Corrosion behavior and kinetics model of rare earth low-alloy steel in a soil simulation solution

Abstract

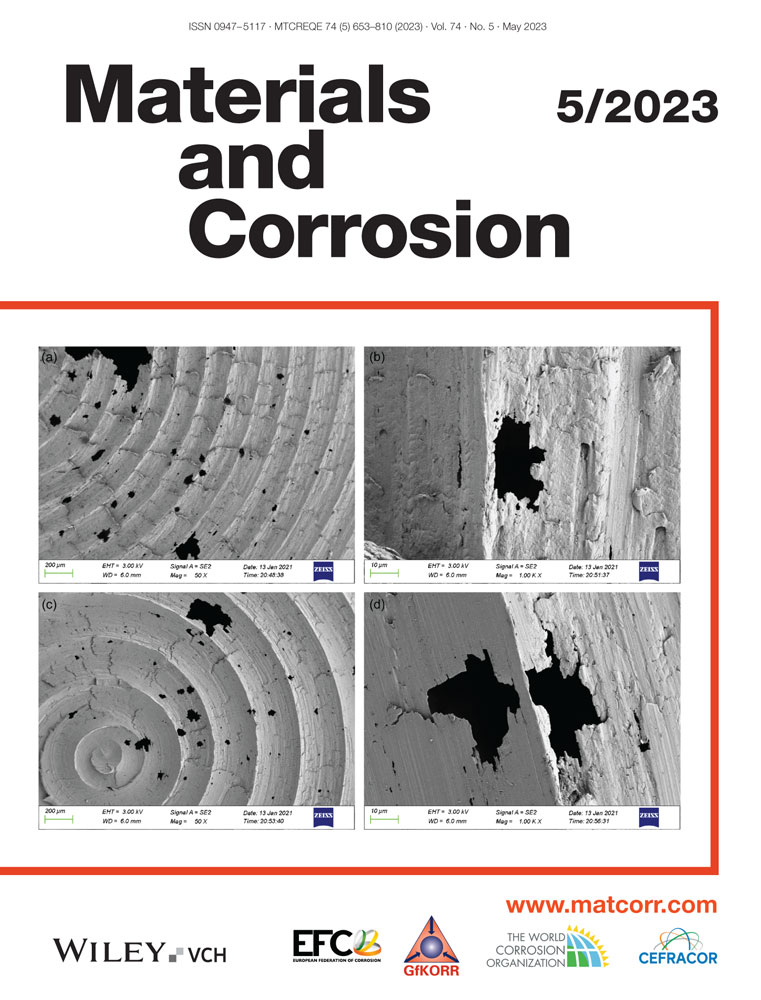

The corrosion behavior of rare earth (RE) low-alloy steel in soil simulation solution was investigated by immersion test, electrochemical experiment, scanning electron microscopy, and X-ray diffraction, compared with Q450 weathering steel. The kinetics model of all steels in soil simulation solution was established. The pitting corrosion mechanism of nonmetallic and RE inclusions was discussed. The results revealed that the RE improved the corrosion resistance of low-alloy steel by modifying inclusions and promoting the formation of a dense protective film. The steel containing 0.0047% RE achieved the best corrosion resistance. The corrosion product layers were mainly composed of γ-FeOOH, α-FeOOH, Fe3O4, and Fe(OH)3. The results of the kinetic model showed that the dissolution of the anode was the restricted link of the whole process. The lowest apparent corrosion rate constant k of the sample containing 0.0047% RE was 2.359 × 10−4 μm/h in the soil simulation solution. The kinetic model could serve as a method to predict the service life of steel parts.

CONFLICT OF INTEREST

The authors declare no conflict of interest.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.