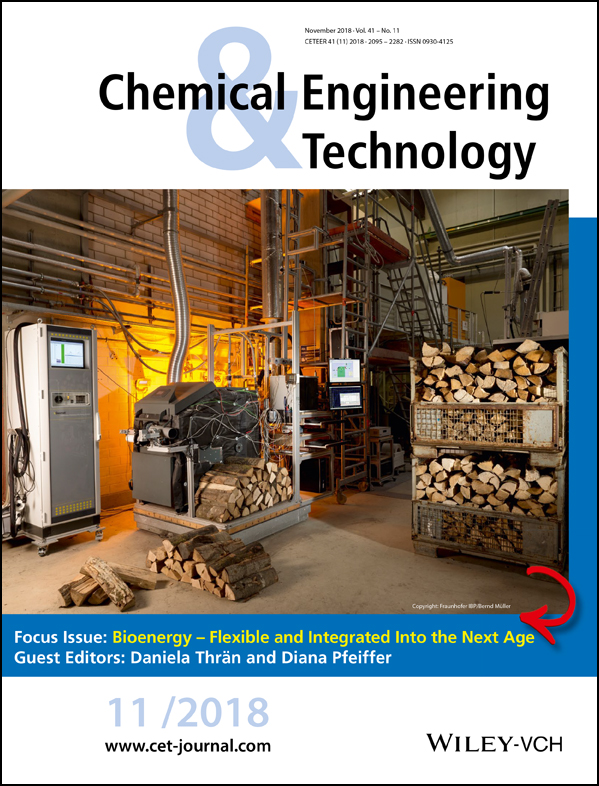

Cover Picture: Chem. Eng. Technol. 11/2018

Graphical Abstract

Test bench for developing and testing of automatic and manually loaded biomass boilers in accordance with DIN EN 304 and DIN EN 303-5 using a special controllable heat dissipation system for the simulation of practical operation. Fraunhofer IBP/Bernd Müller

The special device pictured on the cover is accredited by the German Accreditation Body (DAkkS) and, in addition to the boiler (combustion system), consists mainly of a high-precision weighing machine, an exhaust gas measurement set and delivery system with regulated delivery pressure, a controllable heat dissipation system for simulating the real operation, a control, monitoring and data acquisition system as well as an exhaust gas analyzer for cold- and heated gas sampling. Using this novel technical equipment, not only research and normative testing of automatic and manually loaded biomass boilers in accordance with DIN EN 304, DIN EN 303-5, and Machinery Directive 2006/42 will be carried out, but also the combustion process with regard to energy and emissions flows will be analyzed in detail.

In comparison to the common laboratory apparatus, the combustion and exhaust gas treatment technologies can be developed target oriented by using this novel testing set-up. Moreover, fuels with high heterogeneity can be more accurately investigated for their energy content and the potential for formation of dust (organic and inorganic fine particles) and gaseous pollutant emissions (NOx, SO2, HCl, dioxins, and furans).

Thanks to the self-developed control and data acquisition system, all results can be calculated and monitored online while being visualized accordingly and saved in a big data cloud.