Nixtamalization and Extrusion Processes: Effects on Physicochemical, Nutritional, and Nutraceutical Properties in the Processing of Corn Into Tortilla

Abstract

Corn is a vital cereal produced globally, especially in Mexico and other Latin American countries, where it is a daily dietary staple, primarily consumed in various corn products prepared through nixtamalization. Tortillas are a significant component of the Mexican diet, serving as a major source of protein and energy. The average consumption of nixtamalized corn tortillas in Mexico is around 80 kg per capita per year. Tortilla production, over 12 million tons annually, is a key sector in Mexico’s food industry, ranging from artisanal to industrial methods. Tortillas are made from fresh nixtamal masa, instant nixtamalized corn masa flour, or both. More than 50% of the tortillas in Mexico are commercially produced and distributed through various channels. Consumer preferences vary regionally, with instant corn masa flour tortillas favored in the north and fresh nixtamal masa tortillas preferred in central and southern Mexico. Globally, tortillas are usually made from instant masa flour. The instant flour offers advantages such as vitamin and mineral enrichment, easier handling, and longer shelf life (about 3 months), compared to fresh nixtamal masa, which typically lasts only 4–24 h depending on storage conditions. However, the nixtamalization process requires a substantial consumption of water and energy, and their byproduct, known as nejayote, contributes to water pollution. Mexico alone produces approximately 14.4 million cubic meters of nejayote daily, which negatively impacts the environment due to its highly alkaline pH (> 10). In response to these challenges, the scientific community has been exploring alternative methods to reduce resource consumption and mitigate the environmental impact of tortilla production, focusing on processes such as extrusion cooking. While nixtamalization by extrusion presents a potential alternative, previous studies have highlighted significant starch damage that affects the rheological, functional, and textural attributes of the corn, impacting the quality of instant corn masa flour, fresh nixtamal masa, and tortillas, as well as consumer acceptance of nixtamalized products. Therefore, the objective of this review is to describe in detail the nixtamalization and extrusion processes utilized in tortilla production, including the requirements and elements involved in both processes, as well as their advantages and disadvantages. In past research and articles about nixtamalization and extrusion processes, the data and information contained within them are insufficient to thoroughly explain the modifications that occur along these processes and how those changes could affect the characteristics that consumers expect from the final product. The relevance of this investigation in food science and technology revolves around the comparison of traditional nixtamalization and extrusion to determine their viability as alternative methods to produce maize-derived products to diminish the use of resources and pollutants identified in the traditional nixtamalization process.

1. Introduction

Corn is the main cereal produced globally, playing a significant role in the economic contributions of many countries. It is widely cultivated for various purposes, including human consumption, livestock feed, and as a raw material for industrial products [1]. In the Americas, particularly Latin America, corn is a fundamental component of the diet. Corn products made through nixtamalization (tamales, totopos, tostadas, tortilla chips, and others) are staples that are customarily consumed [2–4].

Tortillas are a fundamental part of the Mexican diet and the most significant source of calories and protein [5, 6]. On average, the Mexican population consumes more than 80 kg of corn tortillas annually, amounting to about 1400 million tortillas per day [4]. According to Žilic et al. [7], in recent decades, the consumption of tortillas has spread rapidly around the world due to their health benefits, such as high levels of digestible fiber, antioxidants, vitamins, minerals, and resistant starch (RS) [8]. The instant corn masa flour and tortilla markets are crucial to both the Mexican economy and Mexicans, as tortillas are a staple in the Mexican diet. Macroeconomically, these markets are strategic tools used to stabilize and control inflation. Tortillas are made both domestically and commercially from fresh nixtamal (corn cooked in limewater) masa (cohesive dough), dehydrated nixtamal masa flour (instant nixtamalized corn flour, often referred to as instant corn masa flour), or blends of both. The choice of method depends on production factors and consumer preferences. Before the 1950s, the instant corn masa flour industry in Mexico and internationally did not exist. It was established with the founding of the Mexican company Gruma in 1949, which later expanded significantly in the 1950s and 1960s. Over the past 70 years, the demand for instant corn masa flour in Mexico has risen due to shifts in consumption patterns. The Mexican population has transitioned from traditionally prepared foods to fast food or precooked food, driven by the industrialization of the past century, population growth across the country, and modern commercialization and marketing techniques. Today, the Mexican instant corn masa flour industry is dominated by a duopoly, with Gruma SAB de CV and Minsa SAB de CV producing over 90% of the instant corn masa flour in the country. They control the corn-tortilla value chain and have successfully embedded themselves in the consumer’s mind, so much so that most of the population associates tortillas with corn flour brands like Maseca or Minsa, rather than the traditional nixtamalization process for producing fresh nixtamal masa [9].

Consumer preferences for homemade, artisanal, or industrial tortillas vary by region: in northern Mexico, tortillas made from instant corn masa flour are preferred, while in central and southern Mexico, tortillas made from fresh nixtamal masa are more popular. The traditional nixtamalization process has continued to dominate fresh nixtamal masa production due to its high consumer acceptance. This process modifies the grain, inducing structural changes that enhance the rheological, functional, and textural properties, ultimately improving the quality of the final product. While the industrial nixtamalization process cannot replicate all the steps of traditional nixtamalization, it is more commonly employed since instant corn masa flour has advantages over fresh nixtamal masa. This is primarily because it is easier for consumers to access, and its quality and sensory characteristics can be enhanced by incorporating additives into the process [10]. Both nixtamalization processes involve boiling the kernels in a ~1% Ca(OH)2 solution until they soften, then allowing them to settle in the same solution (nejayote). However, the industrial process is more efficient, reducing the steeping time from 12 to 4 h and producing instant corn masa flour as the final product, unlike traditional nixtamalization, which results in wet nixtamal masa [10–12]. Instant corn masa flour also has the advantage of being enriched with vitamins and minerals [1, 5], providing a higher yield (1 kg of corn transformed into instant corn masa flour produces 1.69 kg of tortillas, while the same amount of corn processed using the traditional method to produce fresh nixtamal masa is transformed into 1.40 kg of tortillas), easier handling and transport, longer shelf life (approximately 3 months; or 6–12 months with proper storage), and better resistance to high temperatures. Fresh nixtamal masa, in contrast, is harder to manage and distribute, with a shelf life of only 4–24 h. This limitation restricts its distribution area and use, limiting its market to areas surrounding the mill, unlike instant corn masa flour, whose longer shelf life allows it to be distributed and sold in a larger geographic area. Globally, tortillas are typically made from instant corn masa flour, as it is the only available raw material outside Mexico.

Although nixtamalization provides nutritional benefits, it requires the use of excessive amounts of energy and water. Additionally, the residue from this process, known as nejayote, contributes to the pollution of water bodies [13]. In countries where traditional nixtamalization is frequently used for tortilla production, guidelines for the management of nejayote waste are often inadequately implemented or completely absent. These regulations are usually enforced only at an industrial scale and exclude small businesses [14]. Mexico produces approximately 14.4 million cubic meters of nejayote daily, posing environmental risks due to its alkaline pH (> 10) and elevated biological oxygen demand (BOD) [15, 16]. This leads to increased water turbidity and decreased levels of dissolved oxygen, which have a discernible impact on aquatic ecosystems. Consequently, emphasis on sustainable and resource-efficient production methods has grown to address these environmental and health concerns [10]. Nejayote contains about 2% solids, which include corn pericarp, arabinoxylans, dextrins, starch, proteins, calcium, ferulic acid, coumaric acids, and other antioxidant phenolic compounds. Despite their role in water contamination, these solids have potential applications in animal diets as food additives and sources of phytochemicals due to their nutritional value [13, 15]. However, due to the lack of interest from most enterprises, the associated costs, and the poor enforcement of environmental laws, nejayote pollution remains a significant environmental challenge [14]. As a result, the scientific community has explored processes like extrusion-cooking to reduce resource consumption and the environmental impact of tortilla production [12].

During extrusion, food components are subjected to intense heat treatment, ranging between 100 and 150°C, and high pressure for a short period of time. The applied shear forces during this process cause molecular and chemical transformations in the food matrix, breaking down strong blend particles. These changes have significant implications for the nutritional quality of flours processed through extrusion. However, the extrusion process enhances the digestibility of starches and proteins and increases the retention of biologically active molecules, including soluble dietary fiber (DF) (SDF) [17, 18]. The intention of this review is to describe in detail the nixtamalization and extrusion processes used in tortilla production, including the requirements, elements, benefits, and limitations of both processes.

2. Nixtamalizaton

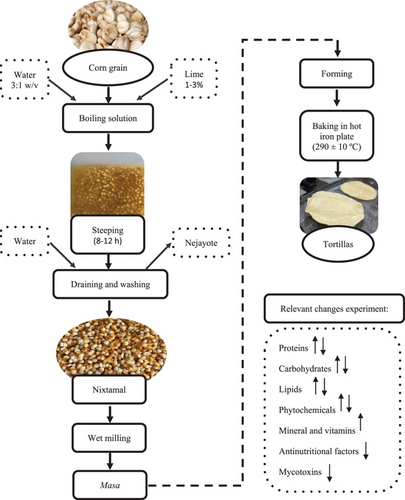

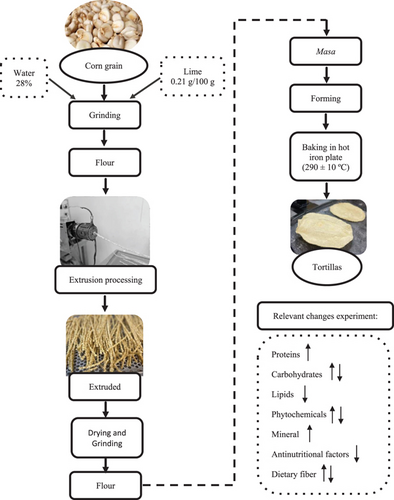

The common nixtamalization process to obtain nixtamalized products consists of boiling the corn kernels in a solution with 1%–2% of Ca(OH)2 and water (1:3 relative to the corn mass) for 20–60 min. Subsequently, the boiled corn (nixtamal) is allowed to settle in the same solution (called nejayote) generally for 8–12 h. After the settling period, the nixtamal is drained and washed to remove the pericarp and excess lime before it is ground (wet milling) to obtain fresh masa for tortilla production [11, 12] (see Figure 1).

2.1. Effect of Nixtamalization on Proteins

Corn protein content represents around 8–10% of its composition, primarily found in the endosperm, which contains 70% of the total protein [19]. The most representative proteins in corn are prolamins, glutelin, globulins, and albumins. Prolamins are proteins that can be dissolved in an alcohol suspension [20]. Corn zeins, the main prolamins, represent more than 60% of the protein in whole grain and can be classified as α-, β- and γ-zeins [21]. Glutelin can be dissolved in alkaline solutions, while albumins and globulins are dissolved in water and saline mixtures, respectively [20].

Solubility is a relevant functional property of proteins; however, corn proteins have low solubility due to their high hydrophobicity and the presence of disulfide bonds [16]. Boiling and lime treatment of corn improve the digestion of the protein available in corn by enhancing its quality, increasing solubility, and balancing the ratio of essential amino acids [18, 22]. Moreover, high temperature during boiling causes perceptible structural changes, such as protein denaturation and hydrolysis of the tertiary molecular structure, due to the formation of covalent, noncovalent, and hydrophobic interactions [8].

Different research about the topic has shown that each step in the tortilla process affects proteins in three different ways. One of these steps is the boiling and lime treatment, which is responsible of the physical changes in the protein bodies that mainly affect protein solubility [23]. This treatment also increases the dissolution of low-molecular-weight compounds such as globulins, albumins, and prolamins [24]. Additionally, it promotes a more ordered structure, harder to disrupt, by increasing protein thermoresistance and enhancing protein–starch, calcium–protein, and protein–calcium–protein interactions. These interactions result from the formation of disulfide cross-bond among adjacent polypeptides and calcium bridges [1, 25, 26]. It is also expected to observe highly polymerized zeins as a consequence of extensive disulfide bonding of zein monomers during heat treatment [25]. During the boiling process, albumins and globulins are the proteins commonly degraded due to exposure to hot water [1].

After milling and mixing nixtamalized corn, the next step is to form the masa. This process provokes the hydrolysis of noncovalent and covalent bonds due to the physical forces applied, increasing the proportion of high-molecular-weight molecules and soluble polymeric proteins. It also promotes the aggregation of the smaller polymers by exposing more molecule sites, enhancing textural features such as cohesiveness and adhesiveness. Additionally, the mixing process induces structural modifications, reducing the α-helix content and increasing the β-sheet secondary structures, which significantly impact dough functionality [27]. The last step in the process is tortilla baking, which decreases the solubility of corn proteins due to the applied heat treatment. This treatment also increases the portion of soluble polymeric proteins, including albumins, globulins, amino acids, and small peptides. Additionally, the heat treatment induces protein aggregation through the formation of covalent bonds other than disulfide bonds [27].

Research articles by Ortega et al. [28] indicate that the modifications to protein solubility observed during traditional nixtamalization are primarily due to proteins located within the germ of the grain, which are likely the main components responsible for reduced solubilization after thermal alkaline processing. The main protein affected during this process is zein, whose solubility is reduced by 58% during nixtamalization, because of hydrophobic interactions, protein denaturation, and protein cross-linking [28].

Diverse authors have concluded that the nixtamalization process modifies the aggregation of prolamins, responsible for forming weak fibrous networks in gluten-free dough during mixing. Canelo-Alvarez et al. [29] evaluated the effect of nixtamalization on gluten-free whole corn, finding that traditional nixtamalization improved protein polymerization due to Ca–zein or zein–Ca–zein interactions induced by the temperature and basic pH of the process. Zein interactions during nixtamalization create extensive fibril formations (zein fibers) through α-helix reduction and intermolecular β-sheet formation, positively affecting starch and protein swelling and entanglement, resulting in good sensory properties for tortillas. Hu et al. [30] reported that heat conditions transform proteins, altering β-turns and coil α-helices into β-sheet conformations and forming a viscoelastic dough. Rincón-Aguirre [31] concluded that nixtamalization with 0.7% Ca(OH)2 induces random coils associated with protein structure disorder and α-helix conformations correlated with masa elasticity and dough volume. Cabra et al. [32] demonstrated that nixtamalization promotes zein–starch polymerization and calcium–zein interactions due to high temperatures. Zein unions reflect partial protein unfolding, with successive unions during nixtamalization potentially caused by intermolecular disulfide covalent bonds, the driving force of the union process. Conversely, weak noncovalent bonds (ionic, van der Waals, and hydrophobic), especially hydrophobic interactions, have a lesser effect on the union process.

The nixtamalization process is influenced by physicochemical factors such as processing time, temperature (> 60°C for partial starch gelatinization), steeping temperatures (30°C–60°C for starch and protein annealing), and pH [33]. These factors synergistically impact starch and protein swelling and complexity, contributing to quality, milling yield, and favorable rheological characteristics [31]. The increase in β-sheet arrangement is attributed to hydrogen bonds between zein molecules, which form stable, extensive protein aggregates [34]. Consequently, nixtamalization could modify the secondary protein structure through hydrogen bond formation, resulting in protein aggregation [31].

2.2. Effect of Nixtamalization on Carbohydrates

Nixtamalization affects the structure of carbohydrates (see Table 1), significantly impacting starch. During traditional nixtamalization and tortilla production, corn grains are exposed to various physical and thermal variables across four distinct phases. The aforementioned phases involve cooking (thermoalkaline), steeping, wet milling (thermomechanical), and a final thermal process during baking. Each phase can trigger individual physicochemical alterations that can modify the final properties of the nixtamal, masa, and tortilla [35].

| Corn grain | Flour | Masa | Tortilla | References |

|---|---|---|---|---|

| Nixtamalization | ||||

|

|

|

|

[35] |

|

|

|

|

[12] |

| Extrusion | ||||

|

|

|

|

[12] |

|

|

nr | nr | [36] |

|

|

nr | nr | [37] |

- Abbreviation: nr, not reported.

In the case of starch, the masa, using water as a solvent, undergoes at least three different gelatinization alterations. The first one occurs during cooking and steeping, where starch gelatinization is observed in the outer layers of the endosperm, representing approximately 30% of the total starch, which makes the endosperm penetrable. The second alteration occurs during the wet milling process, resulting in about 15% of gelatinization due to the thermomechanical process. The third alteration is associated with the gelatinization during the baking of the tortilla, where it is heated three times. During baking, one side is heated for approximately 10 s and then flipped over on two different occasions before the baking process is complete. Additionally, during the tortilla baking process, the moisture content is reduced but still high enough to allow the third stage of gelatinization to occur [16, 35].

According to Serna-Saldivar [5], the most relevant process during tortilla production is the thermoalkaline process, due to its capacity to modify the functionality and features of finished products. Those changes are primarily caused when water and lime permeate the corn, typically through the tip cap, increasing their concentration in the germ and then flowing to the tube cells of the rest of the corn. The damage caused by the thermoalkaline process includes the swelling and loss of structure of the starch granules as the cooking process progresses [16, 22].

Moreover, during the thermoalkaline process, the pericarp experiment alters in two phases. The first phase consists of the solubilization of starch, pectin, and lipid, while the second involves the breakage and solubilization of cell wall elements. Additionally, the hydrolysis of ester bonds found in cellulose–hemicellulose–lignin structures, leads to the generation of heteroxylans, such as galacto and glucuronoarabinoxylans [11], and increases the RS in corn. The increase in RS, according to different studies conducted by Rodriguez et al., may originate from the merging of starch with calcium ions due to ionic interactions between RS and calcium ions, which can create a crosslinking structure [38].

Applying heat to corn grain, during nixtamalization, leads to a decrease in the crystallinity and birefringence starch. This occurs because of the reorganization of amylose into a V-type (helical) crystalline form, which is typically absent in unprocessed starch. The newly formed V-type structure results from changes in the A and B crystal structures due to the disarrangement of amylose and amylopectin found in native starch [22, 39, 40]. Furthermore, the previously mentioned cooking process induces complete gelatinization of the starch fragments on the outer surface of the endosperm and partial gelatinization on the inner surface [28]. Research on nixtamalization concludes that the ability of calcium to bind to amylose in the starch is due to the high pH generated during the nixtamalization process. This high pH results in the ionization of hydroxyl groups within the amylose, creating binding sites for calcium ions to cross-link amylose molecules [8, 23, 41].

During the steeping period, heat promotes the progressive gelatinization of starch granules, leading to better calcium assimilation, hardening the plant cell layer, and making water more inclined to enter the protein matrix of corn grains [12]. The water used in steeping penetrates the external layer more than the internal layer of corn grains, solubilizing an average of 15% of the hemicellulose into the nejayote [16]. Additionally, steeping water decreased the glass transition temperature and enhanced the movability of the amorphous zone of the starch granule, making it softer, more malleable, and more elastic [12].

Annealing during the steeping of the cooking liquid significantly impacts the texture of tortillas [11]. This reaction occurs within the glass transition and gelatinization temperatures, an increase of 45%–60% (w/w) in the water content of masa and enhancing the interaction between starch granules and calcium [12]. This phenomenon can be attributed to the deterioration of the pericarp, reduction in solubility, lipid saponification, and the incomplete gelatinization and formation of amylose–lipid complexes known as RS [42]. In other words, this results in the reinforcement and an increment of starch molecules, driven by annealing and the combination of starch and calcium [8].

Wet milling is a crucial step in the nixtamalization process that involves rinsing the corn grains previously modified during the steeping period. The primary objective of this step is to remove the cooking liquor from the grain, which affects the properties of the final product (tortilla) and, if not properly managed, can pollute water bodies due to its high alkalinity. Wet milling plays a key role by disrupting the swollen starch molecules in the nixtamal and distributing the hydrated starch and proteins around the nongelatinized fractions of the endosperm [16]. This process results in the formation of a flexible masa matrix structure, which is the product of the complex formation reaction between amylose and lipid, resulting in a crystalline domain [12]. Wet milling also promotes intense interactions with calcium ions, leading to the progressive gelatinization of the grain [43]. Additionally, it facilitates the unfolding of starch molecules from the protein structure, allowing for an increase in water content that causes the starch to expand its volume by 30%–40%, while simultaneously elevating the concentration of RS found in the masa [6, 12, 35].

The final step in the nixtamalization process is baking, a thermal process that involves applying heat to the masa, which has been previously shaped into a tortilla. While this process can increase the amount of RS [35], it also significantly damages the starch in the masa used to produce tortillas [12].

The tortilla production process increases the gelatinization of starch molecules, creating an amorphous structure in the form of agglomerates [44]. In addition, it favors the generation of amylose–lipid complexes formed through interactions between amylose and lipids in the corn flour [45]. Under storage conditions, this process promotes further gelatinization and enhances the formation of retrograded starch, as shown in Table 2 [8]. The formation of the amylose–lipid complex improves the functionality of starch by transforming its pasting characteristics, solubility, viscosity, absorption, and swelling capacity. The complex forms after the starch is cooked and then cooled, causing alterations in its crystalline structure. Heat increases the diameter of the amylose double helix, allowing lipids to bond through electrostatic interactions [53].

| Starch (%) | Corn grain | Nixtamalization | Extrusion | References | ||||

|---|---|---|---|---|---|---|---|---|

| Nixtamalized flour | Masa | Tortilla | Extruded flour | Masa | Tortilla | |||

| Resistant starch | nr | 0.79 | 0.85 | 0.90 | 1.01 | 1.43 | 1.64 | [12] |

| 0.60 | 1.40 | 1.20 | 2.10 | nr | nr | nr | [46] | |

| 1.99 | 2.18 | 2.05–2.27 | 3.12–3.87 | nr | nr | nr | [8] | |

| 0.24 | 1.10 | nr | 2.30 | 1.20 | nr | 2.5 | [47] | |

| 0.86–0.93 | nr | nr | 2.15–3.06 | nr | nr | nr | [48] | |

| nr | 1.62 | nr | 2.61 | 1.33 | nr | 3.20 | [49] | |

| nr | nr | nr | nr | 1.6 | nr | nr | [50] | |

| nr | nr | nr | nr | 2.02 | nr | nr | [51] | |

| Retrograded starch | nr | 1.02 | nr | 1.67 | 0.99 | nr | 1.42 | [47] |

| nr | 0.60–0.85 | 0.65–0.86 | 0.5–3.20 | nr | nr | nr | [8] | |

| nr | 1.51 | nr | 1.50 | 1.11 | nr | 1.57 | [49] | |

| Damaged starch | nr | 19.21 | 21.73 | 29.75 | 16.97 | 23.23 | 32.25 | [44] |

| Gelatinization of starch | nr | 14.7 | 22.9 | 67–75 | 38–74.5 | nr | nr | [30, 52] |

- Abbreviation: nr, not reported.

Retrogradation is correlated with the value of RS [46]. The rearrangement of interactions among amylose and amylopectin in retrograded starch depends on the long lifetime and the capacity of these polymers to create a different crystalline structure. Amylose can affect shelf life and is responsible for hardening and reducing the elasticity in tortillas. Amylopectin influences tortillas after a long period of time, which is associated with the recrystallization process [48, 54]. Retrogradation is key in the formation of RS in cooled tortillas [55].

RS is the portion of starch that is not digested in the small intestine; however, it is fermented by the microbiota in the large intestine, leading to the formation of short-chain fatty acids and providing metabolic effects, such as lowering blood cholesterol and triglyceride levels and controlling glycemic homeostasis. RS, compared to common starch, also modifies food functionality, digestibility, and fermentability after consumption.

RS is classified into five groups according to its botanical source and processing. Type RS1 is the type that is not available to digestive enzymes, as a consequence of being surrounded by a protein matrix and enclosed by cell walls that block enzymatic action. Type RS2 is the native starch granule that is highly resistant to enzymatic hydrolysis due to its high density [55]. Type RS3 is formed by retrograded starch, caused by temperature changes, which increases the predisposition to form double helices and is affected by factors such as starch components (amylose and amylopectin), food ingredients (e.g., water, lipids, proteins, carbohydrates, and salt ions), and processing conditions like temperature, retrogradation time, and retrogradation order [56, 57]. Type RS4 results from chemical alterations (conversion, substitution, and cross-linking) with a functional group that cannot be hydrolyzed in the small intestine but can be fermented in the colon. RS5 can be associated with complexes like glycerol, amino acids, peptides, proteins, lipid–protein, polyphenols, and other polysaccharides. All these V-type starch complexes are responsible for reducing the swelling and hydrolysis of starch granules by inhibiting the amylolytic activity of digestive enzymes [55].

Traditional nixtamalization is a continuous process involving several phases, such as the thermo-alkaline process, steeping, wet grinding, and baking. During traditional nixtamalization, a fraction of the corn starch undergoes partial or total modification, which increases the RS value due to exposing the food matrix to heat (220°C) [55]. Crude corn is associated with type RS1 (not available for digestion), and isolated native starch is classified as type RS2 [55]. During thermoalkaline cooking and steeping, the increase in RS could be associated with the development of amylose–amylopectin complexes or other nonstarch particles situated in the external layers of the endosperm [55]. In the internal layers of the endosperm, starch undergoes partial gelatinization in the early steps of the nixtamalization process. Additionally, at this stage, the arrangement of V-type starch complexes with various types of nonstarch molecules may occur, creating new complexes that can be classified as RS5 [58]. Specifically, it has been reported that during its processing by nixtamalization, maize starch forms complexes with fatty acids, resulting in the creation of amylose–lipid complexes [45]. It has been observed that both physical and chemical changes occur in starch due to the development of amylose–lipid complexes, which influence properties such as pasting behavior, water absorption capacity, solubility, swelling capacity, and viscosity [53]. Moreover, the presence of divalent cations (Ca+2) during this step plays an important role in the formation of RS3 by promoting short-chain glucan within starch, modifying its surface charge, and favoring the arrangement of cross-links between linear chains, thereby increasing the RS value [55, 59].

From nixtamal to tortilla (wet grinding and baking), cooked grains are milled, which increases their temperature due to friction and generates a heterogeneous matrix [55]. Tortilla baking involves three steps. First, the tortilla is baked on one side, then flipped over twice for a few seconds each time, and finally, removed from the iron plate [35]. This thermal treatment induces starch gelatinization, which promotes the formation of complexes between free lipids (located in the germ) and lixiviated amylose, which can be categorized as RS5 [55]. During the production of tortillas through the traditional nixtamalization process, the total RS is a combination of RS1 (physically inaccessible starch), RS2 (native starch), RS3 (retrograded starch), and RS5 (amylose–lipid complexes) [30].

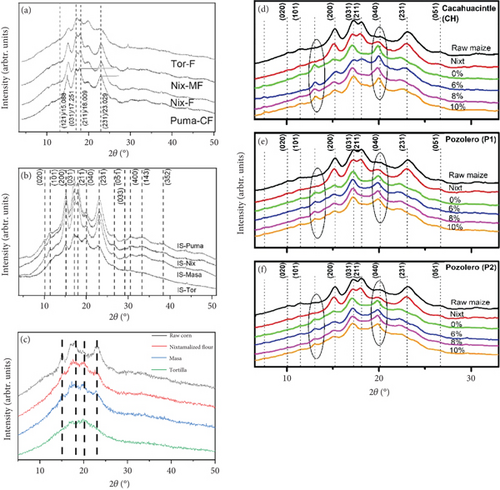

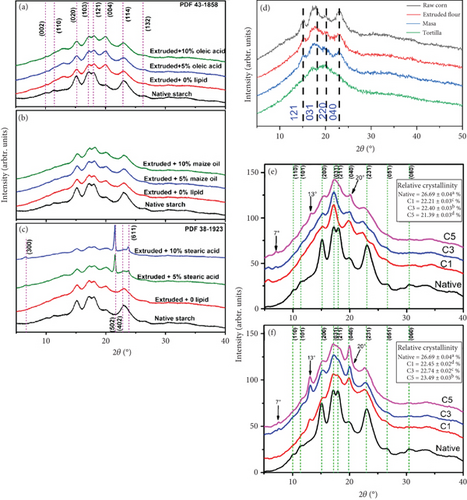

Starch presents three nanocrystalline structures: A-type, which refers to nanocrystals with an orthorhombic crystal structure; B-type, which refers to nanocrystals with a hexagonal crystal structure; and C-type, a combination of A- and B-types. The A-type starch (indicating the presence of orthorhombic nanocrystals) is commonly observed in cereals such as corn [53]. Various authors have investigated changes in starch’s X-ray patterns during tortilla production (see Figure 2). X-ray diffraction is commonly used to examine changes in crystalline structures during thermal, mechanical, and chemical processes [55]. The width of the peaks in the diffraction patterns determines the crystallinity of the sample. In the specific case of maize, the angles and planes (Miller indexes) where X-ray diffraction is observed are 15.140°/(200), 17.251°/(031), 18.009°/(211), and 23.029°/(231) (2𝜃) [53]. Rojas-Molina et al. [55] evaluated X-ray diffraction patterns from corn, nixtamal, masa, and tortilla by traditional nixtamalization, observing diffraction peaks. They concluded that during the process to obtain tortillas, the starch is not completely gelatinized, which means that crystal structures are preserved in starch (see Figure 2a,b). Enríquez-Castro et al. [44] observed that during the transformation of corn into tortillas, a reduction in the crystalline structures can be observed as X-ray pattern peaks gradually disappear after analyzing raw corn, nixtamalized flour, masa, and tortilla individually (see Figure 2c). Dorantes-Campuzano et al. [45] evaluated the effect of nixtamalization on three varieties of corn using XRD and observed a reduction in peak intensity compared to raw corn at the following angles and planes (Miller indexes): 10°/(052), 11°/(223), 15°/(140), and 17°/(251). As only the intensity is reduced, it can be concluded that corn does not undergo complete gelatinization, maintaining 80% of its starch integrity (see Figures 2d, 2e, and 2f) [45].

2.3. Effect of Nixtamalization on Content and Bioactivity of Phytochemicals

Food is considered functional in its unprocessed form due to the presence of bioactive compounds without nutrimental contribution, known as phytochemicals [38]. Different researchers have concluded that nixtamalization causes a significant reduction of nutrients and bioactive compounds due to the removal of the pericarp and germ in the cooking water (nejayote) during the washing steps [60].

Phenolic compounds are present in soluble form (free) and insoluble form (bound) [61]. Free phenolics are usually flavanols, while bound phenolics are typically acids [6]. These phytochemicals are abundant in the corn grain and frequently found with different macromolecules in the food matrix, with around 80% in insoluble form and the rest in soluble form (see Table 3) [6, 66]. The main phenolic acid in corn grain is ferulic acid, followed by 4-hydroxybenzoic acids [62]. Ferulic acid is an ester-bonded to the cell wall polysaccharides, such as pectin and arabinoxylans [6, 18, 63]. Nixtamalization disrupts the cell matrix and induces hydrolysis of the ester bond that binds the phytochemicals to the cell wall compounds, releasing the bound phenolics into free phenolics. The disruption in the cell wall matrix caused by nixtamalization provokes a reduction in the phenolic compound content in corn that can be up to 80% [63, 64]. However, a high content of free phenolics and soluble ferulic acid can be observed when comparing processed to nonprocessed grains. This behavior is caused mainly because phenolic compounds are not attached to the pericarp and remain principally in the germ and endosperm [67].

| Compound (mg/100 g) | Product | References | ||

|---|---|---|---|---|

| Corn grain | Nixtamalized flour | Tortilla nixtamalized | ||

| Free phenolic compounds | ||||

| Ferulic acid | 0.23 | 7.41 | nd | [60] |

| nr | nr | 1.12–5.15 | [62] | |

| 0.34–0.99 | nr | 97.09–205.79 | [63] | |

| Gallic acid | 6.559 | 1.167 | nd | [60] |

| Chlorogenic acid | 4.33 | nd | nd | [60] |

| 12.4 | 21.20 | nd | [63] | |

| Coumaric acid | nr | nr | 0.013–0.789 | [62] |

| 28.91 | 45.40 | 38.77 | [63] | |

| Catechin | 5.312 | nd | nd | [60] |

| Rutin | 6.06 | nd | nd | [60] |

| Quercetin | 4.60 | nd | nd | [60] |

| Caffeic acid | nr | nr | 0.18–0.52 | [48] |

| 2.74 | 3.90 | nd | [64] | |

| Syringic acid | nd | nd | 1.11–5.71 | [62] |

| 3.21 | 3.90 | 3.32 | [64] | |

| 4-Hydroxybenzoic acid | nr | nr | 1.06–1.77 | [62] |

| 2.39 | 4.02 | nd | [64] | |

| Vanillic acid | 8.15 | 15.90 | nd | [64] |

| Total free phenolic | 27.10 | 8.58 | nr | [60] |

| nr | nr | 4.31–6.90 | [62] | |

| 57.80 | 94.32 | 42.09 | [64] | |

| 3.49 | nr | 2.46 | [65] | |

| Bound phenolic compounds | ||||

| Ferulic acid | 36.81 | 15.79 | nd | [60] |

| 82.27 | 47.90 | 24.87 | [64] | |

| 330.06–529.34 | nr | 97.09–205.79 | [63] | |

| Gallic acid | 3.22 | 2.86 | nd | [60] |

| Chlorogenic acid | 0.51 | 0.65 | nd | [60] |

| 3.50 | 7.20 | 4.03 | [64] | |

| Coumaric acid | 16.46 | 11.34 | nd | [60] |

| 4.39 | 7.03 | 6.38 | [64] | |

| Catechin | 2.04 | 3.31 | nd | [60] |

| Rutin | 8.08 | 9.17 | nd | [60] |

| Caffeic acid | nd | 2.6 | 0.87 | [64] |

| Syringic acid | 0.86 | 5.37 | 3.21 | [64] |

| Vanillic acid | nd | ≈0 | 8.90 | [64] |

| Total bound phenolic | 67.14 | 43.14 | nr | [60] |

| 91.02 | 70.10 | 39.36 | [64] | |

| 140.9 | nr | 38.50 | [65] | |

| Total phenolics | 94.24 | 51.72 | nr | [60] |

| 148.82 | 164.42 | 81.45 | [64] | |

| 144.39 | nr | 40.96 | [65] | |

- Abbreviations: nd, not detected; nr, not reported.

The disruption of the cell wall matrix caused by nixtamalization increases the bioaccessibility of bioactive compounds within corn grains [44]. According to Menchaca-Armenta et al. [65], the traditional nixtamalization process used to elaborate corn tortillas contributes to the increase in bioaccessibility of phenolics during digestion by reducing particle size, modifying the cellular matrix, or degrading the fibrous structure of the grain [46]. As digestion continues, the quantity of phytochemicals improves in the soluble fraction of whole grain and tortillas. The high solubilization of these components indicates their increased availability to be beneficial to different organs and tissues. Phenolic compounds affect the physical and chemical characteristics of starch, consequently increasing its solubility in water while decreasing viscosity, hardness, adhesiveness, cohesion, and elasticity, which has a clear effect on the final product [68]. Phenolic compounds are released during lime cooking and are related to cell wall deterioration, starch alterations, and the functional attributes of nixtamalized products [69].

Corn contains various pigments, such as carotenoids and anthocyanins, that enhance its antioxidant activity. The predominant carotenoids found in corn, based on their activity, are as follows: (1) vitamin E activity: α-tocopherol and α-tocotrienol (found in the germ); (2) provitamin A activity: α-carotene and α-cryptoxanthin; and (3) nonprovitamin A activity: lutein and zeaxanthin (found in the endosperm). These pigments are observed in yellow, red, and orange corn varieties [6]. Anthocyanins, on the other hand, are pigments mainly present in black, purple, and blue corn varieties, with less concentrations in pink, red, and orange varieties. The most abundant anthocyanins found in corn grain include cyanidin-3-glucoside, pelargonidin-3-glucoside, and peonidin-3-glucoside. Acetylated anthocyanins are also present, though their overall concentration in the grain is low.

Studies have shown that nixtamalized products, such as tortillas, experience a significant reduction in anthocyanins (46%–88%), provitamin A (15%), and carotenoids (including β-cryptoxanthin at 84% and β-carotene at 38%). The reduction of these components is attributed to chemical alterations caused by alkaline pH parameters and thermal treatment, which may lead to oxidation and isomerization of the pigments. Additionally, the physical reduction of the pericarp and the leaching of phytochemicals into the nejayote contribute to this loss [67, 70, 71].

2.4. Effect of Nixtamalization on Minerals, Vitamins, and Antinutritional Factors

Micronutrients, such as vitamins and minerals, positively impact on the human body regardless of their quantity. The pericarp, germ, and aleurone layer of the corn grain contain the highest concentrations of micronutrients; however, these components are mostly removed during the thermomechanical processes involved in nixtamalization [72].

Minerals are inorganic elements, essential for proper nourishment of the human body. Major minerals found in most food groups include calcium, phosphorus, magnesium, and potassium, with lesser amounts of iron, zinc, copper, manganese, and selenium. These minerals are crucial for various vital processes in living organism; for instance, iron is necessary to produce hemoglobin, and iodine is essential for balancing thyroid hormones [72].

Traditional nixtamalization uses calcium hydroxide to modify the corn structure, increasing the calcium content of products by up to 400%, which makes them a significant calcium source for consumers [73–75]. The changes induced during nixtamalization result in ionic bonds between calcium cations and hydroxyl groups within the starch. This process also facilitates the dispersion of water in the germ and endosperm, enhancing starch gelatinization and visibly increasing the viscosity of masa and tortillas [41, 76]. However, higher calcium concentrations significantly reduce water absorption into the starch [73]. In the first 60 min of steeping, calcium is retained in the pericarp’s outer layers [8]. Studies have shown that calcium is primarily located in the pericarp, influencing corn flour thickness, so tortillas made with soft kernels will retain more calcium [23, 77].

During nixtamalization, iron levels in masa can be reduced by approximately 15%. This reduction varies depending on the corn phenotype, which has a more substantial impact on yellow varieties compared to white corn [73]. Selenium content in corn is also reduced by heat treatment (boiling and baking) by 51% and 61%. Despite this reduction, the remaining selenium levels do not significantly affect the average daily intake, allowing for continued benefits to the thyroid gland and immune system functions [72, 75]. Magnesium content increases after nixtamalization [18], likely due to the detachment of this mineral from cooking equipment and its subsequent incorporation into the mix during cooking [74].

Zinc bioavailability is influenced by phytic acid, which binds to zinc to form zinc phytate [78]. Although zinc levels are reduced during milling, the remaining zinc is more bioavailable due to the reduction of phytate levels from the thermomechanical process [72]. The high retention of zinc can be attributed to its location in the endosperm and germ, with the pericarp being the only outer layer removed during nixtamalization [8].

According to scientific evidence, mineral conservation when preparing tortillas depends on the variety and amount of Ca(OH)2 added during heat treatment and the steeping period [79, 80]. Lime cooking treatment negatively affects the concentration of vitamins (thiamine, riboflavin, niacin, and carotene), reducing their levels by 50%–70% [73, 81]. However, niacin (vitamin B3) becomes more bioavailable as the process releases B vitamins. Whole grain releases niacin during boiling and enzymatic digestion of corn [8, 82].

Corn contains certain antinutritional elements, including phytate (phytic acid), which inhibits mineral absorption by binding to them and obstructing enzymatic activity essential for the gastrointestinal system to digest and absorb protein and carbohydrates [83]. Corn kernels contain 80% of their phytate in the germ, 3% in the endosperm, and about 10% in the outer layers. Phytate is crucial for grain germination but significantly affects the bioavailability of other micronutrients in corn [72]. Phosphorus, the most common phytic acid in corn, is present at about 210 mg/100 g [74]. Heat treatments can decrease phytic acid content. Suri and Tanumihardjo [74] found that nixtamalization reduced phytic acid by 20%. Various researchers have concluded that even with high phytic acid levels (> 833.3 mg/100 g of tortilla), calcium absorption remains elevated. This behavior is explained by the incomplete digestion of calcium phytate in the lower intestine, which facilitates calcium absorption and the breakage of phytates during the traditional nixtamalization process [84].

2.5. Effect of Nixtamalization on Lipids

Nixtamalization leads to physicochemical modifications in the lipids present in corn. The germ oil in corn, which contains the highest oil content of the grain, is a rich source of essential fatty acids. These fatty acids include unsaturated fatty acids such as linoleic acid (indispensable for human health). Because essential fatty acids are not synthesized by the human body, they must be consumed from external sources [85, 86]. Corn is an excellent example of such a source, containing an average of 4.5% total oil. This oil consists of approximately 46% linoleic acid, 52% oleic, and 2% stearic and palmitic acid [87, 88].

Generally, lipids are susceptible to alterations due to factors such as light, oxygen, temperature, the content of unsaturated fatty acids, and the presence or absence of antioxidants [85]. During the nixtamalization process, physicochemical changes induce three main reactions in lipids: saponification, oxidation, and reduction. These reactions are predominantly observed during the washing and draining of the nejayote [8].

Various studies have determined that calcium hydroxide can saponify free fatty acids, producing glycerol by reacting with calcium salts present in aliphatic acids or through the breakage of ester bonds in mono, di, and triglycerides. This interaction of alkaline substances with free fatty acids to generate soap leads to undesirable effects such as excessive foaming and altered flavor, which negatively impact the oil’s quality [89–91].

Lipid oxidization is an autocatalytic reaction that modifies the structure of polyunsaturated fatty acids, generating compounds that induce the production of free radicals capable of forming peroxides and hydroperoxides, which are potentially harmful to human health [86]. However, highly polyunsaturated corn oil has a stable structure due to its elevated levels of natural antioxidants [92]. Depending on the oxidation degree of polyunsaturated groups, the number of free radicals produced by exposure to oxygen can either increase or decrease. The presence of sterols, stanols, and ferulates in corn reduces oxidation, making the production of free radicals during tortilla production less likely. Consequently, a lower degree of unsaturation and a smaller number of unsaturated groups are expected in corn and tortillas [93].

Amylose–lipid complexes are composed of single-helix amyloses (leached due to gelatinization) and free lipids (monoglycerides and fatty acids), which form amorphous crystalline structures [88, 94]. Various studies have concluded that the generation of amylose–lipid complexes influences the rheological properties of masa and tortillas and has been correlated with health benefits such as hypoglycemia control, risk reduction of colon cancer, and better digestibility of bioactive compounds [8, 48, 88, 93, 94]. Amylose–lipid complexes are classified into two forms depending on the melting temperature of the crystalline structure. Type I complexes have a less ordered structure, while Type II complexes have a more ordered structure [95]. An experimental study conducted by Santiago-Ramos et al. [96] demonstrates that both types are present in tortillas. Type I complexes result from nixtamalization at temperatures below 90°C, while Type II complexes result from heating to temperatures above 100°C during the tortilla baking process.

Analysis of data from numerous investigations indicates that due to the loss of matter during the nixtamalization process, a reduction in lipid content in tortillas is expected compared to the lipid content in the corn kernel at the beginning of the process. Bedolla et al. [97] observed a 28% decrease in lipid content between raw corn and tortillas. Pflugfelder et al. [98] reported a reduction in lipids of around 11%–18% due to the loss of corn parts and soluble elements, without affecting the distribution of different types of fatty acids [81, 88]. Martínez-Flores et al. [85] concluded that the decrease in fatty acid content coincides with the reduction of total oil value after the nixtamalization and tortilla process, making fatty acids easier to extract. This can be deduced from the saponification of fatty acids, especially when calcium ions react with carboxyl groups within them, and the interaction of fatty acid molecules in the formation of amylose–lipid complexes.

Recently, Alberdi-Cedeño et al. [93] reported that the presence of certain quantities of sterols, stanols, and ferulates acts as an antioxidant and can affect the oxidative stability of tortilla preservation and potential consumer health. Fatty acids, being the main minor components eliminated during processing, are found in low-concentration tortillas. This is due to the susceptibility of fatty acids to oxidation, which results in an increment in the oxidative stability of lipids in tortillas compared to raw corn. The loss of lipids can be attributed to the formation of salts due to a reaction with calcium hydroxide, which is subsequently removed during washing. However, the distribution of lipids in corn remains almost in the same proportion.

2.6. Effect of Nixtamalization on Mycotoxins

Mycotoxins are secondary fungal metabolites frequently found in food, mainly as a result of specific molds, which can form either in the soil or during grain storage. These compounds represent a significant health risk to consumers due to their toxic and carcinogenic potential [18, 99]. Corn kernels naturally harbor fungi such as Aspergillus, Fusarium, Alternaria, and Penicillium, which can contaminate the grain with various mycotoxins [100]. The most common mycotoxins in corn include can aflatoxins, cyclopiazonic acid, fumonisins, and zearalenone; however, other mycotoxins like cereulide and patulin have also been detected in corn products [100, 101].

Maize is highly susceptible to mycotoxin contamination, as this can occur both during the growth of the crop and after postharvest processing [100, 102]. Generally, food processing can alter the presence of mycotoxins in raw materials [100]. During traditional tortilla production, various physicochemical changes can occur in corn kernels due to the high temperatures and the presence of calcium, which creates an alkaline environment. These changes may lead to the reduction of certain mycotoxins, such as fumonisin and deoxynivalenol, through their removal into the nejayote; however, aflatoxins and zearalenone remain unaffected because they are not water-soluble [18, 99, 103]. In such cases, the structural changes described in the previous paragraph might still conceal an unknown toxic structure or may be transformed into another toxic configuration. Additionally, the level of available toxins could increase due to the hydrolysis of mycotoxins from matrix components during food processing [99], with aflatoxins and fumonisins being the primary mycotoxins of public health concern [104].

Aflatoxins are the most common and dangerous mycotoxins found in corn, including B1 (AFB1), B2 (AFB2), G1 (AFG1), and G2 (AFG2). AFB1 is particularly noteworthy as it is the most prevalent aflatoxin in corn produced in tropical areas, posing a constant threat to human health. The strategy to reduce aflatoxins varies depending on the location where the corn is harvested [102, 104, 105].

Different countries around the world have robust regulations to define acceptable levels of aflatoxin concentration in grain, with particular attention to AFB1. According to the International Agency for Research on Cancer (IARC), AFB1 is the most toxic aflatoxin, known to cause liver damage. High levels of exposure to AFB1 can significantly increase the risk of developing hepatocellular carcinoma, esophageal cancer, and neural tube defects and may even result in death [104].

Aflatoxins consist of a coumarin nucleus bound to a bifuran ring and contain either a pentanone ring or a 6-membered lactone. Additionally, the lixiviation of aflatoxins into liquid fractions, along with alkaline treatment, induces the opening of the lactone ring in aflatoxins, which results in a reduction of the fluorescence of these structures, thereby decreasing their detectability through fluorescence. Furthermore, a reduction in toxicity and mutagenicity can be expected following the separation of the lactone ring [106]. However, the changes observed in aflatoxins during alkaline processing are not permanent and can be reversed under acid conditions, such as those found in monogastric digestive systems [99]. The reduction in aflatoxins and their lixiviation into lime water depends on the type of aflatoxin and the specific processing conditions [107].

Previous investigations into the exposure to mycotoxins during the nixtamalization process have yielded varying results regarding the reduction of aflatoxins. Ulloa-Sosa and Schroeder [108] found that during the thermoalkaline and thermomechanical processes, AFB1 + AFB2 levels decreased less (40%–50%) in nixtamal and masa compared to AFG1 + AFG2 (≈75%), resulting in an overall aflatoxin reduction of about 65%. De Arriola et al. [107] reported a reduction in AFB1, AFB2, AFG1, and AFG2 levels in masa by approximately 93%, 90%, 98%, and 97%, respectively. Price and Jorgensen [109] observed that aflatoxin levels decreased by approximately 50%–70% in tortillas compared to the raw grain. Moreno-Pedraza et al. [110] achieved a complete reduction of AFB1 contaminations during the nixtamalization process and found that tortilla baking could reduce AFB1 levels entirely or almost entirely. Another study reported a 90% reduction in aflatoxins in corn tortillas following nixtamalization [111]. Torres et al. [112] concluded that traditional nixtamalization reduced aflatoxin levels in tortillas and byproducts by 52%–85%.

Variations in aflatoxin reduction reported by different authors depend on factors such as processing conditions, levels of contamination, and the type of contamination, all of which can influence mycotoxin reduction. Consequently, results regarding aflatoxin toxicity in alkali-processed corn products, such as tortillas, may vary [99].

Fumonisins are another group of mycotoxins, classified as B1 (FB1), B2 (FB2), and B3 (FB3), with FB1 being the most abundant, constituting about 70% of all fumonisins found in contaminated food [104]. Evidence of negative health impacts caused by fumonisins in humans is limited, and studies focused on this issue are inconclusive [103]. Fumonisins can be eliminated during various steps of the nixtamalization process due to their ability to dissolve in water and, consequently, into a liquid fraction during the cooking and steeping processes. This means that fumonisins can be reduced through the removal of nejayote. Moreover, the thermoalkaline treatment induces the breakage of the O-acyl chains of fumonisins, allowing the hydrolysis of fumonisins to form and contributing to a detoxification [99].

Due to its widespread consumption, various studies have evaluated the presence of fumonisins in corn tortillas. Wall-Martínez et al. [104] found that the probability of fumonisin intake was less than 5% due to its low concentration in corn tortillas. Palencia et al. [113] determined that fumonisins could be reduced by up to 72% during the tortilla-making process. Similar findings were observed by Dombrink-Kurtzman et al. [21], who concluded that nixtamalization retained 18% of the initial fumonisin content, and by the end of the process, 75% of it was removed.

Although various researchers have concluded that aflatoxins and fumonisins can be significantly reduced during the production process from masa to tortilla, they do not guarantee a mycotoxin-free product. Further investigation is needed to gain a better understanding of the effects of nixtamalization on these mycotoxins.

3. Extrusion

Extrusion is a continuous process that applies high temperature, shear forces, and pressure for a short period. This, combined with unit operations such as mixing, forming, and sizing, homogenizes and disperses the ingredients within the food matrix, leading to molecular and chemical modifications in extruded products. In the nixtamalization extrusion process to obtain nixtamalized extruded flour, corn grain grits are mixed with lime (in a proportion between 0.2% and 0.3% of corn’s mass) and water to reach a humidity of 18%–20%. The mixture is then continuously fed into an extruder. When the humidity drops below 10%, the extrudates are ground into flour to produce nixtamalized extruded flour for tortilla production (see Figure 3) [1, 5, 18].

3.1. Effect of Extrusion on Protein Digestibility and Bioavailability

Food protein quality, influenced by its bioavailability and digestibility, is the main indicator of its contribution to nutrition and health, as it helps improve the absorption and metabolic requirements of amino acids and nitrogen [18, 114]. The digestibility of food proteins can be affected by proteolysis, which breaks down protein into smaller polypeptides or amino acids that can be absorbed by the body [115, 116].

Digestibility can be affected by exogenous (antinutritional) and endogenous (cross-linking, hydrophobicity, and alterations in protein secondary structure) factors. Changes to proteins are induced by degradation, dissociation, aggregation, thermal processing, and the presence of antinutritional factors that are detrimental to protein absorption. The elimination or even the reduction of exogenous and endogenous factors is key to increasing the biological utilization of cereal proteins, which can have digestibility rates of up to 80% [116, 117].

Heat, shear forces, and humidity applied during extrusion have a profound effect on protein availability, as they reduce antinutritional factors and trypsin inhibitors, which would otherwise inhibit enzymes involved in protein digestion [18]. Protein digestibility, affected by conformation, structure, and degree of hydrolysis, increases in extruded products [114, 117, 118]. Easier digestibility, due to extrusion, is caused by modifications to proteins such as denaturation, association, dissociation, and aggregation with noncovalent bonds or cross-links with covalent bonds within the protein or other compounds in the food matrix, which promotes the exposure of enzyme access sites and hinders antinutritional factors that negatively effect on digestion [18, 117, 119].

Different investigations have detected an increase in digestibility during the extrusion process. Zhang et al. [117] observed an increase in digestibility in extruded canola meal when added moisture is up to 30% of the mix. Gámez-Valdez et al. [120] evaluated a functional extruded tortilla made from amaranth and blue corn against a tortilla made from commercial flour (Maseca) and determined a significant effect on digestibility with an average increase of 3.29%.

Gutierrez-Dorado et al. [47] compared tortillas made from commercial nixtamalized flour (Maseca) with tortillas made from extruded quality protein maize (QPM) flour, reporting protein digestibility values approximately 3% higher in the QPM tortillas than in those made with commercial flour. Furthermore, León-Murillo et al. [4] studied the protein digestibility of tortillas produced with commercial nixtamalized blue corn flour, extruded native blue corn flour, and a mixture of extruded blue corn flour with defatted chia flour, reporting values of 75.82%, 77.01%, and 84.01%, respectively. Additionally, Bon-Padilla et al. [121] evaluated tortillas produced from nixtamalized corn and extruded chickpea flours, finding that extrusion improved protein digestibility to 82.01% for extruded tortillas compared to 76.82% for commercial tortillas. Similar results were observed by Qi et al. [122], who examined the impact of extrusion temperature on pea flour and concluded that protein digestibility increased from 84.37% to 90.21% when the extrusion temperature was raised from 50°C to 90°C.

Previous reports indicated that protein digestibility either did not change or was only minimally reduced after baking the masa to prepare tortillas [4, 47, 121]. In relation to the extrusion process, digestibility can be affected by independent variables such as temperature and moisture [117, 121].

3.2. Effect of Extrusion on Carbohydrates

Starch, an important polysaccharide macronutrient in the human diet, is both a functional component of foods and a source of energy. Starch is composed of amylose (a more soluble linear polymer) and amylopectin (a branched polymer). Additionally, it enhances desired physicochemical and sensory properties in foods, such as texture, mouthfeel, and appearance [123, 124]. In fact, starch is the principal carbohydrate present in cereals, and it reduces their crystalline arrangement and swelling. Moreover, during extrusion, starch takes on an irregular polyhedral form [36, 125] due to the partial or complete release of amylose, which can alter viscosity. Furthermore, the structure of starch is affected by extrusion parameters such as moisture, temperature, processing time, and shear forces [18, 122], which can cause considerable damage to starch during flour production and the transformation of masa into tortilla (see Table 1) [12].

The extrusion nixtamalization process includes dry milling, cooking, and baking, where starch molecules undergo more intense mechanical and thermal conditions to produce an extruded corn product [49]. During extrusion, the thermal and mechanical changes to starch are exacerbated by dry milling and various factors that may arise throughout the process [51]. Throughout this process, starch granules experience several transformations, such as gelatinization, depolymerization, dextrinization, and retrogradation, due to high temperature, high pressure, low moisture, and shearing forces [50, 126]. Moisture content plays a crucial role in extrusion, influencing the degree of gelatinization, crystallinity, and the degradation of amylose and amylopectin in corn starch [51]. The degree of gelatinization is directly related to moisture; however, as moisture decreases, the crystallinity, order, and double helix structure of corn starch also decrease [37].

During gelatinization, starch granules transform from a highly ordered crystalline structure to a disordered amorphous structure when heat and shear forces are applied [11, 51]. Moreover, high shear forces increase the available area for the hydrolysis of intermolecular hydrogen bonds and cause partial depolymerization of amylose and amylopectin [37, 119]. Extrusion has been reported to be more effective at degrading amylopectin than amylose molecules [50, 51, 127]; as a result, the branched structure decreases, while the amylose content increases, leading to the subsequent recrystallization of starch molecules [51]. Higher availability of hydrogen bonding sites, due to the removal of amylose and amylopectin structures, promotes the absorption of moisture by starch molecules, causing them to swell [126, 128].

X-ray diffraction plays an important role in the analysis of crystalline structures of various materials. As a result, it can be an excellent tool to identify whether a gelatinization process has occurred. Cervantes-Ramirez et al. [53] evaluated extruded corn and observed modifications in the orthorhombic structure (known as A-type, typically found in corn), as well as reductions in the intensity of peaks at planes 103, 114, and 121, indicating a decrease in crystallinity (see Figures 4a, 4b, and 4c). Enríquez-Castro et al. [44] evaluated the effect of extrusion on corn flour, masa, and tortilla, observing a gradual reduction in the intensity of the peaks during the transformation of corn into tortilla, which indicates a decrease in crystallinity (see Figure 4d). Huang et al. [129] evaluated the effect of extrusion temperature on starch and found a reduction in the peak intensity after the extrusion process. Additionally, they observed the formation of new peaks related to V-type crystals (located at 2θ of 7°, 13°, and 20°), which can be attributed to the breakage of orthorhombic crystals during the extrusion process (see Figure 4e,f).

Furthermore, dextrinization, defined as partial hydrolysis of starch, involves the breakdown and re-polymerization of starch into dextrins and pyrodextrins, which may occur under conditions of low feed moisture and high shear stress [130]. Greater damage to the starch structure during dry milling increases flour density, which in turn reduces water uptake capacity, rheology, and viscosity of masa [12].

Retrogradation can be classified into two stages: short-term and long-term storage. Short-term storage affects amylose by reducing flexibility in tortillas. In contrast, during long-term storage, amylopectin is involved in the starch’s recrystallization process [11]. Recent studies have shown that changes in starch after extrusion and recrystallization can induce the formation of RS [11, 51, 131]. The content RS is related to retrogradation and the reorganization of amylose. However, amylopectin in retrograded starch promotes hydrogen bonding across the dispersed amylose and amylopectin structures, which are influenced by storage duration. This ability of starch to form cross-links and localized crystallized regions can generate a new crystalline network [11, 50].

The RS content in corn flour, masa, and tortillas is higher during extrusion compared to the traditional nixtamalization process, as shown in Table 2. This behavior can be attributed to the dry milling process used to produce corn flour, which may cause an abrasive disruption of the starch’s crystalline structure and a reduction in starch molecules, resulting in a fine particle distribution where low water content promotes gelatinization [27, 43, 47]. The presence of RS also offers nutritional and health benefits to tortilla consumers due to its ability to resist decomposition by stomach enzymes such as α-amylase, pepsin, and pancreatin. Consequently, it can be degraded in the colon through anaerobic fermentation by the microbiota, thereby improving intestinal health and helping to prevent metabolic diseases [132].

Extrusion improves starch digestibility by breaking covalent hydrogen bonds and disrupting the starch’s molecular structure, thereby reducing its resistance to enzymatic digestion [119]. Studies have shown that starch digestibility can be enhanced by increasing moisture and barrel temperature during extrusion [133]. However, starch digestibility may be reduced if the low moisture content in the raw materials and the formation of complexes such as amylose–lipid and protein–starch occur during the process [51, 119].

3.3. Effect of Extrusion on Content and Bioactivity of Phytochemicals

Phytochemicals have received special attention for their potential benefits to health and can be defined as strong antioxidants capable of scavenging free radicals associated with oxidative stress, increasing the activity of antioxidant enzymes, and exhibiting antimutagenic, anticarcinogenic, and chemoprotective properties [62, 66]. The stability and antioxidant activity of phytochemicals can be influenced by various factors, such as the food matrix, pH, and temperature [66]. Antioxidants, primarily polyphenols, are used in the food industry to prevent oxidation and extend the shelf life of final products [134]. The polyphenol family includes flavonoids, stilbenes, lignans, and phenolic acids, all of which have a relevant biological, microbicidal, antioxidant, and antimutagenic activity [135].

Food processing induces chemical and physical changes that can modify bioaccessibility [65]. These modifications include the following: (1) chemical alterations, (2) the breaking of covalent bonds, hydrogen bonds, or hydrophobic interactions that bind phenolic compounds to the macromolecular matrix, (3) effects on microstructural barriers such as cell walls that impede the release of the matrix, and (4) the formation of microstructures that protect the phenolic acids until they can be absorbed by the body. Biochemical compounds such as flavonoids, anthocyanins, phenolic acids, catechin, free forms of ferulic acid, and other compounds within the phenolic compound family can be reduced by the thermal impact generated during the cooking of tortillas [66].

Extrusion can break down the bound phenolics in foods into biologically available forms (see Table 4) [134]. Bound phenolic compounds in cereals can enhance bioaccessibility by reducing particle size, improving the cereal matrix, or degrading the fibrous structure after consumption. In contrast, free phenolic components are quickly absorbed by the small intestine [136]. Bound phenolic compounds are not digested in the stomach but are released in the colon through fermentation [137]. This process makes the nutrients within these compounds for absorption in the intestine after digestion [65].

| Compound | Product | References | |||

|---|---|---|---|---|---|

| Corn grain | Commercial flour | Extruded flour | Tortilla extruded | ||

| Free phenolic compounds (mg/100 g) | |||||

| Ferulic acid | 0.34–0.99 | nr | nr | 0.58–0.75 | [63] |

| Total free phenolic | 34.9 | nr | nr | 33.0 | [65] |

| nr | 61.85 | 64.18 | nr | [120] | |

| nr | 65.07 | 68.01 | nr | [4] | |

| nr | 63.04 | 41.76 | nr | [121] | |

| Bound phenolic compounds (mg/100 g) | |||||

| Ferulic acid | 330.06 | nr | nr | 313.41–406.04 | [63] |

| Total bound phenolic | 140.9 | nr | nr | 159.3 | [65] |

| nr | 134.59 | 218.43 | nr | [120] | |

| nr | 147.29 | 239.71 | nr | [4] | |

| nr | 139.12 | 81.96 | nr | [121] | |

| Total phenolics | 175.8 | nr | nr | 192.30 | [65] |

| nr | 196.44 | 282.61 | nr | [120] | |

| nr | 212.36 | 307.72 | nr | [4] | |

| nr | 202.16 | 123.72 | nr | [121] | |

| Antioxidant activity (μmol/100 g) | |||||

| Free phenolics | nr | 2146 | 3159 | nr | [4] |

| nr | 2295 | 3021 | nr | [120] | |

| nr | 3186 | 1659 | nr | [121] | |

| Bound phenolics | nr | 10,239 | 12,614 | nr | [4] |

| nr | 10,108 | 12,566 | nr | [120] | |

| nr | 7090 | 1114 | nr | [121] | |

| Total | nr | 12,385 | 15,773 | 15,531 | [4] |

| nr | 12,403 | 15,587 | 15,298 | [120] | |

| nr | 10,276 | 2773 | 8031 | [121] | |

- Abbreviations: nd, not detected; nr, not registered.

Extrusion is a versatile process where raw materials are subjected to varying conditions such as temperature, pressure, and shear forces. This process has the potential to enhance foods by retaining or even increasing the level of biochemical compounds related to antioxidant activity, which can influence the biochemical composition of extrudates [18, 138]. Antioxidant activity is associated with the quantity and composition of bioactive compounds in foods and can be altered, either increased or decreased, by adjusting extrusion parameters, particularly temperature [119, 139]. Extrusion also modifies the structure and concentration of components in corn, primarily phenolic compounds. In the human diet, phenolic acids are the main phenolic compounds [140], present in both free and bound forms, with antioxidant activity being primarily linked to free-form phenolic compounds [64].

The increment in antioxidant activity through extrusion can be attributed to the breaking of complex polyphenols, which are present in the cell wall membrane, into low molecular weight phenolic compounds, as well as the formation of Maillard’s reaction products, primarily generated at high temperature. These low molecular weight phenolic compounds and Maillard’s products interact with proteins, improving their stability [134]. Maillard’s products are formed during the extrusion of raw materials that contain amino acids and reduced sugars [120].

Various studies have focused on the antioxidant activity caused by the extrusion process. Liu et al. [141] reported that extruded apple pomace has higher oxygen radical absorbance capacity (ORAC) values, despite a lower content of extractable polyphenol. These results may be explicated by the generation of bioactive components and pigments due to Maillard’s reactions during extrusion. Arribas et al. [142] studied the changes in bioactive compounds and antioxidant capacity in expanded products formulated with carob fruit, pea, and rice blends. Their findings indicated that extrusion could enhance total phenolic content. Moreover, the study determined that when phenolics in the initial flour are bound to the DF of the cell walls, the extrusion process can partially disrupt the DF, thereby exposing phenolics within the blend and increasing the total phenolic content available to react with free radicals. Additionally, extrusion cooking prevents the oxidation of phenolic compounds by inactivating oxidative enzymes that would otherwise induce their degradation.

León-Murillo et al. [4] observed that antioxidant activity in extruded seed flours was enhanced due to an increase in total phenolic compound. Other studies have similarly concluded that extrusion can lead to an increase in free phenolic content following the release of these compounds from ruptured cell walls [142]. Additionally, the extrusion process can result in the generation of Maillard’s reaction products, which absorb light at wavelengths similar to those of phenolic compounds and may contribute to the observed increase in free phenolic content [143]. Similar results were obtained by Gámez-Valdez et al. [120], who analyzed tortillas made from commercial nixtamalized blue corn flour (blue MASECA), extruded creole blue maize flour (ECBMF), and a functional tortilla mixture (70% ECBMF + 30% extruded amaranth flour). Their study found that extruded flours exhibited higher antioxidant activity, as measured by ORAC with values of 12,031, 15,298, and 13,187 μmol TE/100 g, DW, respectively.

Bon-Padilla et al. [121], after reviewing nixtamalized corn and extruded chickpea flours, observed that while extruded chickpea flours had lower antioxidant activity, they exhibited better antihypertensive activity compared to commercial nixtamal corn tortillas. The increase in antihypertensive activity can be attributed to the release and formation of bioactive compounds with antihypertensive potential, such as phenolic compounds and Maillard’s reaction products, during extrusion. These findings are supported by other researchers who have reported that phenolic compounds (phenolic acids, flavonoids, stilbenes, and tannins) inhibit angiotensin-converting enzyme activity [144, 145]. Menchaca-Armenta et al. [65] evaluated the phytochemical content of extruded nixtamalized corn tortillas through simulated in vitro gastrointestinal digestion and found that these tortillas are rich in phytochemicals, contributing to a healthy diet due to their high bioaccessibility and antioxidant characteristics.

3.4. Effect of Extrusion on Minerals and Antinutritional Factor Complexes

Antinutritional factors are biological compounds that can decrease the nourishment of food by reducing the digestibility or bioavailability of nutrients such as proteins, vitamins, and minerals. These compounds achieve this by binding to the nutrients and hindering their absorption in the gastrointestinal tract [146, 147]. The most common antinutritional factors in corn include phytates, saponins, oxalates, enzyme inhibitors, and phenolic compounds [83, 119, 146, 148].

Phytates, or phytic acids, have a negatively charged structure that can bind with positively charged ions, primarily found in minerals such as zinc, iron, magnesium, and calcium, forming complexes that reduce their bioavailability. In terms of proteins, phytates can obstruct enzyme activity, thereby affecting protein absorption and degradation [83, 146, 147, 149]. Saponins are steroids or triterpenes with sugars incorporated into their structures. Studies have shown that saponins possess inhibitory activities because they cannot be hydrolyzed by digestive enzymes such as amylase, glucosidase, trypsin, chymotrypsin, and lipase, which are essential for gastrointestinal health [83, 150]. Oxalates can bind with metals like calcium, magnesium, and iron, adversely affecting human metabolism. Additionally, a high intake of oxalate-rich foods can lead to the formation of calcium oxalate crystals, which are a significant factor in the development of urinary tract illnesses [151]. Enzyme inhibitors hinder the catalytic action of enzymes, such as protease and amylase, making proteins more challenging to digest in the small intestine (leading to lower bioavailability of amino acids) and often resulting in their excretion from the body [146].

The presence of phenolic compounds like tannins can inhibit mineral absorption. Tannins are water-soluble and can form insoluble complexes with minerals in the gastrointestinal tract, leading to a significant reduction in their bioavailability [37]. The increase in mineral absorption following extrusion may be partially attributed to the degradation of phenolic compounds during heat treatment [152].

As a result of the changes generated by extrusion, the absorption of minerals, such as iron, copper, and phosphor, increases, and consequently, an improvement in their bioaccessibility can be observed. The improvement of bioaccessibility is a result of the destruction of antinutritional factors by deactivating absorption inhibitors with the application of high temperatures [18, 152]. Additionally, elevated temperature and low moisture conditions along the extrusion process reorganize the DF structure of the extrudates provoking the fiber matrix to hydrolyze which enhances the mineral absorption and fermentation in the colon due to the increment of the soluble fiber available [125, 153, 154].

3.5. Effect of Extrusion on Lipids

Although lipid content is usually low during the extrusion process, it plays an important role by reducing friction, acting as a lubricant inside the extruder, and providing adhesive texture and expansion to the final product [121, 155, 156]. However, the changes that lipids undergo during the process create challenges related to rancidity and oxidation. Elevated amounts of free fatty acids, resulting from the hydrolysis of triglycerides, can provoke undesirable flavors and decrease the shelf life of the final product. Unsaturated lipids are prone to oxidation, a characteristic that poses a potential risk to consumers due to its strong correlation with cancer [155]. This oxidation is triggered by metal residues left from screw wear, which act as pro-oxidants, and by an increase in air cells generated during the expansion of extrudates, creating a favorable environment for lipid oxidation [18, 114]. Although extrusion can create the ideal conditions for lipid oxidation, it is also capable of generating Maillard’s reaction products that can serve as antioxidants, while simultaneously denaturing hydrolytic enzymes responsible for the liberation of free fatty acids [18, 157].