In situ study of the deep sea electrochemical performance of aluminum-based galvanic anodes

Abstract

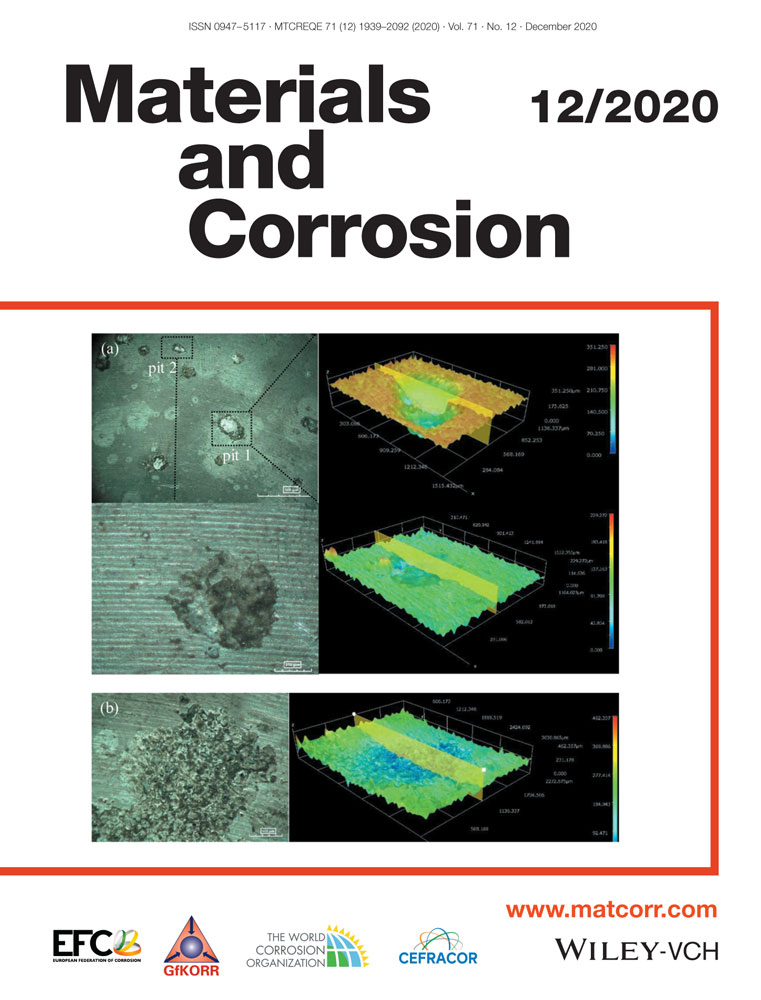

The galvanic performance of Al–Zn–In–Mg–Ti–Ga–Mn and Al–Zn–In–Si anodes was studied in situ in the South China Sea at a depth of 1,420 m when coupled to E355DD structural carbon steel. Deep-sea field tests showed that Al–Zn–In–Mg–Ti–Ga–Mn anode surface degradation mainly occurred via uniform corrosion accompanied by some minor evidence of pitting and intergranular corrosion, whereas the Al–Zn–In–Si anode was subject to extensive intergranular corrosion. Pitting and intergranular corrosion were primary reasons for degrading the galvanic anode performance, and overall the Al–Zn–In–Mg–Ti–Ga–Mn performed better than the Al–Zn–In–Si in the deep-sea environment. There was no evidence that calcareous sediments were deposited on the protected steel surface and the protection current density in the deep sea was 72% higher than that required at the ocean surface.