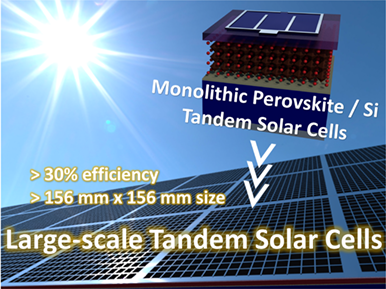

Strategy for large-scale monolithic Perovskite/Silicon tandem solar cell: A review of recent progress

Chan Ul Kim

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorEui Dae Jung

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorYoung Wook Noh

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorSeong Kuk Seo

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorYunseong Choi

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorHyesung Park

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorCorresponding Author

Myoung Hoon Song

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Correspondence

Myoung Hoon Song and Kyoung Jin Choi, Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), UNIST-gil 50, Ulsan 44919, Republic of Korea.

Email: [email protected] (M. H. S.) and [email protected] (K. J. C.)

Search for more papers by this authorCorresponding Author

Kyoung Jin Choi

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Correspondence

Myoung Hoon Song and Kyoung Jin Choi, Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), UNIST-gil 50, Ulsan 44919, Republic of Korea.

Email: [email protected] (M. H. S.) and [email protected] (K. J. C.)

Search for more papers by this authorChan Ul Kim

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorEui Dae Jung

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorYoung Wook Noh

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorSeong Kuk Seo

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorYunseong Choi

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorHyesung Park

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Search for more papers by this authorCorresponding Author

Myoung Hoon Song

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Correspondence

Myoung Hoon Song and Kyoung Jin Choi, Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), UNIST-gil 50, Ulsan 44919, Republic of Korea.

Email: [email protected] (M. H. S.) and [email protected] (K. J. C.)

Search for more papers by this authorCorresponding Author

Kyoung Jin Choi

Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Correspondence

Myoung Hoon Song and Kyoung Jin Choi, Department of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), UNIST-gil 50, Ulsan 44919, Republic of Korea.

Email: [email protected] (M. H. S.) and [email protected] (K. J. C.)

Search for more papers by this authorFunding information: KOREA East-West Power Co., LTD. (EWP), Grant/Award Number: 2.190433.01; Korea Institute of Energy Technology Evaluation and Planning, Grant/Award Numbers: 20163010012450, 20193091010460; National Research Foundation of Korea, Grant/Award Number: 2019M1A2A2072416

Abstract

For any solar cell technology to reach the final mass-production/commercialization stage, it must meet all technological, economic, and social criteria such as high efficiency, large-area scalability, long-term stability, price competitiveness, and environmental friendliness of constituent materials. Until now, various solar cell technologies have been proposed and investigated, but only crystalline silicon, CdTe, and CIGS technologies have overcome the threshold of mass-production/commercialization. Recently, a perovskite/silicon (PVK/Si) tandem solar cell technology with high efficiency of 29.1% has been reported, which exceeds the theoretical limit of single-junction solar cells as well as the efficiency of stand-alone silicon or perovskite solar cells. The International Technology Roadmap for Photovoltaics (ITRPV) predicts that silicon-based tandem solar cells will account for about 5% market share in 2029 and among various candidates, the combination of silicon and perovskite is the most likely scenario. Here, we classify and review the PVK/Si tandem solar cell technology in terms of homo- and hetero-junction silicon solar cells, the doping type of the bottom silicon cell, and the corresponding so-called normal and inverted structure of the top perovskite cell, along with mechanical and monolithic tandemization schemes. In particular, we review and discuss the recent advances in manufacturing top perovskite cells using solution and vacuum deposition technology for large-area scalability and specific issues of recombination layers and top transparent electrodes for large-area PVK/Si tandem solar cells, which are indispensable for the final commercialization of tandem solar cells.

Supporting Information

| Filename | Description |

|---|---|

| eom212084-sup-0001-supinfo.docxWord 2007 document , 94.3 KB | Table S1 2-T perovskite/Si tandem solar cell list. Table S2. 4-T Perovskite/Si tandem solar cell list. |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

REFERENCES

- 1Philipps S, Warmuth W. Photovoltaics report—Fraunhofer ISE; 2020.

- 2Saga T. Advances in crystalline silicon solar cell technology for industrial mass production. NPG Asia Mater. 2010; 2: 96-102.

- 3Qiu L, Ono LK, Qi Y. Advances and challenges to the commercialization of organic–inorganic halide perovskite solar cell technology. Mater Today Energy. 2018; 7: 169-189.

- 4Tawada Y, Yamagishi H. Mass-production of large size a-Si modules and future plan. Sol Energy Mater Sol Cells. 2001; 66: 95-105.

- 5Reichelstein S, Yorston M. The prospects for cost competitive solar PV power. Energy Policy. 2013; 55: 117-127.

- 6Zhou Y, Fuentes-Hernandez C, Khan TM, et al. Recyclable organic solar cells on cellulose nanocrystal substrates. Sci Rep. 2013; 3:1536.

- 7Fischer M, Woodhouse M, Herritsch S, et al. International Technology Roadmap for Photovoltaic (ITRPV) Result 2019 including maturity report 2020; 2020.

- 8Smith DD, Cousins P, Westerberg S, Jesus-Tabajonda RD, Aniero G, Shen YC. Toward the practical limits of silicon solar cells. IEEE J Photovolt. 2014; 4: 1465-1469.

- 9Yamaguchi M, Takamoto T, Araki K, Ekins-Daukes N. Multi-junction III–V solar cells: current status and future potential. Sol Energy. 2005; 79: 78-85.

- 10Takamoto T, Washio H, Juso H. Application of InGaP/GaAs/InGaAs triple junction solar cells to space use and concentrator photovoltaic. 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC); 2014; 0001-0005. https://doi.org/10.1109/PVSC.2014.6924936

- 11Fthenakis VM, Bowerman B. Environmental health and safety (EHS) issues in III-V solar cell manufacturing. Proceeding of 3rd World Conference on Photovoltaic Energy Conversion; 2003; Vol 1. 681-684.

- 12Jain N, Hudait MK. III–V multijunction solar cell integration with silicon: present status, challenges and future outlook. Energy Harvest Syst. 2014; 1: 121-145.

10.1515/ehs-2014-0012 Google Scholar

- 13Li K, Li Z, Feng K, Xu X, Wang L, Peng Q. Development of large band-gap conjugated copolymers for efficient regular single and tandem organic solar cells. J Am Chem Soc. 2013; 135: 13549-13557.

- 14Kwon J, Im MJ, Kim CU, et al. Two-terminal DSSC/silicon tandem solar cells exceeding 18% efficiency. Energ Environ Sci. 2016; 9: 3657-3665.

- 15Wang Z, Song Z, Yan Y, et al. Perovskite—a perfect top cell for tandem devices to break the S–Q limit. Adv Sci. 2019; 6:1801704.

10.1002/advs.201801704 Google Scholar

- 16Bailie CD, Christoforo MG, Mailoa JP, et al. Semi-transparent perovskite solar cells for tandems with silicon and CIGS. Energ Environ Sci. 2015; 8: 956-963.

- 17Meng L, Zhang Y, Wan X, et al. Organic and solution-processed tandem solar cells with 17.3% efficiency. Science. 2018; 361: 1094-1098.

- 18Al-Ashouri A, Magomedov A, Roß M, et al. Conformal monolayer contacts with lossless interfaces for perovskite single junction and monolithic tandem solar cells. Energ Environ Sci. 2019; 12: 3356-3369.

- 19Chen X, Jia Z, Chen Z, et al. Efficient and reproducible monolithic Perovskite/organic tandem solar cells with low-loss interconnecting layers. Joule. 2020; 4: 1594-1606.

- 20Lin R, Xiao K, Qin Z, et al. Monolithic all-perovskite tandem solar cells with 24.8% efficiency exploiting comproportionation to suppress Sn(II) oxidation in precursor ink. Nat Energy. 2019; 4: 864-873.

- 21Al-Ashouri A, Köhnen E, Li B, et al. Monolithic perovskite/silicon tandem solar cell with >29% efficiency by enhanced hole extraction. Science. 2020; 370: 1300-1309.

- 22Köhnen E, Jošt M, Morales-Vilches AB, et al. Highly efficient monolithic perovskite silicon tandem solar cells: analyzing the influence of current mismatch on device performance. Sustain Energy Fuels. 2019; 3: 1995-2005.

- 23Filipič M, Löper P, Niesen B, et al. CH3NH3PbI3 perovskite/silicon tandem solar cells: characterization based optical simulations. Opt Express. 2015; 23: A263-A278.

- 24Jiang Y, Almansouri I, Huang S, et al. Optical analysis of perovskite/silicon tandem solar cells. J Mater Chem C. 2016; 4: 5679-5689.

- 25Qian J, Ernst M, Wu N, Blakers A. Impact of perovskite solar cell degradation on the lifetime energy yield and economic viability of perovskite/silicon tandem modules. Sustain Energy Fuels. 2019; 3: 1439-1447.

10.1039/C9SE00143C Google Scholar

- 26Cho Y, Soufiani AM, Yun JS, et al. Mixed 3D–2D passivation treatment for mixed-cation lead mixed-halide perovskite solar cells for higher efficiency and better stability. Adv Energy Mater. 2018; 8:1703392.

- 27Bush KA, Frohna K, Prasanna R, et al. Compositional engineering for efficient wide band gap perovskites with improved stability to photoinduced phase segregation. ACS Energy Lett. 2018; 3: 428-435.

- 28Kothandaraman RK, Jiang Y, Feurer T, Tiwari AN, Fu F. Near-infrared-transparent perovskite solar cells and perovskite-based tandem photovoltaics. Small Methods. 2020; 4:2000395.

- 29Hu J, Cheng Q, Fan R, Zhou H. Recent development of organic–inorganic Perovskite-based tandem solar cells. Sol RRL. 2017; 1:1700045.

- 30Hörantner MT, Snaith HJ. Predicting and optimising the energy yield of perovskite-on-silicon tandem solar cells under real world conditions. Energ Environ Sci. 2017; 10: 1983-1993.

- 31Aydin E, De Bastiani M, Yang X, et al. Zr-doped indium oxide (IZRO) transparent electrodes for Perovskite-based tandem solar cells. Adv Funct Mater. 2019; 29:1901741.

- 32Kanda H, Shibayama N, Uzum A, et al. Effect of silicon surface for perovskite/silicon tandem solar cells: flat or textured? ACS Appl Mater Interfaces. 2018; 10: 35016-35024.

- 33Wang Z, Zhu X, Zuo S, et al. 27%-efficiency four-terminal perovskite/silicon tandem solar cells by sandwiched gold nanomesh. Adv Funct Mater. 2020; 30:1908298.

- 34Duong T, Lal N, Grant D, et al. Semitransparent perovskite solar cell with sputtered front and rear electrodes for a four-terminal tandem. IEEE J Photovolt. 2016; 6: 679-687.

- 35Ren Z, Zhou J, Ng A, et al. Record high performance of perovskite/crystalline silicon four-terminal tandem solar cells. 2016 IEEE 43rd Photovoltaic Specialist Conference (PVSC); 2016; 0816-0820. https://doi.org/10.1109/PVSC.2016.7749719.

- 36Ren Z, Zhou J, Zhang Y, et al. Strategies for high performance perovskite/crystalline silicon four-terminal tandem solar cells. Sol Energy Mater Sol Cells. 2018; 179: 36-44.

- 37Dewi HA, Wang H, Li J, et al. Highly efficient semitransparent perovskite solar cells for four terminal perovskite-silicon tandems. ACS Appl Mater Interfaces. 2019; 11: 34178-34187.

- 38Najafi M, Zardetto V, Zhang D, et al. Highly efficient and stable semi-transparent p-i-n planar perovskite solar cells by atmospheric pressure spatial atomic layer deposited ZnO. Sol RRL. 2018; 2:1800147.

- 39Ramírez Quiroz CO, Shen Y, Salvador M, et al. Balancing electrical and optical losses for efficient 4-terminal Si–perovskite solar cells with solution processed percolation electrodes. J Mater Chem A. 2018; 6: 3583-3592.

- 40Duong T, Pham H, Kho TC, et al. High efficiency perovskite-silicon tandem solar cells: effect of surface coating versus bulk incorporation of 2D perovskite. Adv Energy Mater. 2020; 10:1903553.

- 41Löper P, Moon S-J, Martín de Nicolas S, et al. Organic–inorganic halide perovskite/crystalline silicon four-terminal tandem solar cells. Phys Chem Chem Phys. 2015; 17: 1619-1629.

- 42Werner J, Dubuis G, Walter A, et al. Sputtered rear electrode with broadband transparency for perovskite solar cells. Sol Energy Mater Sol Cells. 2015; 141: 407-413.

- 43Werner J, Barraud L, Walter A, et al. Efficient near-infrared-transparent perovskite solar cells enabling direct comparison of 4-terminal and monolithic perovskite/silicon tandem cells. ACS Energy Lett. 2016; 1: 474-480.

- 44Yang M, Kim DH, Yu Y, et al. Effect of non-stoichiometric solution chemistry on improving the performance of wide-bandgap perovskite solar cells. Mater Today Energy. 2018; 7: 232-238.

- 45Zhang D, Najafi M, Zardetto V, et al. High efficiency 4-terminal perovskite/c-Si tandem cells. Sol Energy Mater Sol Cells. 2018; 188: 1-5.

- 46Jaysankar M, Filipič M, Zielinski B, et al. Perovskite–silicon tandem solar modules with optimised light harvesting. Energ Environ Sci. 2018; 11: 1489-1498.

- 47Jaysankar M, Raul BAL, Bastos J, et al. Minimizing voltage loss in wide-bandgap perovskites for tandem solar cells. ACS Energy Lett. 2019; 4: 259-264.

- 48Gharibzadeh S, Hossain IM, Fassl P, et al. 2D/3D heterostructure for semitransparent perovskite solar cells with engineered bandgap enables efficiencies exceeding 25% in four-terminal tandems with silicon and CIGS. Adv Funct Mater. 2020; 30:1909919.

- 49Rohatgi A, Zhu K, Tong J, et al. 26.7% efficient 4-terminal perovskite–silicon tandem solar cell composed of a high-performance semitransparent Perovskite cell and a doped poly-Si/SiOx passivating contact silicon cell. IEEE J Photovolt. 2020; 10: 417-422.

- 50Dewi HA, Wang H, Li J, et al. Four-terminal perovskite on silicon tandem solar cells optimal measurement schemes. Energ Technol. 2020; 8:1901267.

- 51Leijtens T, Bush KA, Prasanna R, McGehee MD. Opportunities and challenges for tandem solar cells using metal halide perovskite semiconductors. Nat Energy. 2018; 3: 828-838.

- 52Ou Q, Bao X, Zhang Y, et al. Band structure engineering in metal halide perovskite nanostructures for optoelectronic applications. Nano Mater Sci. 2019; 1: 268-287.

10.1016/j.nanoms.2019.10.004 Google Scholar

- 53Zheng J, Mehrvarz H, Liao C, et al. Large-area 23%-efficient monolithic perovskite/homojunction-silicon tandem solar cell with enhanced UV stability using Down-shifting material. ACS Energy Lett. 2019; 4: 2623-2631.

- 54Kim CU, Yu JC, Jung ED, et al. Optimization of device design for low cost and high efficiency planar monolithic perovskite/silicon tandem solar cells. Nano Energy. 2019; 60: 213-221.

- 55Bett AJ, Schulze PSC, Winkler KM, et al. Two-terminal perovskite silicon tandem solar cells with a high-bandgap Perovskite absorber enabling voltages over 1.8 V. Prog Photovolt. 2020; 28: 99-110.

- 56Mazzarella L, Lin Y-H, Kirner S, et al. Infrared light management using a nanocrystalline silicon oxide interlayer in monolithic perovskite/silicon heterojunction tandem solar cells with efficiency above 25%. Adv Energy Mater. 2019; 9:1803241.

- 57Mailoa JP, Bailie CD, Johlin EC, et al. A 2-terminal perovskite/silicon multijunction solar cell enabled by a silicon tunnel junction. Appl Phys Lett. 2015; 106:121105.

- 58Werner J, Walter A, Rucavado E, et al. Zinc tin oxide as high-temperature stable recombination layer for mesoscopic perovskite/silicon monolithic tandem solar cells. Appl Phys Lett. 2016; 109:233902.

- 59Wu Y, Yan D, Peng J, et al. Monolithic perovskite/silicon-homojunction tandem solar cell with over 22% efficiency. Energ Environ Sci. 2017; 10: 2472-2479.

- 60Zheng J, Lau CFJ, Mehrvarz H, et al. Large area efficient interface layer free monolithic perovskite/homo-junction-silicon tandem solar cell with over 20% efficiency. Energ Environ Sci. 2018; 11: 2432-2443.

- 61Zheng J, Mehrvarz H, Ma F-J, et al. 21.8% efficient monolithic perovskite/homo-junction-silicon tandem solar cell on 16 cm2. ACS Energy Lett. 2018; 3: 2299-2300.

- 62Shen H, Omelchenko ST, Jacobs DA, et al. In situ recombination junction between p-Si and TiO2 enables high-efficiency monolithic perovskite/Si tandem cells. Sci Adv. 2018; 4:eaau9711.

- 63Zhu S, Hou F, Huang W, et al. Solvent engineering to balance light absorbance and transmittance in perovskite for tandem solar cells. Sol RRL. 2018; 2:1800176.

- 64Kanda H, Uzum A, Nishino H, et al. Interface optoelectronics engineering for mechanically stacked tandem solar cells based on perovskite and silicon. ACS Appl Mater Interfaces. 2016; 8: 33553-33561.

- 65Hoye RLZ, Bush KA, Oviedo F, et al. Developing a robust recombination contact to realize monolithic perovskite tandems with industrially common p-type silicon solar cells. IEEE J Photovolt. 2018; 8: 1023-1028.

- 66Kanda H, Shibayama N, Uzum A, et al. Facile fabrication method of small-sized crystal silicon solar cells for ubiquitous applications and tandem device with perovskite solar cells. Mater Today Energy. 2018; 7: 190-198.

- 67Choi IY, Kim CU, Park W, et al. Two-terminal mechanical perovskite/silicon tandem solar cells with transparent conductive adhesives. Nano Energy. 2019; 65:104044.

- 68Werner J, Weng C-H, Walter A, et al. Efficient monolithic perovskite/silicon tandem solar cell with cell area >1 cm2. J Phys Chem Lett. 2016; 7: 161-166.

- 69Albrecht S, Saliba M, Correa Baena JP, et al. Monolithic perovskite/silicon-heterojunction tandem solar cells processed at low temperature. Energ Environ Sci. 2016; 9: 81-88.

- 70Bush KA, Palmstrom AF, Yu ZJ, et al. 23.6%-efficient monolithic perovskite/silicon tandem solar cells with improved stability. Nat Energy. 2017; 2: 17009.

- 71Fan R, Zhou N, Zhang L, et al. Toward full solution processed perovskite/Si monolithic tandem solar device with PCE exceeding 20%. Sol RRL. 2017; 1:1700149.

- 72Zhu S, Yao X, Ren Q, et al. Transparent electrode for monolithic perovskite/silicon-heterojunction two-terminal tandem solar cells. Nano Energy. 2018; 45: 280-286.

- 73Qiu Z, Xu Z, Li N, et al. Monolithic perovskite/Si tandem solar cells exceeding 22% efficiency via optimizing top cell absorber. Nano Energy. 2018; 53: 798-807.

- 74Sahli F, Kamino BA, Werner J, et al. Improved optics in monolithic perovskite/silicon tandem solar cells with a nanocrystalline silicon recombination junction. Adv Energy Mater. 2018; 8:1701609.

- 75Stannowski B, Mazzarella L, Lin Y, et al. Nanocrystalline silicon oxide interlayer in monolithic perovskite/silicon heterojunction tandem solar cells with total current density >39 mA/cm2. 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC); 2018; 2627-2630. https://doi.org/10.1109/PVSC.2018.8547825.

- 76Bush KA, Manzoor S, Frohna K, et al. Minimizing current and voltage losses to reach 25% efficient monolithic two-terminal perovskite–silicon tandem solar cells. ACS Energy Lett. 2018; 3(9): 2173-2180.

- 77Sahli F, Werner J, Kamino BA, et al. Fully textured monolithic perovskite/silicon tandem solar cells with 25.2% power conversion efficiency. Nat Mater. 2018; 17: 820-826.

- 78Jošt M, Köhnen E, Morales-Vilches AB, et al. Textured interfaces in monolithic perovskite/silicon tandem solar cells: advanced light management for improved efficiency and energy yield. Energ Environ Sci. 2018; 11: 3511-3523.

- 79Hou F, Yan L, Shi B, et al. Monolithic perovskite/silicon-heterojunction tandem solar cells with open-circuit voltage of over 1.8 V. ACS Appl Energy Mater. 2019; 2: 243-249.

- 80Hou F, Han C, Isabella O, et al. Inverted pyramidally-textured PDMS antireflective foils for perovskite/silicon tandem solar cells with flat top cell. Nano Energy. 2019; 56: 234-240.

- 81Kamino BA, Paviet-Salomon B, Moon S-J, et al. Low-temperature screen-printed metallization for the scale-up of two-terminal perovskite–silicon tandems. ACS Appl Energy Mater. 2019; 2: 3815-3821.

- 82Park IJ, Park JH, Ji SG, Park MA, Jang JH, Kim JY. A three-terminal monolithic perovskite/Si tandem solar cell characterization platform. Joule. 2019; 3: 807-818.

- 83Nogay G, Sahli F, Werner J, et al. 25.1%-efficient monolithic perovskite/silicon tandem solar cell based on a p-type monocrystalline textured silicon wafer and high-temperature Passivating contacts. ACS Energy Lett. 2019; 4: 844-845.

- 84Chen B, Yu Z, Liu K, et al. Grain engineering for perovskite/silicon monolithic tandem solar cells with efficiency of 25.4%. Joule. 2019; 3: 177-190.

- 85Hou Y, Aydin E, De Bastiani M, et al. Efficient tandem solar cells with solution-processed perovskite on textured crystalline silicon. Science. 2020; 367: 1135-1140.

- 86Xu J, Boyd CC, Yu ZJ, et al. Triple-halide wide–band gap perovskites with suppressed phase segregation for efficient tandems. Science. 2020; 367: 1097-1104.

- 87Chen B, Yu ZJ, Manzoor S, et al. Blade-coated perovskites on textured silicon for 26%-efficient monolithic Perovskite/silicon tandem solar cells. Joule. 2020; 4: 850-864.

- 88Kim D, Jung HJ, Park IJ, et al. Efficient, stable silicon tandem cells enabled by anion-engineered wide-bandgap perovskites. Science. 2020; 368: 155-160.

- 89Ahn N, Son D-Y, Jang I-H, Kang SM, Choi M, Park NG. Highly reproducible perovskite solar cells with average efficiency of 18.3% and best efficiency of 19.7% fabricated via Lewis base adduct of lead(II) iodide. J Am Chem Soc. 2015; 137: 8696-8699.

- 90Whitaker JB, Kim DH, Larson BW, et al. Scalable slot-die coating of high performance perovskite solar cells. Sustain Energy Fuels. 2018; 2: 2442-2449.

- 91Kim JH, Williams ST, Cho N, Chueh CC, Jen AKY. Enhanced environmental stability of planar heterojunction perovskite solar cells based on blade-coating. Adv Energy Mater. 2015; 5:1401229.

- 92Zuo C, Vak D, Angmo D, Ding L, Gao M. One-step roll-to-roll air processed high efficiency perovskite solar cells. Nano Energy. 2018; 46: 185-192.

- 93Cotella G, Baker J, Worsley D, et al. One-step deposition by slot-die coating of mixed lead halide perovskite for photovoltaic applications. Sol Energy Mater Sol Cells. 2017; 159: 362-369.

- 94Ulicna S, Dou B, Kim DH, et al. Scalable deposition of high-efficiency perovskite solar cells by spray-coating. ACS Appl Energy Mater. 2018; 1: 1853-1857.

- 95Park M, Cho W, Lee G, et al. Highly reproducible large-area Perovskite solar cell fabrication via continuous Megasonic spray coating of CH3NH3PbI3. Small. 2019; 15:1804005.

- 96Giacomo FD, Shanmugam S, Fledderus H, et al. Up-scalable sheet-to-sheet production of high efficiency perovskite module and solar cells on 6-in. Substrate using slot die coating. Sol Energy Mater Sol Cells. 2018; 181: 53-59.

- 97Deng Y, Van Brackle CH, Dai X, et al. Tailoring solvent coordination for high-speed, room-temperature blading of perovskite photovoltaic films. Sci Adv. 2019; 5:eaax7537.

- 98Liu M, Johnston MB, Snaith HJ. Efficient planar heterojunction perovskite solar cells by vapour deposition. Nature. 2013; 501: 395-398.

- 99Zhao D, Ke W, Grice CR, et al. Annealing-free efficient vacuum-deposited planar perovskite solar cells with evaporated fullerenes as electron-selective layers. Nano Energy. 2016; 19: 88-97.

- 100Ma Q, Huang S, Wen X, Green MA, Ho-Baillie AWY. Hole transport layer free inorganic CsPbIBr2 perovskite solar cell by dual source thermal evaporation. Adv Energy Mater. 2016; 6:1502202.

- 101Zheng Z-H, Lan H-B, Su Z-H, et al. Single source thermal evaporation of two-dimensional perovskite thin films for photovoltaic applications. Sci Rep. 2019; 9:17422.

- 102Lei T, Li F, Zhu X, et al. Flexible perovskite solar modules with functional layers fully vacuum deposited. Sol RRL. 2020; 4:2000292.

- 103Roß M, Gil-Escrig L, Al-Ashouri A, et al. Co-evaporated p-i-n perovskite solar cells beyond 20% efficiency: impact of substrate temperature and hole-transport layer. ACS Appl Mater Interfaces. 2020; 12: 39261-39272.

- 104Li J, Wang H, Chin XY, et al. Highly efficient thermally co-evaporated perovskite solar cells and mini-modules. Joule. 2020; 4: 1035-1053.

- 105Longo G, Gil-Escrig L, Degen MJ, Sessolo M, Bolink HJ. Perovskite solar cells prepared by flash evaporation. Chem Com. 2015; 51: 7376-7378.

- 106Li G, Ho JYL, Wong M, Kwok HS. Low cost, high throughput and centimeter-scale fabrication of efficient hybrid perovskite solar cells by closed space vapor transport. Phys Status Solidi RRL. 2016; 10: 153-157.

- 107Aitola K, Domanski K, Correa-Baena J-P, et al. High temperature-stable perovskite solar cell based on low-cost carbon nanotube hole contact. Adv Mater. 2017; 29:1606398.

- 108Kim Y, Jung EH, Kim G, Kim D, Kim BJ, Seo J. Sequentially fluorinated PTAA polymers for enhancing VOC of high-performance perovskite solar cells. Adv Energy Mater. 2018; 8:1801668.

- 109Zhou L, Chang J, Liu Z, et al. Enhanced planar perovskite solar cell efficiency and stability using a perovskite/PCBM heterojunction formed in one step. Nanoscale. 2018; 10: 3053-3059.

- 110Abzieher T, Moghadamzadeh S, Schackmar F, et al. Electron-beam-evaporated nickel oxide hole transport layers for perovskite-based photovoltaics. Adv Energy Mater. 2019; 9:1802995.

- 111Yang IS, Sohn MR, Sung SD, et al. Formation of pristine CuSCN layer by spray deposition method for efficient perovskite solar cell with extended stability. Nano Energy. 2017; 32: 414-421.

- 112Yun AJ, Kim J, Hwang T, Park B. Origins of efficient perovskite solar cells with low-temperature processed SnO2 electron transport layer. ACS Appl Energy Mater. 2019; 2: 3554-3560.

- 113Feng J, Yang Z, Yang D, et al. E-beam evaporated Nb2O5 as an effective electron transport layer for large flexible perovskite solar cells. Nano Energy. 2017; 36: 1-8.

- 114Zhai Y, Wang Z, Wang G, Peijnenburg WJGM, Vijver MG. The fate and toxicity of Pb-based perovskite nanoparticles on soil bacterial community: impacts of pH, humic acid, and divalent cations. Chemosphere. 2020; 249:126564.

10.1016/j.chemosphere.2020.126564 Google Scholar

- 115Zhang X, Wang W, Xu B, et al. Less-lead control toward highly efficient formamidinium-based perovskite light-emitting diodes. ACS Appl Mater Interfaces. 2018; 10: 24242-24248.

- 116Soleimanioun N, Rani M, Sharma S, Kumar A, Tripathi SK. Binary metal zinc-lead perovskite built-in air ambient: towards lead-less and stable perovskite materials. Sol Energy Mater Sol Cells. 2019; 191: 339-344.

10.1016/j.solmat.2018.11.021 Google Scholar

- 117Shao S, Liu J, Portale G, et al. Highly reproducible Sn-based hybrid perovskite solar cells with 9% efficiency. Adv Energy Mater. 2018; 8:1702019.

- 118Chen S, Deng Y, Gu H, et al. Trapping lead in perovskite solar modules with abundant and low-cost cation-exchange resins. Nat Energy. 2020; 5: 1003-1011.

- 119Zhao Z, Gu F, Rao H, et al. Metal halide perovskite materials for solar cells with long-term stability. Adv Energy Mater. 2019; 9:1802671.

- 120Yi C, Luo J, Meloni S, et al. Entropic stabilization of mixed A-cation ABX3 metal halide perovskites for high performance perovskite solar cells. Energ Environ Sci. 2016; 9: 656-662.

- 121Noh JH, Im SH, Heo JH, Mandal TN, Seok SI. Chemical management for colorful, efficient, and stable inorganic–organic hybrid nanostructured solar cells. Nano Lett. 2013; 13: 1764-1769.

- 122Grancini G, Roldán-Carmona C, Zimmermann I, et al. One-year stable perovskite solar cells by 2D/3D interface engineering. Nat Comm. 2017; 8:15684.

- 123Gharibzadeh S, Nejand AB, Jakoby M, et al. Record open-circuit voltage wide-bandgap perovskite solar cells utilizing 2D/3D perovskite heterostructure. Adv Energy Mater. 2019; 9:1803699.

- 124Chen P, Bai Y, Wang S, Lyu M, Yun JH, Wang L. In situ growth of 2D perovskite capping layer for stable and efficient perovskite solar cells. Adv Funct Mater. 2018; 28:1706923.

- 125Cheacharoen R, Boyd CC, Burkhard GF, et al. Encapsulating perovskite solar cells to withstand damp heat and thermal cycling. Sustain Energy Fuels. 2018; 2: 2398-2406.

- 126Boyd CC, Cheacharoen R, Bush KA, Prasanna R, Leijtens T, McGehee MD. Barrier design to prevent metal-induced degradation and improve thermal stability in Perovskite solar cells. ACS Energy Lett. 2018; 3: 1772-1778.

- 127Cheacharoen R, Bush KA, Rolston N, et al. Damp heat, temperature cycling and UV stress testing of encapsulated perovskite photovoltaic cells. 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC); 2018; 3489-3502. https://doi.org/10.1109/PVSC.2018.8547430.

- 128Levrat J, Allebé C, Badel N, et al. High-performance hetero-junction crystalline silicon photovoltaic technology. 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC); 2014; 1218-1222. https://doi.org/10.1109/PVSC.2014.6925134.