Radiative Recombination and Carrier Injection Efficiencies in 265 nm Deep Ultraviolet Light-Emitting Diodes Grown on AlN/Sapphire Templates with Different Defect Densities

Abstract

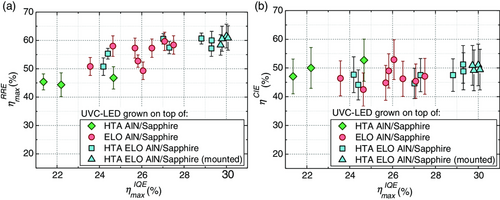

The electro-optical characteristics of deep ultraviolet light-emitting diodes (DUV LEDs) emitting at 265 nm and grown on AlN/sapphire templates with different threading dislocation densities, i.e., high-temperature annealed (HTA) AlN, epitaxially laterally overgrown (ELO) AlN, and HTA-ELO AlN are analyzed. The external quantum efficiency of each individual device is separated into maximum radiative recombination efficiency, carrier injection efficiency, and light extraction efficiency. This is achieved by combining an ABC-model-based fit of the current-dependent external quantum efficiency together with calibrated Monte Carlo ray-tracing simulations. A maximum radiative recombination efficiency between 50% and 60% is estimated for DUV LEDs grown on ELO and HTA-ELO AlN/sapphire, whereas the values for devices grown on HTA AlN/sapphire are around 45%. The extracted radiative recombination efficiency does not scale with the measured threading dislocation density (TDD), even when accounting for the inhomogeneous TDD in the AlN base layers. This discrepancy is attributed to the formation of dislocation half-loops introduced by additional compressive strain caused by the HTA process and may result in the formation of additional nonradiative recombination centers in the AlGaN multi-quantum well region. In addition, the carrier injection efficiency values ranging from 45% to 55% are determined for devices grown on all three templates.

1 Introduction

AlGaN-based deep ultraviolet light-emitting diodes (DUV LEDs) with emission wavelengths shorter than 280 nm have multiple applications ranging from disinfection of surfaces[1-3] and virus inactivation[4-6] to chemical and biochemical sensing.[7, 8] Nevertheless, the external quantum efficiency () of these devices remains far below the values reached by blue LEDs.[9-11] In fact, due to several drawbacks, the , which consists of the radiative recombination efficiency (), the carrier injection efficiency (), and the light extraction efficiency (), decreases drastically at shorter wavelengths.[9-13] The is the most limiting factor to the efficiency of DUV LEDs.[10, 14] The outcoupling of photons emitted by radiatively recombined charge carriers becomes increasingly difficult with increasing Al mole fraction in the multiple quantum well (MQW) regions due to transverse-magnetic polarized emission emerging as dominant over the transverse-electric polarized emission.[15-17] Since it is very difficult to overcome this fundamental material property, present research mainly focuses on increasing and . However, the determination of absolute values for both these quantities, especially separately and under electrical injection, is not straightforward. Therefore, some of the most exigent questions regarding the performance of DUV LEDs are still under debate, e.g., how strongly and to which extent the individual crystal defects, i.e., threading dislocations (TD) and point defects affect the .[18, 19] Additionally, despite the consensus about the decrease in with shorter emission wavelengths,[12] reports on the quantitative values for DUV LEDs are rare. In addition to the simulation results, most publications discussing the of DUV LEDs limit the analysis to a comparison of device performance with different carrier confinement and electron blocking concepts.[20-22] Thus, reliable values for and are required in order to identify the key aspects with the highest potential for further optimization of DUV LEDs. In this article, DUV LEDs grown on three types of templates with different threading dislocation densities (TDDs) are analyzed and compared. The and the were extracted from Monte Carlo ray-tracing simulations and from the generalized ABC model fit of the current dependent , respectively. This way, it was then possible to derive the carrier injection efficiency from the measured external quantum efficiency.

2 Experimental Section

AlGaN-based DUV LEDs with an emission wavelength of 265 nm were grown side by side in one growth run by metal–organic vapor phase epitaxy (MOVPE) on three different templates: high-temperature annealed (HTA) AlN/sapphire, epitaxially laterally overgrown (ELO) AlN/sapphire, and HTA-ELO AlN/sapphire, as shown in Figure 1. These templates were overgrown with an AlN buffer and a Si-doped n-AlGaN current spreading layer followed by a threefold Al0.62Ga0.38N/Al0.48Ga0.52N MQW, an electron blocking layer (EBL) consisting of a 10 nm thick undoped Al0.85Ga0.15N and a 25 nm thick Al0.75Ga0.25N:Mg layer, capped by a 200 nm thick GaN:Mg contact layer. To analyze the defect densities in the AlGaN MQW regions, samples with identical heterostructure to the DUV LEDs without p-side and with a thicker last AlGaN barrier (40 nm) were grown on the three different templates. Further details on the heterostructure, growth conditions, and template fabrication process are reported in reference.[23] After thermal activation of Mg acceptors, the DUV LEDs were fabricated simultaneously by standard micro-fabrication techniques using Pd/Au p-contacts and V/Al/Ni/Au n-contacts.[24] All relevant device characteristics are summarized in Table 1.

| AlN/sapphire template | Specification | DSD × 109 [cm−2] | [%] | [%] | [%] | [%] | [%] |

|---|---|---|---|---|---|---|---|

| ELO | on-wafer | 1.6 ± 0.2 | 1.7 | 6.8 ± 0.7 | 25 | 57 | 45 |

| HTA | on-wafer | 1.1 ± 0.05 | 1.4 | 6.1 ± 0.6 | 23 | 45 | 51 |

| HTA-ELO | on-wafer | 0.95 ± 0.1 | 1.8 | 6.7 ± 0.7 | 27 | 58 | 46 |

| HTA-ELO | mounted | 0.95 ± 0.1 | 2.6 | 9.2 ± 0.9 | 30 | 60 | 52 |

| HTA-ELO | mounted and encapsulated | 0.95 ± 0.1 | 4.7 | 12.8 ± 1.3 | 35 | 60 | 58 |

The for the DUV LEDs was calculated by Monte Carlo ray-tracing simulations taking into account the degree of polarization of the MQW emission as well as far-field measurements.[25] The light extraction efficiency of the DUV LEDs grown on ELO and HTA-ELO template was found to be similar with 6.8% ± 0.7% and 6.7% ± 0.7%, respectively, whereas the value for devices grown on the HTA template is slightly lower with 6.1% ± 0.6%. This is attributed to light scattering at the air voids in the ELO structure and thus a change in the angular distribution of the light at the sapphire–air interface.

The TDD within the AlN base layers and the MQW regions was estimated by high-resolution X-ray diffraction (HR-XRD), cross-sectional transmission electron microscopy (TEM) diffraction, and plane-view panchromatic cathodoluminescence (CL) on the AlGaN MQW samples. All three methods showed comparable results, i.e., the dark spot density (DSD) from the CL measurements, which is assumed to be identical to the TDD,[19] has the lowest value for the MQW structure grown on the HTA-ELO AlN/sapphire (0.95 ± 0.1 × 109 cm−2), followed by the sample grown on HTA AlN/sapphire (1.1 ± 0.05 × 109 cm−2) and by ELO AlN/sapphire (1.6 ± 0.2 × 109 cm−2).[23]

The electro-optical on-wafer measurements of the DUV LEDs were carried out in continuous wave mode up to current densities j < 1 A cm−2 using a picoammeter (Keithley 6487). Measurements for higher current densities were performed in pulsed mode (Avtech, AV-1010-B) with a pulse width (tpulse) of 5 μs and a duty cycle of 1% using a current probe and a digitizing oscilloscope (Tektronix, TDS 2024B). This combined procedure enables us to resolve low current densities and to reduce the Joule heating at higher j. The negligible influence of the pn junction heating during the pulsed operation was verified by applying lower duty cycles and shorter pulses, resulting in identical DUV LED characteristics.

3 Data Processing

By plotting / versus and fitting the data points by a linear function, Q and therefore can be directly evaluated from the slope of the fitting line. However, the described relations are only valid if and are current (I) independent. It is fairly safe to assume that the light extraction efficiency is independent of the drive current, since its value mostly depends on the refractive index values of the heterostructure layers.[28] To satisfy the constant condition, the linear fitting of data points in the / versus plots was carried out only for values around . This narrow fitting range corresponds to current densities between 0.6 and 60 A cm−2 and ensures only minor changes in . Any deviations from or being constant or from the ABC model itself lead to a nonlinear behavior in the / versus plots and are considered in the evaluation by an increased fitting error.[28] Finally, as a result of the simulated and the extracted values, is calculated by using Equation (1).

4 Results and Discussion

The measured electro-optical characteristics of typical unmounted DUV LEDs grown on different templates are shown in Figure 2. The highest optical output power of 12.3 mW at 100 A cm−2 is achieved for devices grown on HTA-ELO AlN/sapphire, having a maximum external quantum efficiency of ≈1.9%. DUV LEDs grown on ELO AlN/sapphire exhibit a slightly lower performance: = 11.6 mW at 100 A cm−2 and = 1.8%. The lowest optical output power of = 9.2 mW at 100 A cm−2 and = 1.4% is reached by devices grown on HTA AlN/sapphire templates. Both and do not follow the TDD trend for the individual AlN base layers and the AlGaN MQW region, as shown in Table 1. This is unexpected, as one would anticipate the TDD to have a major impact on the and thus on the LED performance due to changes in non-radiative SRH recombination rates.[29] To eliminate the influence of the different light extraction efficiencies, which might explain the aforementioned disagreement, the peak internal quantum efficiencies are determined by dividing the measured by the simulated . In fact, among all characterized devices the highest around 28.5% is reached by LEDs grown on the HTA-ELO AlN/sapphire, having the lowest TDD. However, the average of LEDs grown on the HTA-ELO AlN/sapphire (27%) is similar to the one grown on the ELO template (25%) despite the significant TDD difference of more than 70%. Additionally, the of the devices grown on ELO AlN/sapphire is higher compared to that of LEDs grown on the HTA AlN/sapphire (23%) in spite of the higher TDD.

4.1 Determination of the Radiative Recombination Efficiency

To understand how the TDD influences solely the radiative recombination efficiency, without the influence of the carrier injection efficiency, the is extracted from the electro-optical device characteristics by applying the method described in Section 3. An example of an / versus plot is shown in Figure 3a for an LED grown on HTA-ELO AlN/sapphire. As it is indicated by the thick red line, the experimental data points are in good agreement with a linear fit function allowing for a reliable estimation of 62 ± 3% in this case. Furthermore, Figure 3b shows the excellent fit of the measured dependence on the normalized optical output power from Equation (2) obtained from the LED reported in Figure 3a. The remarkable agreement over more than six orders of magnitude justifies the previous assumption of being only weakly dependent on j within the fitting range. In addition, the robustness of the method was validated by analyzing DUV LEDs grown on HTA-ELO AlN/sapphire at different stages of the fabrication process. For this purpose, the LEDs on the wafer were diced and flip-chip mounted on AlN ceramic packages, as shown in Figure 3d. The best performing device ( = 35%) was then encapsulated by a UV-transparent silicone resin “Deep UV200,”[30] as shown inFigure 3e. The MQW region area (A) of the mounted devices (A = 5.7 × 10−7 m2) differs from that of DUV LEDs measured on-wafer (A = 1.5 × 10−7 m2). Also the light extraction efficiency of mounted DUV LEDs ( = 9.2 ± 0.9%) is higher compared to unmounted devices ( = 6.7 ± 0.7%) due to packaging and increases further for the encapsulated LED ( = 12.8 ± 1.3%). An emission power of 103 mW at 90 A cm−2 was reached by the encapsulated LED having a maximum external quantum efficiency of 4.7%. As it is shown in Figure 3b, regardless of the different geometries and light extraction efficiencies, the extracted values of the representative mounted LED with ( = 58 ± 4%) and without encapsulation ( = 60 ± 3%) is almost equal to the one from the on-wafer measurements. Furthermore, considering the simulated and the extracted values, the was calculated from the measured by using Equation (1). Despite different values, the carrier injection efficiency for mounted and unmounted devices is in the same range, between 45% and 55%. Only the . of the encapsulated LED is with 58 ± 8% higher compared to other devices which is the reason for its outstanding performance. In addition, the AlGaN MQW structure grown on an ELO AlN/sapphire was analyzed by selective excitation time-resolved photoluminescence (TRPL).[31] It was found that at room temperature (RT) the reaches values of 60% ± 10% and, as it will be shown next, is in line with the values extracted in this work. This agreement underlines the reliability of the Titkov method for the given case.

Next, being confident about reproducibility and the absolute values of the determined results, the influence of the template on the radiative recombination efficiency can be discussed. The extracted values for all characterized devices are summarized in Figure 4a. As is the case for external and internal quantum efficiencies, the of DUV LEDs grown on the ELO and the HTA-ELO AlN/sapphire are in the same range and vary between 50% and 60%. The values for DUV LEDs grown on the HTA AlN/sapphire are lower and scatter around 45%. This suggests that the HTA step introduces additional nonradiative recombination centers besides the TDs and therefore reduces further the efficiency of devices grown on HTA and HTA-ELO AlN/sapphire.

4.2 Influence of the HTA Process on ηRRE

There are two critical impacts of the HTA process which can impede the radiative recombination efficiency: the incorporation of impurities and the increased compressive strain (ε) of AlN. The incorporation of silicon, carbon, and oxygen into HTA-AlN is a well-known side effect of the HTA step.[32-35] Indeed, according to secondary ion mass spectrometry (SIMS) analysis, O, C, and Si levels in the HTA-AlN are high and reach concentrations of 5 × 1020, 4 × 1018, and 9 × 1016 cm−3, respectively (shown in Supporting Information). However, there is no significant diffusion of these impurities from HTA-AlN into the AlN base layers of the subsequently grown LED heterostructure. For the investigated devices grown on the HTA AlN/sapphire template, the MQW region is separated by almost 2 μm from the HTA-AlN and in the case of DUV LEDs grown on the HTA-ELO template by more than 5 μm. Therefore, it is unlikely that some of the incorporated impurities can reach the MQW region and act there as nonradiative recombination centers. The second point, the introduction of compressive strain to HTA-AlN, has its origin in the relaxation of AlN during high-temperature annealing. Upon cooling to RT, the different thermal expansion coefficients of AlN and sapphire result in an increase of ε.[36-38] The compressive strain implies a decrease of the a-lattice constant of AlN and thus can be quantified by HR-XRD measurements and a comparison with the a-lattice constant of bulk-AlN (a = 0.3111 nm).[39]

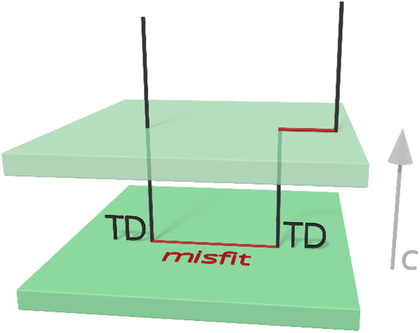

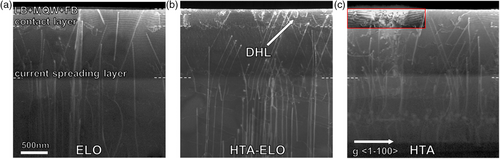

For the AlN layer of the ELO template, an a-lattice constant of a = 0.31105 nm is found, leading to ε = −0.02%. The compressive strain increases further to ε = −0.12% (a = 0.31072 nm) and to ε = −0.4% (a = 0.30985 nm) for AlN layer of the HTA-ELO and HTA templates, respectively. As the DUV LED heterostructure is grown fully strained to AlN, the additional compressive strain affects all layers grown on top of it. Especially in case of layers with low TDD, already minor increase of the compressive strain can lead to the formation of new relaxation paths.[36, 40] As a consequence, misfit dislocations can be introduced in the AlN and AlGaN layers by the formation of dislocation half-loops (DHLs).[36, 40, 41] The DHLs have an in-plane misfit component with one TD aligned in the growth direction on each side, as shown in Figure 5. By interacting with each other, the threading components of the individual half-loops can annihilate and form DHLs of an irregular shape.[40] As it is schematically shown in Figure 6, the DHLs can propagate over tens and hundreds of nanometers within the MQW region due to their in-plane misfit component. For this reason, the non-radiative recombination volume of a DHL is much larger compared to that of a TD propagating in the growth direction. Therefore, the appearance of DHLs inside the MQW region is much more detrimental to the radiative recombination efficiency compared to TDs. Figure 7 shows TEM dark-field micrographs, obtained with the <1–100>-diffraction vector g of the earlier-described AlGaN MQW samples. The formation of DHLs with an irregular shape can be observed for all samples, especially in the contact and in the current spreading layers. However, only a few DHLs penetrate the AlGaN MQW region in the sample grown on ELO AlN/sapphire. In contrast, the MQW region of the sample grown on the HTA-ELO template demonstrates a significant number of DHLs, while defect bunching for the sample grown on HTA AlN/sapphire is observed. Therefore, it can be concluded that the HTA process reduces the TDD but simultaneously introduces compressive strain to the DUV LED heterostructure, leading to the formation of DHLs which act as additional nonradiative recombination centers. One way to release the compressive strain is the Si-doping of the AlN buffer layers were grown on top of HTA-AlN.[40, 42] By combining the HTA-ELO approach with the Si-doping of the AlN buffer, the radiative recombination efficiency of DUV LEDs grown on AlN/sapphire templates might be increased even further. In addition, it should be pointed out that the DHLs are not visible in typical CL images.[23] The reason might be that the charge carriers are not only excited within the QWs but also within the material above and below them leading to a strong contrast for vertically propagating TDs but a low contrast for DHLs. However, this subject requires further investigation.

4.3 Determination of the Carrier Injection Efficiency

Finally, as a result of the extracted and the values, the is calculated by using Equation 1. As can be seen from Figure 4b, the for DUV LEDs grown on all three templates is mainly ranging between 45% and 55%. Similar values for all devices, regardless of the template, are expected since the heterostructures of all DUV LEDs are identical. Hao et al.[43] and Ishii et al.[44] investigated the under electrical injection for DUV LEDs emitting at 267 and 265 nm, respectively. Both reported values around 50% at RT using polynomial fitting of a modified rate equation to electroluminescence data. In addition, it should be highlighted that despite the optimization of the EBL heterostructure, the extracted is far from unity. In fact, of almost all devices grown on HTA-ELO and ELO templates is in the same range compared to . Hence, for the DUV LEDs, roughly half of the injected charge carriers recombine outside of the AlGaN MQW region, i.e., by electron leakage over the EBL toward the p-side and the subsequent recombination with holes in Mg-doped layers and at the p-contact. Therefore, optimizing the , e.g., by implementing concepts like multi-quantum barriers[45, 46] and polarization-induced hole-doping[47] might be the most promising and feasible way for further development of high-power DUV LEDs grown on ELO and HTA-ELO templates.

5 Conclusion

In this work, values of ≈45% are determined for DUV LEDs grown on the HTA AlN/sapphire template. The of devices grown on the ELO and HTA-ELO AlN/sapphire templates are higher and range between 50% and 60%. In addition, the of the sample grown on an ELO template was independently confirmed by selective excitation TRPL. Contrary to expectations, the extracted values, as well as the emission power, do not follow the TDD trend. This discrepancy was attributed to the introduction of compressive strain by the HTA process leading to the formation of DHLs, which act beside TDs as nonradiative recombination centers within the AlGaN MQW region. One approach to compensate for the compressive strain is the overgrowth of HTA-AlN with Si-doped AlN, which might promote of devices grown on HTA and HTA-ELO AlN/sapphire even further. In addition, the extracted was in the range between 45% and 55% for DUV LEDs grown on all three templates. These results show that for DUV LEDs grown on ELO and HTA-ELO templates, the carrier injection efficiency is far from unity and limits the external quantum efficiency to a similar extent as the radiative recombination efficiency.

Acknowledgements

This work was partially supported by the German Federal Ministry of Education and Research (BMBF) within the Advanced UV for Life project consortium. Furthermore, the authors thank Carsten Netzel (Ferdinand-Braun-Institut, Berlin, Germany) for valuable discussions regarding the CL measurements.

Open Access funding enabled and organized by Projekt DEAL.

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.