Corrosion news

The German News Section ,,Korrosionsnachrichten“ is available free of charge on the homepage of Materials and Corrosion: www.matcorr.com

The German News Section ,,Korrosionsnachrichten“ is available free of charge on the homepage of Materials and Corrosion: www.matcorr.com

Community News

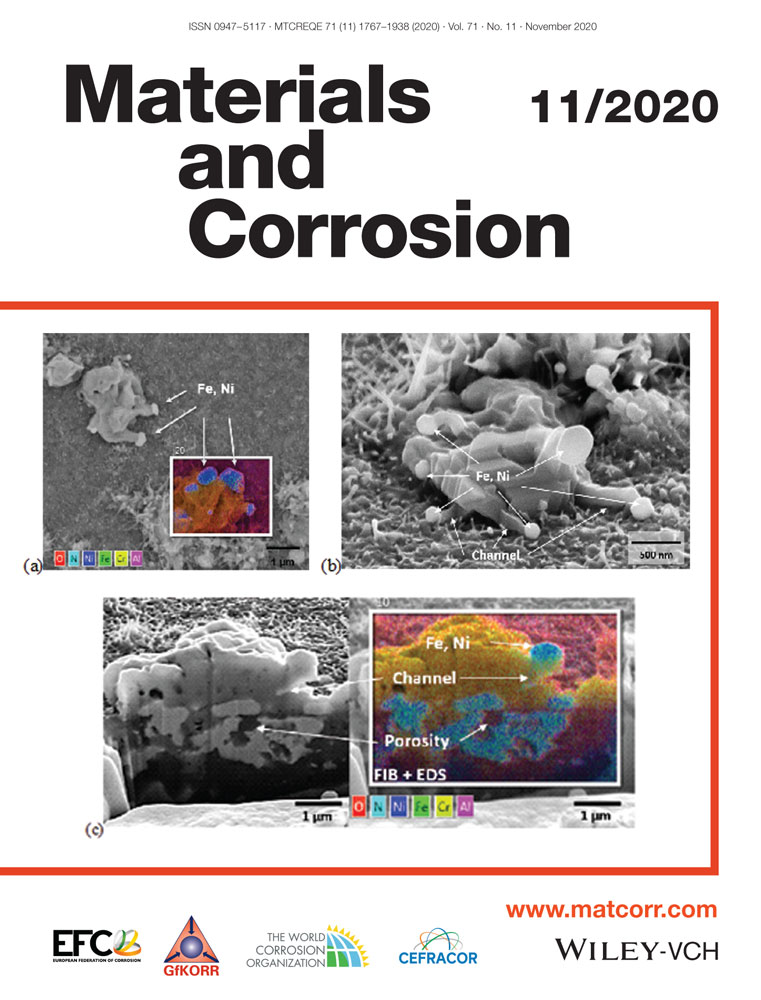

Additive manufacturing of multi-functional parts

Additive manufacturing is currently one of the most significant trends in industry. Now a team from the Fraunhofer Institute for Ceramic Technologies and Systems IKTS has developed a Multi Material Jetting system that allows different materials to be combined into a single additively manufactured part. This makes it possible to create products with combined properties or functions. The new system can be used with particularly high-performance materials such as ceramics and metal.

Additive manufacturing technologies such as 3D printing involve building up a desired product layer by layer instead of producing it from a single piece. This enables high-precision, custom manufacturing with precisely defined product characteristics – and the technology is continuously being improved. Although the early years of additive manufacturing were dominated by polymers, this expanded some time ago to include metals and ceramic-based materials.

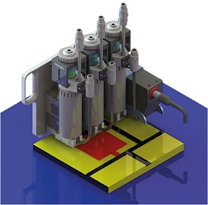

Fraunhofer IKTS has now taken another major step forward. Researchers have developed a system that enables additive manufacturing of multi-material parts based on thermoplastic binder systems. Known as Multi Material Jetting, or MMJ, this process combines different materials and their various different properties into a single product. “Right now, we can process up to four different materials at a time,” says Uwe Scheithauer, a researcher at Fraunhofer IKTS. This opens the door to a diverse range of applications, allowing companies to produce highly integrated multifunctional components with individually defined properties.

Manufacturing products drop by drop

The new system fabricates parts in a continuous process. In the first step, the ceramic or metal powder from which the part will be made is distributed homogenously in a thermoplastic binder substance. The slurries produced in this way are loaded into micro-dosing systems (MDS) to commence the actual manufacturing process. These slurries are melted in the MDS at a temperature of around 100 degrees Celsius, creating a substance that can be released in very small droplets. The IKTS researchers also developed a corresponding software program to ensure precise positioning of the droplets during manufacturing. The micro-dosing systems operate in a high-precision, computer-controlled process, depositing the droplets one by one in exactly the right spot. This gradually builds up the part drop by drop at rates of up to 60 mm and 1,000 drops a second. The system works with droplet sizes of between 300 and 1000 μm, creating deposited layers with heights of between 100 and 200 μm. The maximum size of parts that can currently be manufactured is 20 × 20 × 18 centimeters. “The critical factor here is the custom dosing of the metal or ceramic slurries. Getting the dosing right is key to ensuring that the additively manufactured final product takes on the required properties and functions during subsequent sintering in the furnace, including properties such as strength, thermal conductivity and electrical conductivity,” says Scheithauer.

Ceramic satellite engine with built-in ignition

The new IKTS system can be used to make highly complex parts such as the ignition system in a satellite propulsion engine made of ceramics. Satellite engine combustion chambers reach extremely high temperatures, so the ability of ceramics to withstand heat makes them an ideal choice of material. MMJ can be used to produce an ignition system that is directly integrated within the engine. This ignition system combines electrically conductive and insulating areas in a single, extremely robust component. In this case, the MMJ process requires three dosing systems: one for a support material that disintegrates during heat treatment in the furnace, a second for the electrically conductive component, and a third for the electrically insulating component. MMJ also has plenty of conceivable applications in the consumer products market – for example a two-tone ceramic watch bezel made for an individual customer as a one-off item.

Thanks to its high precision and flexibility, the MMJ system is suitable for more than just manufacturing multifunctional components. “We could also use it to make blanks for carbide parts, for example. Thanks to the tremendous precision of the dosing systems, the contours of the blanks would already be very close to those of the end product. They would therefore require very little subsequent grinding as compared to conventional methods. That's a big advantage when you are working with carbide,” says Scheithauer.

Validation and commercialization

The project at Fraunhofer IKTS has demonstrated that the technology also works in practice and is scalable. The next step is to validate the technology for industrial use. As well as supplying the hardware, Fraunhofer IKTS can also help industry customers develop the materials and software required for process monitoring and automation. Customers can therefore get everything from a single source, all tailored to their specific requirements.

Fig.: System for Multi Material Jetting of high-performance components with combined properties or functions. (© Fraunhofer IKTS)

Fig.: High-precision material deposition at a rate of up to 1,000 drops a second. (© Fraunhofer IKTS)

Fig.: Schematic illustration of the micro-dosing system. (© Fraunhofer IKTS)

For further information, please contact: Uwe Scheithauer, Shaping and Additive Manufacturing, Fraunhofer Institute for Ceramic Technologies and Systems IKTS, Winterbergstr. 28, 01277 Dresden, Germany, Tel.: + 49 351 2553-7671, Fax + 49 351 2554-216, www.ikts.fraunhofer.de –CNE1420

Books

Materials Informatics – Methods, Tools, and Applications, ed. by Oleksandr Isayev, Alexander Tropsha, and Stefano Curtarolo, Wiley-VCH, Weinheim, 2019, 293 pages, 120 figures, 16 tables, 150 $, ISBN: 978-3-527-34121-4 (e-book: 978-3-527-80225-8)

Since data processing has now also found its way into materials science, there has been a great demand from users for a corresponding textbook. This book provides a guide to the latest advances of materials informatics and data mining for materials science. 46 authors introduce readers to methods, present tools and case studies to illustrate the power of materials informatics within this new field of application.

The first chapter deals with the Crystallography Open Database. By this example a historically grown database and its development and perspectives for its future use are presented, showing, how that database can be used.

Another database – the Inorganic Crystal Structure Database (ICSD) – is described as a tool for materials sciences within the next chapter.

In chapter 3 two initiators of the Pauling File project (the world's largest materials database) present their work to get a holistic overview on inorganic compounds from crystal structures and phase diagrams.

Chapter 4 shows the route from topological descriptors to expert systems, discussing differences between topological and crystallographic approaches and their correlations to be used for predicting materials properties.

A high-throughput computational study driven by the AiiDA materials informatics framework and the Pauling File as reference database is shown in chapter 5 as an example for how complex it is to predict novel inorganic solids.

A brief overview on modeling materials quantum properties by machine learning is the content of the 6th chapter, followed by chap-ters on automated computation of materials properties to create new materials, like superalloys, thermoelectrics and magnets.

Cognitive chemistry, as the marriage of machine learning and chemistry, can accelerate materials discovery.

The book ends with a chapter on machine learning interatomic potentials for global optimization and molecular dynamics simulation.

Finally, this book provides an introduction in the methods of materials informatics. Reader can find interesting examples for implementation of informatics in materials science. For materials scientists it provides a slight insight into the thinking of data processing professionals and their view on future materials design. –CBE1520

Ralph Bäßler

Science, Technology and Applications of Metals in Additive Manufacturing, Bhaskar Dutta, Sudarsanam Babu and Bradley Jared, Elsevier, Amsterdam, Oxford, Cambridge, 2019, 351 pages, 206 figures, 11 tables, 155 U$, ISBN: 978-0-12-816634-5

Often 3D-printing and additive manufacturing are mentioned as the 3rd industrial revolution. In this conjunction this book provides a brief overview on additively manufactured metal pieces.

Within 9 chapters authors introduce into the world of additive manufacturing of metals.

After a brief introduction, covering definition, history, technologies, relevance and challenges, the basic manufacturing technologies are described, followed by a comparison of these technologies.

Chapter 4 is dedicated to raw materials to be used for additive manufacturing. Usually powders are used. But some applications use electro-beam or plasma to melt wire material. Microstructure and properties of additively manufactured pieces are described in chapter 5, whereas chapter 6 deals with modeling and simulation of the manufacturing process.

In chapter 7 special aspects necessary to be considered in the design phase are presented. Tools, materials, processing and treatment are some of these aspects, being important for a successful manufacturing. In the chapter on qualification current applicable standards and regulations are addressed. The last chapter gives an overview on market, application, costs and benefits.

All chapters are well structured and equipped with supporting figures. Readers get an insight, showing the advantages and possibilities of this relatively new technology.

Finally, this book fulfills its intension to serve as an educational guide, providing a holistic picture encompassing science, technology and applications for the real-life use of Metal Additive Manufacturing. –CBE1620

Ralph Bäßler

Conferences

Workshop on structural integrity, NDT and CM requirements for industry 4.0

March 9 – 10, 2021, Coventry (United Kingdom)

The British Institute of Non-Destructive Testing (BINDT), in collaboration with the UK Research Centre in Non-Destructive Evaluation (RCNDE) and the UK Forum for Engineering Structural Integrity (FESI), has scheduled a workshop considering the path to Industry 4.0.

Industry 4.0 will completely change the production and operation of nearly every manufactured item in the developed world. Intelligent systems will enhance and sometimes supersede human decision-making in production and operation, and industry will no longer be limited by human cognitive ability. Outcomes will be higher productivity, lower through-life costs and greater safety and reliability, benefitting industry, the global economy and everyone who uses machines or travels in vehicles.

The autonomous, intelligent systems of Industry 4.0 will need high-rate, complex information about operational loads and structural condition, available non-destructively and throughout life, thereby building confidence in their integrity and reducing costs. Assets could become continuously self-verifying, requiring no external intervention to maintain fitness for purpose. There is a need to bridge the emerging gap between current reality and these integrity information requirements: the current state-of-the-art falls significantly short.

What are the specific non-destructive testing (NDT), structural health monitoring (SHM) and condition monitoring (CM) requirements that should be focused on to allow this step change and how will they relate to structural integrity and design philosophies? This will be the focus of the workshop, where experts in these fields will meet with designers, manufacturers and regulators to determine what success will look like, what challenges will be faced and what steps must be taken. For more information, please contact: Conferences and Events Department, The British Institute of Non-Destructive Testing, Midsummer House, Riverside Way, Bedford Road, Northampton NN1 5NX, UK, Tel.: + 44 1604 438-300; Fax: -301; [email protected], www.bindt.org –CCE3020

LCF9 ninth international conference on low cycle fatigue

June 22 – 24, 2021, Berlin (Germany)

Continuing the successful series of LCF conferences established in 1979, the Ninth International Conference on Low Cycle Fatigue (LCF9) will be held in Berlin, Germany, from 22 to 24 June 2021. The permanent and even growing interest of the scientific community in lowcycle fatigue, including thermomechanical fatigue addresses on the one hand a broad range of applications, e.g. in energy technology, transportation, civil engineering, and several other topics. On the other hand, many scientific questions on fundamental deformation and damage mechanisms, influence of multiaxial stresses/strains, creep-fatigue and TMF/HCF interaction as well as crack initiation and growth are investigated with increasing experimental efforts.

As a bridge between fundamental research and application in component and structural design, simulation approaches for cyclic plasticity, crack initiation and growth have made impressive and still continuing progress in the recent decades: FEM-based deformation and life assessment models at different scales, from the microstructure to macroscopic structures, are state-of-the art and under further successful development, especially for reliable design of components undergoing complex thermomechanical loadings. Current research activities show that LCF research keeps being a hot topic in material research and in structural integrity considerations as well.

This development is augmented by the current megatrend in digitalization imposing new challenges in data acquisition and storage in appropriate database structures as well as in data processing and usage of cloud computing approaches in fatigue research which is a-priori associated with handling big data volumes in experiment and simulation. The increase in 2D-3D full-field measurements by image-volume correlation associated to high-fidelity FEM simulations are a major challenge in this context.

The objective of LCF9 is to provide a worldwide platform for scientific communication and discussion as well as a point of origin for collaboration of scientists and engineers interested in fundamental aspects and practical application as well as novel challenges in the context of digitalization.

The conference comprises plenary lectures given by outstanding international scientists and contributed oral presentations.

Topics

-

Isothermal LCF, Thermomecha-nical Fatigue (TMF) and Multiaxial LCF

-

Superimposed LCF/HCF & TMF/HCF Loadings and Creep-Fatigue Interaction

-

In-situ Fatigue Testing

-

Microstructural Aspects of Cyclic Plasticity, Fatigue Damage, Crack Initiation and –Growth

-

Influence of Surface, Environment and Protective Coatings

-

Advanced Materials and Case Studies

-

Novel Experimental Methods and Standardization

-

Deformation & Damage Modelling and Simulation Based Life Assessment

-

Fatigue Research 4.0: Future Approaches in Data Acquisition, Handling and Processing

For more information, please contact: Deutscher Verband für Materialforschung und -prüfung e.V., Gutshaus Steglitz, Schloßstr. 48, Berlin 12165, Tel.: + 49 30 811-3066, Fax: -9359, [email protected], www.dvm-berlin.de –CCE3120

6th international conference on steels in cars and trucks (SCT 2021)

September 5 – 9, 2021, Milan (Italy)

With more than 160 presentations from industry and research summarized in 50 technical sessions, the upscale lecture program promises to be once again highly interesting.

The SCT 2021 topics will be of interest to all engineers from the industrial sector as well as scientists in related disciplines who participate in the event, i. e. the automotive industry with passenger cars, trucks and busses as well as the suppliers and steel industries.

Sustainable reduction of both cost and energy consumption while at the same time improving the safety of vehicles over a complete lifecycle assessment through the optimal integration of steel, design and manufacturing processes plays a leading role in these future trends. The content of the SCT 2021 takes into account the change in driving systems in the global mobility.

The topics

-

Steel Components in Cars and Trucks

-

Manufacturing of Components

-

New high performance Steels

-

Modelling, Simulation and Testing

-

LIGHTWEIGHT forging

-

e-Mobility

For more information, please contact: TEMA Technologie Marketing AG, Carsten Scheele, Aachener-und-Münchener-Allee 9, 52074 Aachen, Germany, Tel.: + 49 241 88970-300, Fax: -999, [email protected], www.sct-2021.com –CCE3220

Calendar of Events

New Entry

New Entry

Conference/Workshop/Symposium

Conference/Workshop/Symposium

Fair

Fair

Course

Course

| December 2020 | ||

2. – 3.12. Dresden (Germany)

|

ALD for Industry |

Europäische Forschungsgesellschaft Dünne Schichten e.V. Dresden Germany |

9. – 11.12. Ingolstadt (Germany)

|

Application and Utilisation of Protective Coatings for Electronic Assemblies |

GfKORR - Gesellschaft für Korrosionsschutz e.V. Frankfurt/Main Germany |

15. – 17.12.

|

Virtual Conference 5th International Conference on Maintenance, Condition Monitoring and Diagnostics, MCMD 2020 |

MCMD 2020 Secretariat Jyväskylä Finland |

| January 2021 | ||

10. – 14.1. Milan (Italy)

|

6th International Conference on Steels in Cars and Trucks, SCT 2021 |

TEMA Technologie Marketing AG Aachen Germany |

| February 2021 | ||

3. – 5.2. Sugar Land, TX (USA)

|

International Chemical and Petroleum Industry Inspection Technology Conference 2021 (ICPIIT 2021) |

American Society for Nondestructive Testing International Service Center Columbus USA |

16. – 17.2. Tokyo (Japan)

|

Stainless Steel World Japan |

Ms Kiyo Ichikawa Conference Organizer |

24. – 25.2. Rotterdam (Netherlands)

|

Duplex World Seminar & Summit 2021 |

Stainless Steel World/KCI GmbH Kleve Germany |

24. – 25.2. Rotterdam (Netherlands)

|

Heat Exchanger World |

John Butterfield |

| March 2021 | ||

1. – 3.3. Darmstadt (Germany)

|

InCeight Casting |

Fraunhofer-Institut für Betriebsfestigkeit und Systemzuverlässigkeit LBF Darmstadt |

9. – 10.3. Coventry (United Kingdom)

|

Workshop on structural integrity, NDT and CM requirements for Industry 4.0 |

Conferences and Events Department The British Institute of Non-Destructive Testing Northampton UK |

23. – 27.3. Bologna (Italy)

|

12th Aluminium Two Thousand World Congress together with the 7th ICEB (International Conference on Extrusion and Benchmark) |

Interall Srl Modena Italy |

22. – 26.3. Bremen (Germany)

|

8th European Coke an Ironmaking Congress (ECIC) and 9th International Conference on Science and Technology of Ironmaking (ICSTI) |

TEMA Technologie Marketing AG Carsten Scheele Aachen Germany |

25. – 28.5. Osaka (Japan)

|

AMSE 2021 - International Conference on Advanced Materials Science and Engineering |

Conference Secretary Ms. Maggie X. Xu |

| April 2021 | ||

18. – 22.4. Salt Lake City, UT (USA)

|

CORROSION 2021 |

NACE International Houston, Texas USA |

21. – 22.4. Bristol (United Kingdom)

|

Aerospace Event 2021 |

Conferences and Events Department The British Institute of Non-Destructive Testing Northampton UK |

28. – 29.4. Aachen (Germany)

|

Advanced Battery Power Conference 2021 |

Haus der Technik e.V. Essen Germany |

| May 2021 | ||

5. – 6.5. Brno (Czech Republic)

|

Stainless 2021 |

Verlag Focus Rostfrei GmbH Xanten Germany |

10. – 12.5. Florence (Italy)

|

Third International Workshop: Analysing Art: New Technologies – New Applications |

Workshop Chair Professor Roman Gr Maev, |

17. – 21.5. San Diego, CA (USA)

|

SMST 2021 Shape Memory and Superelastic Technologies |

ASM World Headquarters Materials Park, OH USA |

19. – 21.5. Osaka (Japan)

|

9th Annual World Congress of Advanced Materials (WCAM-2021) |

Ms. Elsa Wang Program Coordinator of WCAM-2021 |

24. – 27.5. Quebec (Canada)

|

ITSC 2021 International thermal spray conference and exposition “Versatile Surface Engineering for Environmental Solutions” |

ASM World Headquarters Materials Park, OH USA |

27. – 29.5. Istanbul (Turkey)

|

Corrosion and Surface Protection for Steel CASP 2021 |

Turkish Constructional Steelwork Association Istanbul Turkey |

31.5. – 4.6. Incheon (Korea)

|

!POSTPONED! 20th World Conference on Non-Destructive Testing (WCNDT 2020) |

The Korean Society for Nondestructive Testing Seoul Korea |

| June 2021 | ||

8. – 10.6. Antibes Juan-les-Pins (France)

|

7th Days Cathodic Protection & Associated Coatings EFC Event No. 455 |

CEFRACOR Centre Français de l′Anticorrosion Paris France |

14. – 18.6. Frankfurt (Germany)

|

ACHEMA 2021 |

DECHEMA e.V. Frankfurt am Main Germany |

15. – 17.6. Munich (Germany)

|

International Conference on NDE 4.0 |

German Society for Non-Destructive Testing (DGZfP e.V.) Berlin Germany |

20. – 24.6. Vienna (Austria)

|

GALVATECH 2021 |

The Austrian Society for Metallurgy and Materials (ASMET) Leoben Austria |

22. – 24.6. Berlin (Germany)

|

LCF9 Ninth International Conference on Low Cycle Fatigue |

Deutscher Verband für Materialforschung und -prüfung e.V. (DVM) Berlin Germany |

22. – 25.6. Malaga (Spain)

|

Symposium on Corrosion and Surface Protection Methods - CNMAT 2020 EFC Event No. 460 |

Secretaría Técnica Sevilla Spain |

| July 2021 | ||

20. – 23.7. São Paulo (Brazil)

|

21st International Corrosion Congress & the 8th International Corrosion Meeting |

ABRACO – Events Department |

| August 2021 | ||

8. – 13.8. Berlin (Germany)

|

26th International Conference on Structural Mechanics in Reactor Technology |

German Society for Non-Destructive Testing (DGZfP e.V.) Berlin Germany |

| September 2021 | ||

5. – 8.9. Cambridge (United Kingdom)

|

Advances in Corrosion Protection by Organic Coatings – ACPOC EFC Event No. 451 |

Stuart Lyon AkzoNobel Professor of Corrosion Control University of Manchester, [email protected] |

5. – 9.9. Milan (Italy)

|

6th International Conference on Steels in Cars and Trucks SCT 2021 |

TEMA Technologie Marketing AG Aachen Germany |

12. – 16.9. Graz (Austria)

|

EUROMAT 2021 |

The Austrian Society for Metallurgy and Materials (ASMET) Leoben Austria |

13. – 17.9. Aachen (Germany)

|

9th European Oxygen Steelmaking Conference (EOSC) and 6th Clean Technologies in the Steel Industry (CTSI) |

Steel Institute VDEh Dr.-Ing. Hans Bodo Lüngen Düsseldorf Germany |

19. – 23.9. Budapest (Hungary)

|

EUROCORR 2021 |

European Federation of Corrosion c/o DECHEMA e.V. Frankfurt am Main Germany |

| October 2021 | ||

6. – 8.10. Bardolino (Italy)

|

11th European Stainless Steel Conference Science & Market and the 7th European Duplex Stainless Steel |

Siderweb The Italian Steel Company Flero (Brescia) Italy |

| March 2022 | ||

6. – 10.3. San Antonio, TX (USA)

|

CORROSION 2022 |

NACE International Houston, Texas USA |

| August 2022 | ||

28.8. – 1.9. Berlin (Germany)

|

EUROCORR 2022 |

European Federation of Corrosion c/o DECHEMA e.V. Frankfurt am Main Germany |

| March 2023 | ||

19. – 23.3. Denver, CO (USA)

|

CORROSION 2023 |

NACE International Houston, Texas USA |

| September 2023 | ||

3. - 7.9. Dresden (Germany)

|

EUROMAT 2023 |

DGM-Inventum GmbH Sankt Augustin Germany |