In vivo formation and bioavailability of isothiocyanates from glucosinolates in broccoli as affected by processing conditions

Abstract

Scope

To study the effect of residual myrosinase (MYR) activity in differently processed broccoli on sulforaphane (SR) and iberin (IB) formation, bioavailability, and excretion in human volunteers.

Methods and results

Five different broccoli products were obtained with similar glucoraphanin (GR) and glucoiberin (GI) content, yet different MYR activity. Excretion of SR and IB conjugates in urine were determined in 15 participants after ingestion of the broccoli products. A reduction of 80% of MYR in the product did not cause differences in the total amount of SR and IB found in urine compared to the product with 100% MYR. Complete inactivation of MYR gave the lowest total amount of SR and IB in urine (10 and 19%). A residual MYR of only 2% in the product gave an intermediate amount (17 and 29%). The excretion half-lives of SR and IB conjugates were comparable for all the products (2.5 h on average), although the maximum excretion peak times were clearly shorter when the residual MYR was higher (2.3–6.1 h).

Conclusion

For the first time, the effect of residual MYR activity on isothiocyanate bioavailability was systematically and quantitatively studied. Processing conditions have a large effect on the kinetics and bioavailability of isothiocyanates from broccoli.

Abbreviations

-

- GI

-

- Glucoiberin

-

- GL

-

- Glucosinolate

-

- GR

-

- Glucoraphanin

-

- High MYR BP

-

- High MYR broccoli powder

-

- High MYR BF

-

- High MYR broccoli florets

-

- IB

-

- Iberin

-

- ITCs

-

- isothiocyanates

-

- Low MYR BF

-

- Low MYR broccoli florets

-

- Medium MYR BF

-

- Medium MYR broccoli florets

-

- MYR

-

- Myrosinase

-

- No MYR BF

-

- No MYR broccoli florets

-

- SR

-

- Sulforaphane

1 Introduction

The protective effect of vegetables against many types of cancer is known 1-3, although the mechanisms behind it are still not well understood. The seasonal nature of vegetable production has called for the use of food processing, such as drying and freezing, allowing consumers to find these vegetables on the market anytime. As a result, people often consume processed vegetables. This is the case of many types of Brassica vegetables. Among those, broccoli (Brassica oleracea var. italica) is often consumed cooked. But cooking or other processes can also reduce the occurrence of those compounds that are accountable for the healthiness of such vegetables 4.

The health-promoting effect of Brassica vegetables has been ascribed in part to glucosinolates (GLs)5. GLs are a group of secondary plant metabolites (β-thioglycoside N-hydroxysulfates linked with a sulfur β-d-glucopyranose) and depending on the side chain, GLs can be classified as aliphatic, aromatic, or indolic. GL can be hydrolyzed by myrosinase (MYR) (thioglucoside glucohydrolase, EC 3.2.3.147), an enzyme present in Brassica vegetables as well. Among the breakdown products, isothiocyanates (ITC) are accountable for the anticarcinogenic properties of Brassicaceae 6, 7. In particular glucoraphanin (GR), which is an aliphatic GL, is the precursor of sulforaphane (SR), the ITC that shows the highest potency to induce phase II detoxification enzymes in humans 7, 8.

Food processing can reduce GLs concentrations, MYR activity and in turn, ITCs formation and their intake by humans 4. During heat treatment, several mechanisms take place. In particular high temperatures cause GLs degradation and MYR inactivation 9. GLs are stable during mild cooking, but their content may be reduced by leaching into the cooking water 10. MYR is often inactivated even during mild cooking 11. As a consequence, consumed broccoli is mainly without MYR activity.

In cooked vegetables where GLs are still present and MYR is inactivated, GLs hydrolysis occurs during digestion. In fact during digestion, the GLs hydrolysis is mediated by MYR-like activity of the enteric microbiota, but to a lesser extent than in plant 12.

ITCs uptake, both as fraction formed by MYR present in the vegetable and as fraction formed by MYR-like activity of the enteric microbiota, can be assessed by measuring the ITC conjugates excreted in urine. In the human body, absorbed ITCs are conjugated to glutathione, further metabolized to ITC conjugates, and subsequently excreted in urine 12-15. Many investigations on this topic focus on ITC conjugates excreted in urine and/or blood after consumption of different forms of broccoli: (i) raw broccoli where MYR is still active, (ii) cooked broccoli where MYR is inactivated 12, 14, 16, and (iii) crushed broccoli where ITCs are already formed prior to consumption 15, 17. The main finding of these researches is that the excretion of ITC conjugates is higher when consuming raw broccoli than consuming cooked broccoli 12, 14, 16 and it is the highest when consuming a product with already formed ITC 15, 17. Besides, ITC excretion after consumption of broccoli sprouts, with active MYR, and broccoli supplement, no MYR activity, was compared 18. These studies confirmed that the ITCs excretion is higher when in subject who consumed broccoli sprouts, with active MYR, than supplements. No study investigated the influence of different MYR activity on ITC formation and uptake yet.

The aim of this study is to investigate the effect of residual MYR activity, on the ITC formation, bioavailability and excretion kinetics upon broccoli consumption in human volunteers. For this purpose, a batch of broccoli was divided into five sub-batches and each sub-batch was processed in order to obtain batches with the same GLs content but different MYR activity. These broccoli products were consumed by 15 human volunteers in a cross-over design study. GR, glucoiberin (GI), the most abundant GLs in that broccoli batch, and their ITCs, SR, and iberin (IB) were determined in the broccoli products and their excreted metabolites were measured in urine. The role of different MYR activity in the broccoli products on ITC formation, bioavailability, and excretion kinetics was determined.

2 Materials and methods

2.1 Participants

Fifteen apparently healthy human volunteers (aged 26–50 years, body mass index 21 ± 2 kg/m2, six men and nine women, 13 Caucasian, two Asian, and one Latin American), were recruited at Wageningen University. Each subject gave written informed consent after being informed about the study. The study was positively advised by an external Medical Ethical Committee and was conducted at the Food Quality and Design group at Wageningen University.

2.2 Study design

Each participant joined five sessions at 10.00 a.m. with at least 1 day of washing out in between, in a randomized cross-over trial. In every session, the participant consumed one of the five different broccoli products along with a raisin bun and ad libitum water. Participants were not fasted before the consumption of broccoli products. Participants were asked to not consume any other Brassica vegetables and condiments (mustards) during the 3 weeks of treatments.

2.3 Broccoli products

A batch of Beneforte® broccoli grown in open fields in The Netherlands, was harvested in December 2012. The batch was divided into five sub-batches. The edible florets (floret plus approximately 1 cm stalk) were separated from the stem, the florets were chopped into smaller pieces (size approximately 2 × 2 × 2 cm) and processed further as follows.

Sub-batch 1: High MYR broccoli powder (High MYR BP) product. Fresh florets were frozen overnight at −20°C and then freeze-dried. The dried florets were ground to a fine powder using a Waring blender (model 34BL99, Dynamics Corp. of America, New Hartford, CT, USA).

Sub-batch 2: High MYR broccoli florets (High MYR BF) product. Fresh florets were frozen overnight at −20°C and then freeze dried.

Sub-batch 3: Medium MYR broccoli florets (Medium MYR BF) product. Fresh florets (300 g) were heated in a microwave oven at 180 W for 8 min to partially inactivate MYR 19. After cooling down on ice, broccoli was frozen overnight at −20°C. Then frozen broccoli was subsequently freeze dried.

Sub-batch 4: Low MYR broccoli florets (Low MYR BF) product. Fresh florets (300 g) were heated in a microwave oven at 540 W for 3 min to partially inactivate MYR 19. After cooling on ice, broccoli was frozen overnight at −20°C and subsequently freeze dried.

Sub-batch 5: No MYR broccoli florets (No MYR BF) product. Fresh florets (300 g) were heated in a microwave oven at 900 W for 5 min to totally inactivate MYR 19. After cooling down on ice, broccoli was frozen overnight at −20°C. Then frozen broccoli was subsequently freeze dried.

For freeze drying, a GRInstruments instrument was used, Model GRI 20–85 MP 1996, The Netherlands. A DAEWOO microwave oven was used, Model KOC-87-T, Korea.

After freeze drying, the dried samples were stored at 4°C in sealed containers for 1 week before the intervention study. All the broccoli products consisted of intact florets except the fresh broccoli powder (sub-batch 1) product which was ground. A portion of 5 g of each broccoli product was served after 2 min rehydration with 90 mL of water at 40°C, and with 30 g of raisin bun and water ad libitum.

2.4 Urine collection

Volunteers were asked to drink sufficient water to collect urine frequently during the day. Urine samples (spot urine) were collected before consumption of each experimental rehydrated broccoli product and during 24 h after consumption. Volunteers were asked to collect at least one urine sample every 2 h, during the 10.00 a.m. (session time) and 22.00 p.m. time lapse. Urine samples were collected in separate flasks and were kept refrigerated before analysis. Analyses were performed within 24 h.

2.5 GR and GI determination

GR and GI were determined in fresh broccoli, after microwave cooking, after freeze drying and in the rehydrated broccoli products (broccoli and rehydration water). The following method described in literature 20 was used with minor modifications. Samples were ground in liquid nitrogen using a Waring blender. After grinding, broccoli samples (0.1 g of dry matter), were extracted with 3 mL hot (75°C) methanol (100%) and 200 μL of 3 mM glucotropaeolin solution (internal standard) was added. Samples were incubated in a water bath at 75°C for 25 min, and vortex mixed every 5 min. After incubation, the samples were centrifuged for 10 min at 1363 × g. The supernatant was collected in 15 mL tubes. The pellet was re-extracted twice with 2.3 mL of hot methanol (70%), centrifuged and the supernatants were combined with the first supernatant. The GLs extracts and the water from the rehydrated broccoli products were desulfated and then analyzed using HPLC according to Oerlemans et al. 21. In short, desulfoglucosinolates were separated using a Lichrospher 100 column (Merck RP-18, 5 μm) with a flow rate of 1 mL/min. The injection volume was 20 μL. Elution was performed using a gradient of water and ACN. Detection was performed with DAD detector (Spectra System UV 6000 LP) at 229 nm.

2.6 MYR determination

MYR activity was determined in fresh broccoli, after microwaving, after freeze drying and in the rehydrated broccoli products (broccoli and rehydration water). The method described in literature 22 was used with minor modifications. Samples were ground in liquid nitrogen using a Waring blender. MYR was extracted from 0.05 g dry matter using140 mL of potassium phosphate buffer (50 mM pH 7.0) by overnight stirring at 15°C. Subsequently, the extracts and the rehydration water from the rehydrated broccoli products were centrifuged at 2670 × g for 10 min and the supernatants were filtrated (folded filters Grade 595 ½—4–7 μm, Whatman) to further clean the solution. Then, MYR was concentrated using filter centrifugation tubes (Amicon Ultra-4 cut-off 30 kD, Millipore, centrifugation at 4000 g for 10 min) to remove compounds with low molecular weight (e.g. sugars and GLs). The concentrated MYR was dissolved in 0.5 mL potassium phosphate buffer (50 mM pH 7.0). MYR activity was determined according to a coupled enzymatic procedure described in literature 22, with some modification. In this assay the d-glucose formed due to the reaction between MYR and sinigrin as a substrate could be used to transform NADP+ to NADPH (d-Glucose kit, Enzyplus, Biocontrol). The reaction mixture consisted of 0.9 mL of a water solution containing 0.05 g/L of magnesium chloride and 1 g/L of ascorbic acid, 50 μL of the extracted MYR solution, 50 μL of test kit solution R1 (imidazole buffer, magnesium chloride, and sodium azide), 50 μL of test solution R2 (NADP+, ATP), 5 μL of test solution R3 (hexokinase-300 U/mL), glucose-6-phosphate dehydrogenase (400 U/mL), and 50 μL of sinigrin solution (30 mg/mL). The formation of NADPH was followed by a spectrophotometer (Cary UV 50, Bergen op Zoom, The Netherlands) at 340 nm for 7 min. The activity was determined based on the slope of the linear part of the curve of absorbance versus reaction time. To quantify MYR activity, an external calibration determined by following the same procedure for the samples analysis. In the reaction mixture 50 μL a standard MYR solution (from Sinapsis alba seeds Sigma-Aldrich, calibration solutions ranged from 0.02 to 1.2 U/mL) instead of the MYR sample extract was added. Activity was expressed as U/mg dry weight where, one unit produce 1.0 μmol glucose per min from sinigrin at pH 6.0 at 25°C.

2.7 ITC determination

The ITCs SR and IB were measured after conjugation with 1-butanethiol (method as derived from 15). To quantify the ITCs formed in the broccoli products before consumption, each product was prepared by rehydrating 5 g of dried broccoli with 90 mL of water at 40°C. After 2 min, water and broccoli were separated. The water was kept on ice and the broccoli was ground while kept frozen by liquid nitrogen to prevent MYR to hydrolyze GLs during the ITC extraction. The ITC extraction and conjugation reaction was performed in methanol buffer to inactivate the MYR to prevent any further ITCs formation during the assay. The ground frozen broccoli (1 g) was extracted with 16 mL of buffer (formic acid 0.08 M, triethylamine 15.8 M in methanol) and after centrifugation the supernatant was analyzed. Water from broccoli rehydration and from broccoli extraction (200 μL) was mixed with 20 μL phenyl ITC (20 mM, internal standard) and 800 μL of buffer. Then, 12 μL of 1-butanethiol (99%) was added to the mixture and after incubation at 50°C for 2 h, the samples were diluted with 4 mL of methanol. The n-butanethiol conjugates of SR and IB were analyzed using LC-MS/MS (TSQ Quantum, Thermo Instruments) with an XBridge RP18 column (3.0 × 100 mm, 5 μm). SR (LKT laboratories/Biomol S8040 177.29 g/mol) and IB (LKT laboratories/Biomol I0416, IB 163 26 g/mol) conjugates were prepared by incubation with n-butanethiol at 50°C for 2 h with SR and IB, and were used for quantification by external calibration.

2.8 SR and IB conjugates determination

The ITC conjugates in urine were measured using a method derived from Vermeulen et al. 15. Urine (200 μL) was mixed with 20 μL phenyl ITC (10 μM, internal standard), 800 μL of buffer (formic acid 0.08 M, triethylamine 15.8 M in methanol), and 12 μL of 1-butanethiol (99%). After 2 h incubation at 50°C the samples were diluted with 4 mL methanol. The n-butanethiol conjugates of SR and IB were analyzed using LC-MS/MS as described for ITC determination.

2.9 Statistical and pharmacokinetic analysis

The percentage of IB and SR formation upon rehydration of the broccoli products was calculated as proportion of the GI and GR, respectively, in dried broccoli. Urinary excretion curves of IB and SR conjugates (excretion rate of IB and SR conjugates versus time) were fitted to a one-compartmental model (as initial value the max excretion peak was considered) with the assumption of first-order excretion kinetics. The excretion rate constants (k) for each participant for each broccoli product, were calculated by the software package Athena Visual Workbench (www.athenavisual.com) and expressed as excretion half-life (t1/2 = 0.693/k). The excretion peak time (tmax, h) was graphically determined from the urinary IB and SR conjugates excretion rates plotted versus time. Studies in literature report that an increase in plasma concentration of ITC conjugates results in an increased excretion of ITC conjugates in urine 15, 17, 23. The apparent bioavailability was calculated as cumulative amount (μmol) of excreted SR and IB conjugates divided by the consumed GR and GI amounts (μmol), respectively 15, 17. This calculation includes both the formation step as well as the actual bioavailability and excretion step. Statistical significance of the differences among the five broccoli products with respect to the cumulative amount of SR and IB conjugates, bioavailability, t1/2 and tmax was calculated using repeated measure one-way ANOVA followed by Bonferroni test for multiple comparison.

3 Results

3.1 GR, GI, and MYR content in dry broccoli products

In order to obtain five broccoli products with different MYR activity but similar GR and GI contents, different processing conditions were applied (see Section 2). GI content in fresh broccoli was 2.2 ± 0.8 μmol/g DW and GR content was 14 ±1 μmol/g DW. After processing (microwave and/or freeze drying), GR and GI concentration in all the five broccoli products did not change (p >0.05). Before rehydration, 5 g of dried broccoli contained 10.5 ± 0.8 μmol of GI and 70 ± 2.7 μmol of GR. MYR activity in fresh broccoli (High MYR BF and High MYR BP) was 6.4±0.8 U/g DW. MYR activity of Medium MYR BF, Low MYR BF, and No MYR BF and the different processing conditions are reported in Table 1.

| Broccoli products | Microwave treatment conditions before freeze drying | MYR activity in 5 g of dried broccoli portions (Units ± SD)* | GI and GR content in 5 g of dried broccoli (μmol ± SD) | IB and SR content in rehydrated broccoli product (5 g dried broccoli and 90 mL water, μmol ± SD) | Cumulative IB and SR conjugates excreted in 24 h urine (μmol) | |||

|---|---|---|---|---|---|---|---|---|

| GI | GR | IB | SR | IB conjugates | SR conjugates | |||

| High MYR BP | None | 31 ± 4.3 | 11 ± 3.8a | 73 ± 4.6a | 10 ± 0.1 | 34.0 ± 0.8 | 8.8 ± 2.5a | 40 ± 10.4a |

| High MYR BF | None | 31 ± 4.3 | 11 ± 3.8a | 73 ± 4.6a | 6.8 ± 0.1 | 11.1 ± 0.6 | 4.6 ± 1.3b | 23 ± 8.9b |

| Medium MYR BF | 180 W, 8 min | 5.8 ± 0.7 | 10 ± 1.1a | 69 ± 6.7a | 6.2 ± 0.3 | 6.7 ± 1.9 | 3.7 ± 1.2bc | 15 ± 3.7bc |

| Low MYR BF | 540 W, 3 min | 0.5 ± 0.1 | 9.8 ± 0.3a | 67 ± 3.9a | 3.4 ± 1.8 | 2.8 ± 1.8 | 2.9 ± 0.9c | 11 ± 4.1c |

| No MYR BF | 900 W, 5 min | <0.01 | 9.2 ± 1.1a | 72 ± 4.5a | 0.2 ± 0.1 | 0.3 ± 0.2 | 1.9 ± 1.0d | 7.1 ± 2.9d |

- Different letters within a column indicate significant differences (p < 0.05).

- *MYR activity is expressed as U/mg dry weight where, one unit produce 1.0 μmol glucose per min from sinigrin at pH 6.0 at 25°C.

3.2 MYR activity and SR and IB formation in rehydrated broccoli products

In order to retain GR, GI, and MYR, mild rehydration conditions for the dried broccoli were selected. Rehydration of the broccoli products in 90 mL of water at 40°C for 2 min did not change MYR activity (p > 0.05). SR and IB content of the rehydrated broccoli products are shown in Table 1. The highest SR and IB formation, which took place during rehydration, can be seen in the High MYR BP. The High MYR BP resulted in a double IB and SR formation compared to the High MYR BF product. Besides, in all the products, the percentage of GI hydrolysis was higher than the percentage of GR hydrolysis (calculated as μmol of ITC formed in the broccoli upon rehydration, divided by the corresponding μmol of GLs occurring in the dried broccoli).

3.3 SR and IB conjugates excretion

The cumulative amounts of SR and IB conjugates excreted in 24 h urine after consumption of each rehydrated broccoli product are reported in Table 1. The higher the MYR and SR and IB formation in the rehydrated broccoli products, the higher was the cumulative amount of SR and IB conjugates in urine.

3.4 Bioavailability of SR and IB

The bioavailability of SR and IB, calculated as cumulative μmol of SR and IB conjugates excreted in 24 h urine divided by the μmol GR and GI occurring in the broccoli products, is reported in Table 2. It reflects the fraction of SR and IB formed in the rehydrated broccoli products that reaches the systemic circulation and in addition the fraction of SR and IB formed by the MYR activity of the enteric microbiota. It means that the bioavailability of SR and IB after consumption of No MYR BF, exclusively represents SR and IB formation extent by the MYR activity of the enteric microbiota. The higher the SR and IB formation in the rehydrated broccoli products, which corresponds to higher MYR activity, the higher SR and IB bioavailability. In particular the bioavailability of SR and IB after consumption of High MYR BP was higher than after consumption of No MYR BF.

| Broccoli products | Bioavailability (%) | Peak time (tmax, h ± SD) | Excretion half-life (t1/2, h ± SD) | |||

|---|---|---|---|---|---|---|

| IB | SR | IB conjugates | SR conjugates | IB conjugates | SR conjugates | |

| High MYR BP | 88 ± 24a | 58 ± 14a | 2.3 ± 0.8a | 2.3 ± 0.8a | 2.1 ± 1.0a | 1.9 ± 0.9a |

| High MYR BF | 46 ± 13b | 33 ± 12b | 3.4 ± 1.5ad | 3.1 ± 1.5ad | 2.2 ± 0.8a | 2.2 ± 0.8a |

| Medium MYR BF | 37 ± 11bc | 22 ± 4.8bc | 3.5 ± 2.0ab | 3.4 ± 2.1ab | 2.8 ± 1.4a | 2.7 ± 1.4a |

| Low MYR BF | 29 ± 8.9c | 17± 4.6c | 4.7 ± 2.3bd | 4.5 ± 2.1bd | 2.8 ± 1.4a | 3.1 ± 1.0a |

| No MYR BF | 19 ± 10d | 10 ± 3.8d | 6.1 ± 1.9b | 6.1 ± 1.9b | 2.8 ± 1.1a | 2.5 ± 0.9a |

- Different letters within a column indicate significant differences (p < 0.05).

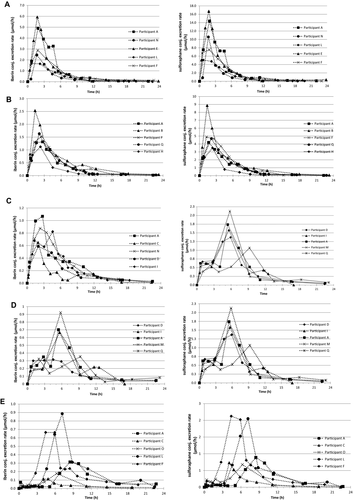

The typical kinetics of SR and IB conjugates excretion curves after consumption of the five broccoli products are shown in Fig. 1. Depending on the consumed broccoli product, five different excretion curves can be noticed. High MYR BP, High MYR BF, and Medium MYR BF curves show similar shapes with an excretion peak 3 h after consumption (Table 2 and Fig. 1). Low MYR BF and No MYR BF curves also show similar shapes but with an excretion peak 4–6 h after consumption (Table 2 and Fig. 1).

4 Discussion

4.1 GR, GI content, and MYR activity in dry broccoli products

Microwave treatments were meant to decrease MYR activity to a different extent, while retaining GLs. As expected the applied microwave treatments and the following freeze drying did not significantly change the GR and GI content in agreement with literature 20. On the contrary, MYR activity changed drastically after microwaving (Table 1). In agreement with Verkerk et al. 19, no detectable MYR activity was found in No MYR BF after microwaving at 900 W for 5 min. In our study 80% MYR activity reduction was found after microwaving at 180 W for 8 min, whereas no MYR reduction was found by microwaving red cabbage at 180 W for 12 min 19. In our study 98% MYR activity reduction was found after microwaving 540 W for 3 min, whereas 60% reduction was found after microwaving red cabbage at 540 W for 4 min 19. Apparently, MYR stability during heat treatments can be very different depending on the vegetables, vegetable chopping size, amount of cooking water, etc. and also on the heating condition 19.

4.2 MYR activity and SR and IB formation in rehydrated broccoli products

Rehydration of dried broccoli did not affect MYR activity. Suitable mild conditions were selected in order to retain MYR activity. No MYR reduction was shown also by heating broccoli at 50°C for 2 min 24. After rehydration, SR and IB were formed due to MYR activity of the samples and the highest formation was seen in High MYR BP. Despite having the same MYR activity and GI and GR initial concentration, in High MYR BP the formed IB and SR were twice the amount formed in High MYR BF. The lower SR and IB formation in the floret products as compared to the powdered broccoli can be explained by the intact structure of the florets that prevented MYR to hydrolase GR and GI during 2 min rehydration.

As expected in the floret products the higher the MYR activity, the more SR and IB were formed. The freeze drying may have partially damaged the broccoli cell structure, allowing the thus released MYR to hydrolyze GR and GI during rehydration.

Under the same rehydration conditions the percentage of GI hydrolysis was higher than the percentage of GR hydrolysis (Table 1). For instance, in the High MYR BP rehydrated broccoli product 91% of IB and 48% of SR (as proportion of the corresponding GL μmol in dried broccoli) was formed, whereas in High MYR BF, 62% of IB and 16% SR were formed. However, when the absolute amount of hydrolyzed GLs is considered (μmol SR or IB formed per time unit), the inverse behavior is observed and more SR formed compared to IB. Very little literature is available on different catalytic efficiencies of MYR. It has been reported that aliphatic GLs are hydrolyzed faster than indolic GLs 25. MYR extracted from cabbage aphid showed higher affinity for sinigrin (allyl glucosinolate) than for glucotropaeolin (benzyl glucosinolate) 26. It is very difficult to infer on the catalytic efficiency of MYR toward different GLs from the present data, because the rate of an enzymatic reaction depends on the amount of substrate and the Km of the enzyme.

4.3 SR and IB conjugates excretion

In this study, GLs and ITCs were ingested and ITC conjugates in urine reflect the hydrolysis, absorption, metabolic conversion, and excretion as also shown by 12, 14. A high SD was found in the cumulative amount of SR and IB conjugates after consumption of the five broccoli products. This variability may be due to variations related to the participants of the study by: (i) different intake of SR and IB during rehydration of broccoli products, that is, different proportion of SR and IB pre-formed in the rehydrated broccoli products ingested by participants, because of different eating time and different chewing intensity among participants. (ii) Difference in MYR-like activity of the enteric microbiota among the participants and other kind of products formed by GLs hydrolysis in the gut 27. (iii) Other metabolic paths such as the interconversion of SR into erucin 18.

The cumulative SR and IB conjugates excretion in urine was positively associated with the amount of residual MYR activity and preformed SR and IB in the rehydrated broccoli products (Table 1). The cumulative SR and IB conjugates excreted in urine was the highest after ingestion of High MYR BP and the lowest after ingestion of No MYR BF. The cumulative SR and IB conjugates excretion was lower in High MYR BF compared to High MYR BP (p < 0.05) due to the higher SR and IB preformed in the High MYR BP. These results are in line with other in vivo studies, where the excretion of ITCs is investigated in Brassica vegetables with and without MYR, in which it is shown that ITCs conjugates excretion is higher after ingestion of Brassica vegetables with active MYR or with higher ITCs 15, 16, 28. Nevertheless, in our study, after No MYR BF rehydrated broccoli product ingestion, that contained 0.2 ± 0.1 and 0.3 ± 0.2 μmol of IB and SR, 1.9 ± 1.0 and 7.1 ± 2.9 μmol of IB and SR conjugates were excreted in urine (Table 1). This ITCs formation can be ascribed to GR and GI hydrolysis catalyzed by the intestinal microbiota 15, 16, 28.

The amount of the cumulative SR conjugates excreted in urine (among the BF products) was higher than the amount of the SR preformed in the rehydrated broccoli products. This result indicates that the SR formed during chewing highly contributed to SR final bioavailability. However, regarding the IB, similar chewing contribution on the cumulative IB conjugates excreted in urine, cannot be seen. The bioavailability of IB is higher than the bioavailability of SR in all the tested products, even if IB and SR differ of only one methyl group on the side chain. Different ITCs bioavailability, between 50 and 113% (calculated as cumulative ITCs conjugated in urine divided by the ITCs found in the vegetables), was also found after ingestion of different raw Brassica vegetables containing different ITCs 17. Also the extent of GI hydrolysis, catalyzed by the MYR-like activity of enteric microbiota, was twofold higher than the GR hydrolysis extent (Table 2). Different hydrolysis intensity by the enteric microbiota, among different GLs present in one Brassica cultivar is also reported in literature 17. For instance, the hydrolysis extent (or bioavailability calculated as cumulative ITCs conjugated in urine divided by the GLs in the vegetable) of GR and sinigrin after ingesting cooked Brussels sprouts, was 5.2% ± 2.3 and 9.3% ± 5.8 17.

4.4 Bioavailability of SR and IB

The bioavailability results (Table 2) show that even if High MYR BP and High MYR BF had similar GLs and MYR, due to the different forms (powder and florets), more ITCs were formed in High MYR BP than in High MYR BF during rehydration, leading to higher ITCs intake. Regarding the broccoli florets products, the Medium MYR BF product showed similar bioavailability values than the High MYR BF product (p > 0.05), suggesting that even if MYR was reduced by 80% during processing, the ITCs bioavailability was as high as after consumption of High MYR BF (100% MYR activity). The Low MYR BF product had a significantly lower bioavailability compared to the High MYR BF, but showed significantly higher bioavailability values than the No MYR BF (p < 0.05), suggesting that even a low MYR activity may lead to a higher bioavailability that No MYR BF. All in all, the results indicate clearly that the bioavailability is highly related to MYR activity of the tested products and dependent on the broccoli product form consumed (powder versus floret).

The excretion kinetics of IB and SR appear very similar to each other after ingesting the five products (Fig. 1). The max excretion peaks of SR and IB conjugates after ingestion of No MYR BF and Low MYR BF appeared 1–3 h later than after ingestion of the rehydrated broccoli product with high IB and SR content and high MYR activity (High MYR BP, High MYR BF, and Medium MYR BF). Such different ITCs conjugates max excretion peaks appearance have been reported after consuming raw and cooked Brassica vegetables in urine and in blood 15-17. In these studies the MYR of the raw and cooked products was not analyzed, but it can be assumed that their cooking methods had completely inactivated MYR. The delay in the ITCs conjugates max excretion peaks, after consumption of cooked broccoli (inactivated MYR) can been ascribed to later dietary GLs hydrolysis that occurred in the intestinal tract catalyzed by the enteric microbiota 15, 23.

Although the max peak time is clearly associated to the MYR activity in the products, no difference in excretion half-life (t1/2, h) of ITCs conjugates among the products, was shown. It suggests that after the max excretion peaks appear, ITCs conjugates elimination was similar regardless the amount of ITC absorbed. Similar half-life ITC conjugates excretion were found after ingesting of many Brassica vegetables and no difference was found between raw and cooked Brassica 15, 17.

The high interindividual variations of the pharmacokinetics data, could be due to (i) different intake of SR and IB formed during rehydration and chewing of broccoli products (ii) different MYR-like activity of the enteric microbiota and other products formed by GLs hydrolysis in the gut 27, (iii) other metabolic paths such as the interconversion of SR into erucin 18.

Although the metabolism and bioavailability of ITCs have been well studied, little is known about the effect of ITCs concentration, ITCs excretion half-life and maximum excretion peak time on ITCs anticarcinogenic efficiency. It is unclear whether a higher and sudden ITCs release in the body would have a better anticarcinogenic effect than a slower and gradual release. On one hand, the epidemiological studies that suggest the inverse association between consumption of Brassica vegetables and the risk of many types of cancer 29, 30 will be mainly based on the consumption of cooked vegetables, as they are the primary source of Brassica's in the diet, suggesting that slower and gradual release of ITCs may be enough to obtain a protective effect against cancer. On the other hand, it is not known if a higher and sudden ITCs release, resulting from raw and semiraw Brassica vegetables consumption, in the body may be beneficial for the protective effect of Brassica consumption towards cancer. A study suggests that temporary or continuous exposure of human colon carcinoma cells to SR may have a different inhibition effect on these cells cycle 31. Further studies are needed to clarify the cell cycle arrest mechanism caused by SR, related to the kinetics of ITC bioavailability upon Brassica vegetables consumption.

The bioformation, bioavailability, and excretion kinetics after consumption of differently microwaved and then freeze-dried and rehydrated broccoli products with the same GLs content and different MYR activity, were systematically investigated. For the first time it was shown that the occurrence of a residual, although low, MYR activity led to a significantly higher ITCs bioavailability than after consumption of broccoli with no residual MYR activity. The bioavailability of ITCs after consuming broccoli, where MYR was reduced by 80% (due to microwave treatment), was not significantly different from consuming minimally processed broccoli with 100% MYR activity. This is a very interesting result because broccoli is recommended to be cooked before consumption, as it contains irritants that can cause bloating, gas and abdominal cramping 32. Moreover, the bioavailability of ITCs after consuming powdered minimally processed broccoli (100% MYR activity) was higher than after consuming minimally processed broccoli florets (100% MYR activity), due to higher ITCs formation in powdered broccoli.

This finding shows that to enhance ITC uptake, from broccoli-based dried products, a powdering process after drying is advisable to obtain a product that lead to high ITCs uptake. Data from literature show that food processing can reduces or increase the bioavailability of healthy compounds of vegetables 33, the healthiness of vegetable consumption, but the use of controlled processing to achieve products with specific characteristics, having specific health effect, would be beneficial for consumers. This study suggests that food processes can be designed to produce products with specific bioactive compounds profiles.

Acknowledgment

We thank Xandra Bakker and Frans Lettink for helping in the execution of the experiments. This work is supported by the Energy Research Program EOS of the Dutch Ministry of Economics under Project EOSLTe7043.

The authors have declared no conflict of interest.