Ni-Based Coordination Polymer as a Promising Anode Material for Potassium Batteries

Olga A. Kraevaya

Center for Energy Science and Technology, Skolkovo Institute of Science and Technology, Nobel str. 3, Moscow, 143026 Russia

Department of Kinetics and Catalysis, Institute for Problems of Chemical Physics RAS, Acad. Semenov str. 1, Chernogolovka, 142432 Russia

Search for more papers by this authorElena V. Shchurik

Department of Kinetics and Catalysis, Institute for Problems of Chemical Physics RAS, Acad. Semenov str. 1, Chernogolovka, 142432 Russia

Search for more papers by this authorCorresponding Author

Pavel A. Troshin

Center for Energy Science and Technology, Skolkovo Institute of Science and Technology, Nobel str. 3, Moscow, 143026 Russia

Department of Kinetics and Catalysis, Institute for Problems of Chemical Physics RAS, Acad. Semenov str. 1, Chernogolovka, 142432 Russia

Search for more papers by this authorOlga A. Kraevaya

Center for Energy Science and Technology, Skolkovo Institute of Science and Technology, Nobel str. 3, Moscow, 143026 Russia

Department of Kinetics and Catalysis, Institute for Problems of Chemical Physics RAS, Acad. Semenov str. 1, Chernogolovka, 142432 Russia

Search for more papers by this authorElena V. Shchurik

Department of Kinetics and Catalysis, Institute for Problems of Chemical Physics RAS, Acad. Semenov str. 1, Chernogolovka, 142432 Russia

Search for more papers by this authorCorresponding Author

Pavel A. Troshin

Center for Energy Science and Technology, Skolkovo Institute of Science and Technology, Nobel str. 3, Moscow, 143026 Russia

Department of Kinetics and Catalysis, Institute for Problems of Chemical Physics RAS, Acad. Semenov str. 1, Chernogolovka, 142432 Russia

Search for more papers by this authorAbstract

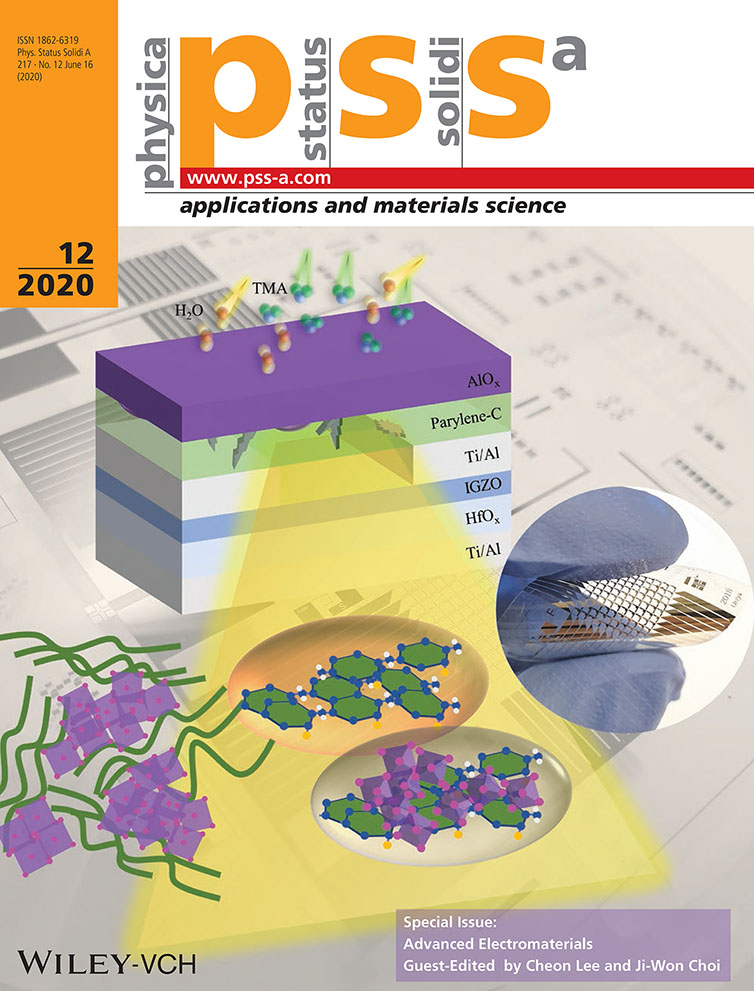

Ni-based coordination polymer derived from 3,3′-diaminobenzidine (Ni-DAB) is reported as a stable potassium battery anode working in the safe voltage window of 0.4–2.0 V versus K+/K. At a low current density of 50 mA g−1, specific discharge capacity of 183 mA h g−1 is reached. Capacity of 158 mA h g−1 is obtained at 1 A g−1, whereas capacity decay is only 0.014% per cycle over 600 cycles, which is among the best cycling stability results reported for electrode materials used in potassium batteries.

Conflict of Interest

The authors declare no conflict of interest.

Supporting Information

| Filename | Description |

|---|---|

| pssa201901050-sup-0001-SuppData-S1.docx1.2 MB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1a) B. Dunn, H. Kamath, J.-M. Tarascon, Science 2011, 334, 928; b) Y.-S. Xu, S.-Y. Duan, Y.-G. Sun, D.-S. Bin, X.-S. Tao, D. Zhang, Y. Liu, A.-M. Cao, L.-J. Wan, J. Mater. Chem. A 2019, 7, 4334.

- 2W. Zhang, Y. Liu, Z. Guo, Sci. Adv. 2019, 5, eaav7412.

- 3J. Zhao, X. Zou, Y. Zhu, Y. Xu, C. Wang, Adv. Funct. Mater. 2016, 26, 8103.

- 4Y. Xu, C. Zhang, M. Zhou, Q. Fu, C. Zhao, M. Wu, Y. Lei, Nat. Commun. 2018, 9, 1720.

- 5a) K. Xie, K. Yuan, X. Li, W. Lu, C. Shen, C. Liang, R. Vajtai, P. Ajayan, B. Wei, Small 2017, 13, 1701471; b) J. Zhou, L. Wang, M. Yang, J. Wu, F. Chen, W. Huang, N. Han, H. Ye, F. Zhao, Y. Li, Adv. Mater. 2017, 29, 1702061; c) C. Yang, J. Feng, F. Lv, J. Zhou, C. Lin, K. Wang, Y. Zhang, Y. Yang, W. Wang, J. Li, Adv. Mater. 2018, 30, 1800036.

- 6a) J. Huang, X. Lin, H. Tan, B. Zhang, Adv. Energy Mater 2018, 8, 1703496; b) K. Lei, C. Wang, L. Liu, Y. Luo, C. Mu, F. Li, J. Chen, Angew. Chem., Int. Ed. 2018, 57, 4687.

- 7X. Wu, W. Zhao, H. Wang, X. Qi, Z. Xing, Q. Zhuang, Z. Ju, J. Power Sources 2018, 378, 460.

- 8Y. Dong, Z.-S. Wu, S. Zheng, X. Wang, J. Qin, S. Wang, X. Shi, X. Bao, ACS Nano 2017, 11, 4792.

- 9a) R. R. Kapaev, S. Olthof, I. S. Zhidkov, E. Z. Kurmaev, K. J. Stevenson, K. Meerholz, P. A. Troshin, Chem. Mater. 2019, 31, 5197;

b) Y. Chen, M. Tang, Y. Wu, X. Su, X. Li, S. Xu, S. Zhuo, J. Ma, D. Yuan, C. Wang, W. Hu, Angew. Chem., Int. Ed. 2019, 131, 14873;

10.1002/ange.201908274 Google Scholarc) R. R. Kapaev, I. S. Zhidkov, E. Z. Kurmaev, K. J. Stevenson, P. A. Troshin, Chem. Commun. 2020, 56, 1541.

- 10a) H. H. Lee, J. B. Lee, Y. Park, K. H. Park, M. S. Okyay, D.-S. Shin, S. Kim, J. Park, N. Park, B.-K. An, Y. S. Jung, H.-W. Lee, K. T. Lee, S. Y. Hong, ACS Appl. Mater. Interfaces 2018, 10, 22110; b) K. Wada, K. Sakaushi, S. Sasaki, H. Nishihara, Angew. Chem., Int. Ed. 2018, 57, 8886; c) S.-H. Kim, H. H. Lee, J.-M. Kim, S. Y. Hong, S.-Y. Lee, Energy Storage Mater. 2019, 19, 130; d) C. Li, X. Lou, M. Shen, X. Hu, Z. Guo, Y. Wang, B. Hu, Q. Chen, ACS Appl. Mater. Interfaces 2016, 8, 15352; e) X. Yin, X. Chen, W. Sun, L.-P. Lv, Y. Wang, Energy Storage Mater. 2020, 25, 846; f) Z. Liang, C. Qu, W. Guo, R. Zou, Q. Xu, Adv. Mater. 2017, 30, 1702891; g) C.-H. Chang, A.-C. Li, I. Popovs, W. Kaveevivitchai, J.-L. Chen, K.-C. Chou, T.-S. Kuo, T.-H. Chen, J. Mater. Chem. A 2019, 7, 23770; h) G. Sun, L. Yu, Y. Hu, Y. Sha, H. Rong, B. Li, H.-J. Liu, Q. Liu, Cryst. Growth Des. 2019, 19, 6503; i) J. Xie, X.-F. Cheng, X. Cao, J.-H. He, W. Guo, D.-S. Li, Z. J. Xu, Y. Huang, J.-M. Lu, Q. Zhang, Small 2019, 15, 1903188; j) Y. Sha, C. Shi, Y. Gao, H. Wen, H. Rong, H.-J. Liu, Q. Liu, Int. J. Electrochem. Sci. 2019, 14, 1658; k) Y. Wu, Y. Chen, M. Tang, S. Zhu, C. Jiang, S. Zhuo, C. Wang, Chem. Commun. 2019, 55, 10856; l) J. Du, Y. Li, H. Liu, W. Shi, L. V. Moskaleva, P. Cheng, ACS Appl. Mater. Interfaces 2019, 11, 25863.

- 11a) F. He, L. Mi, Y. Shen, X. Chen, Y. Yang, H. Mei, S. Liu, T. Mori, Y. Zhang, J. Mater. Chem. A 2017, 5, 17413; b) X.-F. Cheng, E.-B. Shi, X. Hou, J. Shu, J.-H. He, H. Li, Q.-F. Xu, N.-J. Li, D.-Y. Chen, J.-M. Lu, Adv. Electron. Mater. 2017, 1700107.

- 12J. Park, M. Lee, D. Feng, Z. Huang, A. C. Hinckley, A. Yakovenko, X. Zou, Y. Cui, Z. Bao, J. Am. Chem. Soc. 2018, 140, 10315.

- 13C. Dölle, L. A. Bindoff, C. Tzoulis, Sci Rep. 2018, 8, 1272.