Corrosion characterization of NiTi alloy by femtosecond laser surface processing

Abstract

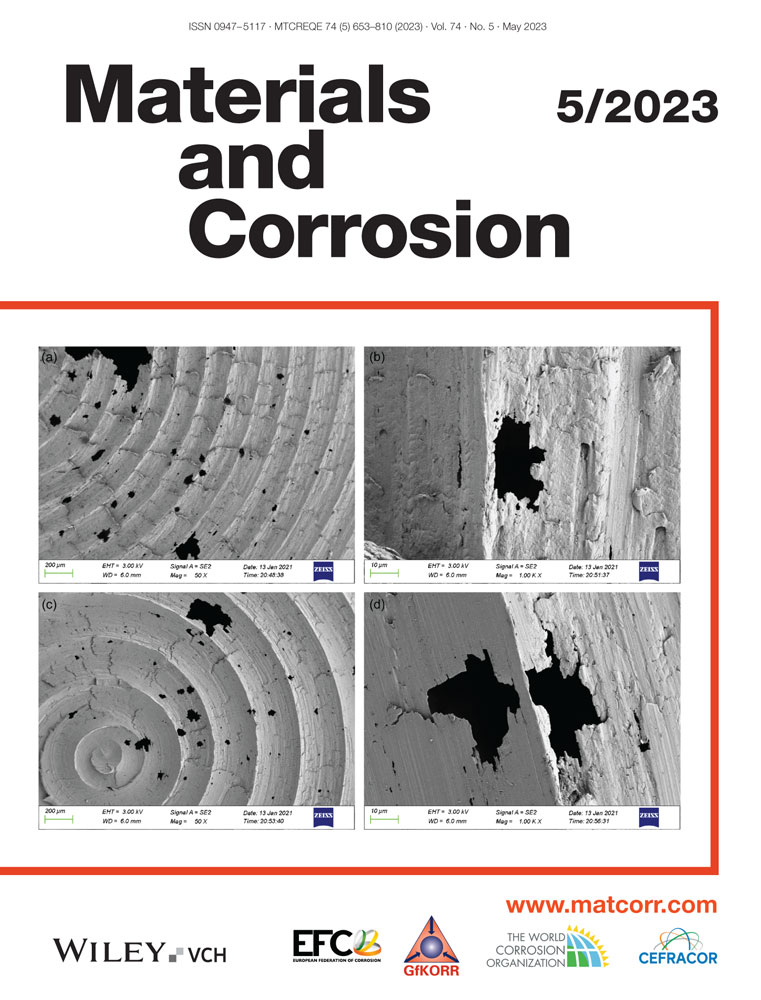

The study of the corrosion resistance of NiTi alloy surfaces with different wettabilities is important to achieve improvements in biocompatibility. In this study, a femtosecond laser was used to process different wettability surfaces on the NiTi alloy. The corrosion resistance of the surfaces was examined via potentiodynamic polarization and electrochemical impedance spectroscopy. Scanning electron microscopy and X-ray photoelectron spectroscopy were used to analyze the morphology and chemical composition of the surfaces. The findings demonstrate that when an original oxide film is destroyed by femtosecond laser processing with a low laser fluence, hydrophilic or hydrophobic surfaces are more vulnerable to erosion. The corrosion resistance of superhydrophilic surfaces is improved to a certain extent, whereas superhydrophobic surfaces exhibit excellent corrosion resistance. Superhydrophilic surfaces are protected from further corrosion by the formation of a dense oxide film after corrosion, whereas superhydrophobic surfaces can inhibit corrosion because of their thicker oxide film and additional air film produced by air trapped in the micro/nanostructure.

CONFLICT OF INTEREST

The authors declare no conflict of interest.

Open Research

DATA AVAILABILITY STATEMENT

Data that support the findings of this study are available from the corresponding author upon reasonable request.