In Situ Reconstruction of a Hierarchical Sn-Cu/SnOx Core/Shell Catalyst for High-Performance CO2 Electroreduction

Prof. Dr. Ke Ye

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Key Laboratory of Superlight Materials and Surface Technology of Ministry of Education, College of Materials Science and Chemical Engineering, Harbin Engineering University, Nantong Street 145, Harbin, 150001 China

These authors contributed equally to this work.

Search for more papers by this authorZhiwen Zhou

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

These authors contributed equally to this work.

Search for more papers by this authorJiaqi Shao

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Key Laboratory of Superlight Materials and Surface Technology of Ministry of Education, College of Materials Science and Chemical Engineering, Harbin Engineering University, Nantong Street 145, Harbin, 150001 China

These authors contributed equally to this work.

Search for more papers by this authorLong Lin

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorDr. Dunfeng Gao

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorDr. Na Ta

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorProf. Dr. Rui Si

Shanghai Synchrotron Radiation Facility, Zhangjiang Laboratory, Shanghai, 201204 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Guoxiong Wang

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorProf. Dr. Xinhe Bao

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorProf. Dr. Ke Ye

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Key Laboratory of Superlight Materials and Surface Technology of Ministry of Education, College of Materials Science and Chemical Engineering, Harbin Engineering University, Nantong Street 145, Harbin, 150001 China

These authors contributed equally to this work.

Search for more papers by this authorZhiwen Zhou

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

These authors contributed equally to this work.

Search for more papers by this authorJiaqi Shao

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Key Laboratory of Superlight Materials and Surface Technology of Ministry of Education, College of Materials Science and Chemical Engineering, Harbin Engineering University, Nantong Street 145, Harbin, 150001 China

These authors contributed equally to this work.

Search for more papers by this authorLong Lin

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

University of Chinese Academy of Sciences, Beijing, 100039 China

Search for more papers by this authorDr. Dunfeng Gao

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorDr. Na Ta

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorProf. Dr. Rui Si

Shanghai Synchrotron Radiation Facility, Zhangjiang Laboratory, Shanghai, 201204 China

Search for more papers by this authorCorresponding Author

Prof. Dr. Guoxiong Wang

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

Search for more papers by this authorProf. Dr. Xinhe Bao

State Key Laboratory of Catalysis, Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Zhongshan Road 457, Dalian, 116023 China

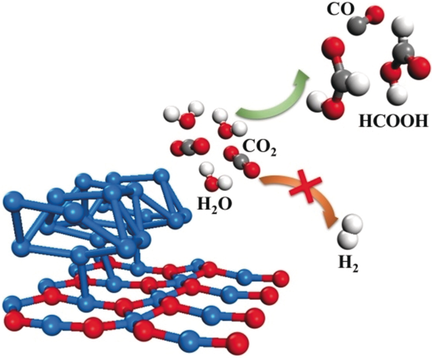

Search for more papers by this authorGraphical Abstract

A Sn/SnOx interface reconstructed in situ facilitates formic acid production by optimizing the binding of the reaction intermediate HCOO* while promotes Faradaic efficiency of C1 products by suppressing the competitive hydrogen evolution reaction. This results in high Faradaic efficiency, current density, and stability of electrochemical CO2 reduction reaction at low overpotentials.

Abstract

The electrochemical CO2 reduction reaction (CO2RR) to give C1 (formate and CO) products is one of the most techno-economically achievable strategies for alleviating CO2 emissions. Now, it is demonstrated that the SnOx shell in Sn2.7Cu catalyst with a hierarchical Sn-Cu core can be reconstructed in situ under cathodic potentials of CO2RR. The resulting Sn2.7Cu catalyst achieves a high current density of 406.7±14.4 mA cm−2 with C1 Faradaic efficiency of 98.0±0.9 % at −0.70 V vs. RHE, and remains stable at 243.1±19.2 mA cm−2 with a C1 Faradaic efficiency of 99.0±0.5 % for 40 h at −0.55 V vs. RHE. DFT calculations indicate that the reconstructed Sn/SnOx interface facilitates formic acid production by optimizing binding of the reaction intermediate HCOO* while promotes Faradaic efficiency of C1 products by suppressing the competitive hydrogen evolution reaction, resulting in high Faradaic efficiency, current density, and stability of CO2RR at low overpotentials.

Conflict of interest

The authors declare no conflict of interest.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie201916538-sup-0001-misc_information.pdf2 MB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1Y. Wu, Z. Jiang, X. Lu, Y. Liang, H. Wang, Nature 2019, 575, 639–642.

- 2C. T. Dinh, T. Burdyny, M. G. Kibria, A. Seifitokaldani, C. M. Gabardo, F. P. G. Arquer, A. Kiani, J. P. Edwards, P. D. Luna, O. S. Bushuyev, C. Zou, R. Quintero-Bermudez, Y. Pang, D. Sinton, E. H. Sargent, Science 2018, 360, 783–787.

- 3J. Gu, C. S. Hsu, L. Bai, H. M. Chen, X. Hu, Science 2019, 364, 1091–1094.

- 4X. Wang, J. F. Araújo, W. Ju, A. Bagger, H. Schmies, S. Kühl, J. Rossmeisl , P. Strasser, Nat. Nanotechnol. 2019, 14, 1063–1070.

- 5Q. Gong, P. Ding, M. Xu, X. Zhu, M. Wang, J. Deng, Q. Ma, N. Han, Y. Zhu, J. Lu, Z. Feng, Y. Li, W. Zhou, Y. Li, Nat. Commun. 2019, 10, 2807.

- 6F. Li, L. Chen, G. P. Knowles, D. R. MacFarlane, J. Zhang, Angew. Chem. Int. Ed. 2017, 56, 505–509; Angew. Chem. 2017, 129, 520–524.

- 7W. Luc, C. Collins, S. Wang, H. Xin, K. He, Y. Kang, F. Jiao, J. Am. Chem. Soc. 2017, 139, 1885–1893.

- 8M. B. Ross , P. D. Luna , Y. Li , C. T. Dinh, D. Kim, P. Yang, E. H. Sargent, Nat. Catal. 2019, 2, 648–658.

- 9X. Zheng, Y. Ji, J. Tang, J. Wang, B. Liu, H. G. Steinrück, K. Lim, Y. Li, M. F. Toney, K. Chan, Y. Cui, Nat. Catal. 2019, 2, 55–61.

- 10W. Zhu, S. Kattel, F. Jiao, J. G. Chen, Adv. Energy Mater. 2019, 9, 1802840.

- 11X. Lu, Z. Jiang, X. Yuan, Y. Wu, R. Malpass-Evans, Y. Zhong, Y. Liang, N. B. McKeown, H. Wang, Sci. Bull. 2019, 64, 1890–1895.

- 12P. Wang, M. Qiao, Q. Shao, Y. Pi, X. Zhu, Y. Li, X. Huang, Nat. Commun. 2018, 9, 4933.

- 13W. Ju, F. Jiang, H. Ma, Z. Pan, Y. B. Zhao, F. Pagani, D. Rentsch, J. Wang, C. Battaglia, Adv. Energy Mater. 2019, 9, 1901514.

- 14J. M. Spurgeon, B. Kumar, Energy Environ. Sci. 2018, 11, 1536–1551.

- 15A. M. Ismail, G. F. Samu, A. Balog, E. Csapo, C. Janaky, ACS Energy Lett. 2019, 4, 48–53.

- 16Z. Cai, Y. Wu, Z. Wu, L. Yin, Z. Weng, Y. Zhong, W. Xu, X. Sun, H. Wang, ACS Energy Lett. 2018, 3, 2816–2822.

- 17Q. Li, J. Fu, W. Zhu, Z. Chen, B. Shen, L. Wu, Z. Xi, T. Wang, G. Lu, J. Zhu, S. Sun, J. Am. Chem. Soc. 2017, 139, 4290–4293.

- 18N. Han, Y. Wang, J. Deng, J. Zhou, Y. Wu, H. Yang, P. Ding, Y. Li, J. Mater. Chem. A 2019, 7, 1267–1272.

- 19X. Hou, Y. Cai, D. Zhang, L. Li, X. Zhang, Z. Zhu, L. Peng, Y. Liu, J. Qiao, J. Mater. Chem. A 2019, 7, 3197–3205.

- 20Y. Chen, M. W. Kanan, J. Am. Chem. Soc. 2012, 134, 1986–1989.

- 21C. Chen, Y. Pang, F. Zhang, J. Zhong, B. Zhang, Z. Cheng, J. Mater. Chem. A 2018, 6, 19621–19630.

- 22S. Wang, J. Wang, H. Xin, Green Energy Environ. 2017, 2, 168–171.

- 23S. Liu, J. Xiao, X. F. Lu, J. Wang, X. Wang, X. W. Lou, Angew. Chem. Int. Ed. 2019, 58, 8499–8503; Angew. Chem. 2019, 131, 8587–8591.

- 24J. Gu, F. Heroguel, J. Luterbacher, X. Hu, Angew. Chem. Int. Ed. 2018, 57, 2943–2947; Angew. Chem. 2018, 130, 2993–2997.

- 25Y. Y. Birdja, R. E. Vos, T. A. Wezendonk, L. Jiang, F. Kapteijn, M. T. M. Koper, ACS Catal. 2018, 8, 4420–4428.

- 26J. Zhang, R. Yin, Q. Shao, T. Zhu, X. Huang, Angew. Chem. Int. Ed. 2019, 58, 5609–5613; Angew. Chem. 2019, 131, 5665–5669.

- 27S. Liu, X. F. Lu, J. Xiao, X. Wang, X. W. Lou, Angew. Chem. Int. Ed. 2019, 58, 13828–13833; Angew. Chem. 2019, 131, 13966–13971.

- 28X. Zhang, X. Sun, S. X. Guo, A. M. Bond, J. Zhang, Energy Environ. Sci. 2019, 12, 1334–1340.

- 29R. He, A. Zhang, Y. Ding, T. Kong, Q. Xiao, H. Li, Y. Liu, J. Zeng, Adv. Mater. 2018, 30, 1705872.

- 30D. H. Won, H. Shin, J. Koh, J. Chung, H. S. Lee, H. Kim, S. I. Woo, Angew. Chem. Int. Ed. 2016, 55, 9297–9300; Angew. Chem. 2016, 128, 9443–9446.

- 31S. Gao, Y. Lin, X. Jiao, Y. Sun, Q. Luo, W. Zhang, D. Li, J. Yang, Y. Xie, Nature 2016, 529, 68–71.

- 32Y. Zhao, C. Wang, G. G. Wallace, J. Mater. Chem. A 2016, 4, 10710–10718.

- 33H. Yang, Y. Hu, J. Chen, M. S. Balogun, P. Fang, S. Zhang, J. Chen, Y. Tong, Adv. Energy Mater. 2019, 9, 1901396.

- 34S. Sarfraz, A. T. Garcia-Esparza, A. Jedidi, L. Cavallo, K. Takanabe, ACS Catal. 2016, 6, 2842–2851.

- 35Z. Weng, X. Zhang, Y. Wu, S. Huo, J. Jiang, W. Liu, G. He, Y. Liang, H. Wang, Angew. Chem. Int. Ed. 2017, 56, 13135–13139; Angew. Chem. 2017, 129, 13315–13319.

- 36X. Jiang, X. Wang, Z. Liu, Q. Wang, X. Xiao, H. Pan, M. Li, J. Wang, Y. Shao, Z. Peng, Y. Shen, M. Wang, Appl. Catal. B 2019, 259, 118040.

- 37M. Schreier, F. Héroguel, L. Steier, S. Ahmad, J. S. Luterbacher, M. T. Mayer, J. Luo, M. Grätzel, Nat. Energy 2017, 2, 17087.

- 38C. Liang, B. Kim, S. Yang, Y. Liu, C. F. Woellner, Z. Li, R. Vajtai, W. Yang, J. Wu, P. J. A. Kenis, P. M. Ajayan, J. Mater. Chem. A 2018, 6, 10313–10319.

- 39J. Wu, F. G. Risalvato, S. Ma, X. D. Zhou, J. Mater. Chem. A 2014, 2, 1647–1651.

- 40L. Vitos, A. V. Ruban, H. L. Skriver, J. Kollar, Surf. Sci. 1998, 411, 186–202.

- 41W. R. Tyson, W. A. Miller, Surf. Sci. 1977, 62, 267–276.

- 42B. Illés, B. Horváth, A. Géczy, O. Krammer, K. Dušek, Soldering Surf. Mount Technol. 2017, 29, 59–68.

- 43Y. Nakadaira, S. Jeong, J. Shim, J. Seo, S. Min, T. Cho, S. Kang, S. Oh, Microelectron. Reliab. 2008, 48, 83–104.

- 44X. Lu, Y. Wu, X. Yuan, L. Huang, Z. Wu, J. Xuan, Y. Wang, H. Wang, ACS Energy Lett. 2018, 3, 2527–2532.

- 45T. Burdyny, W. A. Smith, Energy Environ. Sci. 2019, 12, 1442–1453.

- 46S. Lee, M. Choi, J. Lee, Chem. Rec. 2019, 19, 1–14.

- 47S. Lee, J. D. Ocon, Y. Son, J. Lee, J. Phys. Chem. C 2015, 119, 4884–4890.

- 48C. Shi, H. A. Hansen, A. C. Lausche, J. K. Nørskov, Phys. Chem. Chem. Phys. 2014, 16, 4720–4727.

- 49F. H. Jones, R. Dixon, J. S. Foord, R. G. Egdell, J. B. Pethica, Surf. Sci. 1997, 376, 367–373.

- 50M. Batzill, K. Katsiev, U. Diebold, Surf. Sci. 2003, 529, 295–311.