Reality or fantasy—Perovskite semiconductor laser diodes

Funding information: Hong Kong Polytechnic University, Grant/Award Numbers: 1-BBA5, 1-ZVGH, BCEE, G-YBHG; National Natural Science Foundation of China, Grant/Award Number: 61775187

Abstract

Perovskite semiconductor has emerged as a promising laser gain medium; however, it is still a challenge to fabricate electrically pumped perovskite lasers due to the insufficient electrical-to-optical conversion efficiency. Here, the current progress on the lasing performance of optically pumped perovskite lasers is reviewed. The advancement in the control of carrier transport and recombination properties of perovskite light-emitting diode architectures is also studied. Hence, the obstacles preventing the fabrication of perovskite laser diodes are investigated. More importantly, a strategy toward electrically driven perovskite lasers is proposed base on the successful development of organic semiconductor laser diodes.

1 INTRODUCTION

Although halide perovskites were synthesized 120 years ago,1 they started to receive attention in the late 1990s after showing their prospective optoelectronic properties.2-5 This is because of their excellent electrical characteristics include low trap-state densities6 and low recombination rate of electrons and holes when compare to that of the III-V semiconductor materials.7-10 They also have large carriers' mobility11 which is critically important to the operation of electronic devices. Moreover, the direct bandgap behavior with strong band edge absorption guarantees their excellent optical properties.12 Hence, the use of halide perovskites has led to the fabrication of high-performance solar cells,13, 14 photodetectors,15 and light-emitting diodes (LEDs).16 On the other hand, it is noted that the cations of perovskites can be replaced by other organic or inorganic cations to tune the bandgap energy through the change of lattice constants.17 The dimensionality reduction of halide perovskites, which can lead to an increase of exciton binding energy, supports the generation of strong excitonic gain at a high operating temperature.6, 18, 19 Therefore, these indicate that the halide perovskite semiconductors are also a promising laser gain medium. Eventually, the first hybrid perovskite semiconductor laser has been realized in 2014.20 Subsequently, studies of hybrid and all-inorganic perovskite semiconductors had demonstrated lasing emission at room temperature over the entire visible spectrum.21, 22 Unfortunately, all these perovskite lasers are optically pumped and it remains a challenge today to achieve lasing emission under electrical driven.

The first step toward electrically pumped perovskite lasers is to minimize the corresponding excitation threshold through the appropriate design of gain material compositions and resonators.23 For example, methylammonium lead bromide (MAPbBr3) perovskite thin-film semiconductor laser with distributed feedback (DFB) structure is realized to sustain lasing emission at temperature up to 100°C with a low threshold of 3.4 μJ/cm2 under optical pulses excitation (@532 nm, 0.3 ns, 1 kHz).24 The synthesis of single-crystalline cesium lead bromide (CsPbBr3) perovskites nanowires (NWs) is another effective approach to secure room-temperature operation with a low threshold of 3 μJ/cm2 (@355 nm, 150 fs, 100 kHz). This is because of the high-crystal quality of the gain medium and the defect-free Fabry Perot resonator with extremely low cavity losses.25 The lowest threshold of single-crystalline halide perovskites (MAPbX3 for X = I, Br, and Cl) NWs is recorded to be 0.22 μJ/cm2 (@805 nm, 100 fs, 250 kHz) at room temperature.26 Nevertheless, these perovskite semiconductor lasers are operated under short optical pulses excitation. On the other hand, continuous-wave (CW) operation perovskite laser is achieved by using MAPbI3 perovskite semiconductor as the active layer of a DFB resonator. The laser operating at or below 160 K (ie, below the tetragonal-to-orthorhombic phase transition temperature) with an excitation threshold of 17 kW/cm2.27 Higher operation temperature can also be obtained by using mixed cation perovskite to suppress the phase change due to the increase of temperature.28 Furthermore, the solution-processed CsPbBr3 perovskite NWs are utilized to realize CW operation via polariton lasing at cryogenic temperature (77 K) with an excitation threshold of 6 kW/cm2.29 Moreover, the development of room-temperature MAPbI3 perovskite DFB lasers has shown a low threshold of 13 W/cm2 under CW operation which is due to the extra-low cavity losses of the DFB resonator.30 The current fabrication of vertical-cavity surface-emitting laser (VCSEL) using a 1 μm thick MAPbBr3 perovskite as the active layer has demonstrated an ultralow threshold of 34 mW/cm2 at room temperature under CW operation.31 This may be due to the ultralow cavity losses of the microcavity with Bragg reflectivity as high as 99.9% at the lasing wavelength. On the other hand, formamidinium lead bromide (FAPbBr3)-based quasi-2D perovskites (ie, thickness of ~100 nm) are proposed as the gain medium of DFB resonators to realize green room-temperature CW lasing with excitation threshold of 45 W/cm2.32 It is shown that the reason to achieve high optical gain is the suppression of long-lived triplet excitons.

Table 1 summarizes the recent progress on the development of optically pumped perovskite semiconductor lasers and their related lasing characteristics. The fourth column of the table shows the excitation methods of the lasers, while the sixth column indicates the excitation threshold. Either pulse energy (for pulses excitation), optical power (for CW excitation), or both are given as the excitation threshold of the lasers. The average power, Pave, of the excitation pulses is also indicated in the column. It is observed that the threshold of the excitation pulses reduces from Pave of 0.75 W/cm2 (fs pulses)25 to 4 mW/cm2 (ns pulses)31 and the threshold for the perovskite laser under CW operation significantly reduces from 17 kW/cm227 to 34 mW/cm231 for the past 5 years of progress. This is attributed to the improvement in the fabrication of high-quality perovskite semiconductors, which can reduce the internal absorption losses and enhance the optical gain. Further careful design of laser cavities with strong optical confinement (ie, laser cavity with a high Q-factor such as DFB and VCSEL) leads to ultralow cavity losses. As a result, an ultralow excitation threshold, which suppresses the thermal and optical degeneration of the optical gain arisen from the pump induced heating and the accumulation of photo-induced defects, respectively,39 is obtained to support CW operation at room temperature.

| Materials | Feedback mechanism | Lasing λ (nm) | Excitation method | Temp. | Threshold (Pave of pulses)a | Active layer thickness | Threshold currentb | Year |

|---|---|---|---|---|---|---|---|---|

| MAPbI3 TF20 | ASE | 680 | 150 fs, 600 nm, 1 kHz | RT | 12 μJ/cm2 (12 mW/cm2) | 65 nm | 2014 | |

| CsPbBr3 QD33 | WGM | 524.5 | 5 ns, 400 nm, 20 Hz | 10 K | 11.5 mJ/cm2 (0.22 W/cm2) | in solution | 2015 | |

| MAPbI3 NW26 | FP | 787 | 150 fs, 402 nm, 250 kHz | RT | 0.22 μJ/cm2 (55 mW/cm2) | ~200 nm | 1 MA/cm2 | 2015 |

| CsPbBr3 NW34 | FP | 530 | 150 fs, 402 nm, 250 kHz | RT | 2.8 μJ/cm2 (0.7 W/cm2) | 700 nm | 2016 | |

| CsPbBr3 NW25 | FP | 530 | 150 fs, 355 nm, 250 kHz | RT | 3 μJ/cm2 (0.75 W/cm2) | 300 nm | 2016 | |

| MAPbI3 TF35 | VCSEL | 778 | 0.34 ns, 532 nm, 1 kHz | RT | 7.6 μJ/cm2 (7.6 mW/cm2) | ~305 nm | 17.6 kA/cm2 | 2017 |

| MAPbBr3 TF24 | DFB | 555 | 0.3 ns, 532 nm, 1 kHz | RT | 3.4 μJ/cm2 (3.4 mW/cm2) | ~200 nm | 7.5 kA/cm2 | 2018 |

| MAPbI3 TF27 | DFB | 785 | CW, 445 nm | 102 K | 17 kW/cm2 | 120 nm | 2017 | |

| MAPbI3 TF36 | DFB ASE | 813 | CW, 355 nm | RT | 0.1 W/cm2 | 160 + 70 nmc | 63 mA/cm2 | 2018 |

| CsPbBr3 NW37 | FP | 524 | CW, 405 nm | 4 K | 1.45 nW | ~280 nm | 2018 | |

| 35 fs, 400 nm, 1 kHz | 12.3 μJ/cm2 (12.3 mW/cm2) | |||||||

| CsPbBr3 NW29 | Polariton | 533 | CW, 450 nm | 77 K | 6 kW/cm2 | ~300 nm | 2018 | |

| MAPbI3 TF30 | DFB | 807 | CW, 355 nm | RT | 13 W/cm2 | 145 + 30 nmc | 8.17 A/cm2 | 2018 |

| Cs0.1(MA0.17FA0.83)0.9Pb0.84(I0.84Br0.16)2.68 TF28 | ASE | 790 | CW, 532 nm | 80 K | 387 W/cm2 | ~185 nm | 2019 | |

| MAPbBr3 QD38 | DFB | 539 | CW, 405 nm | RT | 15 W/cm2 | 300 + 700 nmc | 10.7 A/cm2 | 2019 |

| MAPbBr3 TF31 | VCSEL | 565 | CW, 405 nm | RT | 34 mW/cm2 | 1 μm | 24 mA/cm2 | 2019 |

| 8 ns, 355 nm, 1 kHz | 4 μJ/cm2 (4 mW/cm2) |

314 A/cm2 | ||||||

| FAPbBr3 q2DF32 | DFB | ~553 | CW, 488 nm | RT | 45 W/cm2 | ~100 nm | 38.8 A/cm2 | 2020 |

| ASE | ~550 | 3 ns, 337 nm, 20 Hz | 16.7 μJ/cm2 (0.33 mW/cm2) | 3.3 kA/cm2 |

- Abbreviations: ASE, amplified spontaneous emission; DFB, distributed feedback; FP, Fabry-Pérot; NW, nanowire; q2DF, quasi-2D film; QD, quantum dots; RT, room temperature; TF, thin film; VCSEL, vertical-cavity surface-emitting laser; WGM, whispering gallery mode.

- a Pave = pulse energy × frequency (ie, average power of the pulses).

- b Equivalent peak and average injection current density (see Appendix).

- c h1 + h2 (h1—grating height, h2—perovskite residue thickness).

For the VCSEL,31 it is noted that the excitation threshold under pulses and CW operation is found to be 4 μJ/cm2 (ie, 500 W/cm2) and 34 mW/cm2, respectively. The lasers under pulses excitation require higher peak power so that the overall generated carrier concentration can be higher than that of the average threshold value. Hence, the threshold of the same device under CW operation is lower than the peak power of the pulses. On the other hand, the time-average power of the pulses (ie, Pave of 4 mW/cm2) is much less than its CW excitation threshold so that the heating effect is significantly reduced in pulses operation. The eighth column of the table projects the equivalent threshold current of the lasers under electrical pulses and CW operation (see Appendix for the calculation). The equivalent excitation threshold of VCSEL under nanosecond pulses and CW operation are estimated to be 314 A/cm2 and 24 mA/cm2, respectively. In the calculation, the influence of Joule heating and other heating effects are ignored. Now, the question is whether these lasers can be electrically excited by using the available perovskite LED architectures as the carrier injection media. Hence, it is necessary to study the process of achieving electrically pumped organic lasers by using organic LED architectures, which have similar carrier transport layers (CTLs) to that of the perovskite LEDs, to inject carriers.

2 DOES ANYTHING LEARN FROM THE ELECTRICALLY DRIVEN ORGANIC LASERS?

After the demonstration of optically pumped organic solid-state semiconductor lasers in 1996,40 extensive investigations have concentrated on the realization of electrically pumped organic semiconductor lasers. This is the goal of organic laser industries that flexible and compact laser diodes can be fabricated by a low-cost roll-to-roll solution-based process and this is also the reason to develop perovskite semiconductor lasers. Previously, researchers have made use of the electrical injection architectures of organic LEDs and collaborated with optical waveguides/resonators which having spectral filtering properties to achieve “so call” electrically pumped organic lasers. For example, an asymmetric slab waveguide, which supporting resonant leaky mode at a cutoff wavelength, is used to obtain the narrowing of the electroluminescence spectrum.41 On the other hand, a λ/2 microcavity—a Fabry-Pérot interferometer with high mirror reflectivity (>99%) is applied to support the narrowing of emission linewidth.42 However, the operation principle of these devices is equivalent to organic LED integrated with a laser line filter so that their emission characteristics do not satisfy the claim of lasing. Therefore, we should avoid making the same mistake during the development of electrically pumped perovskite lasers.

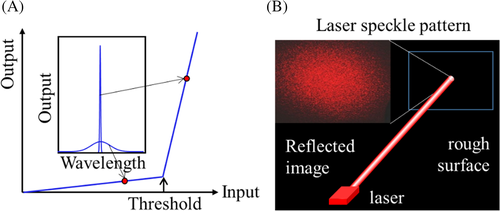

In general, conventional lasing arises from the amplification of spontaneous emission and the coherent optical feedback within the gain medium of a resonator. Hence, the laser beam has spatial and temporal coherence and is strongly polarized. To verify the support of conventional lasing from electrically pumped resonators, it is necessary to demonstrate unambiguously:

- the presence of the threshold—the slope efficiency of the output power shows an abruptly change during the increase of injection current (see Figure 1A);

- the narrowing of emission spectrum above the threshold (ie, due to the requirement of phase coherence of the lasing light, the corresponding spectrum linewidth above the threshold should be <0.2 nm, see Figure 1A);

- the spatial coherence of the laser beam (ie, a speckle pattern can be observed by illuminating a coherent laser beam on a rough surface, see Figure 1B);

- and the strongly linear polarization of the lasing beam above threshold (ie, emitted light varies from unpolarization below to strongly linearly polarized above the threshold).

Hence, to claim a light-emitting device is a conventional laser, its output characteristics should satisfy the above requirements simultaneously. The previously reported electrically pumped organic lasers although show linewidth narrowing, the “lasing linewidth” is too large (ie, >1.9 nm)42 to be phase coherence so that they are not a “laser.”

What is unconventional laser—polariton laser?43 The main difference between a conventional laser and a polariton laser is that the latter case requires no population inversion. Coherent light is generated from the steady-state leakage of an exciton-polariton condensate below the threshold for population inversion. For an ideal polariton laser, there will be no threshold except at a very high excitation power. However, in a normal situation, the polariton lasers will have two excitation thresholds. The first threshold at a lower excitation power is for polariton lasing—we should observe spatial coherence and polarization characteristics of the laser beam. The second threshold at a higher excitation power (ie, an order of magnitude higher than the first threshold) is for conventional lasing—the output characteristics should show the signatures of conventional lasing.

It is believed that the difficulties to realize organic lasers under electrical excitation are due to (a) poor net optical gain of the organic materials and (b) inappropriate design of the laser structure.40 First, the organic materials, which have low stimulated emission cross section (ie, optical gain) and the emission light wavelength overlaps with the triplet excitons and polarons absorption peaks under electrical excitation, have low net optical gain. Second, due to the low mobility (ie, high resistivity) of the organic materials, it is necessary to place the metallic electrodes very close to the active layer of the resonators. As a result, the optical modes are strongly absorbed by the metallic electrodes so that high cavity losses are unavoidable. Hence, these are the main difficulties preventing us to obtain “truly” electrically pumped organic lasers.

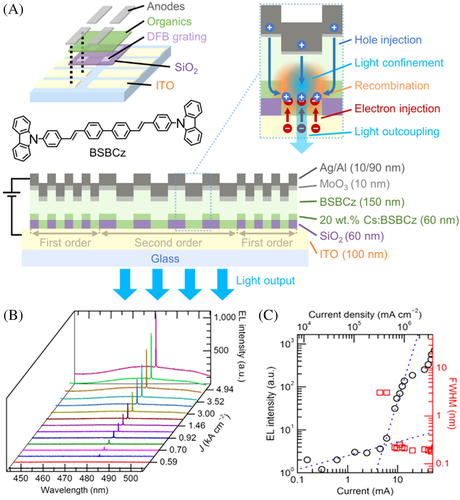

After the observation of room-temperature lasing from an optically pumped organic laser with a threshold of either 0.09 μJ/cm2 @20 Hz excited by 337 nm 800 ps optical pulses (ie, equivalent threshold current is ~61 A/cm2 if α ~ 1.5 × 106 cm−1 is assumed) or 0.06 μJ/cm2 @10 kHz excited by 365 nm 10 ps optical pulses (ie, ~3.5k A/cm2) in 2017,44 an electrically pumped distributed feedback organic diode was achieved 2 years later.45 This is verified by showing unambiguously the signatures of conventional lasing including a clear lasing threshold, linewidth narrowing, and strong polarization dependence. The laser is operating at room temperature under electrical pulses excitation (400 ns, 1 kHz) with a threshold current of ~700 A/cm2. The main reasons to obtain lasing are (a) the selection of a high net gain organic semiconductor and (b) the extremely low-loss resonator design under external injection of carriers. In the fabrication of the resonator, 4,4′-bis[(N-carbazole)styryl]biphenyl (BSBCz) thin film is used to generate high net optical gain under electrical excitation. This is possible as the lasing wavelength is spectrally separated from the triplet-exciton and polaron absorption peaks by using rectangular gratings with appropriate reflection wavelength. Furthermore, the design of the rectangular gratings using SiO2 dielectric suppresses the light absorption at the metallic electrodes as well as allows the effective injection of carriers into the Cs:BSBCz active layer for achieving higher optical gain, see Figure 2A. Here, the architecture design minimizes the number of organic hetero-interfaces so that the accumulation of charges as well as the internal losses of the laser cavity can be suppressed under the injection of high current densities. As a result, the corresponding injection efficiency has been improved over the conventional design of organic LEDs. Besides, the emission characteristics unambiguously fulfill the claim of “lasing,” see Figure 2B,C. On the other hand, thermal degeneration is still the main problem of the electrically pumped organic lasers as strong efficiency roll-off occurs for the injection pulses larger than 2.2 kA/cm2. The influence of thermal degeneration (ie, intrinsic properties of organic materials) is still the remaining challenge to achieve organic semiconductor laser diodes under CW operation at room temperature.

Table 2 shows the physical and electrical properties of some semiconductor materials. It is noted that the low melting point of perovskite semiconductors has the advantage to fabricate light-emitting devices at a low cost. Furthermore, due to the short thermal response time (ie, ∝ κmCp), the dissipation of heat from the perovskite semiconductors is relatively faster than that of the organic materials. Hence, the physical properties of halide perovskite semiconductors are compatible with or better than that of BSBCz. On the other hand, the electrons and holes mobilities of the halide perovskite semiconductors, which are compatible with that of III-V semiconductor materials, are higher than that of the BSBCz. Besides, perovskite single crystals offer even lower bulk defect densities of 109 to 1011 cm−3. Therefore, these indicate that the electrical properties of halide perovskite semiconductors are suitable for the realization of high-performance electronic devices. Furthermore, the optical gain of perovskite semiconductors, which have a direct bandgap with minimal charge-trapping defects supporting band-to-band radiative recombination, can be as high as ~3 × 103 cm−2.69 This value is compatible with that of single-crystal GaAs and higher than that of the BSBCz (ie, the radiative decay time of BSBCz is ~109 seconds−1 or equivalent optical gain of ~8 cm−1 at threshold70). Therefore, the optical characteristics of perovskite semiconductors should be favorable for laser applications. As the architecture design of the organic laser diode shown in Figure 2 can provide injection pulses with a peak value of few kA/cm2 which may be sufficient to drive some of the perovskite lasers shown in Table 1,24, 31 therefore, it is expected with a high chance to realize electrically pumped perovskite lasers.

| Materials | Melting point (°C) | Thermal conductivity, κm (W/m·K @RT) | Specific heat, Cp (J/kg·K) | Electron/hole mobility (cm2/V·s) (@RT) | Minor carrier lifetime (ns) | Intrinsic resistivity (Ω·m) | Intrinsic carrier conc. (cm−3) | Dielectric constant (@RT) |

|---|---|---|---|---|---|---|---|---|

| CsPbX3 | ~580 X = I46 | 0.3 X = I 0.5 X = Cl |

220 X = Cl | 80-290/100-24047 | 1.3 X = Br48 |

2.1 × 1010 X = Br48 |

1015-101747 | 4.1-4.5a X = Cl 3.2-5a X = Br 5-12.7a X = I |

| MAPbI3 | >200 | 1-349 | 30650 | 197/13651 | 224 | ~10104 ~10552 ~10953 |

1016-1018b | ~4.7-9 @visible54 |

| MAPbBr3 | ~22046 | 0.1-1.4 | 35650 | 20-60/20-60 | 414 | ~108 | 5 × 109-5 × 10104 | ~5.7@530 nm |

| BSBCz | ~478c | 0.244 | 140044 | 3/7 × 10−4d 0.4/1.2 × 10-3e |

~1.755 | ~41556 | 2 × 1017 | 457 |

| GaAs58 | 1240 | ~50 | 327 | 8000/400 | ~10 | 1010 | 2.1 × 106 | 10.89 |

| w-GaN | 290059 | 40060 | 49060 | 400/1058 | 6.561 | 1062 | 3-6 × 101962 | ~7.1@370 nm58 |

| w-ZnO | 197763 | 5060 | 49460 | 100-2000/5-30 | 1-2 | 2-564 | <106 | ~4.4@400 nm |

| Diamond65 | 4027 | 3320 | 519 | 4500/3800 | 6 | >1015 | 10−27 | 5.7 |

To the best of our understanding, electrically pumped perovskite lasers have yet to be demonstrated. So, what are remained obstacles required to be overcome before the successful fabrication of perovskite laser diodes? First of all, there is no suitable architecture of injection/transport layers available to achieve effective injection of carriers into the perovskite emitting layer. Furthermore, the heating effect, which arises from the low conversion efficiency of the external carrier injection, significantly deteriorates the optical gain of the perovskite semiconductors. Hence, these may be the main reasons for dragging the development of electrically pumped perovskite lasers. As we know that the key to obtaining organic lasers is to deduce the suitable injection architecture for maximizing the conversion efficiency of the laser diode under high current injection, therefore, it is necessary to investigate the carrier transport process causing the low conversion efficiency of the available perovskite LED architectures.

3 CARRIER TRANSPORT AND RECOMBINATION PROPERTIES OF PEROVSKITE LED ARCHITECTURES

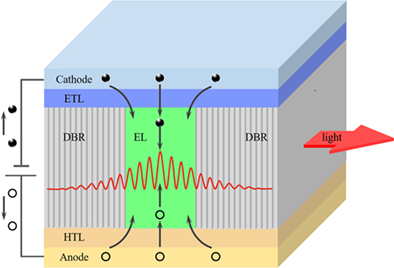

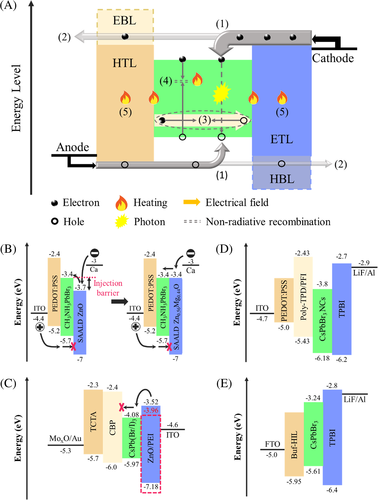

Figure 3 shows the schematic diagram of a standard three-layer architecture under the external injection of carriers. The device consists of an anode, a hole-transport layer (HTL), a halide perovskite emitting layer, an electron-transport layer (ETL), and a cathode. The ideal HTL is also an electron blocking layer (EBL) to block excessive electrons. Similarly, the ETL is also expected as a hole blocking layer (HBL) to block excessive holes. It is believed that (a) charge carrier injection imbalance, (b) overflow of carriers, (c) electric field inside the emitting layer, (d) nonradiative recombination, and (e) Joule heating are the potential mechanisms affecting the conversion efficiency of the standard three-layer LED architecture.

3.1 Charge carrier injection imbalance

The existence of charge injection barriers between the perovskite emitting layer and CTLs leads to the imbalanced injection of electrons and holes. This inefficient injection of carriers, which is a critical problem needed to be addressed to realize electrically pumped perovskite lasers, causes low electroluminescence performance46, 78 and a high turn-on voltage (Von) in the perovskite LEDs.77, 79 Therefore, the electrical properties of the adjacent CLTs, especially the underlayer on which the perovskite emitting layer is deposited, play a crucial role of charge injection efficiency. A prevalent strategy to overcome this issue is to introduce various types of organic materials or metal-doped semiconductors to reduce the injection barriers, improve charge-transporting ability and balance injected charges. Herein, some successful examples of CTL design in perovskite LEDs are reviewed, and these approaches may be utilized to achieve perovskite laser diodes.

The first room-temperature perovskite LED was demonstrated in 2014 but the corresponding external quantum efficiency (EQE) is very low due to the inefficient charge injection.80 To address this issue, Mg-doped ZnO (Zn1-xMgxO) was used to replace ZnO as an ETL,81 and enable the drop of electron affinity from −3.7 to −3.4 eV (Figure 3B) that was similar to that of perovskite materials. This barrier-free charge injection between ETL and the perovskite emitting layer provides a lower Von and a narrower emission linewidth than that of the conventional InGaN LEDs.71 The electron injection level of ZnO film could also be tuned by coating with polyethylenimine (PEI), which has been used to fabricate low work function electrodes in broad application fields.79, 82-84 Comparing with ZnO, the conduction band of ZnO/PEI can be reduced by 0.44 eV (Figure 3C), which enhances the electron injection within the device.73

An interfacial layer of perfluorinated ionomer (PFI) between the HTL and the perovskite nanocrystal emitting layer (Figure 3D) was proved to improve the hole injection efficiency.77 This multilayered structure enables the valence band of HTL to increase to 0.34 eV, which results in efficient charge injection into the emitting layer and leads to three times enhancement of electroluminescence from CsPbBr3 LEDs.77 PFI was also used to modify poly(3,4-ethylenedioxythiophene):poly(styrene-sulfonate) (PEDOT:PSS) as an HTL to decrease the hole injection barrier with reduced work function (Figure 3E). This enhances the hole injection efficiency to improve the balance of electrons and holes so that a high electroluminescence intensity of 13 752 cd/m2 with a pure emission spectrum of 16.5 nm can be obtained.46

The charge carrier mobility also plays an important role in the charge injection balance. For example, it is easy to realize charge injection balance in the LED architecture because the charge mobilities of HTL and ETL are both around 1 × 10−4 cm2 V−1 s−1.77, 85, 86 Modifying the architecture of the emitting layer is also a new strategy to balance the charge injection. The quasi-core/shell structure, consisting of the bottom layer (CsPbBr3/MABr) and top electrical passivating layer (MABr), can achieve a high initial EQE of 17% due to the balance of charge injection.87

3.2 Overflow of carriers

Besides imbalanced charge injection, the low power conversion efficiency is also caused by the overflow of charge carriers, which leads to inefficient recombination of electrons and holes. CTL with a proper energy level of conduction or valence band is also used as the blocking layers to address this issue. For example, TiO2 and poly(9,9′-dioctylfluorene) (F8) was utilized as an efficient HBL and EBL, respectively, to form a standard three-layer architecture TiO2/CH3NH3PbI3-xClx/F8 LED. HBL and EBL are used to confine injected charges inside the emitting layer to obtain effective light emission.80 However, the similar energy level of the valance band of F8 and MAPbBr3 makes F8 not a suitable charge blocking layer in this device. Hence, ZnO was used to replace F8 as a HBL to increase the energy level of the valance band. As a result, ZnO prevents the leakage of injected holes and supports efficiently radiative recombination in the perovskite emitting layer.71 Alternatively, PEI can be used to modify ZnO (ie, a new PEI/ZnO layer) as a suitable HBL due to its deep valence-band energy level of −6.5 eV. Poly(9,9-dioctyl-fluorene-co-N-(4-butylphenyl)diphenylamine) with a low electron affinity (~2.1 eV) can also be utilized as an EBL to avoid carrier overflowing and allow strong confinement of carriers inside the emitting layer so that stable and efficient radiative recombination can be achieved.79

PEDOT:PSS has been successfully used as a traditional HTL in perovskite solar cells, but it is not suitable to use it alone as a HTL in LED due to its weak electron blocking effect.88 Therefore, poly(9-vinlycarbazole) was employed as a blocking layer between HTL and perovskite QDs to overcome the drawback of PEDOT:PSS with shallow LUMO, resulting in blocking of injected electrons and obtaining efficient recombination of electrons and holes.89 NiOx was also used to replace PEDOT:PSS as an HTL because NiOx exhibited a suitable energy level to block the electrons, while the TPBI was utilized to prevent the overflow of holes. As a result, the recombination probability of electrons and holes inside the emitting layer can be enhanced.78

In general, the suitable selection of potential barriers between CTLs and the emitting layer is the common strategy to suppress carrier injection imbalance and overflow from the perovskite LED architectures. Hence, charge carrier injection imbalance and charge overflow of carriers are solvable problems. Table 3 summarizes the recent progress of perovskite LEDs operating at room temperature.

| Emitting layer | LED architecture EBL/EL/HBL or HTL/EL/ETL | λp (nm) | Luminance (cd·m−2) | EQE (%) | Von (V) | CE (cd/A) | CDa (mA/cm2) | Driven | Year |

|---|---|---|---|---|---|---|---|---|---|

| MAPbBr380 | PEDOT:PSS/MAPbBr3/F8 | 517 | 364 | 0.1 | 3.3 | 0.3 | 120 | CW | 2014 |

| MAPbBr390 | Buf-HIL/MAPbBr3/TPBI | 543 | 417 | 0.13 | 0.58 | 90 | CW | 2015 | |

| MAPbBr391 | SOCP/MAPbBr3/TPBI | 540 | ~15 000 | 8.53 | 42.9 | 34.9 | CW | 2015 | |

| MAPbBr379 | TFB/MAPbBr3/PEI:ZnO | 532 | 20 000 | 0.8 | 2.2 | ~500 | CW | 2015 | |

| MAPbBr378 | NiOx/MAPbBr3/TPBI | 550 | 70 000 | 4.0 | 15.9 | ~400b | CW | 2016 | |

| CsPb(Br/I)373 | TCTA/CBP/CsPb(Br/I)3/PEI:ZnO | 648 | 2216 | 6.3 | 1.9 | 3.42 | 8 | CW | 2016 |

| CsPbBr346 | Buf-HIL/CsPbBr3/TPBI | 550 | 13 752 | 1.37 | 5.39 | 220 | CW | 2017 | |

| CsPbBr387 | PEDOT:PSS/CsPbBr3/C37H26N6 | 525 | 14 000 | 20.3 | 2.7 | 78 | ~5 | CW | 2018 |

| CsPbBr392 | PEDOT:PSS/CsPbBr3/TPBI | 520 | 67 300 | 6.28 | 2.6 | 22.5 | ~100 | CW | 2018 |

| CsPbBr393 | PTAA/CsPbBr3/TPBI | 520 | 21 000 | 7.5 | 2.7 | 27 | ~70 | CW | 2020 |

| CsPbBr394 | PVK/CsPbBr3/TPBI | 514 | 2500 | 2.12 | 3.6 | 6.06 | ~5b | CW | 2020 |

| MAPbI3-xClx80 | TiO2/MAPbI3-xClx/F8 | 754 | 6.8 W·sr−1·m−2 | 0.23 | 1.5 | 494 | CW | 2014 | |

| 13.2 W·sr−1·m−2 | 0.76 | 300b | 1 ms, 100 Hz | ||||||

| MAPbI3-xClx79 | TFB/ MAPbI3-xClx/PEI:ZnO | 768 | 28 W·sr−1·m−2 | 3.5 | 1.3 | ~160 | CW | 2015 | |

| FAPbI395 | PEIE:ZnO/FAPbI3/TFB | 800 | 390 W·sr−1·m−2 | 20.7 | 1.3 | 18 | CW | 2018 | |

| MAPbI396 | PolyTPD/MAPbI3/POPy2 | 750 | 2.6 kW·sr−1·m−2 | 17 | 2.0 | ~1 k | CW | 2020 | |

| 59 kW·sr−1·m−2 | 1 | 750 k | 250 ns |

- Abbreviations: λp, peak wavelength of emission spectrum; CD, current density; CE, current efficiency; EL, emitting layer; EQE, external quantum efficiency; LED, light-emitting diode; SOCP:PEDOT:PSS, poly(3,4-ethylenedioxythiophene):poly(styrene-sulfonate); PEIE, polyethylenimine ethoxylated; PFI, perfluorinated ionomer; PTAA, (poly(bis(4-phenyl)(2,4,6-trimethylphenyl)amine)); POPy2, phenyldi(pyren-2-yl)phosphine oxide; PTAA, (poly(bis(4-phenyl)(2,4,6-trimethylphenyl)amine)); PVK, poly(9-vinlycarbazole); TBAB, tetrabutylammonium bromide; TFB, poly(9,9-dioctyl-fluorene-co-N-(4-butylphenyl)diphenylamine); Von, turn-on voltage.

- a Current density at peak EQE.

- b Current density at peak CE.

3.3 Electric field inside the emitting layer

Exciton-exciton annihilation, electric-field-induced dissociation of excitons into electron-hole pairs, and carrier-induced luminescence quenching are the possible mechanisms causing luminescence quenching under the influence of an electric field.97-99 However, not all these mechanisms will appear simultaneously, and their attendance depends on the design of LEDs, dopant, and doping concentration of the emitting layer, and the magnitude of injection carrier densities. For example, the presence of exciton-exciton annihilation is strongly related to the amount of exciton density that can be obtained inside the emitting layer. This mechanism most likely occurs in perovskite polariton lasers especially using multiple quantum wells (MQWs) perovskites as the emitting layer. This is because the exciton binding energy of perovskite MQWs can be as high as 360 meV,100 and the condensation of excitons is required for achieving polariton lasing so that the chance to obtain exciton-exciton annihilation is high. As a result, the lasing threshold of polariton lasers can be significantly increased.101 However, the influence of exciton-exciton annihilation in the conventional perovskite lasers is less important due to the Coulomb effects arisen from the high concentration of injected external carriers.

Electric field-induced exciton dissociation requires the presence of a high local field inside the emitting layer to separate excitons from electron-hole pairs. A halide perovskite MAPbI3 layer sandwiched between two thick insulating polymer layers deposited with metal electrodes is used to investigate the influence of the internal electric field on the corresponding luminescence efficiency. It is found that the quenching factor of the devices can be larger than one if the applied electric field excesses 3.5 × 105 V/cm. As there is no flow of current across the device, the reduction of luminescence emission can be attributed to the separation of electrons and holes obtained from the ionization of photogenerated excitons.102 This mechanism has also been observed from two-dimensional (C4H9NH3)2PbI4103 and CsPbBr3 colloidal QDs perovskite thin-film.104 Furthermore, MQW perovskite LED has observed PL quenching under the influence of field-induced charge separation, but this detrimental effect is less significant as the build-in electric field inside the emitting layer can be effectively reduced by the high forward bias voltage (ie, higher than its build-in potential).105

The decrease in luminescence under external injection of carriers is attributed to carrier-exciton interaction phenomena. The carriers can be either electrons or holes dependent on the carrier transportation mechanism and doping concentration of the emitting layer. For an organic LED with architecture supporting the transportation of electrons and has a buildup of electron density in the emitting layer, luminescence quenching will occur under external injection of electrons due to electron-exciton interaction. However, for another organic LED with standard three-layer architecture (ie, cathode/ETL/Alq3/HTL/anode) under the influence of high electric field bias, no sight of either electric-field-induced or carrier-induced quenching is detected.98 This is also true for a perovskite LED using the standard three-layer architecture (ie, cathode/ETL/MAPbI3/HTL/anode).106 Hence, this implies the quenching mechanisms triggering by the internal electric field inside the emitting layer can be avoided if the proper architecture of LEDs is adopted. Nevertheless, using MAPbI3 as the emitting layer may lead to the slow redistribution of ionic charge, which is the dominant quenching mechanism of perovskite LEDs, changing the internal field profile and nonradiative trap concentration inside the emitting layer. Another investigation on the stability of perovskite solar cells has shown the deprotonation of organic cations by the trapped charge-induced local electric field at the interfaces between the emitting layer and CTLs.107 Recent investigations have shown that the most problematic issue related to the electric field in perovskite devices is its stability. The decomposition of perovskite semiconductors may occur arising from the migration of ionic species/charged defects under the influence of the internal electric field.108 Therefore, it seems that the influence of luminescence quenching (ie, arises from the electric field and external injection of carriers) may be less important than that of the stability of the MAPbI3 emitting layer.

3.4 Nonradiative recombination

Similar to the III-V semiconductors fabricated in their early development stage, nonradiative recombination processes observed from the perovskite semiconductors are dominated by their native defects.109 This is because of the poor crystal quality so that point defects in the crystal lattice, surface pinholes generated from the high surface crystalline process rate, and surface defects at the grain boundaries are found from the perovskite thin films. In general, there are 12 native point defects in bulk MAPbX3 containing the vacancies VMA, VPb, and VX, the interstitials MAi, Pbi, and Xi, and anti-site occupations MAPb, MAX, PbMA, PbX, XMA, and XPb.110 However, only some of the point defects are predominant in the recombination process and their presence is dependent on the growth conditions and ingredients of the perovskite semiconductors. For example, defects of IPb and IMA (ie, anti-site occupations of MAPbI3) with transition energies of 0.6 and 0.75 eV below the conduction band (ie, deep trap levels) are obtained during the fabricated of MAPbI3 films by one-step spin-coating and sequential deposition method, respectively.111 The concentration of IPb and IMA, which varies between 1014 and 1015 cm−3 at room temperature, is about one to two orders of magnitudes higher than that of high-crystal-quality GaAs semiconductors.112 On the other hand, the surface mismatch between the CTLs and perovskite emitting layer generates interfacial defects which causing the annihilation of carriers and affecting the injection efficiency of the devices.

This indicates that for the laser operating above the threshold, n will be clamped at nth which is independent of the external injection of the carrier. Recent studies of MAPbI3 DFB laser operating at 170 K has shown that aN ~ 10−16 cm2, ntr ~ 4.5 × 1018 cm−3, and γ = 70 cm−1 so that the corresponding value of nth is found to be about 5.2 × 1018 cm−3.39 This DFB laser has negligible Auger recombination so that SRH nonradiative recombination is still the dominant mechanism inside the MAPbI3 film for nth < 6 × 1018 cm−3.

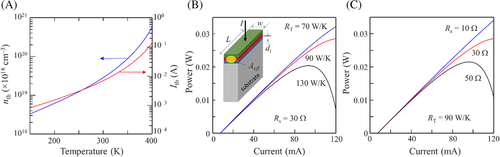

3.5 Joule heating

From the above studies, it is noted that the Joule heating is the dominant factor and directly affects the conversion efficiency of the laser diodes. However, the amount of heat generation can be reduced by improving the heat dissipation inside the cavities through the reduction of RT. This is equivalent to replace the materials of the laser diodes with a higher value of kT but without changing the corresponding electrical and optical properties. Previous investigation has verified that the use of monocrystal Si as the substrate and as a charge injection layer instead of using ITO/glass substrate in perovskite LEDs can alleviate the influence of thermal effects.94 This is because κT (~150 W·m−1·K−1) of monocrystal Si is much higher than that of glass (~1 W·m−1·K−1) at room temperature.96 As expected from Equation (7), heat dissipates to the heatsink can be significantly enhanced using monocrystal Si substrate instead of glass so that only a slight increase of temperature from 28°C to 33°C is recorded. For LEDs using ITO/glass as the substrate, the increase in temperature can be up to 86°C.

Heat generation can also be suppressed by reducing the value of (PIV—P). This is equivalent to minimize the Joule heating inside the laser diode architecture as discussed above (ie, reduces the value of PIV) or suppressing the nonradiative recombination in the emitting layer (ie, increase the value of P). A similar idea has suggested to reduce the resistivity of the CTLs and facilitate heat dissipation in perovskite LEDs.96 They used doped ETL (ie, to increase conductivity from ~10−8 to ~10−2 S·m−1) and HTL (ie, to increase conductivity from ~0.01 to ~0.04 S·m−1) to reduce Joule heating of the device. The LED also has a narrow line-shape device geometry to reduce total power consumption and increase heat dissipation. These design strategies are equivalent to the reduction of PIV in Equation (6). Furthermore, it is proposed to improve the heat dissipation by attaching an additional heat sink and diamond heat spreader (κT > 2000 W·m−1·K−1) on the top Ag contact of the LED. Furthermore, a sapphire substrate with better thermal conductivity is used to replace the bottom glass substrate of the LED. As expected from Equation (7), the total κT can be significantly reduced. As a result, the LED achieves EQE of 17% with a considerable reduction of EQE roll-off due to their proper thermal management. Hence, we have shown that the thermal effect has a direct impact on the performance of perovskite lasers and is unavoidable unless 100% of electrical-to-photon conversion efficiency can achieve.

4 IDENTIFY CRITICAL PROBLEMS AND PROPOSE SOLUTIONS TO REALIZE PEROVSKITE LASER DIODES

4.1 Critical issues

Table 1 estimates that the lowest excitation threshold at room temperature under pulses and CW operation of the DFB lasers are 7.5 kA/cm2 and 8.17 A/cm2, respectively. Table 3 shows the recently developed perovskite LEDs in which the carrier injection architectures can be used to excite the perovskite lasers. Unfortunately, the corresponding current density at the peak EQE is insufficient to sustain lasing from the DFB lasers at room temperature. Further increase of current density for the perovskite LEDs is possible but at the expense of EQE roll-off. This is because the portion of electrical power not contributed to light generation will lead to “heating,” and the temperature will increase with the increase of injection current. From the previous study on the heat generation in LEDs under CW operation, the increase in temperature can be as much as ~20°C per 100 mA/cm2.94 Therefore, heating is the main problem for using the available LED architectures as an excitation source. On the other hand, it is noted that the threshold carrier concentration, nth (=γ/aN + ntr), /or /the threshold current density (ie, Jth ∝ nth) is dependent on the design of laser cavities (ie, γ) as well as the transparency carrier concentration, ntr, of the perovskite semiconductors. From the above study, the value of γ/aN is in the same order of magnitude as that of ntr (ie, based on MAPbI339) so that even if the cavity loss, γ, decreases to zero, the threshold current can only be reduced by 50%. As a result, the injection current below Jth contributes to the nonradiative recombination of carriers and generates heat—pump-induced heating.39 It must be noted that ntr is an intrinsic property of perovskite semiconductors and cannot be changed by improving its crystal quality so that this inherent heating effect of perovskite lasers cannot be avoided. Hence, the main challenges to achieve electrically pumped perovskite DFB lasers can now be focused on two issues: (a) How to minimize the “heating effect” from the LED architectures under CW operation at high current density? (b) How to further reduce the excitation threshold to suppress pump-induced heating?

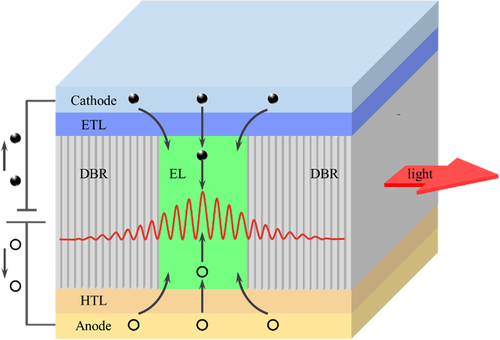

The VCSELs shown in Table 1 have the lowest threshold current of 314 A/cm2 and 24 mA/cm2 for the device in pulses and CW operation, respectively, which can theoretically be utilized to suppress pump-induced heating. It is noted that the perovskite LED architectures can provide enough current to excite the VCSELs at room temperature under either pulses or CW operation although the operation of the pulse of MAPbBr3 LEDs has not been investigated. Nevertheless, the current design of VCSELs is not compatible with the LED architectures. This is because the insulating characteristics of DBRs, which are made by 13.5 pairs of alternating TiO2/SiO2 dielectric layers (ie, 3 μm thick), block the external injection of carriers. Even the DBRs can conduct electricity (eg, using low-index GaN/GaN dielectric layers), the large size of DBRs gives a large value of thermal resistance RT. The low conductivity of the DBRs will also give a large value of equivalent resistance Rs so that strong Joule heating is unavoidable.117 As we can see from Figure 4B,C, either the increase of RT, Rs, or both will have a significant contribution to the EQE roll-off. Hence, the main challenges to achieve electrically pumped perovskite VCSELs can now be focused on two issues: (a) How to integrate the LED architecture with the VCSEL? (b) How to further reduce Joule heating and pump-induced heating for CW operation at room temperature.

4.2 Proposed solutions

Perovskite semiconductors are suitable materials to realize polariton lasing because of their high excitonic binding energy and large exciton oscillator strength. So far, room-temperature optically pumped polariton lasing has been demonstrated from VCSELs,118, 119 microcuboids,120 and NWs29 using perovskite semiconductor as the photon-exciton coupling region. The advantage of achieving polariton lasing is the immediate decay of polariton condensation to generate coherent monochromatic light so that no population inversion is required (ie, zero threshold for ideal polariton lasers). Hence, only a small amount of excitation power is enough to turn on the polariton lasers so that pump-induced heating can be significantly suppressed. However, this is not straightforward to realize polariton lasers when compared to that of the conventional FP or DFB lasers as the strong coupling between excitons and photons within a small volume is required to achieve polariton condensation through the stimulated polariton-polariton scattering.43

Here, we propose to realize electrically pumped perovskite polariton lasers by adopting the design from a room-temperature GaN-based electrically pumped polariton lasers.121, 122 This GaN polariton laser has a VCSEL structure where a thin GaN semiconductor layer is sandwiched between two Bragg reflectors. However, electrodes are not established between the two Bragg reflectors as in the conventional design of VCSELs, instead, the electrical current is injected into the emitting layer in the direction orthogonal to the path of optical feedback (ie, side injection). This laser configuration avoids the injection of carriers through the Bragg reflectors so that Joule heating is mainly dependent on the design of the LED architecture. To realize perovskite polariton lasers, we can replace the GaN layer with a perovskite semiconductor film such as MAPbBr3. A standard LED architecture such as NiOx/MAPbBr3/TPBI can also be used to side-inject electrons and holes to the perovskite semiconductor, in the direction perpendicular to the optical feedback of the resonator, shown in Figure 5. The Joule heating of the LED architecture can be further reduced if doping can be introduced to the CTLs to reduce Rs. Furthermore, the diamond substrate can be used to reduce RT of the LED architecture. Hence, the reduction of Rs and RT allows the room-temperature CW operation of LED architecture to deliver high current. Hopefully, this suggestion can overcome the “two issues” affecting the development of electrically pumped perovskite lasers.

5 CONCLUSION

Even the standard three-layer LED architecture can generate a current density larger than the equivalent excitation threshold of the optically pumped perovskite lasers, it is still not guaranteed to support lasing emission. This is because the strong confinement of light within the emitting layer is not required for the design of LEDs. However, it is a must to simultaneously obtain strong confinement of carriers and photons within the emitting layer of the lasers to achieve stimulated emission. Furthermore, the emitting layer should behave like an optical waveguide collaborating with optical feedback (ie, FP or DFB structure) to generate coherent lasing light. Hence, in the design of standard three-layer LED architecture for laser applications, it is necessary to use CTLs with a refractive index lower than that of the emitting layer so that strong confinement of carriers and photons can be obtained simultaneously. On the other hand, for the design of VCSELs, the refractive index of the emitting layer should also be higher than that of the CTLs for the same reason. These imply that the available design of LED architectures may not be suitable for laser application so that the special design of external carrier injection was used to realize electrically pumped organic lasers.45 Hence, careful redesign of the LED architectures is also required for the fabrication of perovskite laser diodes. In conclusion, it is believed that we are not far from achieving electrically pumped perovskite lasers—(a) based on the successful realization of electrically pumped organic semiconductor lasers reported recently, (b) our investigations on the electrical, thermal and optical properties of perovskite semiconductor materials, as well as (c) our understanding on the optical and electrical characteristics of the optically pumped perovskite lasers and perovskite LEDs, respectively.

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China, grant No. 61775187, and HK PolyU grants (Grant Nos. 1-BBA5, G-YBHG, 1-ZVGH, and BCEE).

APPENDIX

Biographies

Wei Gao is currently a PhD candidate under the supervision of Prof S. F. Y. in the Department of Applied Physics, the Hong Kong Polytechnic University, China. He received his MPhil degree in Chemistry from the Hong Kong Polytechnic University in 2019. His current research focuses on the optical properties of various materials, including semiconductors, organic materials, perovskites, and rare-earth metal-doped materials, and their promising applications in realizing microlasers with the high conversion efficiency.

Siu Fung Yu received B(Eng) degree from University College London, England in 1990 and a PhD degree from Cambridge University, England in 1993. He is now a professor in the Department of Applied Physics, the Hong Kong Polytechnic University, China. His main research interest includes fundamental study, design, and optimization of lasers. He has led to the first realization of random laser diodes, carbon nanodots lasers, and rare-earth-doped nanoparticles upconversion lasers. He has published over 400 international technical papers including patents, journal and conference papers, five book chapters, and one book entitled “Analysis and Design of Vertical-Cavity Surface-Emitting Lasers,” 2003 Wiley, NY.