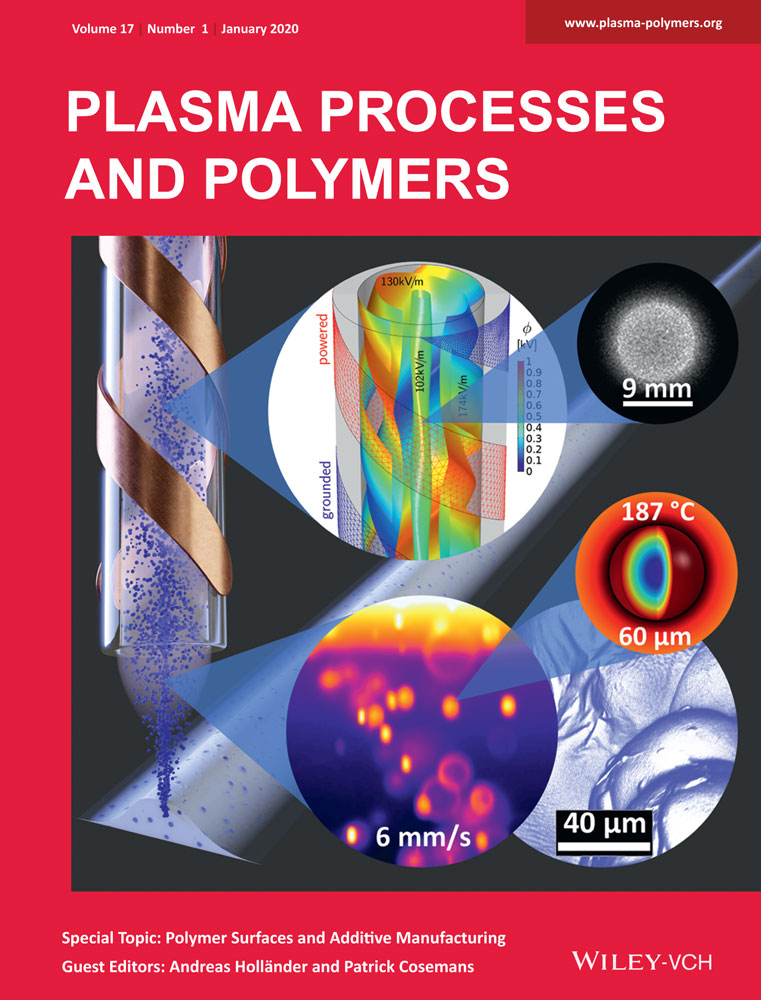

Enhancing the mechanical performance of 3D-printed basalt fiber-reinforced composites using in-line atmospheric plasma pretreatments

Abstract

The objective of this study is to investigate the use of an air atmospheric plasma jet for the treatment of sized basalt fibers, used in the fabrication of continuous fiber-reinforced polypropylene filaments. The plasma treatments were carried out both at a laboratory scale, as well as in-line during the production of fiber-reinforced filaments. The latter was carried out at a fiber processing speeds of approximately 15 m/s, just immediately before the polymer coating of the fiber by extrusion. After the air plasma treatment, the water contact angle of the sized basalt fiber decreased from 86° to <10°. X-ray photoelectron spectroscopy analysis demonstrated that the treatment yielded enhanced levels of oxygen functionality on the fiber surface. After coating with polypropylene, it was observed that there was consistently more homogeneous polymer layer deposited onto the plasma-activated fiber, compared with that on the unactivated control fiber. The resulting polymer filament with embedded basalt fiber was used to fabricate mechanical test specimens by three-dimensional printing (fused filament fabrication method). Both three-point bending tests and short beam strength tests were performed. A comparison study was carried out between test specimens fabricated using sized basalt fiber, with and without the plasma pretreatment. The flexural modulus and maximum shear stress were found to increase by 12% and 13%, respectively, for composite's fabricated using the plasma pretreated basalt fibers. This increased mechanical strength is likely to be due to an increase in interfacial bond strength between the polymer and fiber, with an associated reduction in the level of air incorporation around the basalt filaments as demonstrated using computed tomography analysis.