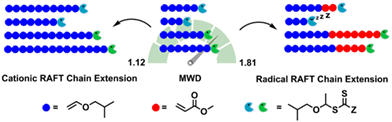

Tuning Polymer Molecular Weight Distribution in Cationic RAFT Polymerization by Mixing Chain Transfer Agents†

Miao Chen

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

Search for more papers by this authorCorresponding Author

Jiajia Li

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

E-mail: [email protected], [email protected]Search for more papers by this authorDong Xing

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

Search for more papers by this authorXiangqiang Pan

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

Search for more papers by this authorCorresponding Author

Jian Zhu

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

E-mail: [email protected], [email protected]Search for more papers by this authorMiao Chen

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

Search for more papers by this authorCorresponding Author

Jiajia Li

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

E-mail: [email protected], [email protected]Search for more papers by this authorDong Xing

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

Search for more papers by this authorXiangqiang Pan

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

Search for more papers by this authorCorresponding Author

Jian Zhu

State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, Jiangsu, 215123 China

E-mail: [email protected], [email protected]Search for more papers by this authorDedicated to the Special Issue of Emerging Themes in Polymer Science.

Comprehensive Summary

Polymer dispersity (Đ) or molecular weight distribution (MWD) is a basic but vital parameter for the properties of polymeric materials. Developing new methodologies for controlling polymer MWD is emerging as a research hotspot. However, the methods to tune polymer MWD in cationic polymerization are still not well explored. Herein, we present a simple method to control the dispersity of poly(isobutyl vinyl ether) (PIBVE) by mixing two different chain transfer agents in batch visible light induced cationic RAFT polymerization. A broad dispersity range (Đ ≈ 1.16—1.80) was successfully achieved while maintaining monomodal MWD. Moreover, chain extension of PIBVE through both cationic polymerization and radical polymerization has been studied, which also provides a method to tune polymer MWD in mechanism transformation polymerization.

Supporting Information

| Filename | Description |

|---|---|

| cjoc202200814-sup-0001-supinfo.pdfPDF document, 1.7 MB |

Appendix S1: Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1 Eric, J. G.; Filip, D. P. Carbocationic polymerizations. Prog. Polym. Sci. 2007, 32, 220–246.

- 2 Kanaoka, S.; Aoshima, S. A Renaissance in Living Cationic Polymerization. Chem. Rev. 2009, 109, 5245–5287.

- 3 Chen, Y.; Zhang, L.; Jin, Y.; Lin, X.; Chen, M. Recent Advances in Living Cationic Polymerization with Emerging Initiation/Controlling Systems. Macromol. Rapid Commun. 2021, 42, e2100148.

- 4 Michaudel, Q.; Kottisch, V.; Fors, B. P. Cationic Polymerization: From Photoinitiation to Photocontrol. Angew. Chem. Int. Ed. 2017, 56, 9670–9679.

- 5 Whitfield, R.; Truong, N. P.; Messmer, D.; Parkatzidis, K.; Rolland, M.; Anastasaki, A. Tailoring Polymer Dispersity and Shape of Molecular Weight Distributions: Methods and Applications. Chem. Sci. 2019, 10, 8724–8734.

- 6 Gentekos, D. T.; Sifri, R. J.; Fors, B. P. Controlling Polymer Properties through the Shape of the Molecular Weight Distribution. Nat. Rev. Mater. 2019, 4, 761–774.

- 7 Rosenbloom, S. I.; Hsu, J. H.; Fors, B. P. Controlling the Shape of the Molecular Weight Distribution for Tailored Tensile and Rheological Properties in Thermoplastics and Thermoplastic Elastomers. J. Polym. Sci. 2022, 60, 1291–1299.

- 8 Kottisch, V.; Gentekos, D. T.; Fors, B. P. “Shaping” the Future of Molecular Weight Distributions in Anionic Polymerization. ACS Macro Lett. 2016, 5, 796–800.

- 9 Gentekos, D. T.; Dupuis, L. N.; Fors, B. P. Beyond Dispersity: Deterministic Control of Polymer Molecular Weight Distribution. J. Am. Chem. Soc. 2016, 138, 1848–1851.

- 10 Whitfield, R.; Truong, N.; Anastasaki, A. Precise Control of Both Dispersity and Molecular Weight Distribution Shape by Polymer Blending. Angew. Chem. Int. Ed. 2021, 60, 19383–19388.

- 11 Tan, R.; Zhou, D.; Liu, B.; Sun, Y.; Liu, X.; Ma, Z.; Kong, D.; He, J.; Zhang, Z.; Dong, X. H. Precise Modulation of Molecular Weight Distribution for Structural Engineering. Chem. Sci. 2019, 10, 10698–10705.

- 12 Wang, T. T.; Wu, Y. Y.; Luo, Z. H.; Zhou, Y. N. “Living” Polymer Dispersity Quantification for Nitroxide-Mediated Polymerization Systems by Mimicking a Monodispersed Polymer Blending Strategy. Macromolecules 2020, 53, 10813–10822.

- 13 Walsh, D. J.; Schinski, D. A.; Schneider, R. A.; Guironnet, D. General Route to Design Polymer Molecular Weight Distributions through Flow Chemistry. Nat. Commun. 2020, 11, 3094–3108.

- 14 Liu, K.; Corrigan, N.; Postma, A.; Moad, G.; Boyer, C. A Comprehensive Platform for the Design and Synthesis of Polymer Molecular Weight Distributions. Macromolecules 2020, 53, 8867–8882.

- 15 Rubens, M.; Junkers, T. Comprehensive Control over Molecular Weight Distributions through Automated Polymerizations. Polym. Chem. 2019, 10, 6315–6323.

- 16 Corrigan, N.; Almasri, A.; Taillades, W.; Xu, J.; Boyer, C. Controlling Molecular Weight Distributions through Photoinduced Flow Polymerization. Macromolecules 2017, 50, 8438–8448.

- 17 Morsbach, J.; Müller, A. H. E.; Berger-Nicoletti, E.; Frey, H. Living Polymer Chains with Predictable Molecular Weight and Dispersity via Carbanionic Polymerization in Continuous Flow: Mixing Rate as a Key Parameter. Macromolecules 2016, 49, 5043–5050.

- 18 Zhou, Y.; Fu, Y.; Chen, M. Facile Control of Molecular Weight Distribution via Droplet-Flow Light-Driven Reversible-Deactivation Radical Polymerization. Chin. J. Chem. 2022, 40, 2305–2312.

- 19 Whitfield, R.; Parkatzidis, K.; Rolland, M.; Truong, N. P.; Anastasaki, A. Tuning Dispersity by Photoinduced Atom Transfer Radical Polymerisation: Monomodal Distributions with ppm Copper Concentration. Angew. Chem. Int. Ed. 2019, 58, 13323–13328.

- 20 Wang, Z.; Yan, J.; Liu, T.; Wei, Q.; Li, S.; Olszewski, M.; Wu, J.; Sobieski, J.; Fantin, M.; Bockstaller, M. R.; Matyjaszewski, K. Control of Dispersity and Grafting Density of Particle Brushes by Variation of ATRP Catalyst Concentration. ACS Macro Lett. 2019, 8, 859–864.

- 21 Plichta, A.; Zhong, M.; Li, W.; Elsen, A. M.; Matyjaszewski, K. Tuning Dispersity in Diblock Copolymers Using ARGET ATRP. Macromol. Chem. Phys. 2012, 213, 2659–2668.

- 22 Wang, J. Y.; Ni, Y. Y.; Cheng, J. N.; Zhang, L. F.; Cheng, Z. P. Molar Mass Dispersity Control by Iodine-Mediated Reversible-Deactivation Radical Polymerization. Chin. J. Polym. Sci. 2021, 39, 1155–1160.

- 23 Li, C.; Han, L.; Bai, H.; Wang, X.; Yin, Y.; Yan, H.; Zhang, X.; Yang, Z.; Liu, P.; Ma, H. Manipulating Molecular Weight Distributions via “Locked-Unlocked” Anionic Polymerization. Macromolecules 2021, 54, 8470–8477.

- 24 Wallace, M. A.; Sita, L. R. Temporal Control over Two- and Three- State Living Coordinative Chain Transfer Polymerization for Modulating the Molecular Weight Distribution Profile of Polyolefins. Angew. Chem. Int. Ed. 2021, 60, 19671–19678.

- 25 Kenyon, P.; Leung, D. W. J.; Turner, Z. R.; Buffet, J. C.; O'Hare, D. Tuning Polyethylene Molecular Weight Distributions Using Catalyst Support Composition. Macromolecules 2022, 59, 3408–3414.

- 26 Wang, D.; Zhou, S.; Liu, Y.; Kang, X.; Liu, S.; Li, Z.; Braunstein, P. Controlling Polyethylene Molecular Weights and Distributions Using Chromium Complexes Supported by SNN-Tridentate Ligands. Macromolecules 2022, 55, 2433–2443.

- 27 Liu, D.; Sponza, A. D.; Yang, D.; Chiu, M. Modulating Polymer Dispersity with Light: Cationic Polymerization of Vinyl Ethers Using Photochromic Initiators. Angew. Chem. Int. Ed. 2019, 58, 16210–16216.

- 28 Liu, X.; Wang, C. G.; Goto, A. Polymer Dispersity Control by Organocatalyzed Living Radical Polymerization. Angew. Chem. Int. Ed. 2019, 58, 5598–5603.

- 29 Chen, M.; Li, J.; Ma, K.; Jin, G.; Pan, X.; Zhang, Z.; Zhu, J. Controlling Polymer Molecular Weight Distribution through a Latent Mediator Strategy with Temporal Programming. Angew. Chem. Int. Ed. 2021, 60, 19705–19709.

- 30 Jia, R.; Tu, Y.; Glauber, M.; Huang, Z.; Xuan, S.; Zhang, W.; Zhou, N.; Li, X.; Zhang, Z.; Zhu, X. Fine Control of the Molecular Weight and Polymer Dispersity via a Latent Monomeric Retarder. Polym. Chem. 2021, 12, 349–355.

- 31 Zhang, M.; Li, J.; Chen, M.; Pan, X.; Zhang, Z.; Zhu, J. Combination of the Photoinduced Atom Transfer Radical Addition Reaction and Living Cationic Polymerization: A Latent Initiator Strategy toward Tailoring Polymer Molecular Weight Distributions. Macromolecules 2021, 54, 6502–6510.

- 32 Xing, D.; Li, J.; Chen, M.; Li, N.; Pan, X.; Zhang, Z.; Zhu, J. Controlling Polymer Molecular Weight Distributions by Light through Reversible Addition-Fragmentation Chain Transfer-Hetero-Diels-Alder Click Conjugation. J. Polym. Sci. 2022, 60, 3463–3460.

- 33 Antonopoulou, M. N.; Whitfield, R.; Truong, N. P.; Wyers, D.; Harrisson, S.; Junkers, T.; Anastasaki, A. Concurrent Control over Sequence and Dispersity in Multiblock Copolymers. Nat. Chem. 2022, 14, 304–312.

- 34 Antonopoulou, M.-N.; Whitfield, R.; Truong, N. P.; Anastasaki, A. Controlling Polymer Dispersity using Switchable RAFT Agents: Unravelling the Effect of the Organic Content and Degree of Polymerization. Eur. Polym. J. 2022, 174, 111326.

- 35 Seno, K. I.; Kanaoka, S.; Aoshima, S. Thermosensitive Diblock Copolymers with Designed Molecular Weight Distribution: Synthesis by Continuous Living Cationic Polymerization and Micellization Behavior. J. Polym. Sci. Part A: Polym. Chem. 2008, 46, 2212–2221.

- 36 Chen, M.; Zhong, M.; Johnson, J. A. Light-Controlled Radical Polymerization: Mechanisms, Methods, and Applications. Chem. Rev. 2016, 116, 10167–10211.

- 37 Corrigan, N.; Jung, K.; Moad, G.; Hawker, C. J.; Matyjaszewski, K.; Boyer, C. Reversible-Deactivation Radical Polymerization (Controlled/ Living Radical Polymerization): From Discovery to Materials Design and Applications. Prog. Polym. Sci. 2020, 111, 101311.

- 38 Parkatzidis, K.; Wang, H. S.; Truong, N. P.; Anastasaki, A. Recent Developments and Future Challenges in Controlled Radical Polymerization: A 2020 Update. Chem 2020, 6, 1575–1588.

- 39 Zhou, Y. N.; Li, J. J.; Wang, T. T.; Wu, Y. Y.; Luo, Z. H. Precision Polymer Synthesis by Controlled Radical Polymerization: Fusing the Progress from Polymer Chemistry and Reaction Engineering. Prog. Polym. Sci. 2022, 130, 101555.

- 40

Thomas, G. M., Fu, Q., Uchiyama, M., Satoh, K., Xu, J., Boyer, C.; Kamigaito, M.; Qiao, G. G. Beyond Traditional RAFT: Alternative Activation of Thiocarbonylthio Compounds for Controlled Polymerization. Adv. Sci. 2016, 3, 1500394.

10.1002/advs.201500394 Google Scholar

- 41 Perrier, S. 50th Anniversary Perspective: RAFT Polymerization-A User Guide. Macromolecules 2017, 50, 7433–7447.

- 42 Nothling, M. D.; Fu, Q.; Reyhani, A.; Allison-Logan, S.; Jung, K.; Zhu, J.; Kamigaito, M.; Boyer, C.; Qiao, G. G. Progress and Perspectives Beyond Traditional RAFT Polymerization. Adv. Sci. 2020, 7, 2001656.

- 43 Uchiyama, M.; Satoh, K.; Kamigaito, M. Cationic RAFT Polymerization using ppm Concentrations of Organic acid. Angew. Chem. Int. Ed. 2015, 54, 1924–1928.

- 44 Uchiyama, M.; Satoh, K.; Kamigaito, M. Cationic RAFT and DT Polymerization. Prog. Polym. Sci. 2022, 124, 101485.

- 45 Guerre, M.; Uchiyama, M.; Folgado, E.; Semsarilar, M.; Améduri, B.; Satoh, K.; Kamigaito, M.; Ladmiral, V. Combination of Cationic and Radical RAFT Polymerizations: A Versatile Route to Well-Defined Poly(ethyl vinyl ether)-Block-Poly(vinylidene fluoride) Block Copolymers. ACS Macro Lett. 2017, 6, 393–398.

- 46 Satoh, K.; Hashimoto, H.; Kumagai, S.; Aoshima, H.; Uchiyama, M.; Ishibashi, R.; Fujiki, Y.; Kamigaito, M. One-Shot Controlled/Living Copolymerization for Various Comonomer Sequence Distributions via Dual Radical and Cationic Active Species from RAFT Terminals. Polym. Chem. 2017, 8, 5002–5011.

- 47 Guerre, M.; Lopez, G.; Améduri, B.; Satoh, K.; Kamigaito, K.; Ladmiral, V. Synthesis of PEVE-b-P(CTFE-alt-EVE) Block Copolymers by Sequential Cationic and Radical RAFT Polymerization. Polym. Chem. 2018, 9, 352–361.

- 48 Rosenbloom, S. I.; Sifri, R. J.; Fors, B. P. Achieving Molecular Weight Distribution Shape Control and Broad Dispersities Using RAFT Polymerizations. Polym. Chem. 2021, 12, 4910–4915.

- 49 Whitfield, R.; Parkatzidis, K.; Truong, N. P.; Junkers, T.; Anastasaki, A. Tailoring Polymer Dispersity by RAFT Polymerization: A Versatile Approach. Chem 2020, 6, 1340–1352.

- 50 Parkatzidis, K.; Truong, N. P.; Antonopoulou, M. N.; Whitfield, R.; Konkolewicz, D.; Anastasaki, A. Tailoring Polymer Dispersity by Mixing Chain Transfer Agents in PET–RAFT Polymerization. Polym. Chem. 2020, 11, 4968–4972.

- 51 Uchiyama, M.; Satoh, K.; Kamigaito, M. A Phosphonium Intermediate for Cationic RAFT Polymerization. Polym. Chem. 2016, 7, 1387–1396.

- 52 Kottisch, V.; Michaudel, Q.; Fors, B. P. Cationic Polymerization of Vinyl Ethers Controlled by Visible Light. J. Am. Chem. Soc. 2016, 138, 15535–15538.

- 53 Perkowski, A. J.; You, W.; Nicewicz, D. A. Visible Light Photoinitiated Metal-Free Living Cationic Polymerization of 4-Methoxystyrene. J. Am. Chem. Soc. 2015, 137, 7580–7583.

- 54 Matsuds, M.; Uchiyama, M.; Itabashi, Y.; Ohkubo, K.; Kamigaito, M. Acridinium salts as photoredox organocatalysts for photomediated cationic RAFT and DT polymerizations of vinyl ethers. Polym. Chem. 2022, 13, 1031–1039.

- 55 Zhang, X.; Jiang, Y.; Ma, Q.; Hu, S.; Liao, S. H. Metal-Free Cationic Polymerization of Vinyl Ethers with Strict Temporal Control by Employing an Organophotocatalyst. J. Am. Chem. Soc. 2021, 143, 6357–6362.

- 56 Yang, Z.; Chen, J.; Liao, S. H. Monophosphoniums as Effective Photoredox Organocatalysts for Visible Light-Regulated Cationic RAFT Polymerization. ACS Macro Lett. 2022, 11, 1073–1078.

- 57 Hartlieb, M. Photo-Iniferter RAFT Polymerization. Macromol. Rapid Commun. 2022, 43, 2100514.