Effects of variety, early harvest, and germination on pasting properties and cooked grain texture of brown rice

This article was published on AA publication on: 21 March 2022.

Funding information: AgriFutures Australia; Australian Centre for International Agricultural Research

Abstract

Brown rice is superior to white rice in nutritional value and in the prevention of chronic diseases. However, it is not the preference of consumers and the relative consumption of brown rice is limited due to a number of factors including chewiness and perceived hard texture after cooking. While both early harvested brown rice and germinated brown rice have been shown to contain superior nutritional components, there is limited knowledge on textural properties of these types of brown rice relative to standard brown rice, and how varieties may affect such properties. Thus, the present study examined the effect of variety, early harvest, and germination on those properties of eight rice varieties with contrasting amylose content and known texture in terms of milled rice. Early harvest and germination decreased pasting viscosities and cooked grain hardness. However, their effect on the characteristics of flour and whole grains differed, in which germination had a greater effect on pasting properties, while early harvest on the texture of cooked grains. The softer texture of brown rice, about 32% lower, could be achieved by germination and 46% by harvesting early. There was a good relationship between pasting characteristics, particularly setback and hardness among different varieties in brown rice, germinated brown rice, and also in early harvest brown rice. This is the first time the comparison of texture between the three brown rice types has been reported. The results also provide new options for the selection of desired characteristics for food processing and brown rice consumption.

1 INTRODUCTION

Brown rice is rich in vitamins, minerals, and other chemical compounds, which are beneficial for a healthy diet. National dietary guidelines in many countries recommend the intake of whole grain, including brown rice in an attempt to combat diseases such as obesity, type 2 diabetes, cardiovascular disease, and cancer (Mohan et al., 2017). However, white rice remains widely preferred in rice-consuming countries and across cultures, and the consumption of brown rice was limited by a number of factors including chewy and hard texture after cooking (Mohan et al., 2017).

Rice is normally harvested when the grain reaches maturity around 35 days after flowering (DAF) for direct consumption or processing into food products. Harvesting at this time is optimal for maximum grain yield and preferred quality of milled rice (Hossain, Bhuiya, Ahmed, & Mian, 2009). A number of methods have been examined to improve the texture of mature brown rice, including soaking, gamma radiation, ultrasonic enzyme treatment, high-pressure cooking, freeze–thaw cycle treatment, and germination (Sabularse, Liuzzo, Rao, & Grodner, 1991; Wang et al., 2021; Yu et al., 2017; Zhang et al., 2015). Meanwhile, germination has been gaining interest due to increased bioactive compounds in germinated grain compared to brown rice and also health benefits (Mir, Shah, & Manickavasagan, 2017). However, the grain harvested earlier than normal harvest (early harvest rice) which is also known to contain higher chemical compounds with higher nutritional values and health benefits than mature grain (Kim, Kim, Ha, & Park, 2016) has not been sufficiently studied.

Early harvest grains of different rice varieties were found to contain higher antioxidant activity and bioactive compounds than mature grains (Jiamyangyuen et al., 2017). Through the development stages, the mineral, vitamin, and nutrient contents of rice grains are gradually decreasing toward its maturity (Ji et al., 2013). For instance, K, Ca, and Vitamin C were found abundant in developing grains compared to mature grains. From 15 to 40 DAF, the content of K reduced by 84–124 mg/100 g, while Ca content decreased by 4–9 mg/100 g. Reducing sugar and Vitamins B2, B3, and B6 were found in the highest level at 15 DAF. Vitamin C and β-carotene decreased from 15 to 25 DAF and they were not found in mature grains. In East Asian countries, a certain type of early harvest grain called “green rice” is roasted and flattened as green rice flake. The flake is then consumed as a snack or used to produce different types of desserts including cake, candy, and ice cream (Kim, Lee, Kim, Keum, & Park, 2011).

Limited studies have been conducted to examine the textural properties of developing grain and studies on early harvest grain published in English were done only on milled rice. Arai and Itani (2000) reported that eating quality scores were significantly higher in grain harvested 10 days before normal harvest than in mature grain of milled rice of Koshihikari. The early harvest grain had a softer texture, sweeter and a delicious taste, and higher preservability after cooking, in which eating properties especially hardness and stickiness remained the same when kept at 25°C for 24 hr. However, little is known about the textural properties of brown rice during grain development and whether those characteristics in milled rice are maintained. The results of pasting viscosities in our preliminary study indicated that the cooked texture of early harvest brown rice might be lower than that of mature brown rice, but this proposition needs to be confirmed as flour and whole grain may differ in processing characteristics and cooking properties. For germinated grain, its softer texture after cooking compared to mature brown rice was widely reported (Chungcharoen, Prachayawarakorn, Tungtrakul, & Soponronnarit, 2015; Jiamyangyuen & Ooraikul, 2008; Watchararparpaiboon, Laohakunjit, & Kerdchoechuen, 2010). The results in our previous study show that the hardness of grain soaked for 12 hr and germinated for 30 hr was on average 24 N (39%) lower than brown rice (Chao, Mitchell, Prakash, Bhandari, & Fukai, 2021).

Similar to textural properties, the knowledge in pasting properties of early harvest rice is limited, and a few studies were conducted only in milled rice and at a later stage of grain development. For example, Champagne et al. (2005) found similar peak viscosity, final viscosity, setback, and pasting temperature among milled rice of M-202 harvested at 32, 38, 45, and 48 DAF. In our preliminary study with brown rice, developing grain tended to have lower pasting viscosities (final, peak, and setback) compared to mature grain, and the viscosities increased with increased harvesting dates from 15 to 35 DAF. Despite limited knowledge in pasting viscosities of flour in early harvest grain, those viscosities of germinated grain are well documented, in which the viscosities were significantly lower in germinated grain than in mature grain. While most studies (Kim et al., 2012; Moongngarm, Moontree, Deedpinrum, & Padtong, 2014; Watchararparpaiboon et al., 2010) found similar pasting temperature in mature grain and germinated grain, a few studies reported about the decrease (Hiremath & Kasturiba, 2018) and increase (Li, Oh, Lee, Baik, & Chung, 2017) in pasting temperature after germination. Chao et al. (2021) found a slight increase in pasting temperature, and the pasting viscosities (final, peak, and setback) further decreased with an increased germination level.

In addition to the grain treatment of early harvest and germination, the selection of suitable varieties can also improve the quality of brown rice as they differ in pasting and textural properties. Among the two japonica varieties studied by Arai and Itani (2004), the texture of Nakateshinsenbon in cooked milled rice remained higher than Koshihikari regardless of harvesting early or at maturity. The results in Chao et al. (2021) show that the eight varieties studied maintained their characteristics in flour paste and textural properties after germination. Varieties with high viscosities and hard texture in brown rice had high viscosities and hard texture in germinated brown rice, but there was a significant variety and brown rice type (brown rice and germinated brown rice) interaction, and variation in cooked hardness was greater in brown rice (35–91 N) than in germinated brown rice (25–55 N) soaked for 12 hr and germinated for 30 hours. In five varieties examined by Pal et al. (2016), there was a significant variation in cooked hardness of brown rice, but there was no significant variation in germinated brown rice from grain soaked for 24 hr and germinated for 48 hr. They also found a significant effect of variety on final, peak, and setback viscosities, but the variation was rather small, particularly in germinated brown rice. Varieties differed in germination speed and pasting viscosities decreased with increasing germination percentage. Thus, germinating grains to a similar germination percentage was more appropriate for variety comparison than germinating for a fixed time for all varieties (Chao et al., 2021).

There are some indications about the effect of early harvest and the effect of germination known to lower the texture and pasting value of brown rice in relation to mature grain, but the extent of interaction effect between the two factors on texture in the same experimental setting has not been reported. Thus, the aim of the present study was to examine the effect of variety, early harvest, and germination on pasting and textural properties of brown rice in eight varieties with contrasting amylose content and known texture in milled rice.

2 MATERIALS AND METHODS

2.1 Selection of rice varieties and field experimentation

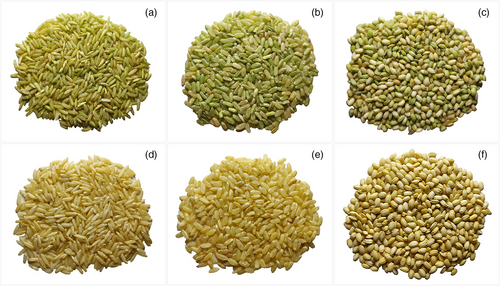

The eight varieties used in this study consisted of standard Australian and international varieties selected from across grain types (short, medium, and long grains) and included two glutinous lines (TDK8 and YRW4; Table 1). Figure 1 shows photographs of early and mature brown rice of three selected varieties representing long grain, medium grain, and short grain.

| Variety name | Variety type | Grain type | Stickiness | Texturea |

|---|---|---|---|---|

| Doongara | Indica/japonica | Long | Non-glutinous | Firm |

| Koshihikari | Japonica | Short | Non-glutinous | Soft, sticky |

| Langi | Japonica | Long | Non-glutinous | Soft |

| Reiziq | Japonica | Medium | Non-glutinous | Medium |

| Sherpa | Japonica | Medium | Non-glutinous | Medium |

| Tachiminori | Japonica | Medium | Non-glutinous | Soft |

| TDK8 | Indica | Long | Glutinous | Soft |

| YRW4 | Japonica | Short | Glutinous | Soft |

- a Texture classification in milled rice.

All varieties were grown in an aerobic rice field with three replications at the Gatton campus, the University of Queensland, Australia, in the summer of 2018–2019. Irrigation water of 72 mm/week was applied. In addition to mature harvest at 43 days after flowering (DAF), early harvest samples were collected either 20 or 25 DAF depending on the variety (Table 2), which was found to result in maximum yield for green rice in the previous season. The paddy samples were dried in the oven at 35°C to reduce the moisture content to 13.5%–14% and stored at 4°C for 5 months. Three biological replications were maintained and used for subsequent laboratory analyses at the University of Queensland, St Lucia campus.

| Variety | Early harvest (DAF) | 100 grain weight (g) | Kernel thickness (mm) | Kernel length (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| EBR | MBR | Mean | EBR | MBR | Mean | EBR | MBR | Mean | ||

| Doongara | 20 | 1.59 | 1.66 | 1.62B | 1.59b | 1.63bc | 1.61B | 6.37 | 6.57 | 6.47E |

| Koshihikari | 20 | 1.43 | 1.60 | 1.51A | 1.71de | 1.86hi | 1.78D | 4.40 | 4.44 | 4.42A |

| Langi | 25 | 1.83 | 1.86 | 1.85D | 1.68cd | 1.72de | 1.70C | 6.84 | 6.99 | 6.92F |

| Reiziq | 20 | 1.87 | 1.95 | 1.91D | 1.65bcd | 1.79fg | 1.72C | 5.59 | 5.67 | 5.63D |

| Sherpa | 20 | 1.71 | 1.84 | 1.77C | 1.61bc | 1.75ef | 1.68C | 5.28 | 5.43 | 5.36C |

| Tachiminori | 20 | 1.80 | 1.93 | 1.86D | 1.71de | 1.89hi | 1.80D | 5.24 | 5.28 | 5.26C |

| TDK8 | 20 | 1.44 | 1.65 | 1.54A | 1.50a | 1.61bc | 1.55A | 6.26 | 6.41 | 6.34E |

| YRW4 | 25 | 1.81 | 1.88 | 1.85D | 1.84gh | 1.92i | 1.88E | 4.61 | 4.67 | 4.64B |

| Mean | 1.68A | 1.80B | 1.74 | 1.66A | 1.77B | 1.71 | 5.57A | 5.68B | 5.63 | |

- Note: Mean values with identical capital letters (A, B, C, …) are not significantly different for main effects (p > 0.05). Values with identical small letters (a, b, c, …) are not significantly different for interaction effect (p > 0.05). Where interaction effect was not significant (p > 0.05), no letters are following values.

2.2 Germination of paddy

After tempering at 30°C for 4 hr, 100 g of mature paddy was placed in a 10 × 15 cm net bag and soaked in distilled water at 30°C for 12 hours. The water was changed after 6 hr to prevent fermentation odor. The soaked bag was left to drain on wire mesh for 2 min before spreading evenly and wrapping in a damp double layer cheesecloth and placed in a 1,000 ml rectangular plastic container. The container with a closed lid was placed in an incubator at 30°C for 12 hr before 20 grains were randomly removed every 3 hr for germination count. After 70% of grains germinated, they were dried in a single layer in an oven tray at 35°C for 10–12 hr to reduce the moisture content to 12%.

2.3 Preparation of rice samples

Early harvest brown rice (EBR), mature harvest brown rice (MBR), and germinated brown rice from mature paddy (GBP, at 70% germination) were produced by dehulling early, mature, and germinated paddy using a rubber roll laboratory husker (Satake Corporation, Hiroshima, Japan). Broken grain was manually removed, and 5 g of whole grain was used for textural property analysis, and the remaining sample was used to produce flour for the analyses of amylose content, protein content, and pasting properties. The three forms of rice retained their germ. The flour of EBR, MBR, and GBP was prepared by grinding 30 g of each brown rice type using an electric grinder (Grain mill SY-2200, CGOLDENWALL). The flour was then sieved using sieve mesh no. 80, in which the particle size corresponded to 180 μm. The yield of sieved flour was 25–27 g.

2.4 Determination of amylose content

The amylose content was determined by the iodine method. A sample of 0.1 g rice flour was placed into a 100 mL volumetric flask and soaked with 1 ml of 95% ethanol. A 9 ml sample of 1 M sodium hydroxide solution was added, and the mixture was left to stand and disperse the starch overnight. Then, the starch solution was filled with deionized water to 100 ml and mixed by inversion. A 0.5 ml sample of the solution was pipetted into a test tube with 9.20 ml deionized water, with 0.1 ml of 1 M acetic acid and 0.2 ml of iodine solution which were added and mixed well on a vortex mixer. The absorption of the mixture was determined using UV1800 Spectrophotometer (Shimadzu Corporation) at the wavelength 620 nm. The amylose content was calculated using a standard curve of known samples of mature white rice (6%, 12%, 17%, 23%, and 32%). The samples used in the analysis were not defatted. The preliminary test results show that there was no significant difference in amylose content between the defatted and undefatted samples of the eight rice varieties studied.

2.5 Determination of protein content

The nitrogen content of EBR, MBR, and GBP was determined by the near-infrared method. A 6 g sample of rice flour was placed and compacted in a 22 × 50 mm diameter vial. Nitrogen content was measured by MPA Multi-purpose FT-NIR Analyzer (Bruker Corporation), and it was converted to protein content by the factor 5.95 (Lamberts et al., 2007).

2.6 Pasting properties of brown rice flour

The determination of pasting profiles of flour of each brown rice type followed AACC international method 61–02.01 by using a Rapid Visco Analyzer (RVA-3D, Newport Scientific). A 3 g rice flour sample was added onto the surface of 25 ml deionized water in the test canister. The test was run for 12 min and 30 sec with 1 min holding at 50°C, 3.45 min heating at 95°C, 2.7 min holding at 95°C before cooling to 50°C for 3.91 min, and 1.24 min holding at 50°C. The speed for the first 10 s was 960 rpm and for the remainder of the test 160 rpm. The viscosity was recorded in the rapid viscosity unit (RVU). Setback viscosity reported was the difference between final and trough viscosities.

2.7 Textural properties of cooked whole grains

The texture of cooked grains was analyzed following the method of Okabe (1979) with some modifications. Broken grains were removed manually, and 5 g of whole grains was soaked at 30°C for 3 hs, drained, and then placed in a single layer in a 75 mm diameter aluminum dish. The sample was cooked at 95°C in a water bath for 30 min with a rice-to-water ratio of 1:1.25 by weight. After removal from the water bath, the cooked sample was kept warm in an electric rice cooker at 60°C for 15 min, then left to cool at room temperature (21 ± 1°C) for 1 h before measurement.

The hardness and stickiness were determined using a texture analyzer TA.XT plus (Stable Micro Systems, Surrey, UK) with 35 mm diameter aluminum probe. Ten grains were arranged closely on the platform below the probe. The probe moved to 2 mm distance at 1 mm/s after a 5 gf trigger force was applied and then immediately retracted at 2 mm/s. The test was repeated five times for each sample, and the result reported for each variety was the average of 15 readings (3 replicates × 5 times). The peak force and the area of the negative force curve generated during probe retraction were designated as hardness in Newton (N) and stickiness (N s), respectively (Li, Prakash, Nicholson, Fitzgerald, & Gilbert, 2016).

2.8 Data analysis

The significant effect of genotypes and brown rice type treatments (EBR, MBR, and GBP) and their interaction effect was determined by two-way ANOVA in a completely randomized design using GenStat 12th Edition (VSN International Ltd.). Means were compared by Fisher's least significant difference (LSD) range test for ρ = 0.05. The significance of relationships between measured variables was evaluated by Pearson's correlation analysis, two-sided tests at ρ = 0.05, using GenStat 12th Edition.

3 RESULTS

3.1 Grain characteristics

One hundred grain weight, kernel thickness, and kernel length of early harvest brown rice and mature brown rice are shown in Table 2. There were significant (p < 0.001) variety differences in these characteristics. The mature grain had a significantly higher mean grain size than early harvest grain, but the difference was small (0.12 g for grain weight, 0.11 mm for kernel thickness and length). The varieties with particularly higher grain weight, kernel thickness, or kernel length in mature grain tended to remain higher when harvested early. The correlation coefficient for grain weight, kernel thickness, and kernel length between early harvest and mature grains was 0.96***, 0.89**, and 0.99***, respectively.

Amylose content varied widely and significantly, ranging from 3% in glutinous variety TDK8 to 24% in non-glutinous variety Doongara (Table 3). Five varieties (Koshihikari, Langi, Reiziq, Sherpa, and Tachiminori) had amylose content in a range of 13.7%–15.6%, but there were significant variety differences in amylose with LSD 0.43% (p < 0.001). There was no significant interaction between genotype and brown rice type. The correlation coefficient between any brown rice types was 0.99***, indicating that the varieties with high amylose content in MBR remained high in amylose even when harvested early or after germination.

| Variety | Amylose content (%) | Protein content (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| EBR | MBR | GBP | Mean | EBR | MBR | GBP | Mean | |

| Doongara | 22.1 | 23.5 | 22.4 | 22.7F | 8.8defg | 8.6cdef | 7.1a | 8.2AB |

| Koshihikari | 15.0 | 15.8 | 14.5 | 15.1D | 7.8abc | 7.8abc | 10.1ijk | 8.5BC |

| Langi | 15.1 | 16.4 | 14.5 | 15.3DE | 9.0efgh | 8.8efg | 9.2fghi | 9.0CD |

| Reiziq | 13.2 | 14.6 | 13.2 | 13.7C | 10.0hij | 9.7ghij | 8.5cdef | 9.4DE |

| Sherpa | 15.2 | 16.0 | 14.2 | 15.1D | 8.2bcde | 7.8abc | 7.3ab | 7.8A |

| Tachiminori | 15.6 | 16.5 | 14.7 | 15.6E | 8.8defg | 7.8abcd | 6.9a | 7.8A |

| TDK8 | 2.6 | 3.1 | 2.4 | 2.7A | 10.4jkl | 10.2jkl | 11.0kl | 10.5F |

| YRW4 | 4.2 | 4.6 | 3.4 | 4.1B | 8.9efg | 8.7cdef | 11.1l | 9.6E |

| Mean | 12.9B | 13.8C | 12.4A | 13.0 | 9.0A | 8.7A | 8.9A | 8.9 |

- Note: Mean values with identical capital letters (A, B, C, …) are not significantly different for main effects (p > 0.05). Values with identical small letters (a, b, c, …) are not significantly different for interaction effect (p > 0.05). Where interaction effect was not significant (p > 0.05), no letters are following values.

There was a significant genotypic difference in protein content with a range of 8%–10% for EBR and MBR and 7%–11% for GBP (LSD = 0.65; p < 0.001; Table 3). Each brown rice type had a similar average protein content of about 9%. However, the genotype by brown rice type interaction was significant (LSD = 1.13; p < 0.001), and there was no correlation between MBR and GBP. Compared to MBR, some varieties such as Koshihikari and YRW4 had higher and others such as Doongara and Reiziq had lower protein content after germination. There was a significant correlation (r = 0.95***) between the protein content of MBR and EBR.

3.2 Pasting properties

Early harvest grain had a slightly lower final, peak, and setback viscosities than MBR, while viscosities were greatly reduced in GBP (Table 4). Genotypic variation was significant (p < 0.001), and the interaction between genotype and brown rice type was also highly significant (p < 0.001), except for pasting temperature (p < 0.05) for the four pasting characteristics.

| Variety | Pasting temp (°C) | Peak Visc (RVU) | Setback Visc (RVU) | Final Visc (RVU) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EBR | MBR | GBP | Mean | EBR | MBR | GBP | Mean | EBR | MBR | GBP | Mean | EBR | MBR | GBP | Mean | |

| Doongara | 73.5f | 74.6f | 74.3f | 74.2D | 1,624fgh | 1,599fg | 864d | 1,363CDE | 2,213n | 2,573° | 869g | 1,885E | 3,246l | 3,585m | 1,059f | 2,630D |

| Koshihikari | 67.8c | 68.1c | 67.5c | 67.8C | 1,639fgh | 1,900ij | 340b | 1,293BCD | 1,091hij | 1,243kl | 230cd | 855BC | 1,997gh | 2,274ij | 362b | 1,544B |

| Langi | 77.7g | 76.7g | 76.5g | 77.0F | 1,771hij | 1,696fgh | 388b | 1,285BC | 1,049hi | 1,389m | 305d | 914C | 1,959gh | 2,213ij | 452bc | 1,542B |

| Reiziq | 68.8cde | 69.6de | 68.1c | 68.9D | 1,591f | 1,866ij | 674c | 1,377DE | 971gh | 1,020h | 478e | 823B | 1,915g | 1,991gh | 840e | 1,582B |

| Sherpa | 70.1e | 68.6cde | 67.5c | 68.7D | 1,577f | 1,871ij | 871d | 1,440E | 1,175ijk | 1,365lm | 641f | 1,061D | 2,098hi | 2,391jk | 1,081f | 1,857C |

| Tachiminori | 67.8c | 68c | 68.3cd | 68.0CD | 1,749ghi | 1,921j | 119a | 1,263B | 1,187jk | 1,449m | 65ab | 900C | 2,257ij | 2,550k | 107a | 1,638B |

| TDK8 | 63.1a | 64.6b | 64.9b | 64.2A | 1,391e | 878d | 32a | 767A | 137abc | 109abc | 12a | 86A | 673de | 490bc | 25a | 396A |

| YRW4 | 65.4b | 65.7b | 65.9b | 65.7B | 949d | 981d | 120a | 683A | 172bc | 188bcd | 30a | 130A | 538bcd | 585cd | 77a | 400A |

| Mean | 69.3A | 69.5A | 69.1A | 69.3 | 1,536B | 1,589B | 384A | 1,170 | 999B | 1,167C | 275A | 814 | 1,836B | 2,010C | 446A | 1,431 |

- Note: Mean values with identical capital letters (A, B, C, …) are not significantly different for main effects (p > 0.05). Values with identical small letters (a, b, c, …) are not significantly different for interaction effect (p > 0.05).

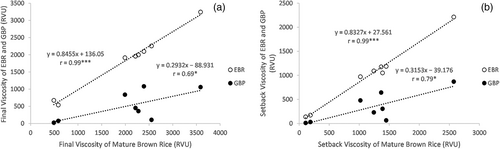

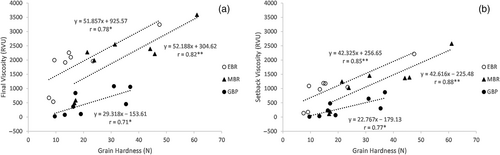

The average final viscosity for EBR, MBR, and GBP was 1,836, 2,010, and 446 RVU. The final viscosity of MBR and EBR among varieties was similar to a correlation coefficient of 0.99***, while GBP had a lower correlation coefficient value of 0.69* (Figure 2a). Varieties with high final viscosity in MBR tended to have high final viscosity in EBR and GBP, but the ranking varied between MBR and GBP. Koshihikari, Langi, and Tachiminori had a final viscosity higher than average in MBR but had viscosity lower than average in GBP, and the final viscosity of Tachiminori in GBP was not significantly different from those in the two glutinous varieties. While most varieties had the highest final viscosity in MBR, TDK8 had the highest viscosity when harvested early. The final viscosity of Reiziq and Sherpa was less affected by germination. The viscosity of germinated grains of the two varieties was above 42% of MBR, while that of other varieties was lower than 30%.

The mean peak viscosity in MBR was similar to that in EBR and was four times higher than that of GBP. There was a positive correlation (r = 0.79*) for peak viscosity between EBR and MBR but not between others with a correlation coefficient below 0.54ns. Koshihikari had one of the highest peak viscosities in MBR, but the viscosity was reduced to about average when harvested early and after germination.

The average setback viscosity in MBR of 1,167 RVU was higher than that in EBR (999 RVU) and GBP (275 RVU), but there was significant genotype and brown rice type interaction. Tachiminori had setback viscosity above average in EBR and MBR but had the lowest setback among non-glutinous varieties in GBP. While there was a highly significant correlation (r = 0.99***) between setback viscosity of MBR and EBR, the correlation coefficient (r = 0.79*) was much lower between MBR and GBP (Figure 2b). The pattern of interaction followed that of final viscosity. The setback viscosity of Reiziq and Sherpa was less affected by germination. The viscosity of germinated grains of the two varieties was above 46% of MBR, while that of other varieties was lower than 34%.

The mean pasting temperature was 69°C, ranging from 63 to 78°C among varieties for each of the three brown rice types. Although there was a significant genotype by brown rice type interaction, the relationship of MBR with EBR and GBP was strong with a correlation coefficient of 0.98*** and 0.99***, respectively, indicating that varieties with high pasting temperature in MBR remained high at early harvest and after germination.

The amylose content of eight varieties in each brown rice type had a significant relationship with final viscosity, peak viscosity, setback viscosity, and pasting temperature. The relationship for both final and setback viscosities was stronger in EBR (r = 0.98***, 0.99***) and MBR (r = 0.97***, 0.98***) compared to GBP (r = 0.71*, 0.78*). The relationship between amylose content and final and setback viscosity of each brown rice type is shown in Table 5. In GBP, final viscosity varied from 107 to 1,081 RVU and setback viscosity from 65 to 641 RVU for varieties with amylose content of about 15%. Protein content had no relationship with the four pasting traits.

| All varieties | Six non-glutinous varieties | |||||

|---|---|---|---|---|---|---|

| EBR | MBR | GBP | EBR | MBR | GBP | |

| Final viscosity | 0.99*** | 0.99*** | 0.71* | 0.98*** | 0.98*** | 0.40ns |

| Setback viscosity | 0.97*** | 0.98*** | 0.78* | 0.99*** | 0.99*** | 0.66ns |

| Hardness | 0.74* | 0.81** | 0.77* | 0.92** | 0.81* | 0.59ns |

| Stickiness | −0.71* | −0.82** | −0.68* | −0.66ns | −0.86* | −0.61ns |

- * Significant difference at p < 0.05.

- ** Significant difference at p < 0.01.

- *** Significant difference at p < 0.001. ns No significant difference at p = 0.05.

3.3 Textural properties

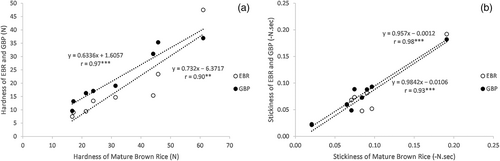

Table 6 shows the textural properties of cooked whole grains of EBR, MBR, and GBP which had an average grain hardness of 18, 33, and 22 N, respectively, and each was significantly different from each other (LSD = 1.85; p < 0.001). Genotypic variation in hardness was significant (LSD = 3.02; p < 0.001) with non-glutinous varieties having a harder texture than glutinous varieties. Doongara had the hardest and Koshihikari had the softest texture among non-glutinous varieties. There was a significant interaction between genotype and brown rice type (LSD = 5.23; p < 0.001). Grain hardness in Reiziq, Sherpa, and Tachiminori was similar in EBR (13.4–15.4 N) but varied greatly in MBR (23.9–44.1 N). Hardness was significantly greater in EBR than in GBP in Doongara, while it was significantly greater in GBP than in EBR in Koshihikari, Langi, and Sherpa. The correlation coefficient between any brown rice types was all significant, but the highest was obtained between MBR and GBP (r = 0.97***) and least between EBR and GBP (r = 0.81*; Figure 3a).

| Variety | Hardness (N) | Stickiness (−N sec) | ||||||

|---|---|---|---|---|---|---|---|---|

| EBR | MBR | GBP | Mean | EBR | MBR | GBP | Mean | |

| Doongara | 47.5j | 61.1k | 36.9i | 48.5G | 0.023 | 0.021 | 0.021 | 0.022A |

| Koshihikari | 9.4ab | 21.4fg | 16.3def | 15.7BC | 0.048 | 0.073 | 0.084 | 0.068B |

| Langi | 23.4g | 45.8j | 35.4hi | 34.9F | 0.052 | 0.093 | 0.097 | 0.080B |

| Reiziq | 13.4bcd | 23.9g | 17.1def | 18.1C | 0.068 | 0.049 | 0.071 | 0.062B |

| Sherpa | 15.4de | 44.1j | 31.0h | 30.2E | 0.073 | 0.088 | 0.075 | 0.079B |

| Tachiminori | 14.7cde | 31.4h | 19.0efg | 21.7D | 0.060 | 0.059 | 0.065 | 0.061B |

| TDK8 | 7.5a | 16.7def | 9.6abc | 11.3A | 0.192 | 0.182 | 0.191 | 0.188C |

| YRW4 | 9.1ab | 17.1def | 13.2bcd | 13.1AB | 0.081 | 0.088 | 0.090 | 0.087B |

| Mean | 17.5A | 32.7C | 22.3B | 24.2 | 0.075A | 0.082A | 0.087A | 0.081 |

- Note: Mean values with identical capital letters (A, B, C, …) are not significantly different for main effects (p > 0.05). Values with identical small letters (a, b, c, …) are not significantly different for interaction effect (p > 0.05). Where interaction effect was not significant (p > 0.05), no letters are following values.

The amylose content of eight varieties in each brown rice type had a positive relationship with grain hardness (Table 5). The correlation coefficient between amylose content and hardness was 0.74* in EBR, 0.81** in MBR, and 0.77* in GBP. However, hardness in any brown rice type varied greatly (9–23 N in EBR, 21–46 N in MBR, and 16–35 N in GBR) among five varieties with a low amylose content of around 16% in MBR. There was no significant relationship between protein content and grain hardness. The 100-grain weight, kernel thickness, and kernel length also had no significant relationship with cooked grain hardness.

There was no significant difference in the stickiness of cooked grains of EBR, MBR, and GBP. Genotypic difference in stickiness was significant (LSD = 0.033: p < 0.001), but the interaction between genotype and brown rice type was not significant. The correlation coefficient between any brown rice types ranged from 0.92*** to 0.98*** (Figure 3b). The stickiness of glutinous varieties was much greater than non-glutinous varieties regardless of brown rice type.

Grain stickiness among varieties was negatively correlated with amylose content in each brown rice type with a correlation coefficient of −0.71*, −0.82**, and − 0.68* in EBR, MBR, and GBP, respectively (Table 5). Protein content had no relationship with grain stickiness.

Final and setback viscosities of flour had a positive correlation with cooked grain hardness for EBR, MBR, and GBP, but setback tended to have a stronger relationship (Figure 4). For a given grain hardness, both final and setback viscosity were greater in EBR, followed by MBR and then GBP. Grain stickiness was negatively correlated with the final and setback viscosity in EBR (r = −0.75*, −0.76*) and MBR (−0.82**, −0.80**), but the relationship was not significant in GBP (r = −0.56ns, r = −0.61ns). There was a positive correlation between pasting temperature and hardness of EBR, MBR, and GBP, with a correlation coefficient of 0.69*, 0.82**, and 0.86**, respectively. The correlation between pasting temperature and stickiness was not significant. Peak viscosity had no relationship with textural properties.

4 DISCUSSION

4.1 Effect on chemical properties

The results of the present study show that the amylose content was about 1% lower in EBR and GBP than MBR. Lower amylose content during the grain filling stage was reported by Shu et al. (2014), in which brown rice of three indica varieties had about 0.8–1.6% lower amylose content in grain harvested at 15 DAF compared to 30 DAF. During grain development, starch and storage protein accumulate (Wang, Lu, Wen, & Lu, 2015), and as a component of starch, the amylose content also increased. The accumulation of starch appeared to be constant at a later stage during grain development. Asaoka, Okuno, Sugimoto, and Fuwa (1985) reported that the amount of amylose per grain increased by about 0.8% per day from 5 to 17 DAF and then plateaued from 19–23 DAF. The slightly higher values in amylose content in early harvest grain were due to lower contents of other constituents including crude fat, fiber, and protein (Kester, Lukens, Ferrel, Mohammad, & Finrock, 1963). There was a slightly lower content in crude fat, crude protein, and ash in grain harvested about 22 days after heading compared to those harvested at maturity (43 days) in Korean varieties Chuchung and Jinbu (Kim et al., 2011; Kim et al., 2016). The amount of minerals also decreased for the two harvest dates, particularly potassium (from 258 to 205 mg/100 g) and calcium (from 15 to 11 mg/100 g). The decrease in amylose content after germination was similar to the result in the previous growing season (Chao et al., 2021). In contrast to the grain filling, starch content in the endosperm depleted during the germination process (Wu et al., 2013), which also resulted in a decrease in the amylose content. The present study also shows that the varietal effect on amylose content was greater than the brown rice type effect. The result in Chao et al. (2021) also indicated that variety had a greater effect on variation in amylose than germination.

The results of the present study in which no significant difference in protein content was found between MBR and EBR harvested at 20–25 DAF were consistent with the previous growing season (data not shown). The amount of protein increased in the early stage of grain development before it plateaued. Cruz et al. (1970) reported that protein content increased rapidly from about 0.4 mg/grain at 4 DAF to 1.6 mg/grain at 16 DAF and remained constant after 16 DAF. Despite the increase in amount, the percentage of protein content decreased due to the faster accumulation of starch during this period. The difference between protein content in EBR and MBR may depend on the accumulation speed of starch in each rice variety. The present study also found a similar protein content on average in MBR and GBP which was in agreement with the result of germinated grains at 70% (Chao et al., 2021). Germination affected varieties differently causing significant genotype by brown rice type interaction. This might be one reason for inconsistent results of protein content after germination reported in the literature (Moongngarm & Saetung, 2010; Veluppillai, Nithyanantharajah, Vasantharuba, Balakumar, & Arasaratnam, 2009; Xu, Zhang, Guo, & Qian, 2011). The result in Chao et al. (2021) also revealed the effect of the germination method, in which GBP incubated for 30 hours with the level of germination differing among varieties had significantly higher protein content than MBR and GBP incubated until 70% grain had germinated.

4.2 Effect on pasting properties

Final and setback viscosities of brown rice flour in eight varieties were reduced by early harvest and particularly with germination. Early harvest did not affect the peak viscosity compared to MBR, but germination reduced the viscosity to less than a quarter of MBR viscosity. The pasting temperature was not affected by early harvest and germination. Champagne et al. (2005) found that there was no significant difference in final viscosity, peak viscosity, and pasting temperature in milled rice of medium grain variety M-202 harvested at 32, 38, 45, and 48 DAF and a slight increase of 35 RVU in setback estimated as the difference between final and trough viscosities. Their result was, thus, different from that of the present study probably as they used milled rice and harvested at a later stage in the grain filling process. During grain development, individual grain weight and total brown rice yield increase after flowering to physiological maturity (Kim, Shin, Kang, Kim, & Park, 2013). By 22–24 DAF, grain that developed early reached the highest grain weight, and the grain yield increase after this date was due to an increase in later developed grain (Nangju & De Datta, 1970). This could explain the marginal variation in pasting characteristics between developing grains harvested at 20–25 DAF and mature grain as both types of grain contained similar cell size in endosperm but in different numbers (Wang et al., 2015). On the other hand, the structure of germinated grain was significantly altered during soaking and the germination process (Li et al., 2017; Wu et al., 2013). The flour of ungerminated brown rice had a continuous structure in which starch granules were surrounded by well-defined protein bodies. Germination damaged the continuous structure and the damage increased with germination. After 2 days, the protein bodies disappeared (Wu et al., 2013). The average branch chain length of amylopectin was significantly lower in germinated brown rice than in brown rice (Li et al., 2017). A greater decrease in pasting values after germination was also observed in the eight varieties grown in the previous season (Chao et al., 2021), in which GBP had a much lower retrogradation compared to MBR as determined by a low setback with germination. The activity of α-amylase also played a role in the determination of the pasting properties of brown rice flour (Han, Arijaje, Jinn, Mauromoustakos, & Wang, 2016), in which higher α-amylase activity resulted in lower pasting viscosities. Among 10 types of α-amylases, some played an important role in the formation of storage starch granules during seed development and some in the hydrolysis of starch to nourish seedling during germination (Damaris, Lin, Yang, & He, 2019). The α-amylases appeared predominantly in germinated grain (Shinke, Nishira, & Mugibayashi, 1973). This could also explain the differences between pasting values of GBP from that of EBR and MBR as α-amylase activity remained the same for grain of two hybrid rice varieties harvested between 25 and 40 DAF (Fu et al., 2016), while the activity in GBP was much higher than in mature grain (Moongngarm & Saetung, 2010).

There was a significant interaction effect of variety and brown rice type on the pasting properties of the eight varieties in the present study. However, varieties tended to maintain their pasting characteristics when harvested early and after germination, although the relationship was stronger between MBR and EBR than between MBR and GBP. There was a positive relationship between amylose content and final viscosity and setback viscosity in the present study. Varieties with high amylose content tended to result in higher final and setback viscosities regardless of brown rice type. Although the linear relationship may be due mostly to two extremely low amylose glutinous varieties (TDK8 and YRW4) and extremely high amylose Doongara, the result followed a similar trend reported by other workers in milled rice using a large number of varieties. A significant positive correlation between amylose content and final and setback viscosities in milled rice was found among 787 non-glutinous varieties by Pang et al. (2016). There was also a good correlation between amylose content and retrogradation in milled rice of 11 Thai varieties (Varavinit, Shobsngob, Varanyanond, Chinachoti, & Naivikul, 2003). The results of the current study show that the relationship is also applied in brown rice. Thus, amylose content in brown rice could be the main reason for the differences in final viscosity, and it also had a strong effect on retrogradation and final viscosity of mostly japonica rice varieties studied. However, the relationship may be applicable only among varieties with contrasting amylose content as varieties within similar amylose content may still result in different pasting characteristics (Champagne et al., 1999). Among five varieties with amylose content around 15% in the current study, Tachiminori had similar amylose content as Sherpa and slightly higher content than Reiziq, but Tachiminori had significantly lower final and setback viscosities than others in GBP, which was also found in the previous study (Chao et al., 2021). This result confirmed that other factors in addition to amylose content affected the pasting properties of brown rice flour. Wu et al. (2013) reported that pasting properties were affected by starch content, amylase activity, amylose and amylopectin ratio, protein, and lipid.

4.3 Effect on textural properties

The instrumental test of cooked rice for textural properties can be done either in bulk (per cup or fixed mass) or using one grain or several grains. Okabe (1979) recommended a 3-grain measurement rather than bulk compression test as the latter had poor reproducibility due to upward displacement of rice by the compression probe. During preliminary tests, we followed Okabe's method but found that 10 grains provided better consistency in the reading of the eight varieties. Consumers generally eat a spoonful amount of cooked rice. The results of 10 grains can be used as indicative of the level of hardness and stickiness in the sensory test. In addition, the instrumental test could provide data with more certainty where sensory data could be influenced by the subjective judgment of the panelists (Yang, Park, Jang, & Lee, 2018). However, there are still weaknesses in instrumental test to accurately represent sensory properties. Full consumer experience, which includes chewiness, mouthfeel, after taste, like and dislike, and sensory tests by the human panel would provide more accurate results.

In the present study, the hardness of cooked grain from different varieties and brown rice types were compared by compressing 10 grains to 2 mm distance regardless of the difference in cooked grain size. A preliminary test has shown the use of the 10 grains and 2 mm distance consistently discriminated varieties and brown rice types. A fixed compression ratio, for example, 80% strain using a single grain could provide more accurate measurement for comparison. However, adjusting measurement with the grain size of each variety in each brown rice type was found to be rather difficult and time consuming and was not adopted in the present study.

Early harvest and germination affected the textural properties of eight varieties in the present study. Compared to mature brown rice, 10 N softer in texture was achieved by germination, and a further 5 N by harvesting early. This is the first time the comparison of texture between the three brown rice types was examined. The softer texture of brown rice after germination was well documented. Chungcharoen et al. (2015) found that the hardness in brown rice was reduced by 13 and 51 N when the grain of Chai Nat 1 was germinated for 60 and 68 hours, respectively. Kaosa-ard and Songsermpong (2012) reported that the hardness of GBP was reduced about 0.01–0.02 N after 12 hours of germination of two Thai varieties (KDML and CNT1), but the hardness remained unchanged until 24 hr for KDML and 48 hr for CNT1. The hardness of CNT1 was higher than that of KDML regardless of brown rice type. The reduction in hardness of about 24 N after 30 hr of incubation of 12 hr soaked grain was found in the eight varieties in our previous study (Chao et al., 2021). The varietal characteristics in hardness were maintained after germination with a strong correlation between MBR and GBP in the present study (r = 0.97***) as also found in the previous season (r = 0.94***).

There appears to be no report of texture in early harvest brown rice. There have been limited reports on early harvest milled rice, and those studies were conducted at a later stage of grain development (about 10 days to maturity vs. 20 days in the present study). Arai and Itani (2000) reported about 1 N softer texture in the cooked milled grain of Koshihikari when harvested 10 days earlier than maturity harvest, while Champagne et al. (2005) found no significant difference in grain hardness in medium grain variety M-202 for the different harvesting dates of 32, 38, 45, and 48 DAF. In the present study, the softer texture found in early harvest grain compared to mature grain could be due to lower amylose content in the former, but the effect of amylose in germinated grain was somewhat different. Thus, factors other than amylose may have been involved.

Langi known to have a soft texture in milled rice had similar hardness as the hard texture variety Doongara in germinated brown rice and tended to have higher hardness than other non-glutinous varieties (Koshihikari, Reiziq, Sherpa, and Tachiminori) in early harvest and mature brown rice. The hard texture of Langi in mature brown rice and germinated brown rice was also found in grains grown in the previous year (Chao et al., 2021). Seed coat and bran layer could be possible factors causing the differences between hardness in milled rice and brown rice (Puri, Dhillon, & Sodhi, 2014).

The texture of cooked rice was affected by variety and cooking methods such as soaking and water-to-rice ratio (W:R), and varietal variations in hardness by the sensory panel were examined by Bett-Garber, Champagne, Ingram, and McClung (2007) with four varieties consisting of medium and long grains of glutinous and non-glutinous types. In practice, rice is cooked with adjusted W:R for acceptable sensory attributes (Crowhurst & Creed, 2001). For screening technique in breeding program, Juliano and Perez (1983) recommended a constant W:R which was more sensitive tool for cooked rice hardness than adjusted W:R. The fixed W:R method was also found to have better correlations between measurements by instrument and sensory test in 15 milled rice (Perez, Juliano, Bourne, & Anzaldúa-Morales, 1993). Assuming that different varieties had similar nutritional values and health benefits, the present study provides additional intervention measures before and after the normal harvest of mature grain besides cooking methods. The measure to achieve softer texture is beneficial for the promotion of brown rice consumption as brown rice has superior health benefits to white rice. For rapid and uniform germination, mature paddy is required (Feyem, Bell, Kenyi, Dougoua, & Moche, 2017), and germination will have to undergo a long process of soaking, incubation, and drying, which will require time and energy. In contrast, the early harvest of rice will save time and energy as the grains can be harvested about 20 days earlier and are not required to undergo the germination process. However, further study is needed to examine the cost benefits of early harvest as the paddy yield of the eight varieties studied was about 66% of mature harvest (unpublished data). The results of the present study also reveal genotype by brown rice type interaction; thus, varieties such as Koshihikari, Langi, and Sherpa should be considered suitable for early harvest rice.

The stickiness of cooked EBR, MBR, and GBP was not significantly different. The result for MBR and GBP was similar to that reported by Chao et al. (2021). Kaosa-ard and Songsermpong (2012) also found similar stickiness in MBR and GBP when cooked grains were measured with instrument, while Jiamyangyuen and Ooraikul (2008) reported lower stickiness in GBP with the sensory test. Chao et al. (2021) suggested that the change in the stickiness of GBP due to germination might be too small to be detected in the instrument test. In milled rice of Koshihikari, Arai and Itani (2000) found higher stickiness in early harvest grains by both sensory and instrument tests. Thus, the results of the present study indicate that other factors such as seed coat and bran layer of brown rice may also affect the measurement of stickiness in cooked grains.

Glutinous varieties resulted in higher stickiness than non-glutinous varieties, whereas the final viscosity of glutinous rice was lower than that of non-glutinous varieties. The two rice groups had contrasting amylose content, in which the glutinous varieties had amylose content less than 5% much lower than non-glutinous varieties (above 13%, Table 3). Amylose content mainly determined starch retrogradation including final viscosity and had negative relationship with the stickiness of cooked grain (Chao et al., 2021). Thus, non-glutinous varieties with higher amylose content will result in higher retrogradation that is, higher final viscosity in flour and lower stickiness in cooked grain. In contrast, glutinous varieties with lower amylose content will result in lower final viscosity in flour and higher stickiness in cooked grain.

There was a good correlation between the hardness of cooked grain and final and setback viscosities of flour paste for each brown rice type, and the relationship appeared to be particularly strong for setback. Thus, varieties with high retrogradation and final viscosity tended to result in harder texture in cooked grain. A similar relationship in mature brown rice and germinated brown rice was reported in the previous season (Chao et al., 2021), in which retrogradation in flour paste was indicative of variation in the texture of cooked grain among varieties. In milled rice, breakdown, setback, and final viscosity of flour were reported to be measurements of hardness and palatability of cooked grains (Bhattacharya, 2011; Butardo, Sreenivasulu, & Juliano, 2019; Tao, Yu, & Prakash, 2020). Therefore, the results of the present study extended the relationship for early harvested brown rice. However, the relationship was not unique among different brown rice types.

On average, EBR had much greater final and setback viscosities than GBP by 1,400 and 720 RVU, respectively. However, EBR had a softer texture than GBP. The results indicated that early harvest and germination have different effects on the characteristics of flour paste and cooked whole-grain hardness, in which germination had greater effects on pasting properties, while early harvest on the texture of cooked grains. The reason was not known. Grain structure and composition may explain the differences between pasting characteristics of EBR and GBP (as described above). While filled grain in EBR had characteristics similar to those in MBR, EBR still contained unfilled grains, and the average molecular weight of starch was lower than MBR (Chrastil, 1993). These factors may have caused the softness in the cooked texture of EBR compared to MBR. MBR had slightly larger uncooked grain size than EBR, and it was likely to have had greater cooked grain size. However, both types of grain were compressed to 2 mm distance. This size effect could also be a reason for the softer texture in EBR. Compression of the sample for a fixed ratio of original size should be examined in the future to determine whether it is more suitable to compare the hardness between the two brown rice types. A slight but significantly higher hardness of cooked GBP over that of EBR may be due to unsubstantial hydrolysis of starch during germination as suggested by Han et al. (2016). The germination level of over 70% may confirm this proposition. The results of the present study also provide new options for the selection of desired characteristics in rice flour as ingredients in the food industry and of whole grain for direct consumption.

The relationships observed between amylose content and most traits of pasting and texture properties examined in respective brown rice type may be due in part to two varieties with extremely low and one variety with extremely high amylose content. However, a similar trend was reported by others who have explored a larger number of varieties in milled rice. Thus, amylose content has potential as a predictor of varietal differences in pasting and textural properties but only between varieties with greatly contrasting amylose content, and not within low amylose group. Langi was known to have soft texture in milled rice, but its texture in each brown rice type was higher than known medium texture varieties Reiziq and Sherpa, although they had similar amylose content. EBR and GBP had similar amylose content on average, but they differed greatly in pasting and textural characteristics, suggesting factors other than amylose affecting these characteristics. Thus, amylose would not be suitable as a predictor for differences in brown rice type.

5 CONCLUSION

We report for the first time the comparison of pasting and textural properties between the three brown rice types in one experimental setting. Both early harvest and germination affected the pasting characteristics of flour and texture of the whole grain of mature brown rice, but early harvest had a greater effect on reducing the hardness of cooked whole grain, while germination substantially reduced viscosities of flour paste. The results could provide new options for the selection of desired characteristics in rice flour as ingredients in the food industry and of whole grain for direct consumption. Although early harvest tended to result in softer grain texture compared to germination, its grain yield was about 66% that of mature grain. Thus, a further study including its nutritional effect is needed to evaluate the cost benefit of early harvesting.

ACKNOWLEDGMENTS

Sinh Chao gratefully acknowledges the financial support of the Australian Centre for International Agricultural Research (ACIAR) through the John Allwright Fellowship. Operational support was partially funded through ACIAR project CSE-2012-077 and partially funded by AgriFutures under project number PRJ-011067. Sincere thanks to Dr. Venea Dara Daygon, Ohnmar Myint (the University of Queensland, Australia), and staff at Yanco Agricultural Institute, NSW for technical support. Open access publishing facilitated by The University of Queensland, as part of the Wiley - The University of Queensland agreement via the Council of Australian University Librarians.

AUTHOR CONTRIBUTIONS

Sinh Chao: Conceptualization (lead); data curation (lead); formal analysis (lead); investigation (lead); methodology (lead); visualization (lead); writing – original draft (lead). Jaquie Mitchell: Conceptualization (supporting); formal analysis (supporting); methodology (supporting); validation (supporting); visualization (supporting); writing – review and editing (supporting). Sangeeta Prakash: Methodology (supporting); supervision (supporting); validation (supporting); writing – review and editing (supporting). Bhesh Bhandari: Conceptualization (supporting); formal analysis (supporting); methodology (supporting); supervision (supporting); validation (supporting); writing – review and editing (supporting). Shu Fukai: Conceptualization (supporting); data curation (supporting); formal analysis (supporting); methodology (supporting); supervision (lead); validation (supporting); visualization (supporting); writing – review and editing (supporting).

ETHICAL STATEMENTS

Conflict of Interest: The authors have no conflict of interest.

Ethical Review: This study does not involve any human or animal testing.

Informed Consent: Written informed consent was obtained from all study participants.

Open Research

DATA AVAILABILITY STATEMENT

Research data are not shared.