3D printing materials for generators of active particles based on electrical discharges

Abstract

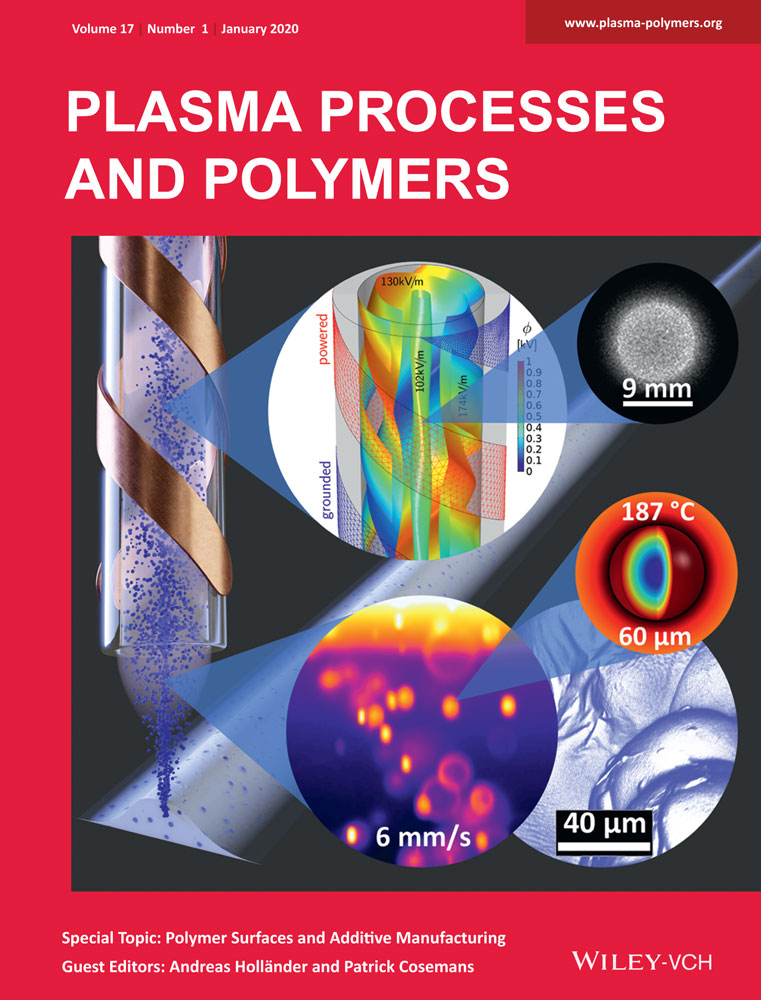

In this study, we focus our attention on the impact of ozone (O3) and ultraviolet radiation (UV) on materials usable for three-dimensional (3D) printing. Specifically, we have studied the potential degradative effect on the most commonly used filaments, such as polylactic acid (PLA) and acrylonitrile–butadiene–styrene (ABS). The effect has been examined on objects printed on a 3D printer and on the materials of discharge chambers of O3 generators from which they were printed. For the purpose of adequate assessment of the actual impact of O3 and UV, samples were monitored for a period of 18-hr of exposure. The methods of Raman spectroscopy, optical and scanning electron microscopy and Fourier-transform infrared spectroscopy (FTIR) have been employed for an objective evaluation of potential modifications. A generator equipped with a chamber printed from a new PLA filament and an active electrode system in the form of a stripes electrode, or more precisely, in the second case, a honeycomb-active electrode, both cut out of a thin copper foil, was used for the generation of O3 and UV radiation. The tested materials showed substantial resistance to O3 exposure under the test conditions. The result of measurements suggested that these materials could be used for chambers for the O3 as well as for active particle generation.