Flexible Amalgam Film Enables Stable Lithium Metal Anodes with High Capacities

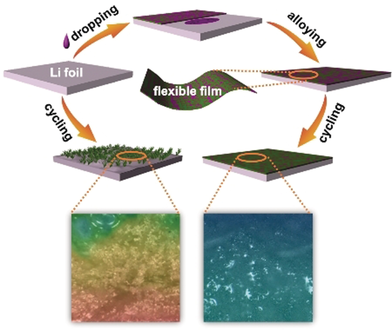

Graphical Abstract

Protective coating: Li amalgam was studied for Li protection. The rational design of a Li anode with such a protective layer affords much improved cycling performance at practically high currents and capacities. Coupled with high-loading cathodes, the protected hybrid anodes demonstrate significantly improved cell stability, indicating its reliability for practical development of Li metal batteries.

Abstract

Dendrite formation is a critical challenge for the applications of lithium (Li) metal anodes. In this work a new strategy is demonstrated to address this issue by fabricating an Li amalgam film on its surface. This protective film serves as a flexible buffer that affords repeated Li plating/stripping. In symmetric cells, the protected Li electrodes exhibit stable cycling over 750 hours at a high plating current and capacity of 8 mA cm−2 and 8 mAh cm−2, respectively. Coupled with high-loading cathodes (ca. 12 mg cm−2) such as LiFePO4 and LiNi0.6Co0.2Mn0.2O2, the protected hybrid anodes demonstrate significantly improved cell stability, indicating its reliability for practical development of Li metal batteries. Interfacial analyses reveal a unique plating-alloying synergistic function of the protective film, where Li beneath the film is actively involved in the electrode reactions upon cycling. Lithium amalgams enrich the alloy anode family and provide new perspectives for the rational design of dendrite-free anodes.