Effect of Ozone Treatment Intensity on Pasting Property, Protein Composition, and Steamed Bread Quality of Ozone-Treated Wheat Flour

Abstract

Wheat flours were treated with ozone gas at low- and high-intensity conditions (0.61 and 3.82 g/h) for different durations (short: 5 min; long: 30 min), and the ozone-treated flours were evaluated in quality properties, including pH, protein component, water molecular mobility of dough, pasting property, and steamed bread quality. At both conditions, ozone treatment decreased the pH of wheat flour. Long duration of high-intensity treatment aroused significant increase in insoluble polymeric protein (IPP) content of wheat flour, but other treatments did not significantly change the IPP content. Dough of ozone-treated flour had higher water molecular mobility than that of native flour. Short duration of low-intensity treatment did not significantly change most pasting viscosity parameters of wheat flour, but other treatments increased the peak viscosity, breakdown viscosity, and setback viscosity. Steamed bread of ozone-treated flour had lower specific volume and pore uniformity than that of native flour. Long duration of high-intensity treatment of flour increased the hardness and chewiness of the steamed bread product, but other treatment showed opposite effect. Among the four ozone treatments, long duration of high-intensity treatment aroused the greatest change in pH, IPP, water molecular mobility of dough, and the quality of steamed bread, while short duration of low-intensity treatment had the minimum effect. Long duration of low-intensity treatment was close to the short duration of high-intensity treatment in quality attributes of wheat flour and the total ozone yield. These results suggested that the quality of wheat flour gradually changed with the increase of total ozone yield, and overozonization would greatly deteriorate the quality of wheat flour.

1. Introduction

Wheat is one of the most significant staple crops, providing nearly 20% of calories and protein in the human diet [1]. During the storage and processing of wheat grains and flours, insects and molds grow under moderate condition, which can impair the quality of wheat [2, 3]. Insects can eat wheat, and their feces can contaminate the wheat. Mycotoxin, the secondary metabolite of certain molds, is toxic to both humans and animals [4].

Ozone (O3) is a highly reactive gas composed of three oxygen atoms. In 2001, the U.S. Food and Drug Administration (FDA) officially granted GRAS (generally recognized as safe) status to ozone for use in food contact application. Ozone is highly unstable and decomposes rapidly to oxygen without leaving residues [5]. Ozone is effective in killing insects and inhibiting the growth of molds. McDonough et al. [6] found that exposing adults of Sitophilus oryzae to 1800 ppm ozone for 60 min can achieve 100% mortality. Wu et al. [7] reported that treating wheat grains (50 g) with 16.5 mg/min ozone for 5 min inactivated 96.9% of the fungal spores. The biocidal activity of ozone is based essentially on its powerful oxidizing capacity, which arouses irreversible change to unsaturated fatty acids of cell membrane and cellular macromolecules, for example, DNA and proteins [8, 9]. Ozone can also degrade mycotoxins and relieve their toxicities. Sun et al. [10] treated deoxynivalenol with aqueous ozone solution (80 mg/L) and found that 7 min of treatment degraded 83% of the toxin. Luo et al. [11] reported that exposing aflatoxin B1-contaminated corn (moisture 13.47%) to 90 mg/L ozone for 40 min reduced the aflatoxin B1 content by 88.1%.

Growing research work reveals that ozone treatment can affect the quality of wheat flour. Lee et al. [12] reported that the ozone treatment decreased the pH value and increased the peak viscosity of wheat flour. Li et al. [13] found that dough development time and stability time of wheat flour increased after ozone treatment. Sandhu et al. [14] reported that short time of ozone treatment decreased the dough stabilities of wheat flour, but long time of ozone treatment had an opposite effect.

So far, most of the research concerning quality of ozone-treated wheat have been done at a single treatment intensity. The quality differences of wheat flours treated at different treatment intensities remain unclear. In the preliminary research of our team, we found that both short and long durations of low-intensity ozone treatment increased the dough stability of wheat flour; at high-intensity condition, short duration of treatment increases the dough stability, but long duration of treatment had an opposite effect [15]. In this research, wheat flours were treated at two different intensities for different durations, and the flours were compared in pH, protein composition, water molecular mobility of dough, pasting properties, and qualities of the steamed bread products. This research can provide scientific reference and basis for the application of ozone treatment in wheat industry.

2. Materials and Methods

2.1. Materials

Wheat grains (variety Xinong 797, moisture 11.6%), harvested in 2019, was kindly supplied by a farmer in Xiangyang (longitude 112°45′E, latitude 31°59′N, China). Wheat grains were milled to flour using a Buhler MLU-202 mill (Buhler Group, Uzwil, Switzerland) with an extraction rate of around 70%. Acetonitrile, trifluoroacetic acid, and 1-propanol, chromatographic grade, were supplied by Sinopharm Chemical Reagent Co. Ltd. (Shanghai, China). Other chemicals were of analytical grade unless otherwise stated.

2.2. Ozone Treatment of Wheat Flour

Ozone treatments of wheat flours were conducted in a Büchner flask (2500 mL). For high-intensity ozone treatment, ozone gas was generated by a HW-ET ozone generator (Guangzhou Huanwei Environment Protection Science and Technology Co., Ltd., Jinan, China) with an ozone flow rate of 3.82 g/h [16]. For low-intensity ozone treatment, ozone gas was generated by a FL-803A ozone generator (Shenzhen Feili Electronic Appliance Technology Co., Ltd.) with an ozone flow rate of 0.61 g/h. For each treatment intensity, wheat flours (300 g) were treated with ozone gas for 5 and 30 min, respectively. Wheat flours treated at low-intensity condition for 5 and 30 min were coded as LOF-5 and LOF-30, respectively. Wheat flours treated at high-intensity condition for 5 and 30 min were coded as HOF-5 and HOF-30, respectively. All flours were stored in polyethylene bags in refrigerator until use.

2.3. Determination of pH of Wheat Flour

The pH of wheat flour was determined according to the AACC method 02–52.

2.4. Protein Composition Analysis of Wheat Flour by Size-Exclusion High-Performance Liquid Chromatography (SE-HPLC)

Protein compositions of native and ozone-treated wheat flours were analyzed by the SE-HPLC method described by Schober et al. [17] with slight modification. In brief, wheat flour was extracted with aqueous 50% 1-propanol, and the unextractable fraction was lyophilized. Protein content of the dried unextractable fraction was determined by the Dumas combustion method to calculate the insoluble polymeric protein (IPP) content. Extractable fraction was analyzed with SE-HPLC to obtain the percentages of soluble polymeric protein (SPP), gliadin (Gli), and albumin and globulin (Alb/Glob). SE-HPLC was performed using a Waters e2695 HPLC system (Milford, MA, USA) and a Biosep SEC-4000 column (Phenomenex, Torrance, CA, USA). The injection volume was 20 μL, and UV detection was conducted at 210 nm. Column temperature was maintained at 40°C, and the mobile phase was 50% acetonitrile and 0.1% (w/v) trifluoroacetic acid at a flow rate of 0.5 mL/min.

2.5. Low-Field Nuclear Magnetic Resonance (LF-NMR) Measurement of Wheat Dough

Doughs of native and ozone-treated wheat flours by mixing flour and water (optimum absorption) for 8 min with a Mixolab (Chopin, Tripette and Renaud, Paris, France). Proton distributions of dough were measured using an NMI20-040V–I LF-NMR analyzer (Niumai Instruments, Suzhou, China). The transverse relaxation (T2) curves were measured using the Carr–Purcell–Meiboom–Gill pulse sequence (CPMG). The experimental parameters were set as follows: SW = 200 kHz (receiver bandwidth), TW = 3000 ms (repeat sampling wait time), NECH = 4000 (number of echoes), TE = 0.1 ms (echo time), and a total of 8 scans.

2.6. Pasting Property Analysis of Wheat Flour

The pasting profiles of wheat flour were determined using a Rapid Visco Analyser (RVA, Newport Scientific Pvt. Ltd., Warriewood, Australia). Flour dispersion (12% w/w) was equilibrated at 50°C for 1 min and then increased to 95°C at a rate of 12°C/min, held for 2.5 min, cooled to 50°C at a rate of 12°C/min, and held for 2 min. The paddle speed was set at 960 rpm for the first 10 s and then was reduced to 160 rpm throughout the rest of the experiment.

2.7. Steamed Bread-Making Process

The steamed bread was made according to Mei et al. [18]. The dough was fermented at 30°C and 85% relative humidity in a GVAS fully automatic proofing cabinet (MIWE Michael Wenz GmbH, Arnstein, Germany). After fermentation, the dough was sheeted 20 times on a dough sheeter (MP800, Yechang Food machinery Co., Ltd., Shanghai, China) and split into 100 g portions. The dough chunks were formed into rounded shapes by hand and fermented at 30°C and 85% relative humidity for 35 min. The proofed doughs were steamed for 25 min in a pot using a steam tray and boiling water. After cooling at room temperature for 1 h, the quality of steamed bread was evaluated.

2.8. Specific Volume, Texture, and Crumb Structure Analysis of Steamed Bread

The specific volume of steamed bread was measured using a BVM-L370 volume measurer (Perten Instruments, Hägersten, Sweden). Texture of steamed bread was measured using the TA-XT2i texture analyzer (Stable Micro Systems, Surrey, UK) with pasta firmness/stickiness rig probe (P35). The steamed bread was cut into pieces of 15 mm in thickness. Texture analyzer were set as follows: trigger type, auto 5 g; pretest speed, 3 mm/s; posttest speed, 1 mm/s; test speed, 1 mm/s; compression ratio, 60%; interval between consecutive compressions, 3 s; compression time, 2 times. Crumb structure of steamed bread was analyzed with a C-cell Imaging System (Perten Instruments, Hägersten, Sweden).

2.9. Statistical Analysis

All experiments were performed three times, and data are expressed as means ± standard deviations. An analysis of variance with a significance level of 5% was conducted, and Duncan’s test was applied to determine differences between means using the commercial statistical package (SPSS Inc., Chicago, IL, USA).

3. Results and Discussion

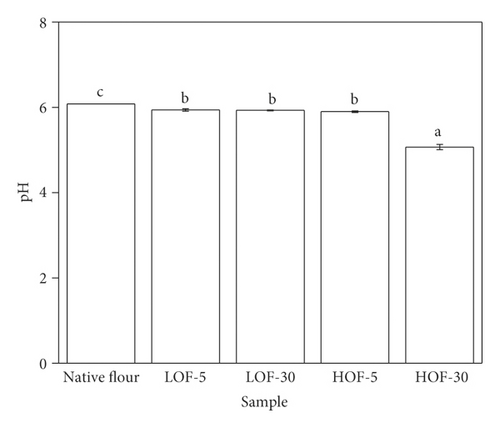

3.1. pH

The acidity of wheat flour directly affects the property of dough. The addition of acid to wheat dough can reduce the stability and extensibility of dough [19]. pH values of native and ozone-treated wheat flours are shown in Figure 1. At both high- and low-intensity conditions, the pH of wheat flour significantly decreased after the treatment. This result might be ascribed to the oxidization of lipids and starch. Carbon-carbon double bonds of unsaturated lipids can react with ozone and produce Criegee intermediates, which are further transformed to acids [20]. Hydroxyl groups of starch can be oxidized to carboxyl and carbonyl groups during ozone treatment [21]. There was no significant difference between the two low-intensity ozone-treated flours in pH value. However, at high-intensity condition, prolonged treatment decreased the pH of wheat flour. Wheat flour treated at low-intensity condition for 30 min and the flour treated at high-intensity condition for 5 min did not have significant difference in pH value. For total ozone yield, 30 min of low-intensity treatment was close to 5 min of high-intensity treatment. These results suggested that, during ozone treatment of wheat flour, the accumulation of acidic products was related to the total ozone yield.

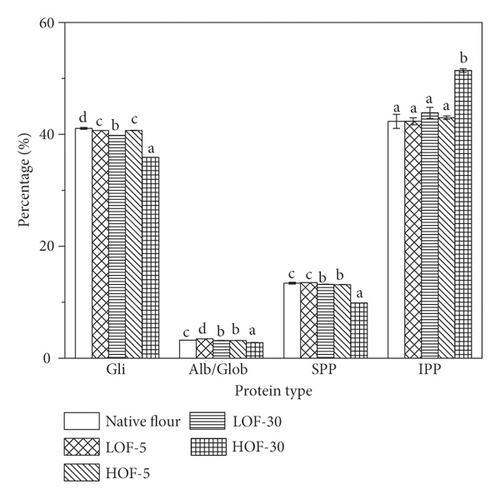

3.2. Protein Composition

Wheat protein is composed of four types of protein components: albumin, globulin, glutenin, and gliadin. Glutenin is a polymeric protein that consists of a number of subunits crosslinked by intermolecular disulfide bonds. The insoluble polymeric protein (IPP) of glutenin is crucial to the gluten quality of wheat flour [22]. HPLC chromatograms of extractable protein of native and ozone-treated wheat flours are shown in Figure 2, and protein compositions of wheat flours are shown in Figure 3. At low-intensity condition, ozone treatment of wheat flour for 5 or 30 min did not arouse significant difference in the IPP content. At high-intensity condition, wheat flour did not show significant difference in the IPP content after 5 min of treatment; while, as treatment was extended to 30 min, wheat flour exhibited a significant increase in the IPP content, as well as a pronounced decrease in SPP (soluble polymeric protein) content. The increase of IPP content can be due to the oxidization of low-molecular weight glutenin. Free thiols of glutenin can be oxidized to disulfide bonds, leading to the crosslinking of low-molecular weight glutenin to form insoluble high-molecular weight glutenin [23]. LOF-30 and HOF-5 did not make significant difference in the contents of SPP and IPP. These results suggested that the IPP content of ozone-treated flour was related to the total yield of ozone gas.

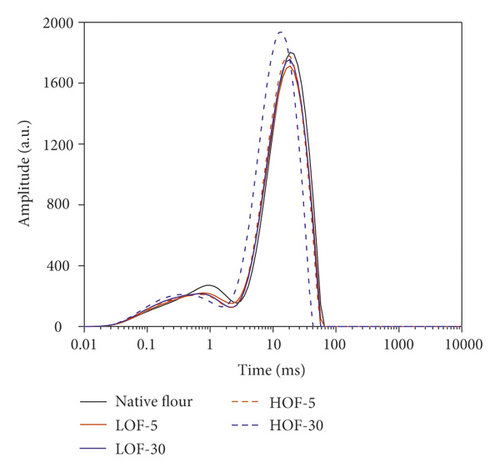

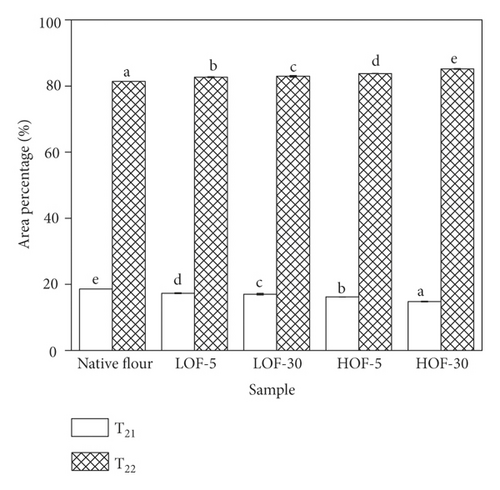

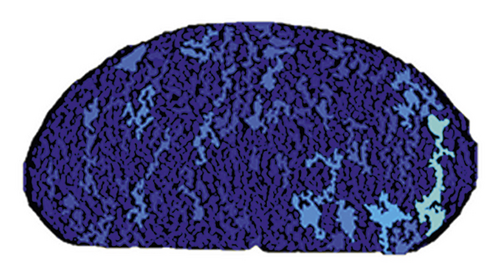

3.3. Moisture Molecular Mobility of Dough

The proton distributions of doughs of native and ozone-treated wheat flours are shown in Figure 4. T21 (0.01–1 ms) and T22 (1–60 ms) indicates tightly and weakly bound water in the dough [24]. Peak area percentages of T21 and T22, reflecting two kinds of water, are shown in Figure 5. At both intensities, the content of tightly bound water in dough decreased and the included weakly bound water increased, indicating an increase of water molecular mobility. This might be due to the oxidation of starch and lipid molecules. Ozone treatment could degrade starch to low-molecular weight fragments [21]. Zhang et al. [25] reported that the incorporation of dextran increased the water mobility of starch gel. The reaction of hydrophobic lipids and ozone can produce amphiphilic acidic products. These products provided more mobility for water [26]. At both intensities, the molecular mobility of water increased as treatment extended. For the same treatment duration, wheat flour treated at high-intensity condition exhibited higher water molecular mobility in dough.

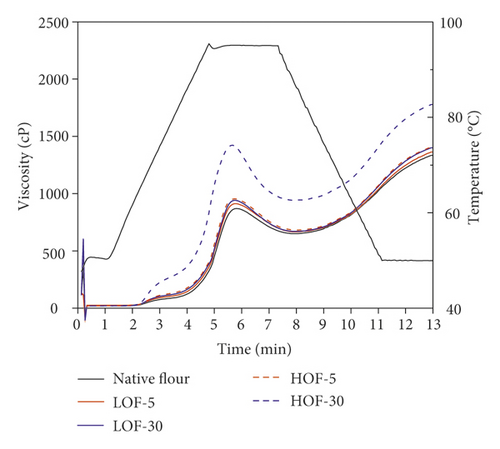

3.4. Pasting Property

Pasting curves of native and ozone-treated wheat flours are displayed in Figure 6, and pasting parameters are shown in Table 1. At low-intensity treatment condition, wheat flour did not show significant difference in most pasting viscosity parameters after 5 min of treatment; while, as treatment was extended to 30 min, peak viscosity (PV), breakdown viscosity (BDV), and setback viscosity (SBV) significantly increased. The increase of pasting viscosity parameters can be attributed to starch oxidation and alpha-amylase denaturation. During ozone treatment, the introduction of carboxyl groups to starch would increase the swelling power of granules [27]. Ozone treatment can denature alpha-amylase and decrease the degradation extent of starch during the pasting process [28, 29]. At high-intensity condition, wheat flour exhibited significant increase in PV, BDV, and SBV after 5 min of treatment; as treatment was prolonged to 30 min, all the pasting viscosity parameters significantly increased. These results suggested that the increase of ozone treatment intensity would increase the pasting viscosity of ozone-treated wheat flour. LOF-30 was close to HOF-5 in all the pasting viscosity parameters. This suggested that the pasting property of ozone-treated wheat flour correlated with the total yield of ozone gas.

| PV (cP) | TRV (cP) | BDV (cP) | FV (cP) | SBV (cP) | |

|---|---|---|---|---|---|

| Native flour | 870.0 ± 26.9a | 651.0 ± 12.7a | 219.0 ± 14.1a | 1334.0 ± 43.8a | 683.0 ± 31.1a |

| LOF-5 | 913.5 ± 33.2ab | 666.0 ± 25.5a | 247.5 ± 7.8b | 1364.0 ± 43.8a | 698.0 ± 18.4ab |

| LOF-30 | 943.5 ± 19.1b | 670.0 ± 19.8a | 273.5 ± 0.7b | 1400.0 ± 18.4a | 730.0 ± 1.4b |

| HOF-5 | 954.5 ± 19.1b | 682.0 ± 14.1a | 272.5 ± 5.0b | 1406.5 ± 29.0a | 724.5 ± 14.9b |

| HOF-30 | 1423.0 ± 33.9c | 941.5 ± 13.4b | 481.5 ± 20.5c | 1778.5 ± 20.5b | 837.0 ± 7.1c |

- †Data were expressed as means ± SD. Means within a column that had the same letter were not significantly different (α = 0.05). LOF-5: wheat flour treated at low-intensity condition for 5 min; LOF-30: wheat flour treated at low-intensity condition for 30 min; HOF-5: wheat flour treated at high-intensity condition for 5 min; HOF-30: wheat flour treated at high-intensity condition for 30 min. PV = peak viscosity; TRV = trough viscosity; BDV = breakdown viscosity; FV = final viscosity; SBV = setback viscosity.

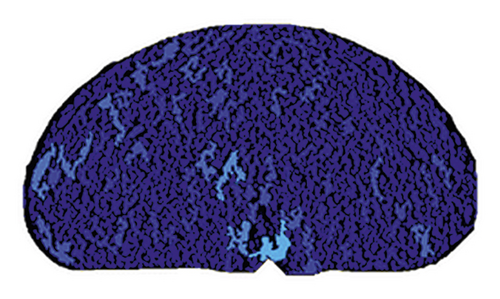

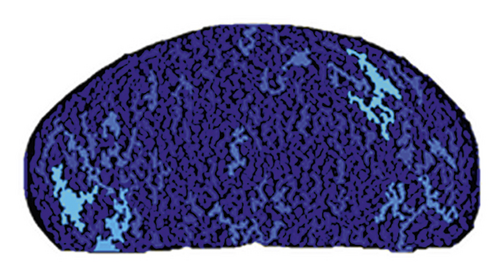

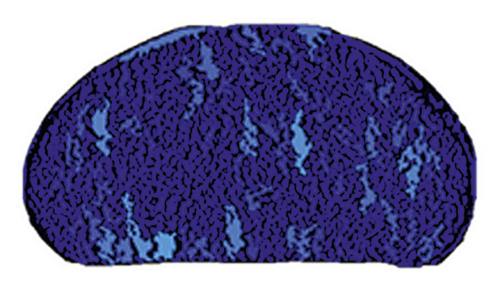

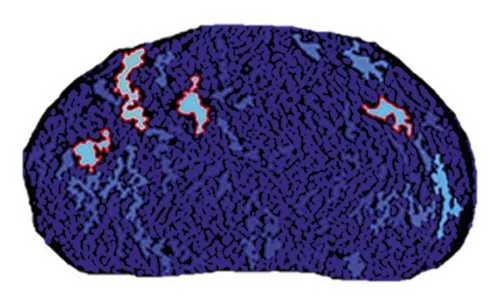

3.5. Specific Volume, Texture, and Inner Structure of Steamed Bread

The specific volume and texture attributes of steamed breads made from native and ozone-treated wheat flours are shown in Table 2, and the C-cell images of steamed breads are shown in Figure 7. Compared with native flour, ozone-treated flours showed decreased specific volumes in steamed bread, while, among the four ozone-treated flours, the change of LOF-5 was not significant and the decrease of HOF-30 was greatest. For texture attributes, compared with native flour, LOF-5, LOF-30, and HOF-5 exhibited significant decrease in hardness and chewiness, but HOF-30 exhibited opposite change in these two parameters. Additionally, steamed bread of HOF-30 showed lower elasticity than steamed breads of native flour, but other three ozone-treated flours and native flour did not have significant difference in elasticity. These results suggested that the ozone treatment of wheat flour would affect quality of steamed bread product, and long duration of treatment at high-intensity condition had an unfavorable effect. The change of specific volume and texture might be due to the formation of acidic products generated by ozonation. Compared with native flour, LOF-5, LOF-30, and HOF-5 showed increase in dough stability time [15], which might be due to the mild ozonation of glutenin. However, the decrease of pH might affect the fermentation process of the wheat dough and do harmful effect to the quality of steamed bread [30]. For HOF-30, the great decrease of pH reduced the stability of dough during mixing and might also affect the later fermentation process [15, 19], thus leading to the great decrease of specific volume and increase of hardness in steamed bread. Ozone treatment of wheat flour reduced the pore uniformity of the steamed bread product. Among four ozone-treated flours, HOF-30 showed the worst pore uniformity in steamed bread. Steamed bread of LOF-5, LOF-30, and HOF-5 only showed slight difference in pore structure.

| Specific volume (mL/g) | Hardness (g) | Chewiness (g) | Elasticity | Resilience | |

|---|---|---|---|---|---|

| Native flour | 2.74 ± 0.10c | 1439.2 ± 31.6c | 1060.8 ± 16.3c | 0.889 ± 0.024b | 0.465 ± 0.008d |

| LOF-5 | 2.64 ± 0.01bc | 965.2 ± 54.9b | 649.6 ± 55.0b | 0.876 ± 0.032b | 0.399 ± 0.012a |

| LOF-30 | 2.55 ± 0.04b | 910.9 ± 40.3b | 639.7 ± 27.7b | 0.887 ± 0.004b | 0.435 ± 0.003bc |

| HOF-5 | 2.57 ± 0.11b | 709.9 ± 10.7a | 530.7 ± 10.2a | 0.909 ± 0.008b | 0.445 ± 0.021cd |

| HOF-30 | 1.84 ± 0.03a | 2413.6 ± 75.8d | 1482.6 ± 103.0d | 0.807 ± 0.057a | 0.414 ± 0.032ab |

- †Data were expressed as means ± SD. Means within a column that had the same letter were not significantly different (α = 0.05). LOF-5: wheat flour treated at low-intensity condition for 5 min; LOF-30: wheat flour treated at low-intensity condition for 30 min; HOF-5: wheat flour treated at high-intensity condition for 5 min; HOF-30: wheat flour treated at high-intensity condition for 30 min.

4. Conclusion

The quality of ozone-treated flour was mainly related to the total yield of ozone gas. As the ozone yield of treatment increased, ozone-treated wheat flour generally exhibited a decrease in pH value and an increase in pasting viscosity and water mobility of dough. Wheat flour had an increase in the IPP content after long duration of high-intensity treatment, but did not show significant change of IPP content after other three treatments. Among the four treatments, long duration of high-intensity treatment aroused an increase in the hardness and chewiness of the steamed bread product, but the other three treatments had an opposite effect. Further research work will be done on the application of ozone-treated flour in other food systems.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This research was kindly supported by the Open Fund of Key Laboratory for Deep Processing of Major Grain and Oil (Wuhan Polytechnic University), Ministry of Education (grant no. 2020JYBQGDKFB09), and the Excellent Science and Technology Innovation Team of Young and Middle-aged Researchers in Universities of Hubei (grant no. LT201911).

Open Research

Data Availability

The data used to support the findings of this study are included within the article.