Physicochemical and sensory properties of biscuits formulated with Tenebrio molitor and Alphitobius diaperinus flours

This article was published on AA publication on: 12 May 2022.

Funding information: Universitat Politècnica de València

Abstract

The use of insects is considered by Food and Agriculture Organization (FAO) as an alternative source of protein for human and animal food in order to reduce the carbon footprint caused by meat production and to supply the expected population increase with food. In this regard, the aim of this study was to analyze the physicochemical aspects (water activity, protein and fat content, size, optical and mechanical properties) of biscuits prepared with two different insect powders (Tenebrio molitor [TM] and Alphitobius diaperinus [AD], in different percentages [0, 13, 17, 20, and 25%]) based on total weight. In addition, the biscuits formulated with the highest insect powder content were subjected to sensory analysis. The results revealed that all the biscuits formulated with insect powders may be labeled as “high in protein” products following Regulation (EC) No. 1924/2006, although they were not as thick as the control biscuits. The L* and b* coordinates were significantly lower when the insect powders were included, which implied a darkening of the biscuits, which were also harder than the control biscuits, regardless the concentration used. According to the sensory analysis, most panelists perceived the biscuits containing insects as too dark and not crunchy enough and an increase in sweetness might improve their acceptability. Finally, further studies should be carried out to analyze the influence of different structural components and flavorings, such as chocolate, in the formulation of biscuits with insect powders to improve their sensory attributes.

1 INTRODUCTION

It is widely accepted that by 2050 the world will be home to 9 billion people. To accommodate this number, current food production will need to nearly double. Land is scarce and expanding the area devoted to farming is rarely a viable or sustainable option. Oceans are overfished and climate change and the resulting water shortages could have profound implications for food production. To meet the food and nutrition challenges of today—there are nearly 1 billion chronically hungry people worldwide—and tomorrow, we need to re-evaluate what we eat and how we produce it. Inefficiencies need to be rectified and food waste reduced. Consequently, it is required to find new ways to grow food (FAO, 2013). It is well known that the production of high-quality protein generates the greatest impact on the environment; since livestock farming requires a large amount of feed that is responsible for significant greenhouse gas (GHG) emissions, among others (Poore & Nemecek, 2018; Smetana, Palanisamy, Mathys, & Heinz, 2016). Furthermore, according to the FAO statement on the development of dietary guidelines, a healthy but also sustainable diet contains fewer common animal-based products (meat, fish, and dairy products) and what is instead recommended are more legumes, wholegrain products and seeds (Biró et al., 2020).

The recognition that insects can contribute to food security has received a remarkable boost from the media and is receiving more attention from researchers and food and feed agencies worldwide (Vantomme, 2015; rtve, 2021). According to FAO, insect production for human consumption is the livestock of the future, being capable of providing sustainable protein to an ever-growing world population (FAO, 2013). A production reduces the use of water, nutrients, or space by 90%, with hardly any CO2, ammonia, or methane emissions as compared to traditional farming and livestock-raising practices (Biró et al., 2020; Vantomme, 2015). For example, pigs produce 10–100 times more GHGs per kilogram of weight than mealworms (Vantomme & Halloran, 2013).

The growing trend among consumers to limit or eliminate animal products from their diet opens up a new market of opportunities. The challenge is to find that perfect protein and achieve a tasty, healthy and sustainable diet. Nowadays, it is possible to find traditional products reformulated using plant and algal protein. However, there are still some problems when it comes to reformulating them with insect protein, since a regulation for all kinds of insects has not yet been approved. In fact, the first safety assessment of an insect (Tenebrio molitor) as food has recently been published in June 2021 by the European Food Safety Authority (EFSA) (Turck et al., 2021). Then, European Commission authorized the placing on the market of the insects Locusta migratoria and Acheta domesticus, as a food, in November 2021 and February 2022, respectively (European Comission, 2022).

Moreover, it is important to bear in mind that in order to label a product as high in protein, certain requirements must be met. According to Regulation (EC) No. 1924/2006 of the European Parliament and of the Council of December 20, 2006, on Nutrition and Health Claims Made on foods, a food is “a source of protein” when at least 12% of the energy value of the food is provided by protein, while a food is “high in protein” when at least 20% of its energy is provided by protein.

New sources of proteins must be searched, being insect one possibility. The adaptation of the legal system to the new trends in the fight against hunger and climate change through food alternatives is quite slow, although some progress has been made. Thus, in 2015, a regulation was published to establish the requirements for novel foods, including insects (Regulation [EU] 2015/2283). A few years later, Commission Regulation (EU) 2017/893 of May 24, 2017, was published.

Some insect species can be consumed whole and can also be processed into pastes or ground into meal, and their protein can be extracted (Vantomme & Halloran, 2013). Therefore, different formats of insects are available to include in foods. In this regard, products containing insects are gaining a greater share of the market. Bakery products are one of the most promising since the added ground insects can improve not only the nutritional quality of the dough, but also the technological parameters and sensory properties of the final products (Biró et al., 2020; González, Garzón, & Rosell, 2019; Homann, Ayieko, Konyole, & Roos, 2017; Zielińska & Pankiewicz, 2020). In cultures whose inhabitants are used to insect consumption, it is quite easy to introduce them into different food matrices. As an example, in a study conducted in the rural Olugboja community (Nigeria) where insects are widely consumed, the biscuits supplemented with 20% of the sorghum–insect meal (in a ratio 3:1) were more acceptable to panelists than the control (100% wheat flour), which indicates that sorghum–insect meal could be successfully incorporated into food products (Awobusuyi, Pillay, & Siwela, 2020). However, these results may not be the same among non-insect-eating populations due to cultural and psychological barriers (Lensvelt & Steenbekkers, 2014; Looy, Dunkel, & Wood, 2014). Moreover, the use of insect flour in biscuits may be a way to fight malnutrition in children in underdeveloped countries, as long as they like the taste. A study among Kenyan school children aged 5–10 years old on the acceptability of biscuits containing 10% cricket powder (Acheta domesticus) compared to milk biscuits revealed that the organoleptic properties of cricket biscuits were rated above average but lower than those of milk biscuits in most aspects (Homann et al., 2017). This reveals that cricket biscuit powder represents a valuable alternative to the shortage of milk powder, since it contains protein, unsaturated fatty acids, vitamins A and B12, iron, and zinc and can create income for the local population.

One of the major challenges is to familiarize people in developed countries with insect consumption. Even though Westerners still have a negative attitude in this regard, knowledge of edible insects and their nutritional value, previous taste experiences, and sensation-seeking seem to increase acceptance (Biró et al., 2020). Thus, according to research aimed at finding out opinions on the consumption of edible insects and insect-based products among the Polish community, there was seen to be some reluctance as regards their consumption. This was not due to a lack of knowledge, but to a prejudice against insects as food (Orkusz, Wolańska, Harasym, Piwowar, & Kapelko, 2020). Nevertheless, many studies have proved that using insects in a non-visible form (e.g., insect powders) can make people more willing to eat them. Consequently, the supplementation of everyday foods (e.g., bread, pasta, and other bakery and snack products), which are able to mask the insect component, could be the first step to introducing insect-based foods on to the market (Looy et al., 2014; Zielińska & Pankiewicz, 2020).

Recently, several studies have been conducted to assess the enrichment of products with insect flours (Biró et al., 2020; Çabuk, 2021; Carcea, 2020; González et al., 2019; Kim, Setyabrata, Lee, Jones, & Kim, 2016; Orkusz et al., 2020; Zielińska & Pankiewicz, 2020). Thus, 10% lean pork meat was replaced by mealworm larvae and silkworm pupae meals in emulsion sausages, which increased the cooking yield and hardness of emulsion sausages, confirming the potential application of those insect meals as a new protein ingredient (Kim et al., 2016). In addition, González et al. (2019) characterized the dough behavior, technological properties, and chemical composition of bread prepared with flours from three different insects (Hermetia illucens, Tenebrio molitor, and Acheta domestica), concluding that when the bread was prepared using A. domestica, it had technological features similar to those of wheat bread, but nutritionally improved in terms of protein and fiber content. In another study (García-Segovia, Igual, Noguerol, & Martínez-Monzó, 2020), extruded snacks were enriched with Alphitobius diaperinus, Tenebrio molitor, and pea protein powder, maintaining the physicochemical characteristics of the products and improving the nutritional aspects. It must also bear in mind that drying method can modify odor and sensory characteristics of locusts and silkworms and, consequently the sensory profile of cookies with these insect species (Mishyna, Haber, Benjamin, Martinez, & Chen, 2020).

In view of the foregoing, the aim of this paper was to analyze the effect of the replacement of wheat flour with two different insect flours (Tenebrio molitor and Alphitobius diaperinus) on the composition, diameter and height, mechanical and optical properties as well as on their sensory acceptability.

2 MATERIALS AND METHODS

2.1 Preparation of biscuits with flours of insect origin

Control biscuits were prepared with 50% wheat flour, 14% sucrose, 15% sunflower oil, 15% eggs, 5% water, and 1% baking powder. Firstly, the flour, eggs, and baking powder were sieved and then mixed with the sucrose, sunflower oil and water for 10 min at maximum speed in an electric mixer (Kenwood, model KM240 series, United Kingdom). The dough was then allowed to settle for 20 min before being stretched to a height of 5 mm using a rolling pin with rings on both sides to set that height. Then, 40 mm diameter circle-shaped biscuits were obtained using a hole puncher. Finally, the biscuits were placed in the oven (Rational AGD-86899 Landsberg a. Lech, Germany) for 20 min at 180°C without air convection. Once cooled, they were stored in airtight glass jars at room temperature for 1 week.

In order to prepare the entomological protein-rich biscuits, part of the wheat flour was replaced by mealworm (Tenebrio molitor [TM]) or buffalo (Alphitobius diaperinus [AD]) powder (Kreca Ento-Feed BV, Netherlands) and a sunflower oil reduction (from 15 to 6%) was also applied. However, this replacement also implied a readjustment of the levels of the other components, since the water-holding capacity of these powders (2.7 ± 0.3 g absorbed water/g powder) is much higher than that of wheat flour (0.9 ± 0.2 g absorbed water/g powder), according to the results obtained following the methodology described by Martínez-Las Heras, Landines, Heredia, Castelló, & Andrés, 2017. Thus, Table 1 shows the different levels of wheat flour replacement considered in the biscuits analyzed in this study after some preliminary trials together with the energy provided for each formulation and the percentage of energy associated with the amount of protein. The theoretical energy (kcal/100 g) of biscuits was obtained considering that sucrose, sunflower oil, wheat flour, eggs, and both TM and AD powders had 385, 884, 340, 143, and 510 kcal/100 g, respectively, according to both USDA-FoodData (2021) and the information on the labels of insect powders. In addition, the amount of protein in wheat flour, eggs, TM powder, and AD powder was 13.2, 12.6, 54.1, and 59.6 g protein/100 g, respectively, using the same sources and considering 4 kcal/g protein. As can be observed, according to the aforementioned Regulation (EC) No. 1924/2006, all the biscuits formulated with the different percentages of insect powders would be labeled as “source of protein” and TM20, TM25, AD20, and AD25 would also be “high in protein.”

| % component | Control | TM13 | AD13 | TM17 | AD17 | TM20 | AD20 | TM25 | AD25 |

|---|---|---|---|---|---|---|---|---|---|

| Sucrose | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

| Sunflower oil | 15 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Wheat flour | 50 | 42.7 | 42.7 | 36.8 | 36.8 | 30 | 30 | 25 | 25 |

| Tenebrio molitor powder | 12.7 | 16.8 | 20 | 25 | |||||

| Alphitobius diaperinus powder | 12.7 | 16.8 | 20 | 25 | |||||

| Eggs | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Water | 5 | 8.6 | 8.6 | 10.4 | 10.4 | 14 | 14 | 14 | 14 |

| Baking powder | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| g protein/100 g | 8.5 | 14.4 | 15.1 | 15.8 | 16.8 | 16.7 | 17.8 | 18.7 | 20.1 |

| Energy (kcal/100 g) | 378 | 338 | 338 | 339 | 339 | 332 | 332 | 341 | 341 |

| % energy from protein | 9.0 | 17.0 | 17.8 | 18.7 | 19.8 | 20.1 | 21.4 | 22.0 | 23.6 |

2.2 Compositional analysis (water, protein, and fat content) and water activity

The water content was obtained by a gravimetric method (AOAC, 20.013, 2000) until a constant weight of the samples was reached after drying at 60°C (VACIOTEM-T, J.P. Selecta Spain) for 7 days. The amounts of protein and fat were analyzed by Kjeldahl (AOAC, 928.08, 1990) (Block digest 6, J.P. Selecta Spain; Distillation unit UDK 127, Velp Cientifica, Italy) using 6.25 as conversion factor and Soxhlet (AOAC, 960.39, 1990) (StarFish multi-experiment Workstation; Radleys, United Kingdom) methodologies, respectively. The water activity was measured with a dew point hygrometer (Decagon Devices, Inc, model 4TR, Pullman, WA) at 25°C.

2.3 Measure of diameter and thickness

After baking, the diameter and height (mm) of 10 biscuits from each formulation were measured using a caliper.

2.4 Determination of mechanical and optical properties

Each biscuit was subjected to a cutting test using a blade on a universal press (Texture analyzer TA.ST.plus, Stable Micro Systems, Godalming, United Kingdom). Ten samples were analyzed for each formulation of biscuits. The parameters obtained were hardness (maximum strength) and area under the curve.

The color of 10 biscuits per formulation was determined using a spectrocolorimeter (Konica Minolta, Inc., model CM-3600d, Tokio, Japan). The results were expressed according to the CIE L*a*b* reference system with the D65 Standard Iluminant and 10° Standard Observer. Browning index was also calculated (Çabuk, 2021).

2.5 Sensory analysis

The possible acceptance of two biscuit formulations with each entomological flour together with the control sample was tested by a panel composed of 30 tasters, all of whom were employees or students of the Universitat Politècnica de València (UPV) and between 18 and 65 years old. This study was carried out in the sensory lab in individual booths at the Institute of Food Engineering for Development (IIAD) of the UPV. Coded with three-digit random numbers, the samples were shown to the tasters simultaneously. The appearance, color, aroma, texture, crunchiness, sweetness, and flavor of each formulation were evaluated on a nine-point hedonic scale (ISO 4121:2003 and UNE-87025:1996) considering different levels from “I dislike it very much” to “I like it very much.” Furthermore, the parameters were evaluated with the Just About Right test to know if they would prefer a higher or lower intensity in the analyzed attributes and a penalty study was performed (Fernández, Fuentes, & García, 2018).

2.6 Statistical analysis

In order to know the possible influence of the insect flours in the studied parameters, different analysis of variances (ANOVAs) were applied with the software Statgraphics Centurion version XVI.I.

3 RESULTS AND DISCUSSION

Table 2 shows the composition of the biscuits in terms of their water, protein, and fat content as well as the water activity of each formulation. In general, all the biscuits formulated with entomological flours showed a higher water content, since more water was used in their formulation, which also implied higher water activity values. As for protein, as expected, the higher the proportion of wheat flour replaced by insect flours, the higher the amount of protein in the biscuits; however, the amount of fat was, in every case, lower than in the control biscuits due to the reduction in the sunflower oil used in their formulations. Overall, the analytical values of the protein were higher than the theoretical (Table 1). These values may have been overestimated due to the non-digestible nitrogenous components of the fibrous cuticle of the insects. Therefore, Haber, Mishyna, Martinez, and Benjamin (2019) suggest the use of 4.50 specific for grasshopper, rather than the conventional nitrogen protein conversion factor of 6.25. The biscuits with AD powder registered more protein than biscuits with TM powder, according to the content expressed on the labels of the product. Therefore, it has been found that all of the biscuits formulated with these insect flours at these concentrations can be classified as “high in protein,” according to Regulation (EC) No. 1924/2006.

| Formulation | Water (g water/g) | % protein | % fat | Aw |

|---|---|---|---|---|

| Control | 0.026 ± 0.003a | 7.8 ± 0.2a | 20.8 ± 0.3g | 0.265 ± 0.004a |

| TM13 | 0.062 ± 0.007cd | 16.11 ± 0.09b | 13.06 ± 0.06a | 0.512 ± 0.006d |

| TM17 | 0.067 ± 0.003de | 19.00 ± 0.07c | 15.32 ± 0.07c | 0.511 ± 0.019d |

| TM20 | 0.026 ± 0.003a | 21.82 ± 0.51e | 16.59 ± 0.12de | 0.288 ± 0.005b |

| TM25 | 0.06 ± 0.06c | 23.98 ± 0.16f | 16.9 ± 0.2e | 0.501 ± 0.006d |

| AD13 | 0.059 ± 0.002c | 18.59 ± 0.15c | 14.0 ± 0.6b | 0.495 ± 0.002d |

| AD17 | 0.034 ± 0.004b | 21.2 ± 0.9d | 16.3 ± 0.7d | 0.3185 ± 0.0002c |

| AD20 | 0.071 ± 0.002ef | 22.0 ± 0.2e | 16.9 ± 0.2de | 0.582 ± 0.003e |

| AD25 | 0.076 ± 0.003f | 25.0 ± 0.6g | 17.9 ± 0.2f | 0.596 ± 0.016e |

- Note: Equal letters refer to homogeneous groups in the ANOVA (level of significance [l.s.]: 99%)

The composition of these biscuits differs significantly from the results obtained by Zielińska and Pankiewicz (2020) due to the fact that their biscuits were prepared as three variants with different amounts of added insect flour, which partially replaced the wheat flour and butter reaching around 10% protein and 27% fat and, therefore, did not meet the criteria for classification as food that is a “source of or high in protein.” However, in another recent study, biscuits formulated with 10 and 15 g/100 g of domestic cricket (Acheta domesticus) could be labeled as “protein sources” according to the European Union's Regulation No. 1924/2006, since they obtained 12.97 and 14.71 g protein per 100 g biscuits, respectively (Biró et al., 2020).

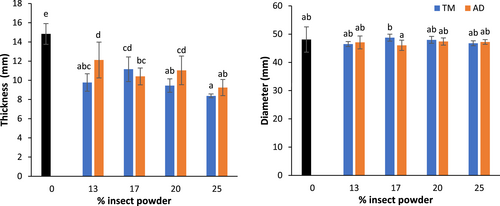

Moving on to the results of the thickness and diameter of the biscuits after baking (Figure 1), it is noticeable that the replacement of wheat flour by insect powder implied a significant reduction in thickness, especially when Tenebrio molitor was used and, more importantly, when the percentage of insect powder was higher. This behavior might be due to the role of gluten in the structure of these products, something which is not present in the insect powders (Akande, Jolayemi, Adelugba, & Akande, 2020). Furthermore, fat is an important ingredient in bakery products since it contributes to the homogenous dispersion of starch molecules and helps the incorporation of air in the kneading process, thus increasing the number of gas cells (Haber et al., 2019). In this sense, the lower fat content of TM and AD biscuits leads to less dough being developed. However, no significant differences were found in the diameter of the studied biscuits.

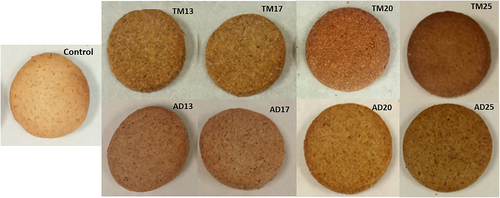

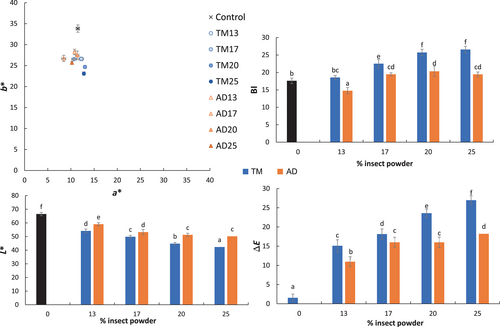

Figure 2 shows the biscuits formulated with different amounts of the insect flours. With regards to optical properties (Figure 3), all of the biscuits were placed in the first quadrant of the chromatic diagram, but the biscuits with insect powder showed a significantly lower value of the b* coordinate (23.1–26.8) than the control (33.8 ± 0.9), which led to a darkening of the samples. Biscuits formulated with Tenebrio molitor powder had a significant higher value of browning indexes. In addition, the luminosity decreased due to the wheat being replaced by insect powder, especially when Tenebrio molitor was used. The higher values of browning index along with the lower L* values observed are possibly related to the Maillard browning reactions due to the cooking, which causes a darker color for the cookies as was observed in for flaxseed cookies by (Khouryieh & Aramouni, 2012). As a result, compared to the control sample the difference in color was more significant for biscuits with Tenebrio molitor than for those with Alphitobius diaperinus and, proportional to the percentage considered, was consistent with the results obtained by Zielińska and Pankiewicz (2020).

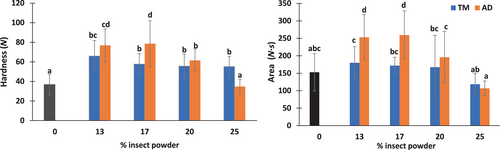

The results of the mechanical properties (Figure 4) reveal that, in general, all the biscuits formulated with insect powders had higher values of both hardness and area under the curve when the level of wheat flour replacement was lower than 20%, especially in the case of Tenebrio molitor powder; there was, however, a high degree of variability. Nevertheless, similar values were found for both parameters of the control samples when 25% of Alphitobius diaperinus powder was used in the biscuit formulation. Therefore, there seems to be a hardening of the biscuits when these kinds of insect powders are used. Similar results were found when analyzing bread with different mixtures of wheat flour and cricket powder (Osimani et al., 2018) or cinereous cockroach flour (de Oliveira, da Silva Lucas, Cadaval, & Mellado, 2017).

Table 3 shows the results of the hedonic scale of sensory analysis. As can be seen, although all the parameters showed significant differences with regard to the type of biscuit tested, aroma exhibited the smallest differences. When compared to the control biscuits, the panelists rated flavor as the worst parameter, especially when the highest proportion of wheat flour was replaced by both insect flours Moreover, although no significant differences in sweetness were found between the control biscuits and those with 20% of Tenebrio molitor powder, the other biscuits received the lowest scores for this parameter. The higher the insect powder concentration, the lower the score in textural parameters. In the case of color, the biscuit with insect powder also showed lower scores than the control, but no significant differences as regards the considered concentration. These ratings may be related to some properties linked to insects. Thus, negative properties, such as a strong, burnt odor, dark color, and strong taste, were more associated with the cricket-enriched cat biscuit (Homann et al., 2017). However, in the study conducted by Çabuk (2021), the sensory characteristics revealed that the enriching of wheat flour with mealworm powder produced a muffin with a liking score ranging from 6.70 to 8.70 for all the attributes tested.

| Formulation | Aspect | Color | Aroma | Sweetness | Texture | Crunchiness | Flavor |

|---|---|---|---|---|---|---|---|

| Control | 7.1 ± 1.5 b | 7.2 ± 1.6b | 6.2 ± 1.6bc | 6.4 ± 2.1c | 7.0 ± 2.0c | 7.1 ± 2.1d | 6.8 ± 2.3c |

| TM20 | 6.4 ± 1.2 a | 6.4 ± 1.2a | 6.5 ± 1.4c | 6.4 ± 2.0c | 5.9 ± 1.9b | 6.2 ± 1.8c | 5.8 ± 2.0b |

| TM25 | 6.0 ± 1.9 a | 5.9 ± 2.1a | 5.7 ± 1.8ab | 3.7 ± 1.6a | 5.0 ± 2.4ab | 5.3 ± 2.0bc | 3.5 ± 2.2a |

| AD20 | 6.0 ± 1.6 a | 6.1 ± 1.5a | 5.8 ± 1.6abc | 4.8 ± 1.9b | 5.3 ± 2.3ab | 4.8 ± 2.1ab | 4.4 ± 1.9a |

| AD25 | 6.2 ± 1.5 a | 6.0 ± 1.6a | 5.4 ± 1.4a | 4.2 ± 1.7ab | 4.7 ± 2.1a | 3.9 ± 2.0a | 3.9 ± 2.0a |

| F-ratio | (4.44)** | (5.48)** | (2.79)* | (18.28)** | (9.97)** | (16.89)** | (21.66)** |

- Note: *95% significance level and **99% significance level. Equal letters mean homogenous groups obtained in the ANOVA analysis.

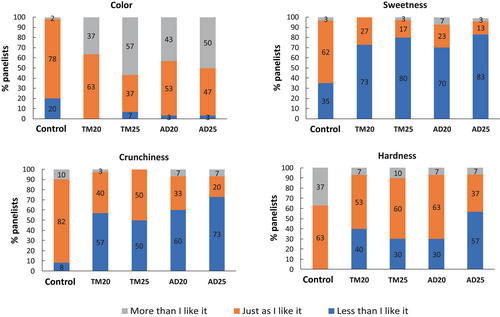

In order to know how to improve the sensory perception of biscuits by increasing or reducing the intensity of the studied parameters, Figure 5 shows the results of the just-about-right (JAR) analysis. These reveal that, regardless of the insect powder used, the biscuits were darker than would have been preferred, while the sweetness was lower than would have been preferred, especially when the insect concentration was higher. Furthermore, both mechanical parameters (crunchiness and hardness) were too low in the panelists' opinions in contrast with the instrumental results described previously where the biscuits with insect flours were harder than control ones.

Finally, Table 4 shows the average drops or penalties obtained for the biscuits formulated with insect powders. More than 20% of the panelists gave a penalty higher than 1 for low sweetness to biscuits with 20% Tenebrio molitor or Alphitobius diaperinus and also to those with 25% Alphitobius diaperinus (in bold in Table 4). According to this analysis, in spite of the differences detected by the panelist in the other attributes, such as texture and color, only the level of sweetness seemed to be determinant in terms to overall acceptance of the product. Therefore, an increase in sweetness, for instance by incorporating some intensive sweetener, such as dry stevia leaves, may improve the acceptability of these biscuits.

| Parameter | Sample | Intensity | % Panelists | Penalty |

|---|---|---|---|---|

| Color | Control | Too low | 1.7 | 0.54 |

| Too high | 20 | −0.21 | ||

| TM20 | Too low | 0 | 0 | |

| Too high | 36.7 | 0.28 | ||

| TM25 | Too low | 6.7 | 0.68 | |

| Too high | 56.7 | 0.53 | ||

| AD20 | Too low | 3.3 | 0.375 | |

| Too high | 43.3 | 0.30 | ||

| AD25 | Too low | 3.3 | 1.43 | |

| Too high | 50 | 0.69 | ||

| Sweetness | Control | Too low | 35 | 0.52 |

| Too high | 3.3 | 0.81 | ||

| TM20 | Too low | 73.3 | 1.34 | |

| Too high | 0 | 0 | ||

| TM25 | Too low | 80 | 0.89 | |

| Too high | 3.3 | 1.60 | ||

| AD20 | Too low | 70 | 1.09 | |

| Too high | 6.7 | 1.64 | ||

| AD25 | Too low | 83.3 | 1.37 | |

| Too high | 3.3 | 2.25 | ||

| Crunch | Control | Too low | 8.3 | 0.90 |

| Too high | 10.0 | 0.37 | ||

| TM20 | Too low | 56.7 | 0.04 | |

| Too high | 3.3 | 1.33 | ||

| TM25 | Too low | 50 | 0.07 | |

| Too high | 0 | 0 | ||

| AD20 | Too low | 60 | 0.64 | |

| Too high | 6.7 | 0.7 | ||

| AD25 | Too low | 6.7 | 0.17 | |

| Too high | 73.3 | 0.17 | ||

| Hardness | Control | Too low | 0 | 0 |

| Too high | 36.7 | 0.16 | ||

| TM20 | Too low | 40 | 0.17 | |

| Too high | 6.7 | 1.25 | ||

| TM25 | Too low | 30 | 0.11 | |

| Too high | 10 | 0.89 | ||

| AD20 | Too low | 30 | 0.47 | |

| Too high | 6.7 | 0.97 | ||

| AD25 | Too low | 56.7 | 0.18 | |

| Too high | 6.7 | 0.68 |

4 CONCLUSIONS

The use of Tenebrio molitor and Alphitobius diaperinus flours might represent a new possibility in the reformulation of traditional products, such as biscuits, in order to sustainably supply the expected increase in world population. However, there is still a cultural barrier which provokes a rejection of the consumption of insects. Furthermore, from a technological point of view, there are some problems related to their influence on the structure of food products, their color or flavor, among other aspects. In this particular study, biscuits formulated with both insect powders may be labeled as “high in protein” products following Regulation (EC) No. 1924/2006, although they were thinner, darker and less crunchy than the control samples. Regarding the penalty sensory analysis, the increased sweetness or other flavorings, such as chocolate, may contribute to improving their overall acceptability. Therefore, further studies should be carried out to optimize these formulations.

ACKNOWLEDGEMENTS

The authors thank the UPV for funding this research.

AUTHOR CONTRIBUTIONS

María Dolores Ortolá: Conceptualization (equal); data curation (equal); funding acquisition (equal); investigation (equal); resources (equal); supervision (equal); writing – original draft (equal); writing – review and editing (equal). Miguel Martínez-Catalá: Formal analysis (equal); investigation (equal); methodology (equal); writing – original draft (equal). Alberto Yuste Del Carmen: Formal analysis (equal); investigation (equal); methodology (equal); writing – original draft (equal). María Luisa Castelló: Conceptualization (equal); funding acquisition (equal); investigation (equal); methodology (equal); resources (equal); supervision (equal); writing – original draft (equal); writing – review and editing (equal).

ETHICAL STATEMENTS

Conflict of Interest: The authors declare that they do not have any conflict of interest.

Ethical Review: A sensory test was conducted with human subjects. The data obtained were treated in accordance with the Regulation (EU) 2016/679 of the European Parliament and of the Council of April 27, 2016, on the protection of natural persons with regard to the processing of personal data and on the free movement of such data, and repealing Directive 95/46/EC (General Data Protection Regulation).

Informed Consent: Written informed consent was obtained from all study participants.

Open Research

DATA AVAILABILITY STATEMENT

Data available on request due to privacy/ethical restrictions The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.