Thiol-X Chemistry: A Skeleton Key Unlocking Advanced Polymers in Additive Manufacturing

Abstract

Using additive manufacturing (AM) technologies for the fabrication of advanced polymeric objects is a logical progression to realize their potential within engineering applications that demand complex geometries. Thiol-X chemistry has presented itself as a diverse and invaluable toolkit to accomplish such, satisfying both the processing requirements and properties desired to fabricate a diverse range of advanced polymeric objects using a variety of AM technologies. The “click” nature of many thiol-X reactions, mechanisms of polymerization, functional group tolerance and orthogonality, and diverse and desirable properties achievable with thiol-X chemistry presents a synergistic opportunity that few other chemistries can as broadly facilitate. As a result, the use of thiol-X chemistry within AM has gained rapid traction in recent years and it is now the case that both thiol-X chemistry and additive manufacturing technologies are being viewed as two sides of the same coin, whereby the scope and limitations of the whole system are appreciated. This review highlights the advancements, status, scope, and opportunities of using thiol-X chemistry in AM to achieve a diverse range of advanced polymers by critically examining the structure-property-processing-performance relationships between different thiol-X chemistries and various AM technologies.

1 Introduction

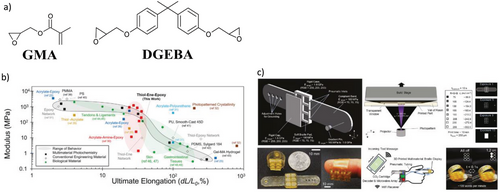

The ongoing development of advanced polymeric materials has facilitated the progress of technologies within a myriad of engineering fields.[1-3] However, their successful implementation within engineering design often demands complex fabrication requirements. One of the challenges faced by emerging advanced polymers is that they are often unsuitable for drop-in use with well-established manufacturing technologies (e.g., injection molding, extrusion, thermoforming) or pose challenges for effective subtractive manufacturing.[4] Furthermore, these traditional fabrication technologies may also be limited in their achievable geometries and physical scale of fabrication. As a result, manufacturing complex geometries is either not possible or time-consuming and expensive, thus limiting their ability to adequately satisfy engineering design constraints. Additionally, conceptual phenomena such as multi-materials, those containing spatially varied polymer properties, are generally unfeasible using many of these traditional fabrication technologies.[5-7] It is thus the logical progression that additive manufacturing (AM) could provide an accessible and effective platform to facilitate complex object fabrication for these materials.[8] Several AM technologies are commonly used for polymeric materials, which can be broadly categorized into either a) melt-processing of thermoplastic polymers (e.g., fused filament fabrication (FFF) and selective laser melting (SLM)) or b) in situ polymerization of monomers such as stereolithography (SLA), digital light processing (DLP), masked stereolithography (mSLA), digital light synthesis (DLS, commercially known as continuous liquid interface polymerization (CLIP)), volumetric polymerization (VP), two-photon polymerization (TPP), direct laser write (DLW) printing, and UV assisted direct ink write (DIW) printing.[9, 10] The use of AM presents appealing opportunities for rapid fabrication of objects benefiting complex geometries, high-resolution fidelities down to micro- and nanoscale, and economic accessibility.[11, 12] However, in order to exploit these AM technologies, the chemistry underpinning the polymers needs to both satisfy the processing constraints imposed by AM, while still successfully imparting desirable properties within the polymer.[11] Within this context, the fact that AM requires spatially selective polymerization or material deposition for fabrication imposes appreciable constraints on the type of polymer that can be employed. It is thus the case that the conceptual marrying of previously siloed development between emerging polymers and AM technologies needs to be sought to fully exploit the potential of using advanced polymers in AM.[13]

In light of this, thiol-X chemistry has proved itself as a valuable toolkit of chemical reactions to satisfy these constraints. Thiol-X chemistry comprises of a family of chemical reactions between thiols and several other functional groups.[14] Many thiol-X reactions have been lauded as “click” type reactions after the landmark description by Sharpless et al.,[15] characterized by mild reaction conditions, high conversions, rapid kinetics, few byproducts, stereoselectivity, and solvent-free conditions. Furthermore, many thiol-X reactions display good functional group tolerance and can facilitate orthogonal reactions, thus enhancing its potential within molecular architectures containing multiple distinct chemistries and the development of multi-material polymers. Due to these oft-favorable properties of thiol-X reactions, their development has flourished, whereby the seminal reviews by Bowman, Hoyle, and co-workers[16-18] on thiol-ene polymers firmly embedded thiol-X chemistry within polymer science. While substantial efforts to incorporate thiol-X reactions as polymerization strategies have already been observed, it is only more recently that their potential within AM has begun being realized and gained traction. Nevertheless, within a relatively short time, a diverse assortment of thiol-X chemical reactions has already shown it as an effective platform for developing a broad array of different advanced polymers with potential in an almost endless list of important contemporary engineering applications. Furthermore, their suitability within several AM technologies makes these reactions synergistically favorable to facilitate both desirable properties and effective AM processing. Practically, many thiol-X reactions also benefit from “drop-in” capabilities within AM, mitigating bespoke AM technology development that inherently limits widespread adoption. Indeed, the vast majority of literature reviewed used unmodified commercially available 3D printers over a range of technologies, including most VAT photopolymerization AM, binder jet printing, DIW printing, and FFF printing.

The goal of this review is to highlight the instrumental role that thiol-X chemistry has contributed to the development of fabricating advanced polymers using AM, critically examine the complex structure-property-processing-performance relationships of thiol-X chemistry within the context of various AM technologies, and explore both the scope and future opportunities thiol-X chemistry may present within AM.

2 Overview of Thiol-X Chemistry

2.1 Properties and Chemistry of the Thiol Group

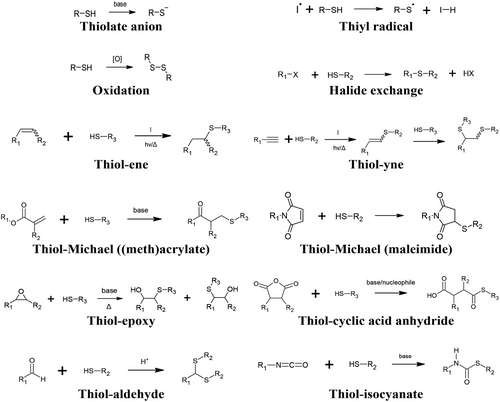

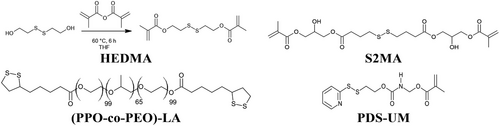

The thiol functional group is a sulfur analog of the hydroxyl group, although the S-H bond dissociation energy is relatively lower (typically ≈330–370 kJ mol−1), and thus the thiol group has a comparatively longer bond length.[19, 20] The relatively weak S-H bond makes the hydrogen on thiols susceptible to abstraction to form a thiyl radical, and thiols can also be deprotonated to form the thiolate conjugate base. Comparatively, the thiol group is more acidic than its hydroxyl analog, and the thiolate acts as a stronger nucleophile than alkoxides; conversely, the thiolate is also generally a weaker base than alkoxides.[21] Thiols and several thiol-X reaction products are amenable to further oxidation reactions under basic conditions, while thiols can also undergo an SN2 reaction with alkyl halides (Figure 1).[22] Remarkably, the thiol group and thioethers can also undergo conjugation with elemental gold.[23]

Thiols thus serve as a versatile functional group that can react with several other functional groups to form products useful within the context of polymer science (Figure 1). These include the reaction of thiols with carbon-carbon double bonds (ene) and triple bonds (yne), (meth)acrylates and maleimides, epoxies, cyclic acid anhydrides, aldehydes, and isocyanates. Further details of each reaction, its product, and properties are described in more detail within each subsection of the review. Most of the outlined chemical reactions are long known from classical organic chemistry and have merely been adopted into the field of polymer science in more recent years. In fact, thiol-X chemistry has been exploited by Nature for millions of years in macromolecules such as polypeptides,[24] with synthetic descriptions from 1905,[25] and yet the development of thiol-X chemistry has continued to generate attention in contemporary literature.[26-33]

In most instances, multifunctional compounds enable thiol-X chemistry to be exploited as appropriate monomers. However, the requirements for different thiol-X chemistries to form polymers vary depending on the specific AM technology. For melt processing AM (e.g., FFF), polymerization of thermoplastic polymers is performed prior to AM, making the polymerization mechanism and kinetics less important, although sufficient molecular weights need to be achieved. On the other hand, for vat photopolymerization AM and DIW printing, in situ polymerization is usually necessary for these technologies. In this case, the polymerization initiation mechanism and reaction kinetics become more important considerations. Within this context, the reaction kinetics of various thiol-X reactions has been well established, and generally present several opportunities for relatively rapid polymerizations.[34] Indeed, some thiol-X reactions are autocatalytic at room temperature and pressure, and thus while they are excellent as general “click” type reactions, they are not always immediately suitable as polymerization mechanisms in AM where spatiotemporally controlled polymerization by external stimulus is imperative. Similarly, in situ polymerization AM is also difficult to achieve when catalysis of the reaction cannot be spatiotemporally controlled. Nevertheless, in several cases, these reactions may be used in monomer/oligomer synthesis, and thus still hold relevance within the context of AM.[35] Furthermore, strategic photoactivation of catalysts for these reactions presents an avenue to access these reactions within AM. Alternatively, in situ mixing of monomers during AM is a logically viable strategy, although this approach comes with several processing considerations and typically entails bespoke AM technologies. Nevertheless, using different thiol-X chemistries either within the monomer structure or as a polymerization strategy, alongside the incorporation of other structural attributes and functional groups within the monomer, can be used to control and tailor desirable engineering properties. However, other factors such as system viscosity, polymerization stimulus, crystallinity effects, interlayer adhesion, polymerization shrinkage, and print resolution fidelity can impose additional constraints on the designing of polymers that can be successfully processed with AM.

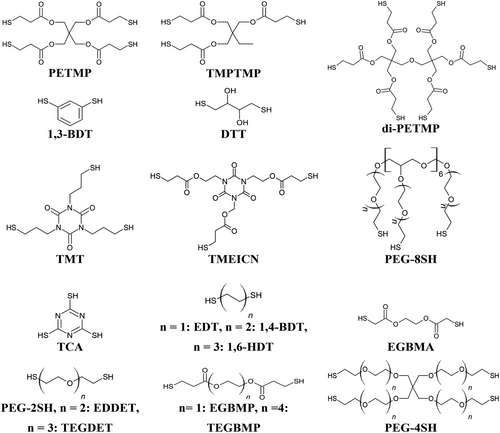

2.2 Thiol Monomers

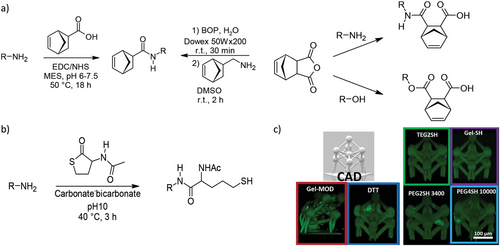

Several thiol monomers of differing molecular structure and functionality are commercially available (Figure 2) and regularly employed in AM. Many of these monomers are ethers and esters of 2-mercaptoethanol and 3-mercaptopropionate, respectively, which can make them hydrolytically labile.[36] On the other hand, the use of ester-free thiols has been demonstrated as an appropriate alternative for applications where hydrolytic stability is important.[36] For most thiol-X reactions, the thiol monomer is required to have a functionality of two or more in order to participate in polymerization, owing to a step-growth mechanism of polymerization. Alternatively, monofunctional thiols may be used to form pendant groups on the monomer/oligomer/polymer to impart desirable properties or functionality, although an alternative mechanism of polymerization is then required.[37]

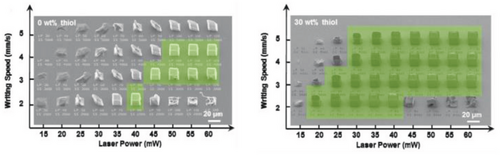

While a few naturally occurring thiol-bearing compounds can serve as suitable monomers (e.g., dithiothreitol, DTT, Figure 2), several synthetic strategies to impart thiol functional groups are also well known. These include the use of isothiouronium salts, alkyl halides, and alkali metal hydrogen sulfides, and the catalyzed reaction of hydrogen sulfide with a variety of functional groups.[38] Alternatively, the reaction of hydrogen sulfide with α,β-unsaturated carbonyls or alcohols is another efficient pathway for thiol preparation.[39, 40] On a laboratory scale, a number of other synthesis pathways present viable strategies to impart thiol functionality. For example, the thiol-ene coupling of thioacetone onto unsaturated compounds, followed by base hydrolysis of the thioacetate to yield free thiols has been established as a convenient synthetic pathway.[41] More recently, a similar synthetic strategy using thiourea has been described for the α,β-unsaturated carbonyl compound crotonic acid, yielding secondary thiols that could be coupled to polyols via simple Fisher esterification.[42] Aside from these examples, several other synthetic avenues have also been reported.[43-48] Although primary thiols are most commonly employed as monomers, secondary thiols are also known to serve as effective functional groups. A systematic investigation into the effect of primary, secondary, and tertiary thiols for DLP 3D printing was performed to ascertain the effect of thiol substitution on the reaction kinetics and resulting polymer properties. Interestingly, negligible differences in kinetics between primary and secondary thiols were observed, and secondary thiols provided improved mechanical properties and lower polymerization shrinkage in DLP-printed polymers.[49] On the other hand, it has been established that tertiary substituted thiols display polymerization rates almost 10-fold lower than primary thiols, yet still reach quantitative conversions similar to that of primary and secondary substituted thiols. Furthermore, this work established that the shelf-life of secondary thiol resins was around 100 times longer than for primary thiols.[50]

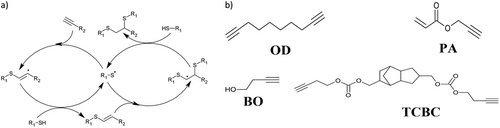

3 Thiol-Ene

3.1 Polymerization and Properties

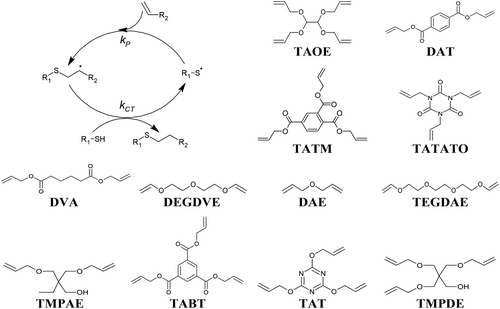

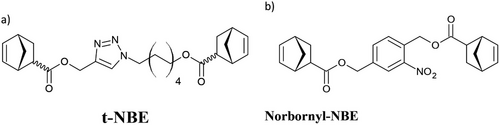

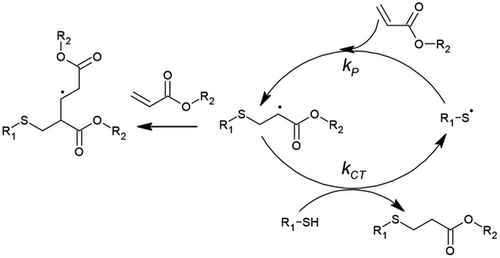

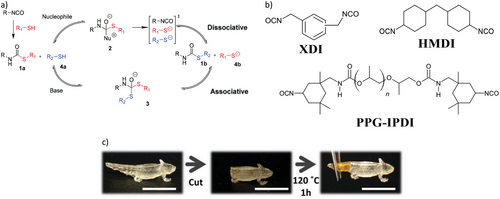

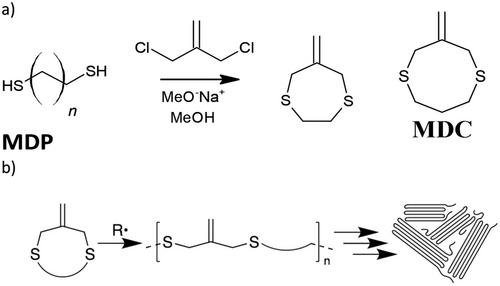

The thiol-ene reaction is well established, having first been described by Posner[25] in 1905 and further identified for photopolymerization by Braun and Murjahn[51] in 1926. The reaction between thiol and alkene (i.e., ene) functional groups results in an alkyl sulfide bond (also referred to as thioether) via light, radical generator, or heat-induced thiyl radical generation. Once the hydrogen has been abstracted from the thiol to form the thiyl radical, propagation occurs through anti-Markovnikov addition with an alkene to generate a carbon-centered radical. In turn, the carbon-centered radical can abstract a hydrogen from another thiol in a chain-transfer step, thus allowing multiple propagation steps for step-growth polymerization (Figure 3).[16] The thiol-ene reaction is thermodynamically favorable, whereby the enthalpy of reaction is ≈3× greater than that of typical free radical acrylate polymerization.[52] However, one of the challenges of the thiol-ene polymerization strategy is that, unlike free radical polymerization that generates a growing chain, the reaction generates a single covalent bond followed by chain transfer, thus lowering the maximum theoretical crosslinking density. Generally, electron-rich alkenes proceed almost exclusively via thiol-ene step-growth with virtually no homopolymerization about the carbon-centered radical.[53, 54] Kinetically, it is thus found that electron-rich alkenes are consumed faster than electron-poor enes.[55, 56] Comparatively, the chain transfer constant (Ctr, calculated as a ratio of thiyl radical propagation to chain transfer kinetic parameters) for norbornenes is 1, vinyl ethers 0.83, while methacrylates and acrylates are as low as 0.26 and 0.08, respectively.[57, 58] Herein, thiol-ene chemistry for polymerization refers to the case whereby the step-growth reaction predominates, and the competing reactivity ratio for chain-growth homopolymerization is negligible. Within this context, where the purely step-growth thiol-ene polymerization is expected, the thiol-ene reaction is characterized by longer induction periods before gel formation and vitrification owing to slower molecular weight increase of the step-growth mechanism, and thus facilitates an overall high degree of polymerization and ideal network structure formation, with reduced polymer shrinkage stresses.[59] While the thiol-ene reaction usually results in relatively better ideal network formation compared to typical free radical polymerization mechanisms, the considerations for the formation of non-ideal networks have also been investigated, establishing that thiol purity and intramolecular cyclization can contribute towards non-ideal networks.[60] An additional benefit of the thiol-ene reaction is that, unlike typical free radical polymerization reactions, it is relatively insensitive to oxygen retardation.[61]

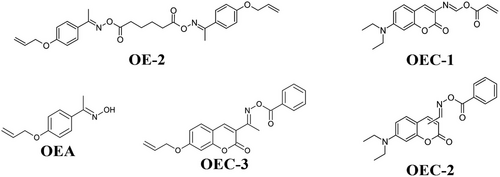

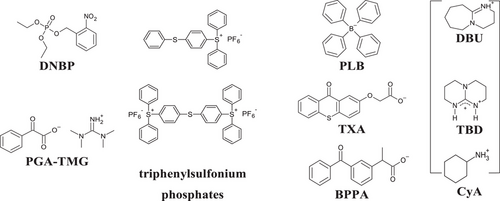

While traditional photoinitiators for the thiol-ene reaction have already been firmly established as a viable route for thiyl radical generation and resultant step-growth polymerization, more recently the use of new catalysts is being explored. A simple example is the use of visible light photoinitiators, offering opportunities for low energy irradiance and for orthogonal wavelength-specific polymerizations.[62-64] Beyond this, more advanced examples of photoinitiators present exciting opportunities for nuanced polymer architecture control.[65-68]

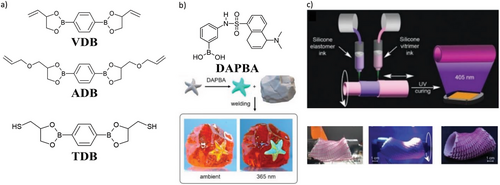

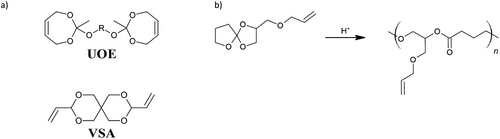

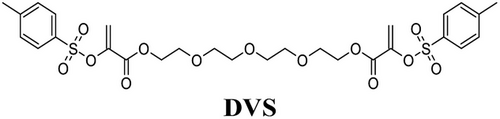

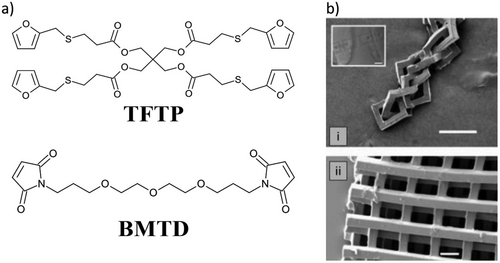

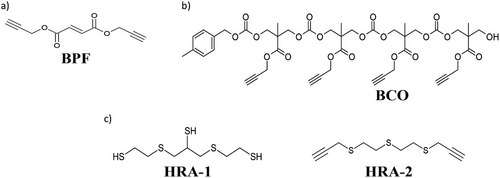

3.2 Thiol-Ene Chemistry using Allyl (ether)s, Vinyl (ether)s, and Derivatives for AM

Allyls, allyl ethers, allyl urethanes, vinyl ethers, vinyl acetates, vinyls, and allyl carbonates are all relatively reactive towards the radical-mediated thiol-ene reaction and thus serve as appropriate ene groups for rapid photopolymerization. For example, the thiol-ene reaction with vinyl esters has been demonstrated to display comparable reactivity to acrylate free radical photopolymerization.[69] Several common commercially available monomers are frequently employed within AM (Figure 3).

3.2.1 Shape Memory, Self-Healing, and Degradable Polymers

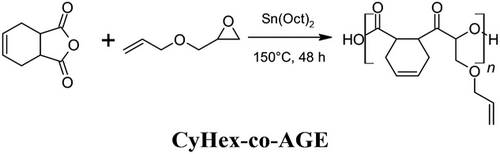

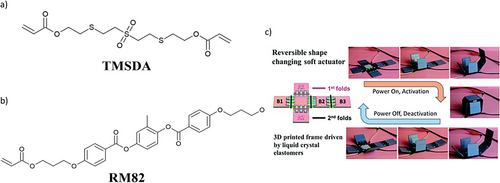

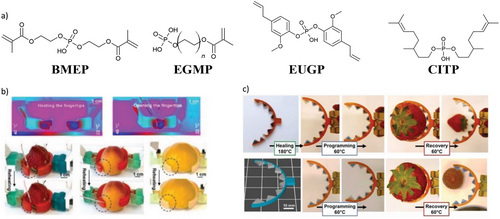

Polymers that can change geometry under stimulus (e.g., heat, light, pH magnetic field) are referred to as SMPs or 4D polymers in AM.[70-73] In particular, the use of covalently cross-linked polymers presents an appropriate strategy for achieving SMPs in vat photopolymerization AM.[74] For cross-linked SMPs, well-defined polymer architectures tailored through network homogeneity can result in narrow glass transition temperature (Tg) and thus facilitate rapid response and recoveries within small temperature windows. It is therefore crucial that the network contains evenly distributed netpoints and switching segments to achieve such.[75] Within this context, thiol-ene polymers can have relatively narrower Tg half-height peak widths compared to (meth)acrylates.[76] Furthermore, for thiol-ene polymers, it is well known that the weak and flexible thioether bonds often result in relatively low Tg polymers. In fact, this can be exploited to tailor SMPs that undergo geometric changes at useful temperatures for many applications. For example, various unsaturated poly(ester)s have been prepared between allyl glycidyl ether and 1,2,3,6-tetrahydrophthalic anhydride (CyHex-co-AGE, Figure 4), as well as incorporating pendant groups of 3-mercaptopropionic acid. These oligomers and co-poly(ester)s thereof were copolymerized with pentaerythritol tetrakis(3-mercaptopropionate) (PETMP, Figure 2) in ethylene carbonate via DLP printing using a 10 s layer cure time. The copolymers displayed a tensile modulus (ET) up to 600 MPa and Tg up to 67 °C, while the pendant addition of 3-mercaptopropionate groups decreased ET, but increased strain at break (εT) up to 52.5%. The CyHex-co-AGE and PETMP copolymer displayed excellent strain fixation release at 50 °C with rapid and complete strain recovery.[77] In an effort to control the (thermo)mechanical properties and associated shape memory capability of these SMPs, several organocatalysts were then explored for tailoring the molecular weight and polydispersity of the polyesters bearing pendant allyl ethers. Copolymerization using different molecular weight (0.4–25.5 kDa) and polydispersity oligomers with PETMP via DLP printing allowed tailorable thermomechanical properties (e.g., Tg 18–49 °C) of the polymers, thus facilitating targeted properties for specific applications.[78] Further to this, the effect of supramolecular thiourea co-catalysts were explored to tailor the polyester molecular weights. The DLP-printed SMPs displayed excellent strain fixations (>99%) and strain recoveries (>99%). However, rapid plateauing of Tg occurred for molecular weights above 1 kDa, rendering further tailoring of negligible effect.[79]

Achieving high-resolution fidelity of detailed features is highly attractive within AM. While achieving high-resolution 3D printing is in-part due to technological factors, the monomer system also plays an important role. For example, a comparative study between the use of acrylates and thiol-ene polymers using either triethylene glycol diallyl ether (TEGDAE) or triallyl-s-triazine-2,4,6(1H,3H,5H)trione (TATATO) and tris[2-(3-mercaptopropionyloxy)ethyl] isocyanurate (TMEICN) for VP 3D printing has been performed to establish optimal systems for high-resolution 3D printing. Here, it was shown that compared to analogous acrylate systems (tetraethylene glycol diacrylate (TEGDA, Figure 3) and tris[2-(acryloyloxy)ethyl] isocyanurate (TAEICN, Figure 3), greater spatial control could be achieved using thiol-ene chemistry.[80] Adding credence to this, SMPs were then produced via VP 3D printing using TEGDAE, TATATO, and TMEICN, whereby increasing the content of TEGDAE could effectively increase the polymers’ Tg to around 37–39 °C. Cycling the temperature 20 °C above and below the Tg under constant tensile strain conditions (9.4%) demonstrated that near-ideal shape recovery (>96%) could repeatedly be achieved. Furthermore, ideal shape fixity was achieved, with rapid shape recovery occurring at 80 °C. Here, the shape memory capability was also demonstrated for 3-arm robotic grippers.[81]

Various biobased polymers that exploit the unsaturation on naturally occurring platform molecules have been developed using thiol-ene polymerization. In most instances, the unsaturation on terpenes and terpenoids is insufficiently reactive for free radical polymerization under mild conditions, yet readily reacts via the thiol-ene mechanism.[82-84] The judicious choice of terpene/terpenoid has still found to be imperative, since examples such as limonene and linalool have been shown to rapidly crosslink (5 s) with PETMP, while nerol and geraniol crosslinked incredibly slowly (1 h) by DLP 3D printing.[85] As such, myrcene, linalool, and limonene have been used for thiol-ene polymerization in AM. Firstly, it was found that the synthesis of poly(myrcene) oligomers promoted polymerization kinetics with PETMP compared to using β-myrcene directly as a monomer. It was further established that either linear or branched oligomers could be prepared by anionic or free radical polymerization, respectively, and these oligomers were then copolymerized with PETMP using DLP printing. The resultant polymers could undergo post-fabrication surface modifications, whereby residual unsaturation on the polymer surface was coupled with either 1-hexadecanethiol or mercaptopropionic acid to produce hydrophobic or hydrophilic surfaces, respectively.[86] A similar approach of using limonene and β-myrcene oligomers has also been used to produce effective SMPs using DLP printing. Here, limonene and β-myrcene homo- and copolymer oligomers were prepared by bulk thermal free radical polymerization, followed by copolymerization with TATATO and PETMP via DLP printing using relatively short layer cure times (3–5 s). Adjusting the relative incorporation of limonene and β-myrcene components resulted in the ability to tailor mechanical properties, and higher contents of β-myrcene also displayed greater hydrophilicity. Furthermore, cell viability was investigated for potential biomedical applications as cellular scaffolds, with the highest cell viability observed for β-myrcene containing copolymers. These copolymers also displayed near-ideal shape fixity and strain fixity, with rapid strain recovery when heated above their Tg.[87]

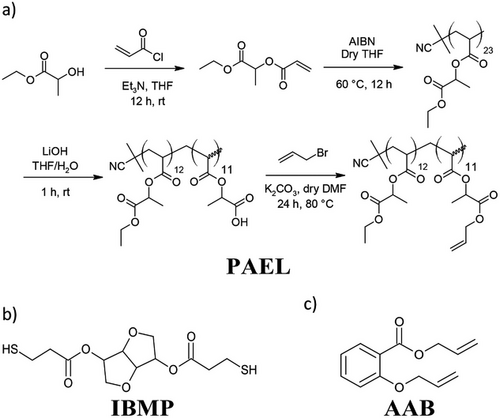

Various biobased polymers have also been used for controlled degradable materials. For example, an allyl ether functionalized oligomer, allyl poly(acrylate ethyl lactate) (PAEL, Figure 5), has been synthesized using the renewably sourced ethyl lactate. Furthermore, a biobased thiol monomer was prepared through Fischer esterification between isosorbide and 3-mercaptopropionic acid, yielding isosorbide bis(3-mercaptopropionate) (IBMP, Figure 5). These monomers were then copolymerized with TTT and PETMP in varying ratios using DLP printing. The copolymer with the highest biobased monomer content (10 wt% PAEL, 5 wt% IBMP, 52 wt% PETMP, 33 wt% TTT) underwent rapid and complete degradation in basic conditions, while remaining relatively impervious to acidic conditions. Furthermore, the introduction of PAEL increased strength properties relative to a reference standard, with the aforementioned copolymer displaying a tensile strength (σT) of around 20 MPa and εT at around 9%.[88]

Derivatives of salicylic acid (bromosalicylic allyl ester, iodosalicylic allyl ester, allyl salicylate, allyl 2-(allyloxy)benzoate (AAB, Figure 5), and allyl 2-(((allyloxy)carbonyl)oxy)benzoate) have been prepared as prodrug monomers for soft tissue scaffold applications. The monomers were copolymerized with PETMP (monofunctional monomers with additional 25 wt% poly(trimethylolpropane allyl carbonate)) using DLP printing with a layer cure time of 5 s. Here, it was found that varying the functional group did not influence layer cure time. Interestingly, strain fixation was only achieved at low temperatures (-20 °C) for all polymers except polymers with iodosalicylic allyl ester, which was performed at 30 °C. A compressive elastic modulus as low as 65 kPa was achieved using AAB, making it comparable to many flexible hydrogels. All the copolymers were degradable in 1 N NaOH yet stable in phosphate-buffered saline (PBS) solution. The polymers successfully released the salicylic acid derivatives at a relatively sustained rate when degraded, which provided a prolonged release compared to other poly(aspirin)s and encapsulated forms of salicylic acid. Furthermore, layered structures composed of different polymer compositions could effectively produce spatially selective differential degradation rates. Lastly, the polymers displayed good cellular proliferations alongside diminished bacterial growth, with AAB displaying 110% ± 3% cell viability after 7 days. Interestingly, only the difunctional salicylic derivatives displayed inhibitory effects against E. coli and S. aureus.[89] In fact, several other allylated phenolic acids have also been shown as effective monomers within thiol-ene polymers, and thus may be of interest within the context of AM for biomedical contexts.[90-92] On that note, it is quite surprising that more biobased compounds containing allyl/vinyl groups have not generally been employed in AM to date. A variety of other highly promising biobased monomers present themselves as readily transferrable into AM, such as limonene,[93-97] eugenol,[98-106] vanillin,[107] rosin,[108] myo-inositol,[109] lignin,[110] levoglucosenone,[111] mangnolol,[112] glutamic acid,[113] isosorbide,[114, 115] and various other plant oils.[116-120]

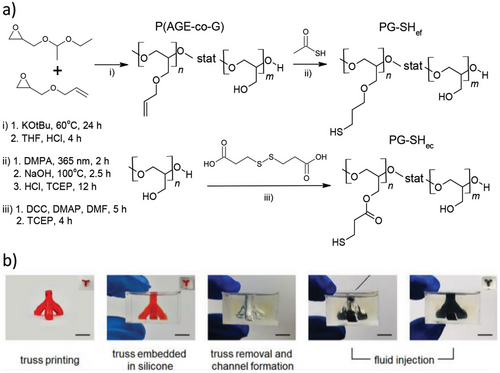

Poly(glycidol) is a biocompatible material that can be exploited as a platform for further functionalization to yield crosslinked degradable materials.[123] For example, it has been partially functionalized with pendant allyl ether P(AGE-co-G), mercaptopropyl (PG-SHef), or propionate groups (PG-SHec) (Figure 6), which were then DIW 3D printed as hydrogels (15 wt% oligomer concentration) alongside 3.5 wt% hyaluronic acid (HA) to increase system viscosity. Human bone marrow-derived stromal cells could also be encapsulated in the hydrogels, which displayed acceptable cell viability after 24 h (78.9 ± 13.5%), although a high variability was observed. Here, it was established that controlled degradation could be achieved when PG-SHec was employed, owing to the hydrolytically labile ester moiety, and that compositional effects could be exploited to tailor cell survivals. These hydrogels displayed complete dissolution after 5 weeks in PBS solution at 37 °C.[121] Furthermore, the effect of positively charged species within thiol-ene hydrogels has shown promising results for the uptake of low molecular mass species, extending its scope within biomedical contexts.[124]

Aside from hydrolytic degradation, other mechanisms can be used for controlled degradable polymers. For example, tetraallyloxyethane (TAOE), 2,4,6-triallyloxy-1,3,5-triazine (TAT), ethylene glycol bis(3-mercaptopropionate) (EGBMP), and PETMP have been used to produce a series of shape memory and degradable thiol-ene polymers via DLP printing. Here, thermal treatment at 140 °C in hexylamine could effectively transform the polymer network through transamidation. Furthermore, the concentration of ester groups within the polymer could be tailored by partially replacing EGBMP with 2,2′-(ethylenedioxy)diethanethiol (EDDET, Figure 2), although it was found that a minimum of 50% EGBMP was required to revert the polymer into a liquid state, which could be used to create channels when the polymer object was molded within a silicone matrix (Figure 6). Treatment with hexylamine was further used to manipulate the Tg of the polymers, thus tailoring the shape memory recovery temperatures.[122]

The extrusion of high-viscosity monomer/oligomer gels in DIW 3D printing offers accessibility for incorporation of composite components into polymer networks such as SMPs. However, during extrusion, the oligomer is typically exposed to atmospheric oxygen, which can retard the kinetics of (meth)acrylate free radical polymerization and thus limit the processability of these systems. On the other hand, the thiol-ene reaction is generally impervious to oxygen sensitivity, making it a highly appropriate polymerization technique within this AM technology. For example, cellulose nanofibrils (CNF) have been modified with succinyl groups, followed by periodate oxidation to form aldehydes and hydrazide ligation using 6-azidohexanehydrazide, which were incorporated into polymers of allyl glycidyl ether functionalized gelatin (Gel-AGE) and PEG-2SH using DIW printing. Mechanical gradients were achieved for hydrogel by dual printing using two different concentrations of Gel-AGE and PEG-2SH (5 kDa). Furthermore, spatially selective functionally graded polymers were fabricated by additionally incorporating modified CNF-bearing azido moieties that could react through strain-promoted azide-alkyne reaction.[125] Given that Gel-AGE polymers have been identified as suitable materials for long-term cell survivals, their use within biomedical applications is promising.[126] In another example of 3D printing composite materials, biobased levoglucosan has been functionalized to form a trifunctional allyl ether monomer, which was copolymerized with PEG-3SH alongside 12-14 wt% fumed silica (SiF) via DIW printing. The polymer was shown to be fully degradable in 1N NaOH owing to the hydrolytically labile bonds within PEG, while no degradation was observed in 1N HCl or synthetic seawater.[127] This pH-specific degradation provides a useful feature for several applications, such as environmentally targeted biomedical applications.

The use of monomers and oligomers bearing carbonate groups have been established as useful within thiol-ene networks for biomedical applications.[128, 129] With this in mind, the DIW printing of poly(trimethyl propane allyl ether carbonate) oligomers and PETMP alongside a graphite filler resulted in SMPs that could be tailored to change geometry around 30 °C for in vivo biomedical applications. Furthermore, these polymers displayed electrical conductivity (resistivity of 1.99 × 10−6 Ω.m and conductance of 1.37 × 103 S at 30 wt% graphite), and high thermal conductivity, while they were also hydrolytically degradable. Interestingly, the addition of the graphite filler resulted in shear thinning behavior, which was beneficial for effective processing.[130] Continuing within the context of biomedical applications, triblock poly(carbonates) of butylene carbonate and cyclohexene carbonate oligomers have been copolymerized with PETMP using DIW printing. Incorporation of NaCl and dissolution of the oligomers in DMF resulted in thixotropic inks, allowing porous materials to be obtained by aqueous washing of the polymer post-fabrication. These porous structures could also be postfabrication modified by the addition of cell growth factors.[131] Further work using this oligomer for off-stoichiometric DLP printing demonstrated postfabrication modification by grafting alkylthiol chains to tailor hydrophobicity as well as halogenation of the polymer with molecular iodine, while still retaining shape memory capability.[132] In another example, a poly(carbonate) oligomer bearing pendant allyl group has been copolymerized with PETMP using 3D micro-stereolithography to produce degradable structures for tissue engineering.[133] With the aim to increase the toughness of polymers designed for bone replacements, an α,ω-allyl carbonate-functionalized PCL oligomer was incorporated into divinyl ether adipate (DVA, Figure 3) and TMPTMP for DLP printing. It was found that increasing the oligomer content from 0-20 wt% resulted in >250% increase in toughness (UT). Interestingly, no difference in photochemical or (thermo)mechanical properties was noticed between allyl, vinyl, or norbornene functionalization of the oligomer.[134] However, it is likely few examples employing allyl/vinyl carbonates are apparent in the literature given the typical cost associated with these monomers, although new synthesis strategies may open further opportunities.[135]

Semi-crystalline elastomeric polymers are an interesting class of polymers that can facilitate useful properties. For example, diallyl terephthalate (DAT) and 1,6-hexanedithiol (1,6-HDT) were copolymerized to form linear oligomers, which were then further crosslinked with low concentrations (<10 mol%) of various trifunctional allyl ether and allyl acetate monomers (TAT, TABT, TATATO, TATM) and either trimethylolpropane tris(3-mercaptopropionate) (TMPTMP, Figure 2) or PETMP to produce lightly crosslinked semi-crystalline polymers. Here, increasing TAT content decreased crystallinity, and thus after initial screening a monomer ratio of 1:0.95:0.05 of 1,6-HDT-to-DAT-to-TAT alongside 0.1 wt% carbon black was chosen for DLP and SLA printing. It was found that annealing the printed polymers above the melting temperature (Tm) of the crystalline component was imperative to achieve properties comparable to bulk specimens, attributed to interlayer adhesion that occurred during annealing. Indeed, the polymer εT increased from 36% to 532%, UT from 2 MJ m−3 to 59 MJ m−3, while σT increased from 7.4 MPa to 15.9 MPa after annealing.[136] Here, the influence of AM processing on the final polymer properties is highlighted as an important consideration for polymer network design and processing. Furthermore, the influence of dynamic bonds and catalytic control of crystallization has been investigated to gain a greater understanding of this interplay within thiol-ene networks.[137]

FFF 3D printing is typically reserved for thermoplastic and thermoplastic elastomeric polymers owing to its use of melt extrusion for manufacturing, which can present limitations in their achievable properties. On the other hand, a thermoplastic elastomer was prepared through the grafting of methyl thioglycolate to the butadiene blocks of poly(styrene-butadiene-styrene) (SBS) via thiol-ene reaction, which was melt extrudable with FFF printing. It was found that a high incorporation of the polar pendant moiety (98.5%) resulted in the interruption of poly(styrene) clustering typical of virgin SBS, owing to a CH···π interaction between adjacent δ+ CH2 or δ+ CH3 groups of the methyl thioglycolate and the δ- aromatic centre of styrene. The resultant microstructural disorganization, alongside abundant electrostatic interactions, resulted in self-healing capability.[138, 139]

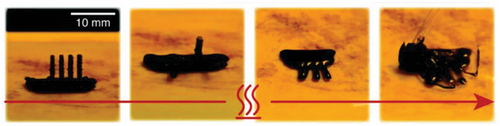

Thermoplastic polymers are typically implausible for use in vat photopolymerization AM, since photopolymerization typically either results in low molecular weight polymers with poor mechanical properties, or the necessary irradiation to achieve acceptable polymers is unfeasibly time-consuming. However, 1,6-HDT and DAT have been successfully employed as bifunctional monomers to produce semi-crystalline linear thermoplastic thiol-ene polymers within vat photopolymerization AM. Indeed, the reaction between 1,6-HDT and DAT was investigated by FTIR, revealing near complete conversions in 3–5 s under low UV intensity. Interestingly, a delayed crystallization was observed that occurred after initial gelation. Given the structural similarities of the monomers used here to those of poly(ethylene terephthalate), many of its well-known molecular attributes such as dipole-dipole interactions of carbonyl groups and π–π stacking could be directly leveraged within this motif. Molecular weights of 104 g.mol−1 were achieved, which was interestingly attributed to near-ideal thiol-ene step-growth with some contribution of homopolymerization of DAT. The polymers also displayed somewhat remarkable mechanical properties, with ET of 75 MPa, σT around 24 MPa, εT of 793%, and UT of 102 MJ m−3. The polymers displayed classic necking and strain hardening in tension, while achieving elastomeric-like strains. The phenomenon of rapid crystallization and overcuring within these polymers initially posed difficulty within SLA and DLP printing, although it was found that the addition of carbon black could effectively act as a photoabsorber, thus mitigating the issue to produce relatively high-resolution objects (Figure 7). It was also noted that crystallization induced shrinkage in the AM-printed polymers. Nevertheless, as is the case for thermoplastic polymers, these could be effectively melt-processed, rendering them conventionally recyclable.[140, 141]

This work was further extended to demonstrate that the addition of a monothiol could be used to effectively decrease molecular weight and increase crystallization rate. Furthermore, the inclusion of 2 wt.% chromium oxide facilitated melting through induction heating, which was shown in fabricated dental molds.[142] This example denotes a remarkable paradigm shift in the molecular architecture achievable within vat photopolymerization AM.

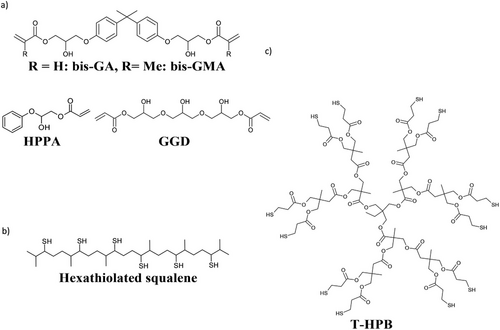

The manufacturing of composite materials is often desirable to increase (thermo)mechanical properties, yet within the context of vat photopolymerization AM this can come with challenges of high viscosity and UV penetration inhibition. Nevertheless, TATATO alongside TMEICN have been used to SLA print composites of hydroxyapatite (HAp) for biomedical bone fixation implants. It was noted that the incorporation of these low-viscosity monomers was imperative to act in a diluent role, thus improving processing and printing resolution. Interestingly, it was established that the incorporation of either micro- or nano-HAp resulted in appreciably different polymers. Here, micro-HAp did increase the resin viscosity, but also successfully increased ET of the polymers. On the other hand, nano-HAp increased the gelation time from 5 min to 4 h, while making no impact on ET of the polymer. As such, a mixture of 0.4 wt% nano-HAp and 36 wt% micro-HAp was chosen for AM, and resulted in non-toxic composites with an ET of 2.4 GPa.[143]

3.2.2 (Thermo)Mechanically Excellent Polymers

It is well known that protonated amides impart strong intermolecular interactions that can affect oligomer viscosity as well as influence solubility in polar solvents. As such, the secondary amides on poly(N,N′-(1,3-phenylene)isophthalamide) oligomers have been functionalized using allyl bromide, thus imparting functional groups to facilitate thiol-ene polymerization, while also reducing oligomer viscosity. This oligomer was copolymerized with PETMP via DLP printing, using N-methyl-2-pyrrolidone (NMP) as a solvent. The printed organogels were then dried under reduced pressure, leading to 30–35% isotropic shrinkage. The resultant polymers were thermally stable with a 10% degradation temperature of 380 °C. Mechanically, the polymers displayed σT of 88 MPa and εT of 22%, thus achieving strong yet relatively ductile polymers, owing to the incorporation of flexible thioether crosslinks.[144] In fact, similar strength with far greater ductility could be achieved here compared to similar 3D printed polymers that did not incorporate thiol-ene polymerization, although in these examples the use of dimethyl acetamide acrylate as a polar reactive diluent mitigated the necessity for organogel printing.[145, 146]

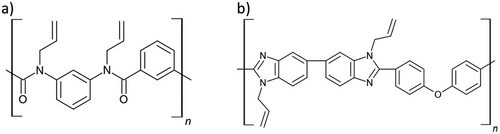

Poly(benzimidazole) polymers are capable of achieving high strength, extremely high Tg (>350 °C), and thermal stability, yet their application in processing technologies has remained limited. To harness the benefits of these polymers within AM, a poly(benzimidazole) oligomer was functionalized with allyl pendant groups through the facile coupling of allyl bromide to the imidazole groups present on the backbone (Figure 8). This oligomer was copolymerized with PETMP via DLP printing using 30 s layer cure time and N-methyl-2-pyrrolidone or N,N-dimethylacetamide as a solvent (6.7 mL/g monomer formulation). Evaporation of the solvent from the printed polymer resulted in 22% shrinkage, although geometric fidelity was reported to be preserved. Nevertheless, the copolymer displayed a σT of 164 MPa and T10% thermal stability of 397 °C.[147] Interestingly, while similar poly(benzimidazole) polymers have been demonstrated to display shape memory behavior, this research did not investigate such. Furthermore, the use of a polar reactive diluent such as vinyl N,N-dimethylacetamide has been shown as an effective alternative to the aforementioned solvents, which could be explored to mitigate the shortcomings of using a non-reactive solvent.[148, 149]

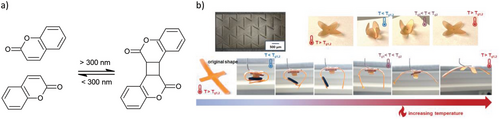

3.2.3 Incorporation of (Hydroxy)Urethanes

Poly(urethane) polymers and associated polymers containing urethane bonds benefit from strong intermolecular hydrogen bonding and environmental stability,[150-152] making it a logical progression to incorporate this group within monomer/oligomers for AM.[153] For example, an allyl urethane-functionalized poly(ethylene oxide-co-tetrahydrofuran) oligomer has been copolymerized with TMPTMP using DLP printing. A comprehensive investigation into the AM parametric optimization and initiator concentration was performed, establishing suitable printing parameters to minimize the risks of printing polymers for its intended application in energetic materials. Here, the use of the thiol-ene reaction was chosen to minimize UV exposures and potential thermal effects during fabrication.[154]

The incorporation of urethane bonds within thiol-ene polymer networks has also been investigated for biomedical applications using poly(δ-caprolactone) (PCL). PCL is well established as a biobased, biocompatible, and biodegradable polymer, making it a highly attractive candidate for these applications.[155-157] Various linear and star-shaped PCL oligomers have been prepared using polyol cores (ethylene glycol, 1,1,1-tris(hydroxymethyl)propane, pentaerythritol) which were terminally functionalized using allyl isocyanate. These oligomers were then copolymerized with PETMP or TMPTMP via DLP printing using 8–15 s layer cure times. Somewhat counterintuitively, using a pentaerythritol core alongside PETMP displayed the lowest mechanical properties, and also the most rapid degradation under basic conditions. On the other hand, using an ethylene glycol core copolymerized with PETMP displayed the highest mechanical properties, yet still degraded at an acceptable rate (100% within 30 days). This behavior was suggested to be due to differences in crystallinity within the polymer, whereby higher functionality oligomers and monomers led to a decrease in the polymers’ ability to crystallize.[158] This example of architectural control within the polymer network presents an invaluable insight into tailoring polymer morphologies for specific application performance, whereby semicrystalline components within the network could be exploited. Extending this motif using VP 3D printing, linear α,ω-terminated allyl urethane PCL oligomers of varying molecular weights (2.3–8.7 kDa) were copolymerized with PETMP to produce semi-crystalline elastomeric polymers. It was found that crystallite melting occurred below physiological temperatures for the short oligomer blocks, while melting was only observed around 50 °C for longer oligomer blocks, which was similar to thermoplastic PCL (80 kDa), suggesting that the longer oligomers with greater Mc could effectively crystallize to a greater degree. The polymers displayed controlled degradation in 5 m NaOH, with kinetics relating to cross-linking density (27–73% residual mass after 10 days), whereby higher residual mass was related to polymers incorporating smaller oligomers with higher crosslinking density. However, under simulated physiological conditions (37 °C, PBS solution) almost no degradation occurred within a month.[159]

A series of linalool-terminated diurethane monomers have been copolymerized with PETMP and propylene carbonate via DLP printing to produce SMPs. It should be noted that an extensive postfabrication photocuring for 24 h followed by thermal curing at 120 °C for 24 h was performed. Nevertheless, altering the isocyanate (isophorone diisocyanate (IPDI), hexamethylene diisocyanate (HDI), or methylene diphenyl diisocyanate (MDI)) could effectively tailor mechanical properties. Furthermore, the incorporation of hydrogen bonds from urethane components was noted to contribute to shape memory capability; the polymers were reported to achieve excellent strain fixation as well as up to 100% strain recovery within 30 s at 60 °C and 15 s at 80 °C. It was, however, noted that HDI (Tg 47 °C) and MDI (Tg of 35 °C) based polymers displayed more rapid rates at 40 °C than IDPI (Tg of 81 °C), given the difference in their Tg.[160]

Non-isocyanate poly(urethane)s (NIPUs) have been established as a sustainable avenue to impart the beneficial properties of the urethane bond without the use of isocyanates, thus mitigating the use of phosgene during synthesis.[161] Furthermore, the resultant β-hydroxy moiety can facilitate interesting physical properties or serve as a functional group for further synthetic modifications.[162] For example, a NIPU oligomer has been further coupled about the hydroxy moiety to yield allyl functional pendant groups (Figure 9). This oligomer was copolymerized with either PETMP, TMPTMP, ethanedithiol (EDT), or combinations thereof via DLP printing using 1-methyl-2-pyrrolidone as a solvent (2 mL/g oligomer). The polymers were targeted for application in biomedical implants, with biocompatibility studies examining its interaction with human fibroblasts, red blood cells human platelets, and platelet-poor plasma. Using thiols with greater functionality (i.e., PETMP) were shown to have good metabolic activity, reduced hemolysis and clotting times, and increased platelet adhesion.[163]

The effect of monomer functionality on controlling the polymer architecture and resultant mechanical properties has also been explored using NIPUs. Here, a diallyl functionalized non-isocyanate diurethane monomer was prepared using an allyl functionalized carbonate and diamine, which was then copolymerized with either PETMP, TMPTMP, 1,6-HDT, or combinations thereof using DLP printing. Varying the thiol monomer resulted in the ability to control the polymer architecture from linear to crosslinked networks, thus controlling the mechanical properties. Using these monomer systems, a multi-material compliant mechanical device was printed and demonstrated as a directionally biased semi-rigid gear with rotational dampening of acceleration, thus highlighting the control of rigid (using PETMP) and flexible (using 50% PETMP and 50% 1,6-HDT) tailorability of the polymers for functional application (Figure 9). Furthermore, the biocompatibility of the polymers was investigated and showed no acutely toxic effects, while low cell adhesion characteristics could make them suitable for applications of anti-fouling.[164] Within this context, thiol-ene polymers have been shown as appropriate polymers for hard and soft networks and dissimilar materials without suffering weak interfaces, making them highly suitable for this type of multi-material.[165-167]

Poly(propylene glycol) has been α,ω-functionalized with diallyl hydroxyurethane functional groups and copolymerized with TMPTMP via DIW printing, followed by postfabrication curing at 60 °C in a UV oven. It was observed that the allyl hydroxyurethane functionalization strongly increased the oligomer viscosity, attributed to hydrogen bonding. Furthermore, the oligomers demonstrated Newtonian shear viscosity behavior between 100 and 2.5 s−1, which alongside the high viscosity, made it a highly appropriate formulation for DIW printing. Interestingly, 3D printed specimens displayed higher gel content and tensile properties compared to bulk polymers, indicative that successful crosslinking between layers was achieved.[168] Lastly, an area of opportunity for the facile synthesis of urethane or amide-bearing monomers suitable for AM is using allyl-functionalized thiolactones, presenting opportunities for biobased developments that could be readily transferred into AM.[169-171]

3.2.4 Poly(Siloxane)s

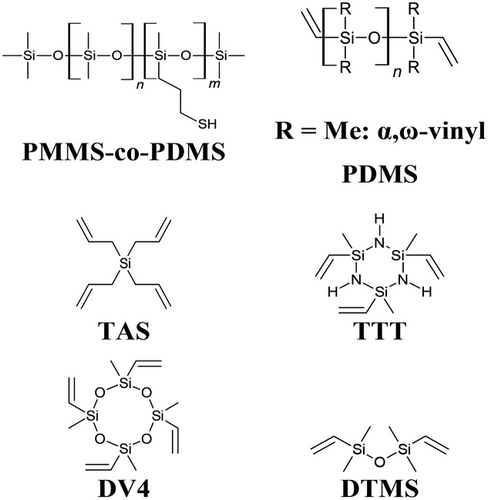

Silicon-based polymers can be achieved in photopolymerization AM through the incorporation of thiol- and alkene-functionalized poly(siloxane) oligomers and silicon-based allyl and thiol monomers (Figure 10).[36, 172] An early example in AM used α,ω-vinyl terminated poly(dimethylsiloxane) (α,ω-vinyl PDMS) and poly(mercaptopropylmethylsiloxane-co-dimethylsiloxane) (PMMS-co-PDMS) (Figure 10) to SLA print soft robotic pneumatic actuators with self-healing capability. Self-healing was assisted by encapsulation of the pre-polymer, which could be released when a puncture occurred, thus rapidly polymerizing on exposure to sunlight. This work also investigated the effect of varying MW of α,ω-vinyl PDMS (186–43 000 Da) and thiol concentration of PMMS-co-PDMS (2–3% to 4–6% mercaptopropyl content), whereby properties could be tailored by adjusting these two oligomer components.[173] In another example, copolymers of α,ω-vinyl PDMS and PMMS-co-PDMS were produced with varying vinyl-to-thiol ratios. A ratio of 1:1.5 produced optimal curing kinetics and tensile properties (σT of 0.2 MPa and εT of 158%), which was used for SLA printing. The printed copolymer was also antimicrobial and biocompatible, hence providing viability for biomedical applications. The polymers were also mask photopatternable by incorporation of a red pigment, making them useful for applications such as chips and microfluidic devices. However, some issues were observed for printing resolution, and layer height discrepancies were reported, whereby for a programmed layer height of 50 µm a measured layer height of only 10 µm was produced.[174]

The effect of different pendant groups on poly(siloxane)s has been explored, showing that incorporating phenyl pendant groups imparted π–π stacking and thus facilitated high toughness.[175] Amorphous terpolymers have also been prepared using several pendant-substituted siloxanes (dimethylsiloxy, diphenylsiloxy, and diethylsiloxy) that allowed SLA printing of tailorable polymers. However, here it was noted that diphenylsiloxy incorporation had deleterious effects attributed to uncontrolled branching.[176] On the other hand, allyl- and thiol-functionalized poly(fluorosiloxane) oligomers have been shown as rapidly UV curable (5 s) with good hydrophobicity and corrosion resistance, making them promising candidates for AM.[177] Within the context of rapid polymerization, poly(siloxane) oligomers α,ω-functionalized with norbornyl groups have been copolymerized with PMMS-co-PDMS. Compared to α,ω-vinyl PDMS, the norbornyl functionalized oligomers displayed 3× faster curing and 5× less oxygen inhibition, with complete overall cure and without tacky surfaces.[178] Although this was not demonstrated within AM, it provides a promising platform for the use of functional groups with rapid kinetics for reducing layer cure times.

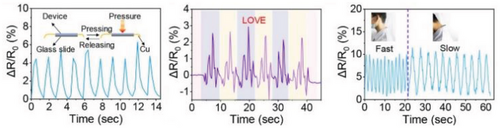

The viability of high molecular mass poly(siloxane) oligomers has been explored for DIW printing with the aim of producing soft elastomeric polymers with dielectric capability. Here, PMMS-co-PDMS (5% mercaptopropyl content) in the range of 7–16 kDa and poly(methylvinylsiloxane-co-dimethylsiloxane) (9% vinyl) (PMVS-co-PDMS) in the range of 55-260 kDa were assessed. High molecular masses, pendant functional groups, and not adding a filler were strategically chosen to enhance low modulus, highly elastic, and efficient dielectric properties. It was found that PMVS-co-PDMS of 55 kDa and PMMS-co-PDMS of 7 kDa was an effective formulation for AM. An optimal thiol-to-vinyl molar ratio of 0.047 was also established to ensure residual vinyl groups for interlayer adhesion. DIW printed grids were shown to withstand 100 compressive cycles to 50% strain without hysteresis, ET of 0.29 MPa, and <2% stress decay after loading to 200% strain for 100 min. Furthermore, the material was demonstrated as a dielectric, displaying an electric field of 41 kV mm−1 at 9.5% strain, which was unaffected by electric field frequencies up to 10 Hz.[179]

It is well known that the incorporation of a filler such as SiF can improve the mechanical properties of poly(siloxane) polymers. Additionally, the incorporation of fillers typically leads to an increase in system viscosity, which can be exploited in DIW printing. For example, DIW printing using poly(siloxane) oligomers with pendant thiol- and vinyl-functional groups of varying molecular weights and functional group concentrations were coextruded to produce multiple modulus poly(siloxanes). Here, by altering the relative ratio of coextruded components (up to three simultaneously), spatially selective property tailoring was achieved. Furthermore, the incorporation of 2 wt% SiF could be used to improve mechanical properties. The printed polymers were demonstrated to achieve high aspect ratio objects, overhanging structures, and discontinuous flow printing, making the fabrication of complex objects possible.[180] Another example of DIW printing developed a functionalized poly(siloxane) oligomer that could serve as both an extrudable ink, a medium for embedded printing of microfluidic devices, as well as a castable medium for a printing support bath. Here, PMMS-co-PDMS and α,ω-vinyl PDMS were copolymerized alongside hexamethyldisilazane-treated silica and a thixotropic agent. When employed as a medium for embedded printing, the polymer was employed as an organogel. Here, the optimization of self-recovery and yield stress was achieved by tuning the relative incorporation of oligomers and filler, which alongside its excellent optical transparency, enhanced its use for embedded printing. Next, it was found that the treated silica filler content was vital to optimize for use as a support bath. However, using a water-based ink within the hydrophobic polymer support bath resulted in resolution and geometric limitations. Nevertheless, microfluidic channels could be fabricated. Lastly, the ink was also demonstrated as an extrudable medium for DIW printing within a support bath. It was reported that the correct support bath medium (xanthan gum) was critical for successful printing, and this optimization led to the successful fabrication of soft robotic objects with embedded piezoresistive pressure sensor components.[181]

Despite the increase in system viscosity that is observed when silica is added as a filler, several examples have successfully employed these systems within vat photopolymerization AM. For example, α,ω-vinyl PDMS and PMMS-co-PDMS (4-6% thiol) oligomers alongside up to 33 phr SiF as a filler have been DLP printed using a 7 s layer cure time. Here, the system viscosity exceeded 100 000 Pa.s, which meant that a custom printer with rotational vat and wiper for recoating was necessary. Nevertheless, the printed copolymers were shown to have tuneable mechanical properties and εT up to 350%.[182] In another example, DLS printing was used to minimize flow pressure within viscoelastic suspensions incorporating SiF. The pressure difference (low pressure under print platform as head moves up) within a DLS printer was used to induce flow of the high viscosity system, and the non-dimensional Peclet number (Pe) for the system was calculated to understand processing limits. Here, α,ω-vinyl PDMS (7 kDa) and PMMS-co-PDMS (6 kDa, 4–6% mercaptopropyl) were copolymerized alongside SiF nanoparticles with 50–500 nm aggregate sizes. It was found that increasing SiF content increased toughness, until Pe was exceeded (μapp around 60 Pa·s, τy around 6 Pa) and printing was no longer viable. This work supported a hypothesis that liquid fracture caused breaking of the seal within the system during printing, and thus provided a basis to quantify the critical limit whereby the phenomenon occurs to mitigate deleterious printing parameters.[183] In another example employing silica as a filler, α,ω-vinyl PDMS and PMMS-co-PDMS were DLP printed alongside the addition of either SiF or precipitated silica (SiP). Increasing the content of SiP resulted in a dramatic increase in mechanical properties; unfilled polymers displayed σT of 0.30 MPa and εT 311%, while 15 wt% SiP displayed σT of 1.69 MPa and εT of 1107%, and 20 wt% SiP displayed σT of 2.59 MPa and εT of 1403%. The use of SiF displayed the same trend, although overall lower strength and elongations were observed, which was attributed to differences in morphology and surface functional groups. However, this trend was not observed when using lower molecular weight oligomers, whereby although σT increased, εT decreased with increasing silica content. The copolymers were then coated with carbon nanotubes and demonstrated as effective conductors for flexible electronics.[184] On the other hand, to overcome the high viscosity of many poly(siloxane) oligomers and addition of fillers that can negatively affect vat photopolymerization AM, the incorporation of a low viscosity chain extender monomer (1,6-HDT) has been used. Here, 50 wt% 1,6-HDT alongside 15 phr silica filler were incorporated into α,ω-vinyl PDMS and PMMS-co-PDMS, which rendered a system with sufficiently low viscosity (3.9 Pa·s) for DLP printing. The resultant polymers demonstrated εT of 601%, which was appreciably higher than polymers printed without 1,6-HDT and filler. Furthermore, acceptable resolutions could be achieved, although only qualitative examples were shown.[185]

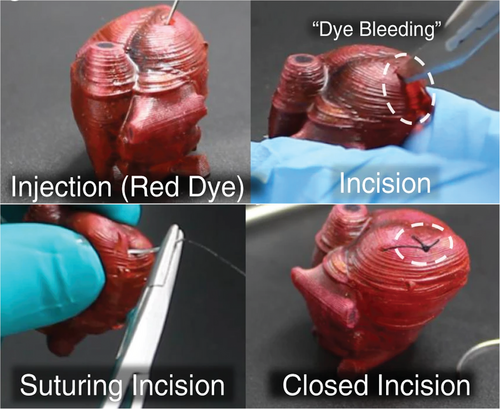

The use of multiple curing mechanisms of poly(siloxane)s has been demonstrated to synergistically enhance the properties of AM polymers and introduce the capability for shape memory and self-healing. Double network polymers were prepared by mixing a Sn-cured room temperature vulcanizing (RTV) poly(siloxane) alongside vinyl- and thiol-functionalized poly(siloxane) oligomers. Here, the mixture was SLA printed via thiol-ene polymerization, followed by slow room temperature condensation polymerization of the RTV poly(siloxane) component to form the double network polymer. These polymers displayed high εT (up to 400%) and UT (1.37 MJ m−3), while maintaining a moderate modulus. Furthermore, the properties were tailorable by changing the RTV poly(siloxane) formulations. Properties such as toughness, strength, and elongation were also magnitudes of order higher than the pure thiol-ene polymers and other analogous poly(siloxane)s. The polymers were used to print an artificial heart for educational surgical practice, whereby the tuneable mechanical properties could be exploited to match the properties of various tissue materials within the body, providing a versatile platform for tissue emulation Furthermore, the self-healing capability could be used to emulate sutured wounds (Figure 11). The polymers were also used to fabricate fluidic actuators for soft robotics and applied in several useful contexts, such as being adhered to orthotic gloves and incorporated onto heat-sensitive LEDs. Adhering of multi-materials could also be achieved through the incorporation of condensable groups at the surface, thus enhancing its adhesion properties between several materials such as glass, aluminum, thermoplastic polymers, and various thermosetting polymers.[186]

Dual network polymers combining an RTV poly(siloxane) alongside photopolymerisable thiol-ene poly(siloxane)s was further extended for use in DIW printing to fabricate multi-material polymeric foams. Here, three oligomer systems were kept in separate pumps: 1) containing α,ω-vinyl PDMS, PMMS-co-PDMS, and RTV poly(siloxane) part A, 2) containing RTV poly(siloxane) part B, and 3) containing α,ω-vinyl PDMS, PMMS-co-PDMS, RTV part A, and ammonium bicarbonate as a foaming agent. These pumps lead to a central nozzle, allowing for control of concentration of the relative oligomer systems to be supplied and varied during printing, thus facilitating spatially controlled multi-material printing. This system provided a highly versatile platform to achieve polymers with both varying thiol-ene and RTV contributions, as well as varied degrees of foaming.[187] The conceptual benefits of double network polymers synergistically enhancing the properties of the overall polymer beyond that of its individual components demonstrate an exciting potential within AM.[188]

The use of multiple crosslinking mechanisms has been extended to the incorporation of covalent thiol-ene bonds alongside physical crosslinks by ionic interactions. A system using a mixture of PMMS-co-PDMS, α,ω-vinyl PDMS, and pendant amine- and carboxylic acid-functionalized poly(siloxane) oligomers were SLA printed, leading to polymers that contained thiol-ene crosslinks and thermally reversible carboxy-amine ionic interactions. Interestingly, the incorporation of these ionic moieties did not strongly influence polymerization kinetics or overall conversion. On the other hand, the incorporation of these ionic interactions resulted in copolymers with relatively low temperature self-healing capability (100 °C), which were able to retain 98% tensile strength compared to original specimens. Here, greater concentrations of ionic moieties promoted self-healing, and slow room temperature self-healing was even demonstrated when sufficiently high concentrations were used. Additionally, the copolymers could be reprocessed, retaining 85% of their original strength. Lastly, they were also demonstrated as having good optical transparency (>90%) and as hydrolysis resistant.[189] Within the context of self-healing poly(siloxane) materials, a photoswitchable poly(siloxane) thiol-ene polymer has been produced that was capable of UV-activated self-healing. Here, a thiol oligomer was prepared between tri(ethylene glycol)divinyl ether and EDDET, followed by oligomerization with PETMP, which was finally copolymerized with α,ω-vinyl PDMS. Interestingly, self-healing, viscosity reduction, and remoulding was observed under UV irradiation. An excess of free thiols was necessary to observe photoswitching, where thiol-to-vinyl ratios ≥1:3 displayed these dynamic properties. It was considered whether disulfides or hydrogen bonding was responsible for this behavior, yet these mechanisms are thermally dependent, and this system did not exhibit such dependence. It was thus suggested that this was indeed a radically mediated mechanism.[190] While not demonstrated for AM, this poses an interesting contextual opportunity for inducing DCC both during and after the fabrication process, such as facilitating dynamic interlayer adhesion during AM.

Solid-solid phase change materials have been explored for regulation of latent heat, which can store and release thermal energy at near constant temperature during transfer. A series of poly(dimethylsiloxane-co-methylvinylsiloxane) oligomers of varying vinyl content were prepared and copolymerized with 1-octadecanethiol (ODT) and 1,6-HDT alongside 3 wt% hydrophobic SiF using SLA printing at 50 °C. The resultant polymers had a comb/bottlebrush morphology, which could be exploited for latent heat regulation. Here, the phase change behavior and latent heat could be tailored by ODT content, and the polymers displayed thermally actuated shape memory, attributed to the entropic elasticity of the ODT components melting. Chemical depolymerization and reprocessing were also possible with these polymers. Furthermore, the production of carbon fiber composites with the polymers displayed photonic/electrical responses, and skin-adhesive properties.[191] Another network polymer incorporating crystallizable alkyl thioether pendant groups has also been shown to achieve thermal energy storage capability, adding credence to this strategy of employing thiol-ene moieties.[192]

Beyond the context of AM, several poly(siloxane) thiol-ene copolymers have been shown to achieve luminescent properties. For example, a system employing allyl-functionalized poly(siloxane) oligomers has been further modified by thiol-ene coupling of several thioacids to enable coordination with Eu3+. Following this, the oligomers containing residual vinyl groups were copolymerized with PETMP to produce photoluminescent network polymers under 617 nm excitation.[193] This work was extended to investigate the incorporation of fluorescent dyes into poly(siloxane) network polymers, as well as the incorporation of imidazole into the poly(siloxane) backbone for switchable fluorescence.[194, 195]

3.2.5 Polymer Derived Ceramics

Polymer derived ceramics (PDC) present another area of opportunity for thiol-ene polymerization with silicon-based polymers.[196-199] For example, functionalized poly(carbosilane) and poly(carbosilazane) oligomers have been DLP printed, thus opening the door for a variety of additively manufactured PDCs. These PDCs were noted to show uniform shrinkage and high density, with manufactured SiOC lattices displaying exceptional specific compressive strength.[200, 201] Further work on SiCNO PDCs demonstrated 41% ceramic yield, a relatively low shrinkage of 24%, and hardness of up to 6.6 GPa.[202] Extending the scope of additively manufactured PDCs, a cyclosiloxane hybrid polymer (CHP) has been prepared through hydrosilylation reaction between 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetrasiloxane and 2,4,6,8-tetramethylcyclotetrasiloxane using Karstedt's reagent as an organo-platinum catalyst.[203, 204] The resultant CHP retained residual ene functionality, making it useful for further thiol-ene reaction during AM. Here, PDMS-co-PMMS with varying thiol concentration (20–50%) was prepared, with photorheological investigations establishing an optimized oligomer system of 40% thiol concentration for PMMS-co-PDMS. This oligomer was copolymerized with CHP (1:1 ene-to-thiol) via DLP printing using 50 µm layer height and 2 s layer cure time. These polymers displayed a low critical energy for gelation of around 10 mJ cm−2, attributed to the high thiol branching degree. Furthermore, the oligomer system had a relatively low viscosity of 380 mPa·s, making it suitable for vat photopolymerization AM. The printed polymers qualitatively displayed low shrinkage, while pyrolysis of the polymer at 1000 °C resulted in 25% isotropic shrinkage, with residual weights up to 68% and without macroscopic voids or defects. Further pyrolysis was then performed at higher temperatures to obtain a semi-crystalline state, whereby the cubic phase appears from 1400 °C. It was unfortunate that no mechanical properties of the final PDC were reported. Nevertheless, the versatility of the polymer was extended beyond its use as a PDC by incorporating 0.5 wt% of Ti3C2Tx as a multilayered structure with light-to-heat conversion properties. This achieved a photothermal effect within the polymer, which was suggested as a useful feature for application in electromagnetic shielding devices. Lastly, a commercial fluorescent “invisible ink” was also incorporated into the oligomer system, which resulted in printed polymers that fluoresced under 365 nm light, which was suggested as a useful feature for anti-counterfeiting marks.[205]

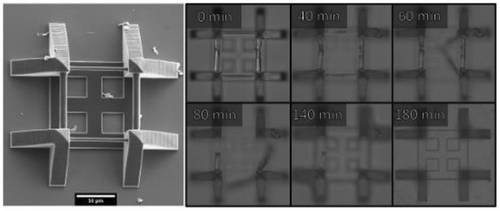

3.2.6 Micro-Structured Polymers

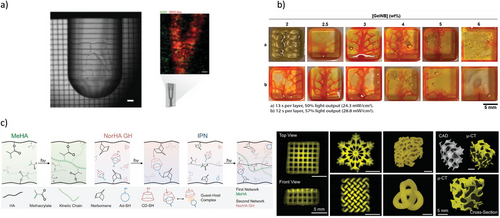

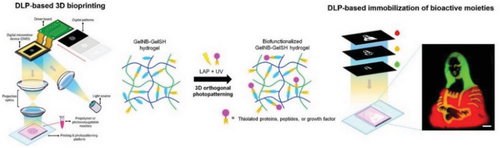

Polymers with micro-level architectures have been identified as promising materials in several applications, including microfluidic devices and biomedical materials. As such, the thiol-ene reaction has been identified as an effective polymerization strategy for photolithography[206] and soft lithography[207-209] of microfluidic devices with 2.5D patterning of hydrophilic/hydrophobic polymers[210] and hydrophilic microfluidic devices.[211] Several early examples of 3D microfluidic devices were prepared using casting and contact liquid photolithographic polymerization (CliPP) fabrication, presenting a viable basis for transfer into other AM technologies.[211, 212] Within this context, an off-stoichiometric approach has been used to DLP print molds for casting microfluidic devices using PDMS.[213] Adding credence to this, a photostructuring effect in off-stoichiometric (excess thiol) monomer compositions can occur. Here, diffusion-induced monomer depletion at the photomask interface can allow intricate composition gradients, thus minimizing feature broadening and enhancing print resolution fidelity.[214] For example, an off-stoichiometric formulation of TATATO with either TMPTMP or PETMP (50% excess thiol) has also been used to produce microfluidic chips using photolithography and soft lithography. The material-induced oxygen scavenging of the off-stoichiometry could be exploited to tailor the oxygen concentration within the microfluidic devices to facilitate physiologically relevant conditions for immobilized enzyme reactors within the polymer.[215] In another example, an off-stoichiometric approach has also been demonstrated using allylsilanes for microfluidics.[216] Moving towards direct AM of microfluidic devices, an early example demonstrating the potential of thiol-ene chemistry within the field used PETMP, TMPTMP, 1,6-HDT, and TEGDAE copolymerized in varying molar ratios using DLS fabrication to produce tailorable, low modulus, microfluidic channels.[212] Within this context, it is known that photoblockers are often imperative to avoid feature broadening in high-resolution photomasking for vat photopolymerized thiol-ene systems, thus facilitating high-resolution fidelity for microfluidics.[207] Lastly, a custom DLP fluorescence microscope has been built that could achieve micro-3D printing. Here, thiol-ene polymers were chosen to obtain high resolutions, adding credence to the capabilities of thiol-ene chemistry for high-resolution AM.[217]

Porous materials offer an alternative mechanism to achieve microfluidic architectures.[218] Microporous structures have been prepared using AM alongside a porogen, which served as a solvent in which the monomer was miscible but the polymer insoluble, thus facilitating polymerization-induced phase separation (PIPS). Here, TMPTMP and TATATO were dissolved in methanol at 60% v/v. Initial runs using photolithography were performed, followed by DIW printing using poly(vinyl alcohol) (PVA) as a binder. Porous structures were then obtained by submersion of the polymer in water, obtaining pores with 66–310 µm diameter.[218] As a greater understanding of PIPS within AM is being established, it may bring more development of its application within the field.[219] Another area of current interest lies in the fabrication of aerogels, which can deliver exceptional specific strength and thermal properties. Given that bulk shape memory aerogels have been demonstrated using thiol-ene networks[220] and the advances in using AM for aerogel fabrication,[221-223] this presents and area of interesting development.

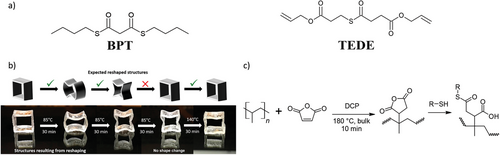

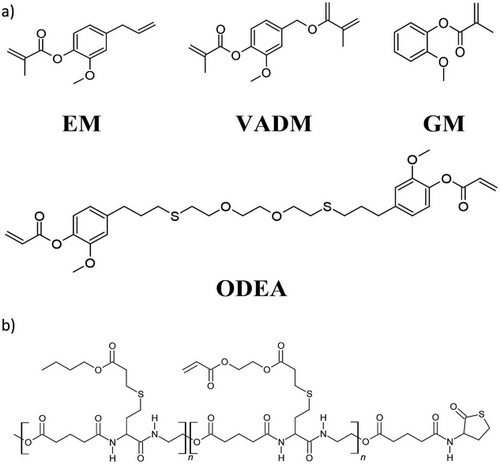

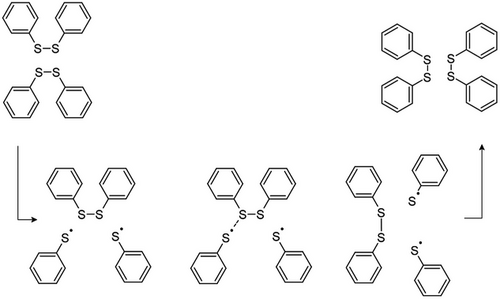

3.2.6.1 Incorporation of Thioesters

Thioester bonds present structural similarity to esters, yet the thioester is relatively more flexible owing to the increased bond length between carbon and sulfur due to the lower polarity of the sulfur atom compared to oxygen.[224, 225] Moreover, owing to their electronic orbital configuration, thioesters are susceptible to nucleophilic attack, making them effective acyl transfer agents.[226] Polymers that contain thioesters and free thiol groups can also undergo transthioesterification, amidation, hydrolysis, and ligation.[227] In an example that produced bulk polymers purely based on thioester bonds, transthioesterification occurred in the presence of a suitable catalyst, such as tin(II) 2-ethylhexanoate (Sn(Oct)2). Here, thioester moieties were introduced using S,S-dibutyl propanebis(thioate) (BPT, Figure 12), and copolymerized alongside PETMP. First, in the absence of Sn(Oct)2, no transthioesterification exchange was observed up to 110 °C. On the other hand, in the presence of 5 mol% Sn(Oct)2, exchange and resultant stress relaxation at temperatures above 100 °C were observed, yet the resultant polymers were creep-resistant at lower temperatures. The thioester-to-thiol molar ratio was adjusted between 0.5 and 0.7 equivalents of thiol, with an optimal ratio of 0.5 equivalents reported. It was also found that dynamic exchange was observed at room temperature in the presence of a tertiary amine and polar solvent. Furthermore, these polymers were depolymerizable for chemical recycling by utilizing a monofunctional thiol, butanethiol, and heating to 90 °C for 9 h. Lastly, the polymers were also biodegradable.[228] To gain a further understanding of the controlled degradation through thiol-thioester exchange this reaction has been modeled, revealing that the oligomer length played a significant role in degradation, while concentration and dispersity of thioesters within the oligomer structure played a less dominant role.[229] Extending this understanding toward AM, a thorough investigation into the thiol-thioester exchange in DLP-printed polymers was conducted. Here, DAA, several thiol comonomers (PETMP, TMPTMP, di-PETMP), alongside a thioester containing monomer (TEDE, Figure 12) were used. Initial kinetic model experiments were performed for the controlled degradation of the thioester polymers using TEA and BMP. This ascertained that an increase in initial free thiol concentration and ratio of base catalyst increased degradation kinetics, while increasing monomer functionality lowered kinetics. Furthermore, the influence of wall thickness on degradation rate of SLA printed polymers showed that for wall thicknesses <<3 mm the rate was independent of thickness as bulk degradation dominated, while at wall thicknesses >>3 mm surface degradation dominated; at 3 mm these models converged as a function of both bulk degradation and surface degradation.[230] The thiol-thioester exchange has also been exploited as a DCC in DLP printed polymers by incorporating TEDE, which was copolymerized with 1,10-decanedithiol (DDT) and PETMP. The printed polymers were semi-crystalline, attributed to a combination of the inclusion pyrogallol as a photoblocker, which could also behave as a nucleating agent, alongside using a decreased light intensity to retard polymerization rate and thus facilitate molecular ordering. Furthermore, adjusting the stoichiometric ratio of thiols, both “tough” (0.95:0.05:0.095 of TEDE-to-PETMP-to DDT) and “elastic” (1:0.15:0.085 of TEDE-to-PETMP-to DDT) polymer networks could be prepared. This molecular tailoring was attributed to an increase in crystallinity and decrease in crosslinking density when excess thiol was present. However, postfabrication annealing at 100 °C for 1 h was imperative to mitigate deleterious effects of crystallization at layer interfaces during 3D printing. After annealing, the polymer displayed UT in excess of 16 MJ cm−3. Alongside these excellent mechanical properties, the polymers were also chemically depolymerizable, reprocessable, shape memory, and self-healing. Here, the polymers were depolymerizable using 8× molar excess in PETMP and 1 molar equivalent TEA in acetone, whereafter the depolymerized mixture could then be directly repolymerized by DLP printing after solvent removal, since the thiol-thioester exchange preserves the functional groups on the monomers. The repolymerized printed polymers displayed only minor decreases in properties compared to original specimens.[231]

Thioesters have also been used to enable controlled degradation in hydrogels, which is of particular value within biomedical contexts.[232] For example, PEG-3SH and PEG 3-arm thioester norbornene monomers were copolymerized using DLP printing to fabricate sacrificial 3D organoid elastomeric hydrogel structures. The use of thioester functional groups within the polymers promoted controlled degradation, whereby dissolution occurred within 2 h when submerged in mercaptoethanol solutions.[233] In another example, DLP printed copolymers of PETMP and TEDE could be tailored by adjusting the stoichiometric ratio of thioester and thiols in the system to tune the depolymerization of the polymers into different molecular weight oligomers, where higher incorporation of thioesters resulted in low viscosity depolymerized oligomers. The depolymerized oligomers could then be repolymerized by DLP printing without appreciable losses in mechanical properties. This conceptual basis was also extended to introducing a variety of different functionality thiol monomers, allowing for tailorable mechanical properties.[234]