Liquid-Crystalline Soft Actuators with Switchable Thermal Reprogrammability

Yahe Wu

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorDr. Yang Yang

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorXiaojie Qian

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorDr. Qiaomei Chen

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorProf. Yen Wei

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Department of Chemistry, Center for Nanotechnology and Institute of Biomedical Technology, Chung-Yuan Christian University, Chung-Li, 32023 Taiwan, China

Search for more papers by this authorCorresponding Author

Prof. Yan Ji

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorYahe Wu

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorDr. Yang Yang

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorXiaojie Qian

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorDr. Qiaomei Chen

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Search for more papers by this authorProf. Yen Wei

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

Department of Chemistry, Center for Nanotechnology and Institute of Biomedical Technology, Chung-Yuan Christian University, Chung-Li, 32023 Taiwan, China

Search for more papers by this authorCorresponding Author

Prof. Yan Ji

The Key Laboratory of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing, 100084 China

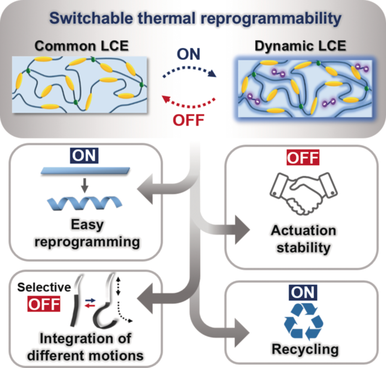

Search for more papers by this authorGraphical Abstract

The old switcheroo: Soft actuators with switchable thermal reprogrammability have been developed. By flexibly switching on/off network dynamics, easy reprogramming and excellent actuation stability can be achieved, as well as efficient recycling and seamless integration of different motions in a very common siloxane liquid crystalline elastomer.

Abstract

Thermal reprogrammability is essential for new-generation large dry soft actuators, but the realization sacrifices the favored actuation performance. The contradiction between thermal reprogrammability and stability hampers efforts to design high-performance soft actuators to be robust and thermally adaptable. Now, a strategy has been developed that relies on repeatedly switching on/off thermal reprogrammability in liquid-crystalline elastomer (LCE) actuators to resolve this problem. By post-synthesis swelling, a latent siloxane exchange reaction can be induced in the common siloxane LCEs (switching on), enabling reprogramming into on-demand 3D-shaped actuators; by switching off the dynamic network by heating, actuation stability is guaranteed even at high temperature (180 °C). Using partially black-ink-patterned LCEs, selectively switching off reprogrammability allows integration of completely different actuation modes in one monolithic actuator for more delicate and elaborate tasks.

Conflict of interest

The authors declare no conflict of interest.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie201915694-sup-0001-misc_information.pdf3.5 MB | Supplementary |

| anie201915694-sup-0001-Movie_S1.mp43.2 MB | Supplementary |

| anie201915694-sup-0001-Movie_S2.mp43.2 MB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1

- 1aL. Hines, K. Petersen, G. Z. Lum, M. Sitti, Adv. Mater. 2017, 29, 1603483;

- 1bJ. A. Lv, Y. Liu, J. Wei, E. Chen, L. Qin, Y. Yu, Nature 2016, 537, 179–184;

- 1cG. M. Whitesides, Angew. Chem. Int. Ed. 2018, 57, 4258–4273; Angew. Chem. 2018, 130, 4336–4353;

- 1dY. Dong, J. Wang, X. Guo, S. Yang, M. O. Ozen, P. Chen, X. Liu, W. Du, F. Xiao, U. Demirci, B. F. Liu, Nat. Commun. 2019, 10, 4087.

- 2

- 2aX. Le, W. Lu, J. Zhang, T. Chen, Adv. Sci. 2019, 6, 1801584;

- 2bA. W. Hauser, A. A. Evans, J. H. Na, R. C. Hayward, Angew. Chem. Int. Ed. 2015, 54, 5434–5437; Angew. Chem. 2015, 127, 5524–5527;

- 2cL. T. de Haan, J. M. Verjans, D. J. Broer, C. W. Bastiaansen, A. P. Schenning, J. Am. Chem. Soc. 2014, 136, 10585–10588;

- 2dJ. Cao, C. Zhou, G. Su, X. Zhang, T. Zhou, Z. Zhou, Y. Yang, Adv. Mater. 2019, 31, 1900042.

- 3

- 3aB. Jin, H. Song, R. Jiang, J. Song, Q. Zhao, T. Xie, Sci. Adv. 2018, 4, eaao 3865;

- 3bM. K. McBride, A. M. Martinez, L. Cox, M. Alim, K. Childress, M. Beiswinger, M. Podgorski, B. T. Worrell, J. Killgore, C. N. Bowman, Sci. Adv. 2018, 4, eaat 4634;

- 3cM. Lahikainen, H. Zeng, A. Priimagi, Nat. Commun. 2018, 9, 4148;

- 3dZ. Jiang, Y. Xiao, X. Tong, Y. Zhao, Angew. Chem. Int. Ed. 2019, 58, 5332–5337; Angew. Chem. 2019, 131, 5386–5391;

- 3eX. Qian, Q. Chen, Y. Yang, Y. Xu, Z. Li, Z. Wang, Y. Wu, Y. Wei, Y. Ji, Adv. Mater. 2018, 30, 1801103.

- 4

- 4aA. Lendlein, O. E. C. Gould, Nat. Rev. Mater. 2019, 4, 116–133;

- 4bM. Behl, K. Kratz, J. Zotzmann, U. Nochel, A. Lendlein, Adv. Mater. 2013, 25, 4466–4469;

- 4cZ. Pei, Y. Yang, Q. Chen, E. M. Terentjev, Y. Wei, Y. Ji, Nat. Mater. 2014, 13, 36–41;

- 4dY. Yang, E. M. Terentjev, Y. Zhang, Q. Chen, Y. Zhao, Y. Wei, Y. Ji, Angew. Chem. Int. Ed. 2019, 58, 17474–17479; Angew. Chem. 2019, 131, 17635–17640.

- 5G. M. Scheutz, J. J. Lessard, M. B. Sims, B. S. Sumerlin, J. Am. Chem. Soc. 2019, 141, 16181–16196.

- 6

- 6aL. Wang, M. Y. Razzaq, T. Rudolph, M. Heuchel, U. Nöchel, U. Mansfeld, Y. Jiang, O. E. C. Gould, M. Behl, K. Kratz, A. Lendlein, Mater. Horiz. 2018, 5, 861–867;

- 6bY. Yang, Z. Pei, Z. Li, Y. Wei, Y. Ji, J. Am. Chem. Soc. 2016, 138, 2118–2121;

- 6cY. Y. Xiao, Z. C. Jiang, X. Tong, Y. Zhao, Adv. Mater. 2019, 31, 1903452;

- 6dA. H. Gelebart, D. J. Mulder, G. Vantomme, A. Schenning, D. J. Broer, Angew. Chem. Int. Ed. 2017, 56, 13436–13439; Angew. Chem. 2017, 129, 13621–13624.

- 7

- 7aT. J. White, D. J. Broer, Nat. Mater. 2015, 14, 1087–1098;

- 7bA. Buguin, M.-H. Li, P. Silberzan, B. Ladoux, P. Keller, J. Am. Chem. Soc. 2006, 128, 1088–1089;

- 7cC. Ohm, M. Brehmer, R. Zentel, Adv. Mater. 2010, 22, 3366–3387;

- 7dT. H. Ware, M. E. McConney, J. J. Wie, V. P. Tondiglia, T. J. White, Science 2015, 347, 982–984;

- 7eH. F. Lu, M. Wang, X. M. Chen, B. P. Lin, H. Yang, J. Am. Chem. Soc. 2019, 141, 14364–14369;

- 7fY. Xia, X. Zhang, S. Yang, Angew. Chem. Int. Ed. 2018, 57, 5665–5668; Angew. Chem. 2018, 130, 5767–5770.

- 8

- 8aQ. Chen, Y. Li, Y. Yang, Y. Xu, X. Qian, Y. Wei, Y. Ji, Chem. Sci. 2019, 10, 3025–3030;

- 8bZ. Wang, H. Tian, Q. He, S. Cai, ACS Appl. Mater. Interfaces 2017, 9, 33119–33128;

- 8cX. Lu, S. Guo, X. Tong, H. Xia, Y. Zhao, Adv. Mater. 2017, 29, 1606467;

- 8dT. Ube, K. Kawasaki, T. Ikeda, Adv. Mater. 2016, 28, 8212–8217.

- 9W. Denissen, M. Droesbeke, R. Nicolay, L. Leibler, J. M. Winne, F. E. Du Prez, Nat. Commun. 2017, 8, 14857.

- 10

- 10aR. C. Osthoff, A. M. Bueche, W. T. Grubb, J. Am. Chem. Soc. 1954, 76, 4659–4663;

- 10bW. Zou, J. Dong, Y. Luo, Q. Zhao, T. Xie, Adv. Mater. 2017, 29, 1606100;

- 10cP. Zheng, T. J. McCarthy, J. Am. Chem. Soc. 2012, 134, 2024–2027;

- 10dW. Schmolke, N. Perner, S. Seiffert, Macromolecules 2015, 48, 8781–8788;

- 10eN. Zheng, J. Hou, H. Zhao, J. Wu, Y. Luo, H. Bai, J. A. Rogers, Q. Zhao, T. Xie, Adv. Mater. 2019, 31, 1807326.

- 11

- 11aM. Camacho-Lopez, H. Finkelmann, P. Palffy-Muhoray, M. Shelley, Nat. Mater. 2004, 3, 307–310;

- 11bM. Wang, B.-P. Lin, H. Yang, Nat. Commun. 2016, 7, 13981;

- 11cI. A. Rousseau, P. T. Mather, J. Am. Chem. Soc. 2003, 125, 15300–15301;

- 11dY. Ji, Y. Y. Huang, R. Rungsawang, E. M. Terentjev, Adv. Mater. 2010, 22, 3436–3440;

- 11eC. Wang, K. Sim, J. Chen, H. Kim, Z. Rao, Y. Li, W. Chen, J. Song, R. Verduzco, C. Yu, Adv. Mater. 2018, 30, 1706695;

- 11fA. Agrawal, A. C. Chipara, Y. Shamoo, P. K. Patra, B. J. Carey, P. M. Ajayan, W. G. Chapman, R. Verduzco, Nat. Commun. 2013, 4, 1739.

- 12M. P. Wolf, G. B. Salieb-Beugelaar, P. Hunziker, Prog. Polym. Sci. 2018, 83, 97–134.

- 13

- 13aB. Donnio, H. Wermter, H. Finkelmann, Macromolecules 2000, 33, 7724–7729;

- 13bH. Finkelmann, H. J. Kock, G. Rehage, Macromol. Rapid Commun. 1981, 2, 317–322.

- 14

- 14aY. Liu, J. K. Boyles, J. Genzer, M. D. Dickey, Soft Matter 2012, 8, 1764–1769;

- 14bJ. Li, R. Zhang, L. Mou, M. Jung de Andrade, X. Hu, K. Yu, J. Sun, T. Jia, Y. Dou, H. Chen, S. Fang, D. Qian, Z. Liu, Adv. Funct. Mater. 2019, 1808995.

- 15

- 15aD. Rus, M. T. Tolley, Nature 2015, 521, 467–475;

- 15bS. A. Morin, R. F. Shepherd, S. W. Kwok, A. A. Stokes, A. Nemiroski, G. M. Whitesides, Science 2012, 337, 828–832.

- 16H. Finkelmann, S. T. Kim, A. Munoz, P. Palffy-Muhoray, B. Taheri, Adv. Mater. 2001, 13, 1069–1072.

- 17Post-synthesis swelling method to switch on network dynamics: The catalyst solution was prepared by dissolving a certain amount of TMA-DMSiO in chloroform. The cured samples (including PDMS and LCE used in this work) were immersed in the solution for 8 h to make the siloxane exchange catalyst enter into the elastomer network through the swelling process. The swollen samples were vacuum dried in the vacuum oven at 30 °C for 24 h to evaporate the solvent.

- 18Preparation of stable siloxane LCE actuators and re-switching on the reprogrammability: The swelling-processed LCE specimen was first deformed into the desired shape by external force or/and using a proper mold. For example, the monodomain one was prepared by uniaxially stretching the film to 130% of its initial length; the bent one was obtained by winding the film around a PTFE pillar (diameter: 1 cm) for a half circle; the helicoidal one was prepared by stretching the film while spiraling it around an iron wire (diameter: 0.5 mm). The deformation was immobilized by Teflon tapes during the following heating processes. The convex actuator was prepared by placing a square LCE sheet on a home-made pin-shaped mold and fixing the deformation by a complementary hole mold. Then, the deformed samples were heated at 100 °C for 1 h to complete network rearrangement. After that, to obtain stable actuators, the final step was to keep heating the deformed samples at 150 °C to quench the catalyst and cool naturally (switching off). If the network-deactivated LCEs need to be reprogrammed once more, the catalyst (TMA-DMSiO) can be introduced into the network via the swelling process again.

- 19Seamless integration of different actuation modes: Black ink patterned LCE sample was prepared by dipping black ink onto the certain region of the swelling-drying-processed LCE and drying the sample in the oven at 60 °C for 4 h. The lower half of the sample was winded around a PTFE pillar (diameter 1 cm) for three quarters of a circle, then irradiated by low-intensity NIR (0.21 w cm−2) for 1 h (temperature 105 °C), followed by irradiated by high-intensity NIR (0.40 w cm−2) for 30 min (temperature: 160 °C). Then, the whole sample was uniaxially stretched to 130 % of its original length, and directly heated in the oven at 100 °C for 1 h and at 150 °C for 1 h.