Novel mechanical vapor recompression-assisted evaporation process for improving energy efficiency in pulp and paper industry

Yurim Kim and Jonghun Lim contributed equally to this work as first authors.

Funding information: Korea Institute of Industrial Technology, Grant/Award Numbers: IZ-21-0052, IR-21-0029, EM-21-0022, JH-21-0006

Summary

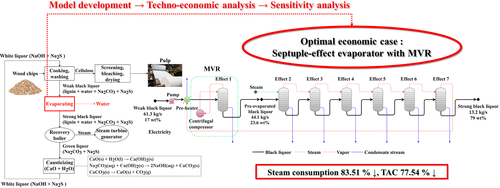

In the pulp and paper industry, black liquor, which is a biomass resource, is burned to produce electricity. Black liquor is concentrated to 21 wt% water through an evaporator before being burned in a boiler. For the evaporator, a multiple-effect evaporator (MEE) is mainly used, but it requires a large amount of energy and cost. Therefore, it is crucial to reduce energy and cost of evaporation process. Hence, this study suggested a novel process model that integrated mechanical vapor recompression (MVR) with MEE to increase the energy efficiency. The suggested MVR-assisted evaporation process was composed of preheating and evaporation processes to effectively concentrate black liquor. In addition, it reduced the steam consumption of MEE by using MVR, which uses relatively inexpensive electric energy in the pre-evaporation process. In the simulation results, the steam, electricity consumption, and the latent heat recovered from the secondary vapor of the suggested process were quantitatively analyzed to verify the energy efficiency. The results indicate that the proposed process increases substantial energy efficiency compared to the conventional process. Then, the appropriateness of the suggested process was evaluated by the techno-economic analysis. The total annualized cost (TAC) is determined for both current and potential future economic benefits. TAC of the MVR-assisted MEE configuration can be reduced by up to 77.54%.

1 INTRODUCTION

The pulp and paper industry uses large amounts of chemical additives and industrial energy to pulp wood.1 Through the kraft pulping process, most pulp and paper plants recover the chemicals needed for the process and the heat generated during the operation.2 In the kraft pulping process, wood chips, which are the main raw material, are pulped by dissolving lignin by white liquor.3, 4 White liquor is an aqueous solution of Na2S and NaOH.5, 6 The used chemicals become weak black liquor (WBL) through the cooking and washing process.7 In this process, black liquor is composed of water and organic and inorganic solid components. The representative organic component is lignin, whereas the representative inorganic components are Na2CO3, Na2S, and NaOH. WBL is about 80 to 85 wt% water, and it is concentrated to strong black liquor (SBL) with about 21 wt% water through the evaporation process. After it has been concentrated, it is burned in a recovery boiler to provide the energy necessary for the pulping process. The energy used in the black liquor evaporation process takes up about 25% to 30% of the total energy needed in the kraft pulping process, and this causes a big problem in the cost of operation.8, 9

To save energy, a multiple-effect evaporator (MEE) is mostly used to increase the concentration of WBL.10 MEE reduces steam consumption of the evaporation process by reusing the heat of secondary steam emitted from the evaporators which are arranged in series under different conditions as a heat source.11-14 Recently, there has been active research undertaken to reduce the steam that is consumed during the black liquor evaporation process by controlling the condition of MEE. Jaishree et al conducted a study to determine the optimal pressure condition of the septuple-effect evaporator and the optimal condition of the flash tank to be additionally installed to minimize the steam consumption in the black liquor evaporation process through mathematical modeling. The results of the study showed that installing seven additional flash tanks reduced 5.77% of steam consumption compared to the conventional evaporation process.15 Verma et al mathematically modeled the black liquor evaporation process and found the optimum point of preheating conditions for WBL, the degree of splitting of the black liquor, and external steam entering the first and second effects. After finding the optimal point, the steam used in the conventional septuple-effect evaporator was decreased by 11.6%.16 Bhargava et al mathematically modeled the condition for the optimal feed flow of black liquor and steam in the septuple-effect evaporator to minimize the steam used in black liquor concentration. The model could further reduce the steam consumed in the evaporation process by supplying black liquor and steam in reverse directions.17

Despite many contributions to reduce the steam consumption of the black liquor evaporation process by changing the conditions of MEE, a severe challenge remain to be solved. The problem to be solved is the limits on the amount of vapor that can be reduced in the evaporation process. The total amount of secondary vapor produced in the evaporation process remains the same because the quantity of water evaporated is fixed when WBL of 85 wt% water is concentrated to SBL of 21 wt% water. As such, the energy that can be recovered in the secondary vapor is limited, and thus the amount of steam consumption that can be reduced in the evaporation process is limited to only changing the MEE conditions.

To deal with this problem, vapor recompression systems are proposed as a technology that can further reduce the energy consumption of MEEs. Vapor recompression systems reduce the energy consumption of the evaporation process by compressing the secondary vapor exiting the evaporator to increase the temperature and pressure, and then reusing it as a heat source for the evaporator. Vapor recompression systems include thermal vapor recompression and mechanical vapor recompression (MVR), and these two systems differ in their vapor compression method. Thermal vapor recompression is a system that compresses secondary vapor using the kinetic energy of a jet of steam generated by a steam jet ejector, and MVR is a system that mechanically compresses secondary vapor using a centrifugal compressor. Among these two compression methods, MVR, which has a compression method that is not affected by the high viscosity of black liquor, is preferred as a solution that can reduce the energy consumption of the black liquor evaporation process.18 The MVR can reduce steam consumption by substituting a part of the steam consumed in the evaporation process with electricity.19-21 However, MVR is disadvantageous regarding the overall equipment cost due to the high price of the centrifugal compressor.

This study suggests a novel process model that integrates MVR and MEE to increase the energy efficiency of the black liquor evaporation process. The aim of this work is to minimize the cost of the evaporation process by increasing energy efficiency. Figure 1 shows the overview of optimization of the evaporation process in the pulp and paper industry.22, 23 First, process models using single-effect evaporator (SEE), MEE, MVR-assisted SEE, and MVR-assisted MEE were developed to predict the energy consumption of the evaporation process, and the simulation result was comparatively analyzed to verify the energy efficiency of the suggested MVR-assisted MEE (Section 2). Second, the economic evaluation was conducted to derive optimal economic MVR-assisted MEE configuration (Section 3). Finally, a sensitivity analysis was conducted to examine the effect of the main economic parameters on the optimal economic MVR-assisted MEE configuration (Section 4).

- This study suggests a novel MVR-assisted evaporation process for improving energy efficiency, and the effectiveness of the proposed process was proved by applying it to the commercial pulp and paper industry.

- All possible process models are developed for SEE, MEE, MVR-assisted SEE, and MVR-assisted MEE. Steam, electricity consumption, and recovered heat were analyzed to verify the energy efficiency of the suggested MVR-assisted MEE process.

- The reliable cost optimal MVR-assisted MEE process is proposed through techno-economic analysis and sensitivity analysis, and the suggested process will have significant economic and environmental improvement because it uses less energy and cost than the conventional evaporation process.

2 MODEL DEVELOPMENT

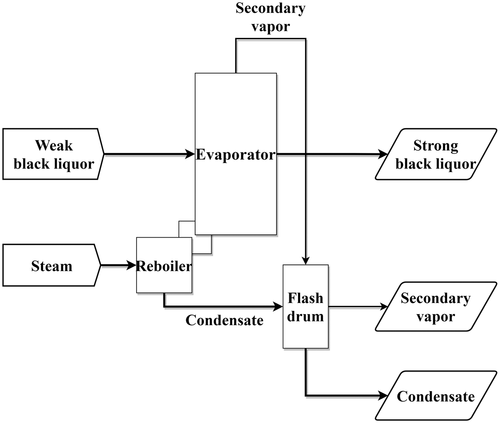

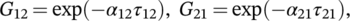

This study used Aspen Plus V11.0 to model the evaporation process and developed the process model using commercial plant data as a reference. As shown in Figure 2, the evaporator was divided into a distillation column (EVAP), virtual reboiler (REB), and flash drum (FD) in the process modeling. The virtual reboiler was added to predict the steam consumption of the distillation column in the modeling. The heat calculated in the virtual reboiler and the heat used in the distillation column were set to be equal to predict the steam consumption. A detailed description is given in Appendix S1.17, 24

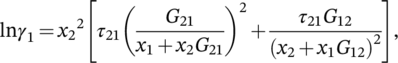

2.1 Assumptions and thermodynamics model

- The process was steady state.

- The temperature differences of the secondary vapor emitted from each effect are constant.25

- Each evaporator has nine stages.

- Black liquor enters the evaporator at room temperature and 7 kg/cm2g pressure.

- The pressure drop of the condenser within the evaporator and the pressure drop between the stages are 1 psia and 0.1 psi, respectively.

- In the centrifugal compressor, the secondary vapor is isentropically compressed.26

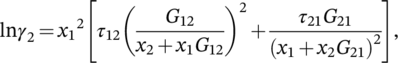

(1)

(1) (2)

(2) (3)

(3) (4)

(4) Activity coefficient of species i in a mixture.

Activity coefficient of species i in a mixture.

Mole fraction of i component of a mixture in the liquid phase.

Mole fraction of i component of a mixture in the liquid phase.

Binary interaction parameter in the NRTL model.

Binary interaction parameter in the NRTL model.

NRTL liquid activity model parameter.

NRTL liquid activity model parameter.

Nonrandomness factor in the mixture.

Nonrandomness factor in the mixture.

The energy interaction between i and j molecules.

The energy interaction between i and j molecules.

The universal gas constant in cal K-1 mol-1.

The universal gas constant in cal K-1 mol-1.

The mixture temperature in K.

The mixture temperature in K.

The NRTL equation is derived by considering the concepts of partial dissolution and complete dissolution, and if  that considers the properties of the system and corrects the nonrandomness of the mixture is appropriately selected, it can be used for nonideal mixtures and partial mixtures.27, 28

that considers the properties of the system and corrects the nonrandomness of the mixture is appropriately selected, it can be used for nonideal mixtures and partial mixtures.27, 28

2.2 Process modeling

In this study, the evaporation process concentrates the WBL with 83 wt% water entered in at 61.3 kg/s into SBL with 21 wt% water. Thus, 21 wt% water of SBL is exited the evaporation process at 13.2 kg/s.

2.2.1 Multiple-effect evaporator

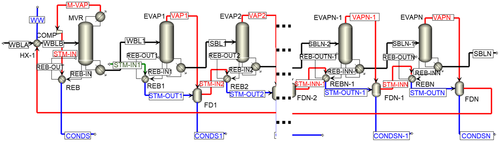

Figure 3 shows the process model of the MEE. The whole black liquor evaporation process model is composed of black liquor preheating and evaporation processes. First, during the evaporation process, the effects are arranged in a way in which pressure is gradually reduced in MEE, so that the secondary vapor produced in the previous effect is reused as the heat source of the next effect.12, 26 The latent heat of the steam entered the first effect of the MEE is used to evaporate the black liquor, and the steam that becomes condensate water is dumped. Next, in the black liquor preheating process, the secondary vapor emitted from the final effect (EVAPN) preheats the black liquor and reduces the amount of steam required for MEE. WBL goes through a MEE and is concentrated to SBL. A detailed description is given in Appendix S1.

2.2.2 Mechanical vapor recompression-assisted single-effect evaporator

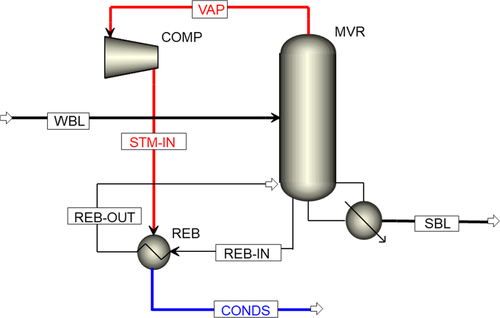

Figure 4 shows the process model of the MVR-assisted SEE. An MVR-assisted SEE uses only the secondary vapor compressed through the centrifugal compressor to concentrate the black liquor, so it uses only electricity as its energy source. In this model, the heat of the compressed secondary vapor is set to be the same as the heat required for the evaporator to predict the electricity consumption in the centrifugal compressor. A detailed description is given in Appendix S1.

2.2.3 Mechanical vapor recompression-assisted multiple-effect evaporator

Figure 5 shows the process model of the MVR-assisted multiple-effect evaporator (MEE). In the MVR-assisted MEE, WBL gets pre-evaporated to 76.4 wt% water due to the first effect using MVR (MVR), and then it gets concentrated into SBL through a series of effects. As such, MVR-assisted MEE uses electricity and steam as energy sources. It uses less steam than MEE and less electricity than MVR-assisted SEE. A detailed description is given in Appendix S1.

2.3 Simulation results

After dividing the results from the developed models according to the presence of MVR, the analysis further divided the results into the steam consumption of the total evaporation process according to the number of effects, electricity consumption, latent heat recovery amount of secondary vapor, and secondary vapor production quantity of each effect. Following the analysis, the energy efficiency of the MVR-assisted MEE was examined.

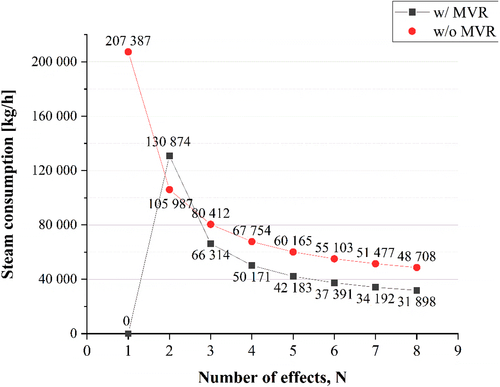

2.3.1 Steam consumption according to the number of evaporators

Figure 6 shows the predicted steam consumption of the developed black liquor evaporation models according to the presence of MVR and the number of effects. First, when MVR is not used, the total amount of steam consumed in the entire evaporation process, as shown in Figure 6, is 207 387 kg/h for an SEE and 48 707 kg/h for an octuple-effect evaporator, showing that the increase in the number of effects led to a decrease in the consumption of steam. This is because as the number of effects increases, the re-usage of the secondary vapor that is produced in the process of concentrating black liquor in the previous effect as the heat source for the next effect increases, and as such, the heat of the secondary vapor produced can be more efficiently used. Next, in the cases of using MVR, an MVR-assisted SEE uses only electricity in the process of concentrating black liquor, and thus, steam is not consumed in the overall evaporation process. When using an MVR-assisted MEE to concentrate black liquor, it uses both electricity and steam as the heat source for the entire evaporation process, and thus, less steam is used compared to the cases of not using MVR. However, this trend is not observed only when the number of effects is two because the heat of the recovered secondary steam is less when the MVR is used only when the number of effects is two. Furthermore, when MVR is used, except for MVR-assisted SEE, the quantity of steam consumed through the entire evaporation process decreases as the number of effects increases. The consumed steam is 130 874 kg/h with two effects, 66 314 kg/h with three effects, and 31 898 kg/h with eight effects.

2.3.2 The amount of steam produced by each evaporator according to the number of evaporators

The quantity of secondary vapor (Vn) that emitted from each effect in the developed evaporation models according to the presence of MVR and number of effects is shown in Tables 1 and 2. First, when MVR is not used, the increase in the number of effects led to a decrease in the quantity of secondary vapor that emitted from each effect as shown in Table 1. This is because the quantity of water that evaporates from black liquor in each effect decreases as the number of effects increases. Next, in the case of using MVR, the quantity of secondary vapor emitted from each effect also decreased as the number of effects increased. In particular, for MVR-assisted MEE models with more than three effects, the quantity of secondary vapor emitted from each effect from the second effect onwards was less than the models that did not use MVR. This is because when MVR is used, black liquor is first concentrated using MVR, and then the remaining effects are used to concentrate black liquor. As such, the quantity of water that the remaining effects have to evaporate decreases. At this time, black liquor is concentrated to 76.4 wt% water in MVR in commercial plants, and as such, the quantity of secondary vapor emitted from the first effect that uses MVR is constant at 61854 kg/h.

| Number of effects, N | nth effect, n | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Preheater |

|

|

| 1 | - | - | - | - | - | - | - | - | 17 127 | 17 127 |

| 2 | - | 55 455 | - | - | - | - | - | - | 17 127 | 72 582 |

| 3 | - | 32 420 | 37 651 | - | - | - | - | - | 17 127 | 87 199 |

| 4 | - | 22 517 | 26 002 | 28 812 | - | - | - | - | 17 127 | 94 548 |

| 5 | - | 16 897 | 19 529 | 21 729 | 23 526 | - | - | - | 17 127 | 98 808 |

| 6 | - | 13 257 | 15 353 | 17 192 | 18 763 | 20 015 | - | - | 17 127 | 101 707 |

| 7 | - | 10 688 | 12 449 | 14 029 | 15 397 | 16 576 | 17 514 | - | 17 127 | 103 780 |

| 8 | - | 8994 | 10 273 | 11 639 | 12 875 | 13 961 | 14 876 | 15 611 | 17 127 | 105 356 |

| Number of effects, N | nth effect, n | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Preheater |

|

|

| 1 | 127 484 | - | - | - | - | - | - | - | - | 127 484 |

| 2 | 40 762 | - | - | - | - | - | - | - | 17 127 | 57 889 |

| 3 | 40 762 | - | 35 332 | - | - | - | - | - | 17 127 | 98 221 |

| 4 | 40 762 | - | 20 485 | 24 088 | - | - | - | - | 17 127 | 102 462 |

| 5 | 40 762 | - | 14 129 | 16 533 | 18 505 | - | - | - | 17 127 | 107 056 |

| 6 | 40 762 | - | 10 526 | 12 343 | 13 884 | 15 165 | - | - | 17 127 | 109 808 |

| 7 | 41 336 | - | 8195 | 9642 | 10 928 | 12 042 | 12 946 | - | 16 553 | 111 642 |

| 8 | 42 998 | - | 6549 | 7765 | 8868 | 9836 | 10 681 | 11 365 | 14 891 | 112 953 |

2.3.3 Electricity consumption according to the number of evaporators

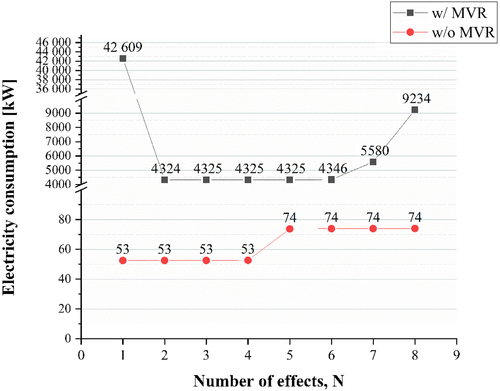

Figure 7 shows the quantity of electricity used in the developed evaporation process models according to the presence of MVR and the number of effects. In the case of MVR-assisted SEE, the energy source used to concentrate the black liquor is only electricity, and as such, the electricity consumption was greater than other cases. Because MVR-assisted MEE uses steam and electricity together as the energy source, the steam consumption was less compared to SEE and MEE while the electricity consumption was greater, and the electricity consumption was less compared to MVR-assisted SEE. From a double-effect evaporator to a sextuple-effect evaporator, black liquor is pre-evaporated in the first effect using MVR. As such, the electricity consumption used in the centrifugal compressor was the same. However, as the number of effects increased, the quantity of secondary vapor emitted from each evaporator decreased, and as such, starting with the MVR-assisted septuple-effect evaporator, the quantity of secondary vapor emitted from the last effect could not sufficiently preheat the black liquor. Therefore, the electricity consumption for concentrating black liquor of the same quantity rapidly increased starting with the MVR-assisted septuple-effect evaporator. In case of not using MVR, although the electricity consumption is much lower than when using the MVR, the electricity consumption slightly increases when the number of effects is 5 or more. This is due to the influence of the flash drum. Whenever the number of effects of MEE is increased, a flash drum is additionally installed. However, there was little difference in electricity consumption of the entire evaporation process by the number of effects, because the electricity consumption of flash drum did not have a critical effect on the entire evaporation process. However, when the number of effects crossed from 4 to 5, the electricity consumption of the flash drum exceeded the threshold of Aspen plus, so the electricity consumption was stepped up.

2.3.4 Latent heat of steam recovery according to the number of evaporators

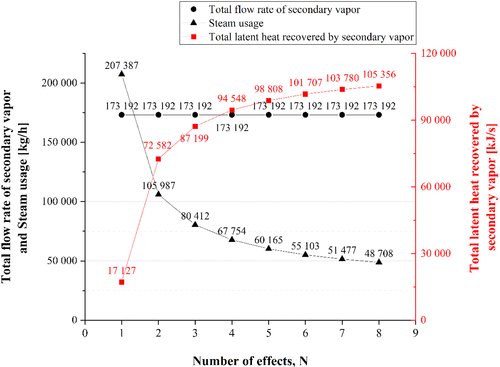

Table 3 shows the heat (Qn) of secondary vapor recovered through the developed process models according to the number of effects not using MVR. In Table 3, the total sums ( ) of the recovered secondary vapor heat in concentrating the same amount of WBL are shown to be 17 127 kJ/s with one effect, 72 582 kJ/s with two effects, and 105 356 kJ/s with eight effects. This indicates that as the number of effects increases, more heat of the secondary vapor could be recovered in the entire evaporation process.

) of the recovered secondary vapor heat in concentrating the same amount of WBL are shown to be 17 127 kJ/s with one effect, 72 582 kJ/s with two effects, and 105 356 kJ/s with eight effects. This indicates that as the number of effects increases, more heat of the secondary vapor could be recovered in the entire evaporation process.

| Number of effects, N | nth effect, n | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Preheater |

|

|

| 1 | - | - | - | - | - | - | - | - | 17 127 | 17 127 |

| 2 | - | 55 455 | - | - | - | - | - | - | 17 127 | 72 582 |

| 3 | - | 32 420 | 37 651 | - | - | - | - | - | 17 127 | 87 199 |

| 4 | - | 22 517 | 26 002 | 28 812 | - | - | - | - | 17 127 | 94 548 |

| 5 | - | 16 897 | 19 529 | 21 729 | 23 526 | - | - | - | 17 127 | 98 808 |

| 6 | - | 13 257 | 15 353 | 17 192 | 18 763 | 20 015 | - | - | 17 127 | 101 707 |

| 7 | - | 10 688 | 12 449 | 14 029 | 15 397 | 16 576 | 17 514 | - | 17 127 | 103 780 |

| 8 | - | 8994 | 10 273 | 11 639 | 12 875 | 13 961 | 14 876 | 15 611 | 17 127 | 105 356 |

Table 4 shows the latent heat of secondary vapor recovered through the developed process models according to the number of effects using MVR. When using MVR, secondary vapor is compressed using the electricity and then reused as the heat source of the first effect using MVR. As such, more energy can be recovered from the secondary vapor compared to the prior state. MVR-assisted SEE concentrates black liquor only reusing the compressed secondary vapor produced in the evaporator. Therefore, it has the greatest amount of recovered latent heat among all of the configurations. From an MVR-assisted double-effect evaporator to an MVR-assisted sextuple-effect evaporator, the same amount of water gets evaporated. As such, the amount of latent heat recovered from MVR is 40 762 kJ/s for all of them. From an MVR-assisted septuple-effect evaporator and on, the evaporators cannot be preheated as much as the MVR-assisted double-effect evaporator to sextuple-effect evaporator. As such, more electricity is required to evaporate the same quantity of water, and secondary vapor gets more compressed, which leads to more latent heat recovered from the MVR. As with MEE, the latent heat of secondary vapor that could be recovered increased as the number of effects increased, with 57 889 kJ/s at two effects, 98 221 kJ/s at three effects, and 112 953 kJ/s at eight effects.

| Number of effects, N | nth effect, n | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Preheater |

|

|

| 1 | 127 484 | - | - | - | - | - | - | - | - | 127 484 |

| 2 | 40 762 | - | - | - | - | - | - | - | 17 127 | 57 889 |

| 3 | 40 762 | - | 35 332 | - | - | - | - | - | 17 127 | 98 221 |

| 4 | 40 762 | - | 20 485 | 24 088 | - | - | - | - | 17 127 | 102 462 |

| 5 | 40 762 | - | 14 129 | 16 533 | 18 505 | - | - | - | 17 127 | 107 056 |

| 6 | 40 762 | - | 10 526 | 12 343 | 13 884 | 15 165 | - | - | 17 127 | 109 808 |

| 7 | 41 336 | - | 8195 | 9642 | 10 928 | 12 042 | 12 946 | - | 16 553 | 111 642 |

| 8 | 42 998 | - | 6549 | 7765 | 8868 | 9836 | 10 681 | 11 365 | 14 891 | 112 953 |

The total sums ( ) of the recovered secondary vapor heat were greater when using MVR than not using it, as shown in Tables 3 and 4. However, since more heat cannot be recovered when using the MVR only when the number of effects is 2, the steam consumption of the MVR-assisted double-effect-evaporator is higher than that of the double-effect evaporator, as shown in Figure 6.

) of the recovered secondary vapor heat were greater when using MVR than not using it, as shown in Tables 3 and 4. However, since more heat cannot be recovered when using the MVR only when the number of effects is 2, the steam consumption of the MVR-assisted double-effect-evaporator is higher than that of the double-effect evaporator, as shown in Figure 6.

Figures 8 and 9 show the total amount of secondary vapor produced in SEE, MEE, MVR-assisted SEE, and MVR-assisted MEE, the total amount of latent heat that could be recovered from secondary vapor, and the amount of steam consumed in the entire evaporation process, which were generated through simulations. When MVR is used or as the number of effects increased, the amount of recoverable latent heat of secondary vapor increased, whereas the amount of steam consumed in the evaporation process decreased, enabling a more efficient operation of the entire evaporation process using less energy. However, except for MVR-assisted SEE, as the number of effects increases, the increment in the latent heat recovery of the secondary vapor and the savings in steam consumption decrease. This is because the quantity of the total secondary vapor that could be evaporated from the raw material is consistent at 173 192 kg/h, and as such, the energy that could be recovered from secondary vapor is limited. As such, as the number of effects increases, the total amount of steam consumed in the entire evaporation process decreases so the cost of operation decreases, but because the cost of equipment increases due to the installation of additional effects, the number of effects is limited. Furthermore, if MVR is used to reduce the amount of steam consumed in the entire evaporation process, steam, and electricity are both used together as energy sources, leading to a decrease in the cost of operation, but because of the additional installation of a centrifugal compressor, the cost of equipment increases. As such, the process with the highest energy efficiency was determined by taking into consideration both the operation cost and the equipment cost through an economic evaluation of an MVR-assisted evaporator, and the details of the economic evaluation are explained in Section 3.

3 TECHNO-ECONOMIC ANALYSIS

To reduce the total cost used in the black liquor evaporation process, it is important to determine the most economically efficient MVR-assisted MEE configuration through an economic evaluation that takes into consideration the equipment cost and the operation cost at the same time. To determine the most economic configuration, an economic evaluation needs to be conducted by taking into consideration the number of effects and the presence of MVR, which are the main parameters of the total annualized cost (TAC). The reasons why the number of effects and the presence of MVR are the main parameters are as follows.

First, with regard to the number of effects, the amount of steam consumed in the entire evaporation process decreases as the number of effects increases, which reduces the total product cost (TPC); however, the equipment cost of the evaporator increases, which means an increase in the total capital investment (TCI), and thus a trade-off occurs between TPC and TCI. Second, with regard to the usage of MVR in the evaporation process, the TPC decreases because electricity is used rather than steam as the energy source of evaporation; however, due to the high price of the centrifugal compressor, the TCI increases, and thus a trade-off occurs between TPC and TCI. In this study, Aspen Process Economic Analyzer (APEA) was used to conduct a techno-economic analysis to determine the most economic model.

3.1 Total capital cost

Total capital cost (TCI) is the cost of the initial construction and installation of the process, and it includes not only the cost for the purchase of the land and building but also the equipment cost.29 Generally, TCI is calculated by adding up the fixed capital investment (FCI), working capital investment (WCI), and start-up cost (SUC)30 where FCI is investment cost in land, building, plant, and equipment. WCI is money required to pay for unexpected and planned expenses to build a business and meet the business's short-term duties and obligations. SUC is money required to begin a business till it yields sufficient revenue. A detailed description of each section is given in Appendix S1.31, 32

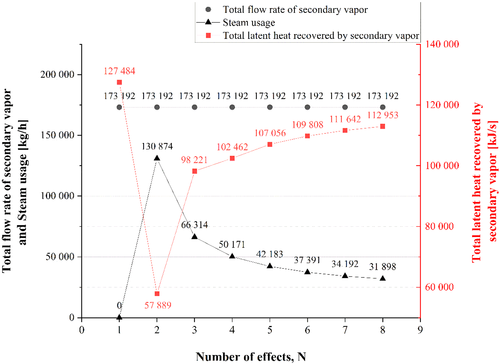

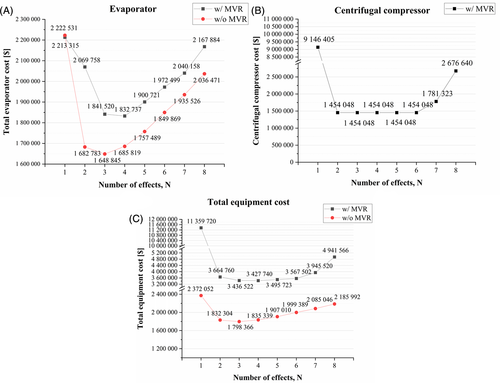

Figure 10 shows the analysis of the cost of the evaporator, centrifugal compressor, and total equipment cost to calculate the TCI. The prices of the evaporators for the developed models are shown in Figure 10A, and the evaporator cost was analyzed with respect to the presence of MVR and the number of effects. First, to examine the influence of the number of effects, SEE and MEE were separated and then analyzed. A SEE uses one effect to concentrate black liquor so an evaporator with a large capacity is necessary, and as such the equipment cost of SEE is high. For MEE, as the number of effects increases, the amount of black liquor that needs to be concentrated in each effect decreases, and thus the capacity of each effect is reduced, which leads to a decrease in the total equipment cost of the evaporator. However, the cost increases according to the number of effects after three effects in MEE and after four effects in MVR-assisted MEE, which increases the total evaporator equipment cost.

Next, MVR-assisted MEE was analyzed to examine the influence of the presence of MVR. In MVR-assisted MEE, the effect including MVR needs to pre-evaporate black liquor to consistent concentration, and as such, the capacity is fixed. The capacity of the evaporator to satisfy this requirement is large, and the first effect using MVR has a great influence on the total evaporator equipment cost of MVR-assisted MEE. Therefore, the total evaporator equipment cost further increases when using MVR due to the cost of the first effect using MVR.

Figure 10B shows the centrifugal compressor cost of SEE, MEE, MVR-assisted SEE, and MVR-assisted MEE. Because MVR-assisted SEE uses only electricity when concentrating black liquor, the centrifugal compressor cost is greater in comparison to MVR-assisted MEE. In the case of MVR-assisted MEE, which has two to six effects, the same amount of electricity is used, so the capacity of the centrifugal compressor is the same, and thus the equipment cost is also the same. However, MVR-assisted septuple and octuple-effect evaporator use more electricity than MVR-assisted double to sextuple-effect evaporator, and so the centrifugal compressor costs are higher than the other configurations.

The total equipment cost is shown as the sum of the evaporator, preheater, and the centrifugal compressor prices as determined above, and the results are shown in Figure 10C. The detailed description for calculating the preheater price is given in Appendix S1. Using MVR had a higher total equipment cost than not using MVR due to the centrifugal compressor cost. Furthermore, an increase in the number of effects led to an increase in the total equipment cost due to the increase in the equipment cost of the evaporator. As such, the analysis verified that the usage of MVR and the number of effects are the main parameters that calculate the total evaporation process cost.

Figure 11 shows the TCI of SEE, MEE, MVR-assisted SEE, and MVR-assisted MEE. A detailed description for calculating TCI is given in Appendix S1.

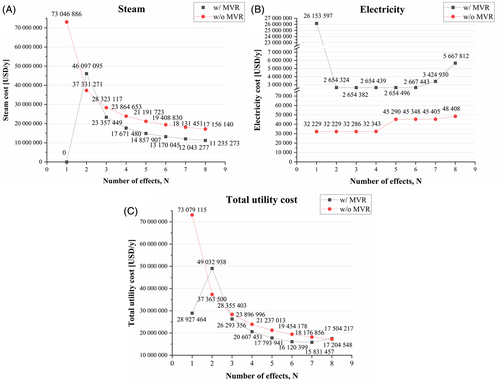

3.2 Total product cost

Total product cost (TPC) is the cost that occurs during production and service, and it includes electricity, raw materials, personnel expenses, and steam cost.29 TPC is composed of direct production cost (DPC), fixed charge (FC), and plant overhead cost (OVHD),33 where DPC is all direct production costs, including specific goods or services. FC is any expense that recurs regularly, including local taxes and insurance. OVHD is any expense incurred to support the business, including maintenance and operating labor. This study set the annual operating time as 365 days to calculate the TPC. A detailed description of each section is given in Appendix S1. Figure 12 shows the analysis of the cost of steam, electricity, and total utility cost to calculate TPC. The total utility cost is the sum of steam and electricity costs, and the results are shown in Figure 12. When not using MVR, the energy source is mostly steam, and as such, the factor that has the greatest influence on the total utility cost is steam, and as the number of effects increases, the amount of steam decreases, which led to a reduction in the total utility cost.34 When using MVR, the cost of steam is more expensive than the cost of electricity, and as such, the cost of steam makes up most of the total utility cost, showing that the total utility cost decreased as the number of effects increases. However, from MVR-assisted septuple-effect evaporator and on, the consumption of electricity rapidly increased, so from the MVR-assisted octuple-effect evaporator, the total utility cost increased as the number of effects increased.

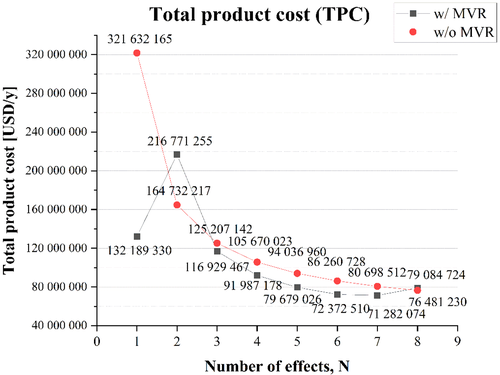

Figure 13 shows the TPC of SEE, MEE, MVR-assisted SEE, and MVR-assisted MEE. A detailed description for calculating TPC is given in Appendix S1.31

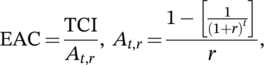

3.3 Total annualized cost

) according to Equations (5)29, 35, 36:

) according to Equations (5)29, 35, 36:

(5)

(5) is the economic depreciation, and

is the economic depreciation, and  is the duration of the project. This study assumed 5% and 30 years, respectively.31

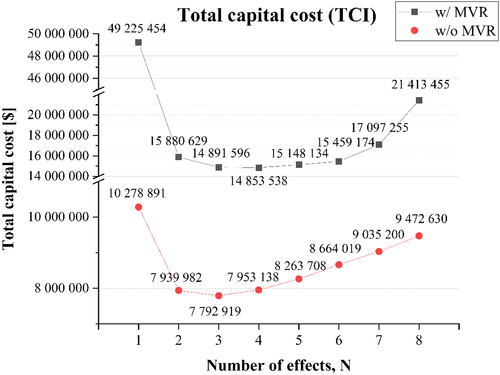

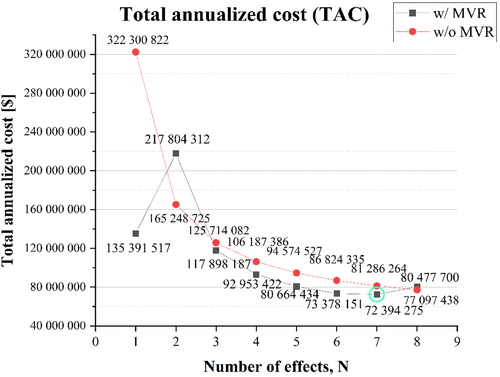

is the duration of the project. This study assumed 5% and 30 years, respectively.31Tables 5 and 6 show the values for EAC, TPC, and TAC calculated according to the presence of MVR for the developed models, whereas Figure 14 shows TAC for each configuration. When using MVR, TAC was smaller compared to the configurations not using MVR up until the septuple-effect evaporator. When using MVR, the amount of steam consumed during the entire evaporation process decreased, and as such, TPC also decreased, so TAC was smaller than when not using MVR. However, when using MVR, electricity consumption rapidly increased from when there were more than seven effects. As such, TPC and EAC also increased, and ultimately, TAC was larger than when not using MVR for when there were more than eight effects. Therefore, through the techno-economic analysis, this study determined that an MVR-assisted septuple-effect evaporator is the optimal evaporation process model because it has the lowest TAC.

| w/MVR | Number of effects, N | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| TPC | 132 189 330 | 216 771 255 | 116 929 467 | 91 987 178 | 79 679 026 | 72 372 510 | 71 282 074 | 79 084 724 |

| EAC | 3 202 186 | 1 033 058 | 968 720 | 966 244 | 985 408 | 1 005 641 | 1 112 201 | 1 392 976 |

| TAC | 135 391 517 | 217 804 312 | 117 898 187 | 92 953 422 | 80 664 434 | 73 378 151 | 72 394 275 | 80 477 700 |

| w/o MVR | Number of effects, N | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| TPC | 321 632 165 | 164 732 217 | 125 207 142 | 105 670 023 | 94 036 960 | 86 260 728 | 80 698 512 | 76 481 230 |

| EAC | 668 657 | 516 507 | 506 941 | 517 363 | 537 566 | 563 607 | 587 753 | 616 208 |

| TAC | 322 300 822 | 165 248 725 | 125 714 082 | 106 187 386 | 94 574 527 | 86 824 335 | 81 286 264 | 77 097 438 |

4 SENSITIVITY ANALYSIS

In general, to verify the stability of the results derived from the study, sensitivity analysis on the variables affecting the results is essential. Therefore, in this study, sensitivity analysis was performed to confirm the stability of the result that the MVR-assisted septuple-effect evaporator had the lowest TAC. The subcategories of TAC were analyzed to identify the variables affecting the TAC of the evaporation process. It was confirmed that TAC is composed of EAC and TPC, and the main parameters of TPC are the price of steam, electricity, and annual operating time, and the main parameter of EAC is the duration of the project. Therefore, in this section, the effect of these four major variables on TAC was confirmed.

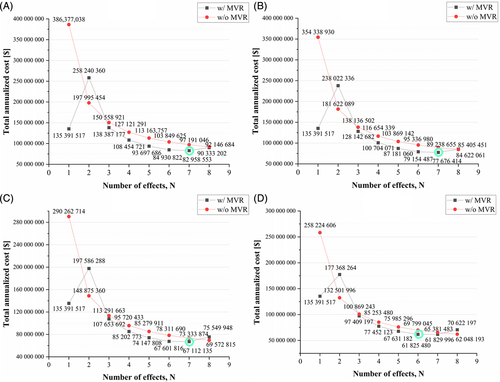

4.1 Effects of the steam price

To calculate TPC, the steam price was set as $40.21/ton using the data of commercial plants as a reference. However, the cost of steam can fluctuate according to the type of fuel used for making steam, efficiency of the boiler, water supply temperature, etc., and as such, the sensitivity of TAC was analyzed according to steam price change.37 Figure 15 shows the results of conducting the TAC sensitivity analysis by taking into consideration a 20% increase and decrease and a 10% increase and decrease of the steam price. According to 20% and 10% increase or decrease of steam price, TAC was increased or decreased by 14.6% and 7.3%, respectively. In addition, when the steam price decreased by 20%, the TAC for an MVR-assisted sextuple-effect evaporator was the lowest, but in all other cases, the TAC was the lowest for an MVR-assisted septuple-effect evaporator, the same as the existing economic evaluation. As the steam cost increased, the influence that it had on TAC increased, and as such, the process model that used less steam was found to have a lower TAC. However, as the steam cost decreased, the influence that it had on TAC decreased, while the influence of the electricity cost increased. Therefore, the model that used less steam as well as less electricity had a low TAC. As such, when the steam cost decreased, the electricity usage cost rapidly increased when the MVR-assisted MEE is 7 or more, leading to an increase in the influence that the electricity bill has on the TAC. Ultimately, the MVR-assisted sextuple-effect evaporator was found to have the lowest TAC. Thus, this analysis showed that TAC has high sensitivity with regard to a decrease in the steam price.

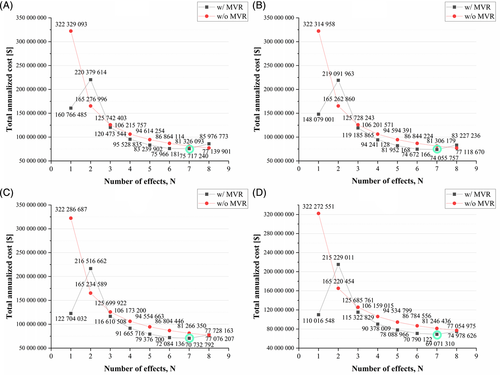

4.2 Effects of electricity fee

The electricity fee used in calculating TPC was set using APEA as a reference. The electricity fee changes every year as it takes into consideration fuel cost adjustment fee and climate and environmental costs, and as such, this study analyzed the sensitivity of TAC with respect to electricity price. Figure 16 shows the results of conducting the sensitivity analysis by taking into consideration a 20% increase and decrease and a 10% increase and decrease of the electricity price. According to 20% and 10% increase or decrease of electricity fee, TAC was increased or decreased by 4.6% and 2.3%, respectively. In addition, in all of the cases, the TAC of the MVR-assisted septuple-effect evaporator was found to be the lowest, as it had been in the existing techno-economic analysis results. This is because the electricity price is lower than the steam price, so the influence of the cost of electricity is less than the influence of the steam price, which in turn means lower sensitivity.

4.3 Effects of annual operating time

The annual operating time was set as 365 days, the same as commercial plants, to calculate TPC. However, as more and more black liquor was evaporated, scaling piles up inside the evaporator due to Na2CO3 and Na2S salts. As such, regularly scheduled scaling removal is mandatory. This means that the annual operating time can be less than 365 days due to maintenance and repairs to the process such as scaling removal. Thus, as shown in Figure 17, sensitivity analysis of TAC was conducted by changing the annual operating time to 350, 335, 320, and 305 days. As the annual operating time is reduced to 350, 335, 320, and 305 days, TAC is reduced by 3.9%, 7.9%, 11.8%, and 15.8%, respectively. The analysis results showed that TAC decreased for all cases with a decrease in the annual operating time, but even as the annual operating time decreased, the TAC of the MVR-assisted septuple-effect evaporator was the lowest, as with the existing economic evaluation results. Thus, this analysis showed that TAC has low sensitivity with regard to the change in the annual operating time.

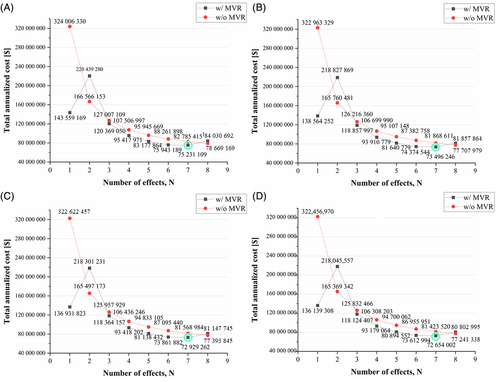

4.4 Effects of the duration of the project

The duration of the project was set as 30 years. However, since 30 years is a very long time, sensitivity analysis of the effect of the shorter duration of the project on TAC is essential. Thus, as shown in Figure 18, the sensitivity analysis of TAC was conducted by changing the duration of the project to 5, 10, 15, and 20 years. As the duration of the project is reduced to 20, 15, 10, and 5 years, TAC is reduced by 0.4%, 0.7%, 1.5%, and 3.9%, respectively. The analysis results showed that TAC decreased for all cases with increase in the duration of the project, but even as the duration of the project decreased, the TAC of the MVR-assisted septuple-effect evaporator was the lowest, as with the existing economic evaluation results. Thus, this analysis showed that TAC has low sensitivity with regard to the change in the duration of the project.

5 CONCLUSION

This study developed a process model that integrates MVR with MEE to increase the energy efficiency of the black liquor evaporation process. This article has three contributions: the development of an MVR-assisted MEE process model for black liquor evaporation that can predict the energy consumption of the evaporation process in various conditions; the simulation result analysis and comparative analysis used to verify the energy efficiency of the suggested MVR-assisted MEE; and the determination of the optimal MVR-assisted MEE model through techno-economic analysis. The proposed model can predict not only the consumption of electricity and steam, but also the amount and latent heat of secondary vapor. Therefore, by analyzing the prediction result of the model, we confirmed the energy efficiency of MVR-assisted MEE. The techno-economic analysis results showed that the TAC of an MVR-assisted septuple-effect evaporator was the lowest, while the steam consumption was reduced by 83.51% and TAC by 77.54% compared to SEE.

This study can provide a guideline for future black liquor evaporation process design because it quantitatively analyzed the energy, cost, and steam and electricity consumption after designing the black liquor evaporation process by taking into consideration both the number of effects and the usage of MVR, which has never been done before. Furthermore, the optimal configuration determined through techno-economic analysis could reduce the cost and energy, and thus, this study can contribute to economic and environmental improvement.

In this study, the distillate rate of MVR was fixed to concentrate on the influence that the usage of MVR and the number of effects have on the total cost of the black liquor evaporation process. However, as the distillate rate of MVR changes, the steam and electricity consumption level for the entire process can change, as well as the total CAPEX and OPEX, and thus, this is another main parameter. Therefore, determining the optimal distillate rate of MVR to maximize the cost and energy efficiency of the black liquor evaporation process is a necessary study to be conducted in the future.

ACKNOWLEDGEMENTS

This study has been conducted with the support of the Korea Institute of Industrial Technology as “Development of hybrid model and software to optimization of as removal system in recovery boiler for power generation (kitech JH-21-0006)” and “Development of Global Optimization System for Energy Process (kitech EM-21-0022, IR-21-0029, IZ-21-0052).”

CONFLICT OF INTEREST

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.