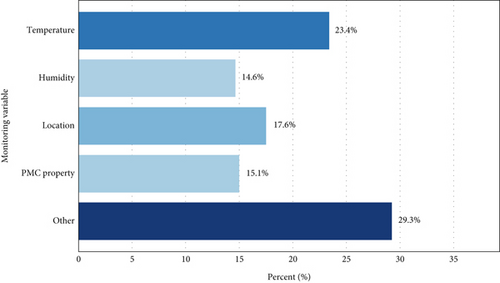

IoT technology offers a trend of remotely monitoring physical variables with the capability to meet the comprehensive needs of any system. Figure 3 illustrates that most of the selected articles studied were focused on monitoring, with 91% contribution beyond the other subdomains of work conducted by authors in our reviews. In the other papers (9%), no sensing variables were considered to be monitored. IoT solutions grouped in this domain are paying attention to monitoring several types of physical variables depending on the subdomain in which they fit. The majority of the sensing variables measured (55.6%) in these studies were temperature (23.4%), humidity (14.6%), and location tracking (17.6%), as illustrated in Figure 4.

Popa et al. [91] proposed a WSN approach with the implementation of a ZigBee communication protocol for monitoring data of food degradation and storage conditions by measuring pathogenic agents, gases, pressure, temperature, humidity, and storage period. Postolache et al. [92] designed a general IoT-based smart agriculture ecosystem for monitoring air temperature, humidity, soil pH, soil nutrition, and moisture data. Witjaksono et al. [93] proposed a three-layer IoT architecture for food quality control by measuring the physical temperature, humidity, pressure, concentration, and multimedia data collected using radiofrequency identification (RFID), ultra-wide band (UWB), near-field communication (NFC), Wi-Fi tags, and camera images. Jagtap et al. [8] developed an automated and real-time system based on the IoT concepts to measure the overall amount of waste as well as the reasons for waste generation in real time within the potato processing industry by using modern image processing and load cell technologies. When the camera detects a potato that does not fit customer specifications, then it will send a signal via computer to reject that potato by the rejecter arm. The computer automatically displays data related to waste, such as time, date, location, weight, image, and reason for the waste, and it is sent to the cloud storage. These works confirm the importance of IoT applications in monitoring the variables data captured by WSN in different food subdomains.

3.2. Communication Technology

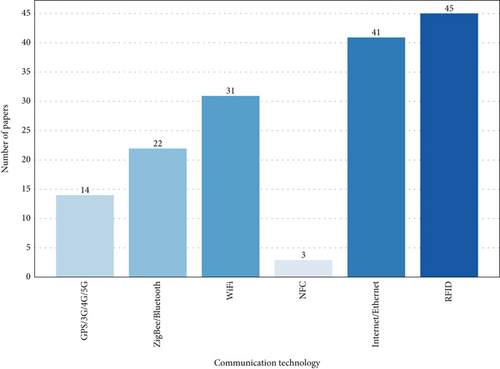

IoT devices transmit data to cloud servers or local data centers through communication techniques. The most frequently used communication technologies in the food sector are GPS/3G/4G/5G, Wi-Fi, and ZigBee/Bluetooth, respectively, as shown in Figure 5. The RFID tags have been used in several IoT projects only to track and trace food products. It has to be mentioned that RFID is not a communication network; it is a WSN tag attached to a product for tracking, which sends signals via radiofrequency for identification. The reason for adding this item to the chart is that products first need to be identified to be able to transmit data. Figure 5 illustrates that in 14 papers, GPS/3G/4G/5G protocols named wireless metropolitan area network (WMAN) supported by cellular technologies were used; in 22 papers, ZigBee/Bluetooth protocols grouped in wireless personal area network (WPAN), in 31 papers Wi-Fi network, in three papers NFC (which is a new emerging connection), and in 41 papers employed Internet/Ethernet connections. However, in 45 papers, RFID tags were used to identify food products. Almost all of the papers used WSN technology in conducting their work. Only in two papers, none of the above communication technology was used due to theoretical study made by authors. From the above presentation, we can conclude that there is no agreement in using a unique communication technique; this is a real challenge in the application of IoT in food domains.

3.3. Food Industry Sectors

More than a billion tons of food gets lost or wasted worldwide every year. The IoT can bridge the gaps in the food industry supply chain. Developed and developing countries are mainly affected by the lack of coordination in the global supply chain [94]. In the following sections, some related work on IoT’s applications in food traceability, food supply chain, food safety and quality, food packaging, food perishables, waste, and contamination among the selected papers are considered. The distribution of papers selected in our studies in food subdomains is illustrated in Figure 6. The “others” column is a subdomain showing work done on food growth, waste, contamination, and perishable food.

3.3.1. Food Safety and Quality

Doinea et al. [9] developed an IoT-based system for food safety management. They proposed a sensor network architecture based on IoT components using autonomous embedded modules and RFID that will automatically collect data, covering the entire life cycle of the food product and all the factors that influence its chemical composition, such as garbage/waste selection preprocessing (glass, plastic, paper, etc.) and weather conditions (humidity, pollution, etc.) needed for environmental monitoring. Jia and Yang [95] proposed a designed Platform of Food Quality Control (PFQC) based on an IoT structure which was focused on supervising and managing the whole process of food production in real time with the use of bar codes and RFID tags to monitor the moisture, pH, oil, fat, sugar, and protein of food and environmental temperature and humidity.

3.3.2. Supply Chain

Pal and Kant [96] proposed an integrated sensing and communications (S&C) module that can be embedded in each package within a box, making it possible to perform communication to enable data transfer to an Analytics and Operations Center (AOC) which can be cloud-hosted server. A local network transmits data via wireless sensing and General Packet Radio Service (GPRS) to the hub in each carrier or warehouse. Real-time measurements include temperature, humidity, vibrations, organic compounds, ethanol, glucose, gas molecules, and item location. Pang et al. [6] proposed a value-centric business–technology joint design framework based on a set of heavyweight sensors, Global System for Mobile Communications (GSM)/GPRS, RFID, WSN global scale Cooperative Food Cloud (CFC) as the service support platform, and the income-centric added-values including shelf-life prediction. Monitoring variables were temperature, humidity, CO2, oxygen, ethylene, soil moisture, vibration shock, and tilt light.

3.3.3. Traceability

Wang et al. [97] proposed a traceability method basic framework with a DNS server named Berkeley Internet Name Domain (BIND) 9.6.0 on Linux OS as the top-level resolution service provider, which is based on the IoT identification service to achieve traceability information of product life cycle with the IoT named Service platform. The data server is provided by MySQL Server 5.5, which was adopted on Apache as the web server software and through Java language implementation of food traceability information query service. Ultimately, utilizing this approach enables the tracking of the entire food process by mapping the relationship between each entity and its corresponding identifier. Jiang et al. [10] studied the integration of information and communication technologies, including automatic induction, wireless communication (QR codes, WSN, RFID, and Bluetooth), data management (NGINX for the webserver), and cloud services (PostgreSQL 9.5 served as the database) with product traceability techniques based on the concept of IoT to develop a product traceability information system for farm animal production and food traceability system.

3.3.4. Food Packaging and Storage

Karim et al. [11] employed a new model of ESP-8266-aka-Node microcontroller unit with a breadboard/veroboard and a DHT-11 sensor to record data in the ThingSpeak cloud. Humidity and temperature data for stored food were measured. Vujovic and Maksimovic [12] developed an economical, sensor-based remote monitoring system with an accredited card-sized Raspberry Pi (RPi) board with RESTful web service matched to a robust and lightweight ARM-based computer board. The RPi runs on Linux/Windows 10, building an IoT solution. Relying on proposed approaches, this intelligent system provides detailed information on foodstuff products.

3.3.5. Food Perishable, Waste, and Contamination

The IoT can help trace loss and spoilage, providing safer food transport conditions and reducing waste. Jagtap and Rahimifard [8] developed a digitized food weighing tracking system that utilized with an intelligent scale to measure the weight of the food waste, CO2, and identify and categorize the waste by the human interface to verify the type of food waste. The data is then stored in a database using a cloud computing facility and further analyzed using the waste tracker system to provide the real-time status of food waste. Tsang et al. [13, 14] employed IoT sensor technology to capture the environmental conditions and to identify a particular batch of perishable food. SensorTag CC3200, which is a cost-effective means for developing environmental monitoring and transmitting the data via the Wi-Fi network, was attached to a batch of perishable food to obtain the environmental data, as well as pressure (kPa). The operation data, including the operational flow and supply chain activities, were also collected via the Wi-Fi wireless network. Jain [15] provided a new automated measuring and accounting system based on RFID, camera, GPS, GIS and GPRS, and Wi-Fi communication modules, which help discover trends in food wastage by correlating the food wastage with the number of people generating that food waste, day of the week, and time of day.

4. Discussion

The results of this review study, focusing on two research questions in Section 2 (what are the leading technical solutions and methods or tools of IoT in agro-food and related fields?), are concisely summarized and discussed in the following sections.

4.1. Monitoring Variables

Most of the papers distributed by application domains focused on monitoring variables. The study of papers shows that at least one variable was monitored remotely, and upon IoT architecture, data acquired through gateways was transmitted without an operator. A weak correlation of 23.4% on temperature, 17.6% on location tracking, and 14.6% on humidity variables measured was found among the selected papers illustrated in Figure 4. The PMC with 15.1%, stands for total physical, mechanical, and chemical properties of food products and other variables of interest under the “others” bar with 29.3% (more than 15 variables) were monitored. However, by referring to our database of recorded variables, more than 200 times, data of monitoring variables with repeated measurement were transmitted via different communication devices to data centers and cloud servers. This is an acknowledgment of the fact that for food sectors and related activities, there is no offer of unique monitoring variables and standardization for measurement in WSN media. To deal with worldwide climatic variability and seasonal changes, commercial IoT solutions should be able to overcome significant changes with variables such as temperature, humidity, and location tracking as the monitoring variables. Most papers selected in this SLR stage can be categorized into more than one subdomain. For example, in addition to monitoring different variables, the authors of selected articles covered at least one other subdomain in almost all the papers.

4.2. Communication Technologies

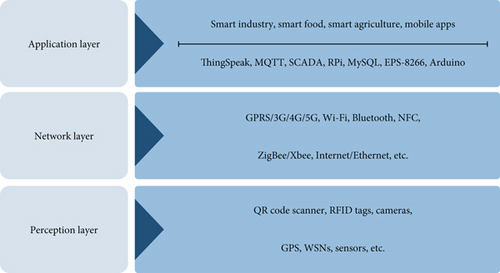

An underaverage correlation within communication networks was found in the application of the IoT used in selected papers. Share of Internet/Ethernet with 26%, followed by Wi-Fi with 20%, next ZigBee/Bluetooth with 14%, and then WMAN (GPS,3G,4G,5G) with 9% usage is proof of the above claim. It is well known that data transmission to a remote database or cloud server is carried out through different communication devices. The present review demonstrates that this unsatisfied correlation exists between the ‘researchers’ work due to a lack of standard protocol in communication networks for a specific purpose. The IoT solutions in agro-food and related fields from the standpoint of Infrastructure and technology are organized by Shi et al. [98] in groups corresponding to (i) sensing variables, (ii) actuator devices, (iii) power sources, (iv) communication technologies, (v) edge computing technologies, (vi) storage strategies, and (vii) visualization strategies. Breaking the layers of IoT architecture may deviate the correlation more. Through a deep insight into the study in the selected paper, a proposed IoT architecture with a sub-division into three layers is offered in Figure 7. This proposed IoT solution is a formation architecture that meets almost all the requirements of IoT applications for smart agriculture and food-related fields.

- 1.

Perception layer: This is where the wired or wireless sensor and actuator status are the domains of operation technology. Most public devices like QR codes, RFID tags, and other devices used in our survey are listed in this layer. The perception layer captures real-time data on food conditions such as temperature, humidity, and movement through sensors and devices, enabling immediate detection of changes.

- 2.

Network layer: In this layer, sensor data is transferred long-distance through gateways to the data center or cloud server. GPRS/3G/4G, Wi-Fi, Bluetooth, and ZigBee have been the most implemented methods of transmitting data. Even though NFC was used less, its features like low cost, compatibility, and low power usage show promising potential in the future. The network layer ensures timely and reliable transmission of this data across distributed food supply chains.

- 3.

Application layer: Here, data is transferred with the ThingsPeak or Message Queuing Telemetry Transport (MQTT) network protocol and stored on a cloud server. Then, the data are analyzed and managed by application software on PCs or mobile apps. The application layer processes analyzes and visualizes the data, supporting informed decisions related to food quality, safety, and logistics management. Together, these layers create a seamless flow from raw data collection to actionable insights, ensuring transparency and efficiency in food system monitoring.

While various communication technologies are applied in IoT-based food systems, each carries distinct limitations that must be considered when designing reliable and scalable solutions. Wi-Fi, though widely used due to its accessibility and high data rates, has limited coverage and can be unreliable in remote or rural areas where many agricultural activities occur. Bluetooth and ZigBee, known for low power consumption and short-range connectivity, are suitable for localized monitoring but may encounter interference and lack the ability to scale in large deployments. RFID offers effective identification and tracking but lacks continuous monitoring capabilities and is sensitive to interference from moisture and metal-rich environments. NFC has a very short range, which makes it unsuitable for applications that require long-distance communication. Cellular networks (e.g., 3G/4G/5G) provide wide coverage and high-speed transmission but are often costly and energy-intensive, which may hinder deployment in energy-constrained or cost-sensitive scenarios. Furthermore, satellite communications, although effective for remote locations, suffer from high latency and operational costs. These challenges underline the importance of selecting communication technologies based on the specific operational context and infrastructure constraints of food systems. The following section discusses the limitations and future challenges of the study.

4.3. Restraint and Open Challenges

- 1-.

Mobile apps: Behind the movement in food commerce, almost every business owner is aware of the important role of mobile applications in their business. The development of mobile apps on smartphones will further simplify the monitoring process in food sectors.

- 2-.

Foodstuffs monitoring: The advantages of the proposed system for monitoring foodstuffs are low cost, small size, flexibility, rapid system expansion, real-time access, and automatic cargo identification [12].

- 3-.

Integrated module: The design of modular hardware and software based on a standard protocol will enable a greater degree of reuse and customization for the end-user [6].

- 4-.

Blockchain IoT: Integration of flows in the supply chain (supply chain level) should also be covered by the blockchain–IoT to create a reliable and secure supply chain in both virtual and physical worlds [13, 14].

- 5-.

Consider security: A significant and widespread challenge of IoT is the security problem. Most search papers did not mention this issue. The agro-food sector needs to apply IoT solutions to address end-to-end information security and the physical integrity of field devices [99]. As digital transformation in food processing increases, so does vulnerability to cyber threats such as data breaches and system disruptions, which can compromise production continuity and consumer trust. Alqudhaibi et al. [100] emphasize that the food industry lacks robust cybersecurity defenses and propose a specialized security framework tailored to its needs. This includes proactive risk mitigation, employee training, and continuous system monitoring to prevent cyberattacks. Therefore, integrating comprehensive cybersecurity protocols early in IoT system design is essential for building resilient and trustworthy digital food infrastructures.

- 6-.

Automation control: Automation is a process that is accomplished with decreased human intervention. Advancements in IoT-connected sensors, actuators, platforms, software programs, structures, apps, and connectivity are the primary elements considered. Food companies and distributors often operate within slender margins and superior standards. Despite this, it still has not reached its full potential.

- 7-.

Interoperability: One of the critical challenges in deploying IoT systems across the food supply chain is the lack of interoperability between devices, platforms, and communication protocols. This leads to fragmented systems that hinder data sharing and scalability. For example, in cold chain monitoring, different vendors often use proprietary data formats and standards, which obstruct integration and seamless communication across the supply chain. The Agri-SCM-BIoT architecture proposed by Bhat et al. [101] addresses these concerns by highlighting the need for crosschain interoperability, optimized storage, and privacy-aware blockchain infrastructure to support scalable and secure IoT-based food systems. Developing such interoperable and resource-efficient systems is essential for effective and trustworthy food supply chain management.

4.4. Integration of IoT With Other Emerging Technologies

The integration of IoT with other emerging technologies, such as artificial intelligence (AI), Big Data analytics, blockchain, and miniature spectral imaging cameras, significantly enhances the effectiveness and versatility of applications within food processing and related fields. For example, blockchain technology, when combined with IoT, ensures greater transparency, traceability, and trustworthiness across the food supply chain, particularly useful during pathogen outbreaks for rapid traceability and food safety assurance [102]. Additionally, AI and Big Data analytics amplify the capability of IoT systems by analyzing large volumes of data collected through IoT sensors. These insights can lead to improved decision-making, more efficient resource utilization, and enhanced productivity, thereby contributing positively to economic, environmental, and social outcomes [102]. Miniature spectral cameras linked with IoT technology have further revolutionized food quality assessments, making real-time authenticity checks feasible at the consumer level. Overall, combining IoT with these complementary technologies represents a critical advancement towards creating a more efficient, sustainable, and resilient food industry ecosystem.

5. Conclusion

In this paper, we conducted a literature review on IoT solutions in food processing and related fields. The reviews were performed on papers documented in two library searches (IEEE and Science Direct), three engine searches (Scopus, Google Scholar, and Web of Science), and one network site (ResearchGate) selected with the phrases “Food” and “Internet of Things” inclusively in the title of papers published in peer-reviewed conferences and journals between the inclusive years of 2011–2024. This comprehensive process resulted in the inclusion of approximately 116 papers published from 2012 to 2024, ensuring broad geographic representation and credible, up-to-date academic sources. The relevant articles were analyzed using the SLR procedure to investigate the relationships in terms of the origin of continents and countries of publication, subject of work, IoT implementation from the standpoint of monitoring variables, communication networks, and findings of innovative work.

This study demonstrated that IoT in the food sector started in 2008 and accelerated in the last 2 years. The mainland of Asia has the most commitment, with over 71%, Europe has 22%, North America under 4%, and Africa and Oceania under 3% and 2%, respectively, with the least commitment. Oceania contributed only one paper, while South America did not have any contribution. China is the leading country in publishing papers, mostly in their universities, and India is second among the Asian nations. The majority of the research papers focused on proposed IoT architectures in food processing with the subdomains of food safety and quality, traceability, supply chain, packaging, storage, waste, contamination, and growth. The output of the papers cannot be relied upon unless it is implemented in manufacturing companies. We could indeed observe a functional need and necessity of a proper architecture framework. To support future work in the food sector, we have proposed an IoT architecture comprising three layers. This structure is designed to address the majority of requirements for IoT applications in smart agriculture and food-related fields.

For future research, several areas are recommended. First, a well-defined standard protocol for communication technologies in IoT-enabled food systems should be developed to enhance integration, compatibility, and scalability across devices and platforms. Second, the exploration of novel IoT-enabled technologies such as edge computing, digital twins, and sensor fusion are encouraged to support real-time analysis, automation, and decision-making in food processing environments. Lastly, more practical studies are required to evaluate the deployment and performance of proposed IoT frameworks in real-world manufacturing and supply chain operations, thereby bridging the gap between theoretical contributions and industrial implementation. In addition, a comparative analysis of existing IoT solutions in terms of efficiency, cost-effectiveness, and ease of implementation is still lacking in the literature and should be prioritized in future research to support more informed decision-making in the food sector. Moreover, industry adoption of IoT can be strengthened by developing scalable pilot programs, improving workforce training in digital technologies, and establishing regulatory guidelines for data security and interoperability. Open challenges such as infrastructure limitations, standardization gaps, and ensuring return on investment should be central themes in future research and collaboration between academia and industry.

Disclosure

The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

No funding was received for this manuscript.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.