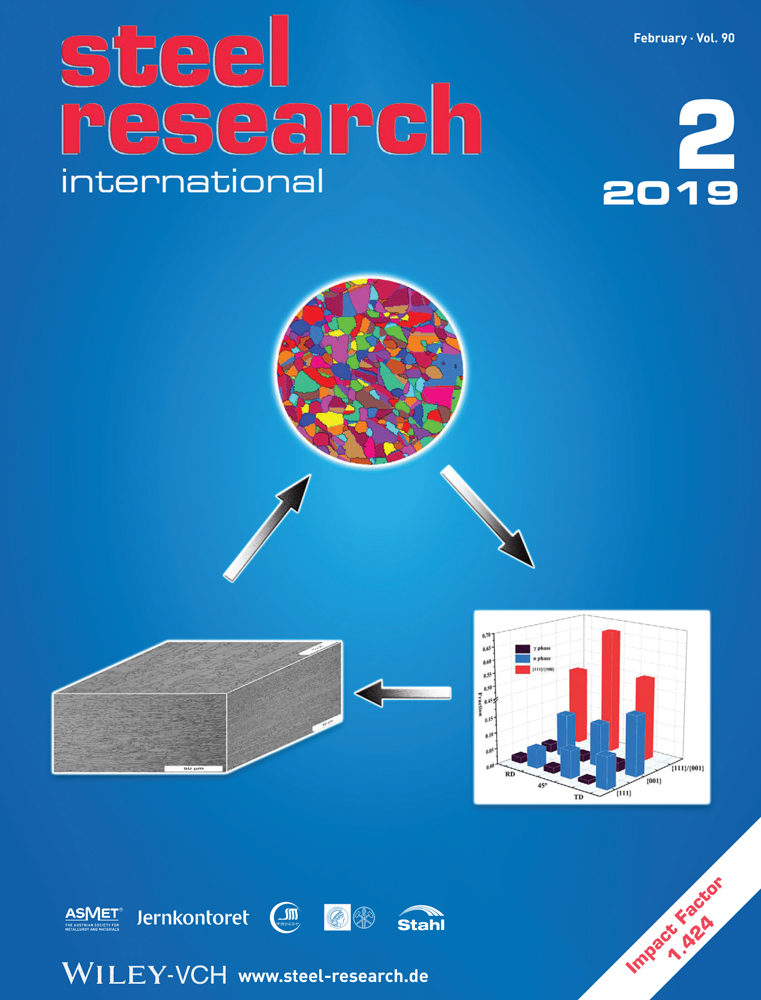

Microstructure and Hardness Evolution during Deformation near Ae3 in a Cr–Mn–Ti Gear Steel

Abstract

Developing appropriate thermomechanical processing routes for decreasing macrohardness of gear steels without heat treatment has a numerous futuristic applications in rolling industry. The effect of different deformation processes applied to Cr–Mn–Ti gear steel on the evolution of microstructure and hardness are studied by using a thermal simulator. It is found that imposing second-pass deformation near Ae3 temperature inhibits occurrence of dynamic recrystallization (DRX), and increases stored deformation energy in austenite, which significantly promotes ferrite and pearlite transformation. As a result, the maximum volume fraction of ferrite and pearlite approaches ≈90%, and the corresponding macrohardness decreases to ≈215 HV. The difference of ferrite transformation between different deformation processes is analyzed using a thermodynamic equation by taking into account the stored deformation energy. The present calculations indicate that interval between Ae3 and deformation temperature can only be avoided at lower deformation temperature of second-pass. This restricts static recovery or recrystallization, and quantities of dislocations that act as nucleation sites are retained before ferrite transformation.

Conflict of Interest

The authors declare no conflict of interest.