Effects of Poly(ethylene glycol), Inorganic Salt, Sodium Dodecyl Sulfate, and Solvent System on Electrospinning of Poly(ethylene oxide)

Abstract

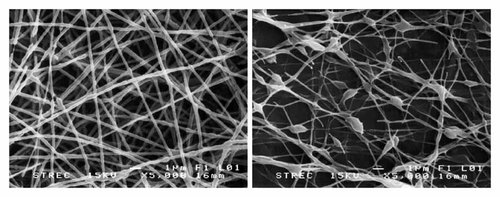

Summary: The effects of PEO concentration, addition of PEG of various molecular weights (1 000–35 000 g · mol−1), inorganic salt of various types (i.e., NaCl, LiCl, KCl, MgCl2, and CaCl2), or SDS, and the solvent system (i.e., mixed solvents of distilled water and methanol, ethanol, or 2-propanol) on the bead formation and/or morphological appearance of electrospun PEO fibers were investigated using SEM. The formation of beaded fibers upon addition of low-molecular-weight PEGs into the PEO solution suggested that the very short relaxation time and/or the plasticizing effect of these low-molecular-weight PEGs contributed to the formation of the bead-on-string morphology of the as-spun fibers. On the other hand, the observed improvement in the electro-spinnability of the PEO solution with increasing PEO concentration and upon addition of NaCl and SDS suggested that the observed increase in the viscosity and conductivity and the observed decrease in the surface tension of the solution were indispensable for total suppression of the beads. However, when the conductivity of the solution increased only marginally, beads could still be obtained.