Characteristics of Fresh and Hardened Sustainable Foamed Concrete for Structural Applications

Abstract

In light of the trends towards producing sustainable lightweight concrete and utilizing local resources and recycled materials, this study explored these possibilities. Foamed concrete is considered ecofriendly because of its lightweight, excellent thermal and acoustic insulation properties, and low environmental impact. Most previous research focused on the properties of foam concrete, whose compressive strength does not exceed 10–15 MPa and is used for nonstructural purposes. However, through this work, foam concrete mixtures were produced with a compressive strength of about 23 MPa, which opens the way for their application in structural members. In this work, foamed concrete was produced to examine the possibility of meeting structural and sustainability requirements with foamed concrete. The properties of this produced concrete were investigated through four sets of tests: tests in the fresh state, including a flow test; tests related to the durability of concrete, or what is called permeation properties, including water absorption, sorptivity, and porosity tests; tests for hardened concrete related to strength, including compressive and indirect tensile tests; and finally, a microstructure test, including a scanning electron microscopy (SEM) test. As a means of improving strength and reducing the use of cement, cement was partially replaced with waste glass powder (WGP), and fly ash was used as cementing material, in addition to the use of superplasticizer and silica sand to produce concrete foam with structural strength. The fresh mix densities all fell within the range for lightweight concrete. The 28-day compressive strength of the mix with the superplasticizer and WGP was moderate, approximately 37.6% greater than that of the control mix, and that of the mix with the superplasticizer alone was approximately 35.9% greater. WGP had a marginal effect on compressive strength. Adding superplasticizer alone reduced the porosity and sorptivity by 32.3% and 63.9%, respectively. Adding WGP alone or with a superplasticizer reduced porosity and sorptivity, but the differences remained insignificant relative to the mix without any additions. The superplasticizer reduced water absorption by approximately 35.9% compared to WGP alone, which only slightly reduced water absorption, or with WGP and the superplasticizer together. The superplasticizer increased the 28-day tensile and flexural strengths by up to 40.5% and 32.1%, respectively, relative to the control mix. Silica sand proved to be a good alternative to normal sand in foamed concrete mixes. For all mixes, the foamed concrete produced exhibited a foamed structure with numerous pores.

1. Introduction

Foamed concrete (FC) can be described as lightweight cellular concrete because it is relatively light, has a density ranging from 400 to 1850 kg/m3, and contains irregular air voids generated in mortar when a foaming agent is added to a fresh mixture or preformed foam is added. Like conventional concrete, FC requires sand and cement, which raises some environmental and sustainability concerns [1]. Silica (SiO₂) sand is a natural sand with a white color, feathered ceramic structure, and a high SiO₂ content (as high as 99%). As a mineral, SiO₂ sand ranks among the most plentiful substances on earth; it can also be acquired as a secondary product from the glass, foundry, and paint industries. The SiO₂ content of SiO₂ sand is high because of the presence of quartz (usually under inert conditions). In contrast to ordinary sands, which are used only for their physical characteristics, SiO₂ sands are valued for both their physical and chemical characteristics. They contain extremely small amounts of impurities, such as clay, iron oxides, and heat-resistant minerals, such as chromite. Their grain size distribution is generally narrow (typically between 0.1 and 2 mm) [2]. There is a strong global trend towards reducing waste through recycling and reuse, and a lot of waste has been incorporated into concrete, and sometimes more than one type of waste is used in concrete to improve one or more of its properties [3].

To improve concrete properties, many materials from waste have been used in concrete as a powder to replace cement partially, like fly ash (FA), SiO₂ fume from waste [4], glass waste powder [5], and SiO₂ fume [6]. WG has positive and negative effects on concrete properties. The weight of concrete decreases as the proportion of WG used as aggregate increases. The compressive strength of concrete decreases with increasing WG content because of poor adhesion between the cement paste and WG. Shrinkage decreases with increasing WG content because WG does not absorb water, so it reduces the heat of hydration [7]. Therefore, it is essential to use an appropriate proportion of WG as aggregate to ensure the concrete’s longevity, strength, and overall performance. Coal FA is primarily produced in power plants as a by-product of coal combustion. The composition of FA varies tremendously depending on the type of coal burned, the state of combustion, cooling control, and burning. A portion of the Portland cement (PC) may be substituted with various complementary substances collected from residues of industrial activities, such as FA. The use of such complementary materials can enhance the hardened concrete’s characteristics and also reduce the carbon emissions associated with concrete production. Using FA as a partial substitute for PC in concrete can decrease the associated greenhouse gas (GHG) emissions by 80% [6]. FA can improve concrete’s workability by reducing bleeding. FA has also been shown to enhance the long-term compressive strength of conventional and recycled aggregate concrete.

FC was invented in 1923, and its use in construction as a lightweight nonstructural or semistructural material has increased in recent years [8]. FC is characterized by its excellent flowability, low cement content, minimal aggregate use, and good thermal insulation. FC is also considered a cost-effective, ecofriendly, lightweight structural substance that is fire-resistant and offers insulation from heat and noise. FC’s exceptional resistance to fire, low heat conductivity, and excellent sound absorption are attributable to its surface texture and cellular microstructure. The compressive strength of traditional FC is typically low (1–10 MPa), making it ideal for use as a void filler and in trench resurfacing. Several years ago, a high-strength FC was patented, with a low water/binder ratio achieved using an ultrafine powder of SiO₂ fume and FA in the absence of sand. FC can achieve compressive strengths up to 60 MPa when cured under controlled conditions, consistent with the relationships among pore size, density, and compressive strength [9].

In 2021, Obaid and Hilal [10] found that substituting traditional sand with microscale SiO₂ sand increased the strength of FC by 169%, reduced water absorption by 38%, and reduced shrinkage by 40%. In 2021, Krishna et al. [11] examined the properties of fresh and hardened FC with FA partially substituted for cement and found that the compressive strength decreased with increasing FA content. FA substitution ratios of 25%, 50%, and 75% corresponded to compressive strength reductions of 24.12%, 37.75%, and 40.85%, respectively, for a density of 800 kg/m3. The consistency (as measured by the flow time) of the FC decreased as the FA ratio increased, and the workability (as measured by the slump) increased. In 2021, Jose et al. [12] reported that a 40% substitution of cement with FA by weight increased the compressive strength by 14.15%. In 2022, Khan et al. [13] studied the effects of FA and SiO₂ sand on FC’s compressive strength and found that replacing coarse sand with FA improved the compressive strength by up to 30%. Similarly, 10% finer SiO₂ increased the compressive by between 5.5 and 9.2 MPa. In 2023, Maglad et al. [14] investigated the effects of substituting sand with glass sheet powder (GSP) on the fresh, mechanical, and microstructural properties of FC and found that a 20% substitution increased the compressive, split tensile, and flexural strengths by as much as 18%, 40%, and 33%, respectively. Initial and final setting times increased by 63% and 31%, respectively, when the substitution percentage was increased to 50%. The addition of GSP decreased the concrete’s porosity, adsorption, and water absorption and enhanced its microstructure.

The lighter the structural element, the less the dead load, thus reducing the load on the foundations, leading to less reinforcing and thinner sections, which means less cost, and this achieves economic gains. In order for concrete to be classified as structural concrete, its compressive strength must not be less than 17 MPa. There is a strong global trend towards reducing waste through recycling and reuse. Within the framework of concrete production, a lot of waste appeared that was used in concrete as a partial replacement of aggregate [15] or cement [16]. It helped produce concrete with new properties that have multiple applications. If the glass waste is ground into a fine powder that passes through a 75 μm sieve, it will work as an effective pozzolanic material that contributes to effectively improving the compressive strength [16]. Hence, the idea came to use it to produce foam concrete with structural strength. Therefore, it will help reduce local glass waste and produce foam concrete with acceptable structural strength and lightweight at the same time. Therefore, producing structural foam concrete that achieves the required strength and is light in weight will be an important breakthrough in the construction sector. Most previous research focused on the properties of foam concrete, whose compressive strength does not exceed 10 MPa and is used for nonstructural purposes. However, through this work, foam concrete mixtures were produced with a compressive strength of about 23 MPa, which opens the way for their application in structural members. In this work, FC was produced to examine the possibility of meeting structural and sustainability requirements with FC. The properties of this produced concrete were investigated through four sets of tests: tests in the fresh state, including a flow test; tests related to the durability of concrete, or what is called permeation properties, including water absorption, sorptivity, and porosity tests; tests for hardened concrete related to strength, including compressive and indirect tensile tests; and finally, a microstructure test, including a scanning electron microscopy (SEM) test. As a means of improving strength and reducing the use of cement, cement was partially replaced with waste glass powder (WGP), and FA was used as a cementing material, in addition to the use of superplasticizer and SiO₂ sand to produce concrete foam with structural strength.

2. Experimental Program

2.1. Materials

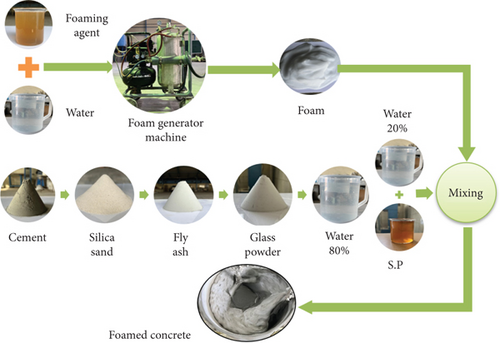

The cement chosen for the mixes prepared was ordinary Portland cement (OPC), which was tested and found to conform to Iraqi Standard Specification IQS No. 5, 2019 [17]. Normal sand (from the quarry east of Ramadi, Iraq) and SiO₂ sand (from the Rutba region, Iraq) with a maximum particle size of 2.36 mm were used as the fine aggregates in the mixes. The fine sand met Iraqi specification No. 45/1984 Zone-II [18]. Broken glass pieces were collected, washed, cleaned, and crushed into smaller pieces. These crushed glass pieces were then ground into powder using a specialized crushing device, and the WGP was sieved on sieve No. 200 (75 μm). Approximately 70% of the WGP prepared was pozzolanic; the remaining 30% served as filler, as per ASTM C618-19 [19]. The FA Type-F manufactured by Eurobuild, according to British standards, was tested and found to conform to ASTM C618-12 [20]. A solution of approximately 40 g of foaming agent per litre of water was used and produced foam with an average density of 40 kg/m3. The superplasticizer used in the concrete mixes produced in this study was Sika-ViscoCrete-180 GS, at a dosage conforming to ASTM C494, Kind F & G [21]. Characteristics of the superplasticizer are provided in Table 1. The water used to prepare and pour the mixes and cast and cure the samples conformed to IQS1703/1992 [22]. Figure 1 illustrates the types of ingredients used in all tested mixtures. Tests were conducted to pinpoint and confirm the compliance of the cement, FA, and WGP (according to limited standards regarding its chemical characteristics), as summarized in Table 2.

| Characteristics | Description |

|---|---|

| Appearance and color | Light brownish |

| Specific gravity | 1.070 g/cm3 |

| pH value | 4–6 |

| Recommended dosage | 0.5%–2% by weight of total cementitious materials |

| Composition | Aqueous solution of modified polycarboxylates |

| Cement | ||

|---|---|---|

| Oxide composition | Content (%) | IQS No. 5, 2019 |

| Lime (CaO) | 62.2 | — |

| Silica (SiO2) | 21.7 | — |

| Alumina (Al2O3) | 2.19 | — |

| Iron oxide (Fe2O3) | 3.77 | — |

| “Lime saturation factor” (LSF) | 0.96 | “0.66–1.02” |

| Magnesium oxide (MgO) | 3.52 | < 5% |

| Sulphate trioxide (SO3) | 2.48 | < 2.8% |

| “Loss on ignition” (LOI) | 2 | < 4% |

| Insoluble residue | 0.92 | < 1.5% |

| Fly ash | ||

| Oxide composition | Content (%) | ASTM C618-12 |

| Lime (CaO) | 4.8% | — |

| Silica (SiO2) | 45.2% | — |

| Alumina (Al2O3) | 28.3% | — |

| Iron oxide (Fe2O3) | 16.4% | — |

| Lime saturation factor (LSF) | 0.02% | — |

| Magnesium oxide (MgO) | 2.4% | ≤ 5% |

| Sulphate trioxide (SO3) | 0.37% | ≤ 5% |

| WGP | ||

| Ingredient | Results | |

| Sulphate content (SO3) | 0.009% | |

| Total suspended solids (TSSs) | 0.078% | |

| Specific gravity | 3.11 | |

| % pass from sieve 75 μm | 98.9% | |

2.2. Mixing Proportions and Procedure

All constituents were divided into two equal parts except the glass powder, all of which was heated in an oven at 100° for 2 min. This process helps to minimize thermal gradients, reducing the risk of cracking or other thermal stress-related issues in the concrete [23]. The superplasticizer was diluted with 20% of the required water after separating this amount from the total amount for mixtures for which it was contended. The fine aggregate, cement, and FA were added in that order by half the amount necessary for every batch. The glass powder was removed from the oven and added in the necessary amount directly into the mixture for which it was contended.

The remaining halves of the quantities of the divided constituents were added but in reverse sequence, with the earlier half of the FA, cement, and fine aggregate placed in the mixture at the end. All dry ingredients were added and blended for approximately 3–4 min.

Following the mixing of the dry constituents, 80% of the required water, or the entire amount, depending on the type of mixture for such a batch, was added and mixed in for approximately 4 min. Next, the diluted superplasticizer was added gradually to the specified mixes until any agglomerated balls in the mixture disappeared, a process that took 3–5 min.

Up to this point, nonfoamed mixes had been prepared. The fresh density and slump flow of each mix were checked. The foam generator was then turned on to mix the foaming agent with water. The foam was extracted from the hose and transmitted to the mixer by hand to avoid breaking the bubbles, as shown in Figure 2. The foam was placed in the mixer gradually as the mixer operated for approximately 2–3 min, depending on the specific amount added, until the foam was completely incorporated, as shown in Figure 3. Fresh density and slump flow tests were conducted again to ensure that a fresh density of at least 1700 kg/m3 was achieved and that each mixture had an appropriate consistency to provide stability to the mixture. Table 3 presents the ratios and quantities of the components of the mixtures. Figure 4 illustrates the mixing procedure.

| Ingredients | FCfs | FCfps | FCfgs | FCgpfs | FCgpfn |

|---|---|---|---|---|---|

| Cement (kg/m3) | 500 | 500 | 500 | 500 | 500 |

| Normal sand (kg/m3) | — | — | — | — | 892.7 |

| Silica sand (kg/m3) | 812 | 860 | 757.5 | 861.5 | — |

| Water (kg/m3) | 288 | 228 | 292.5 | 175.5 | 144.3 |

| W/C ratio | 0.58 | 0.46 | 0.59 | 0.35 | 0.29 |

| Glass powder (kg/m3) | — | — | 50 | 50 | 50 |

| Fly ash (kg/m3) | 100 | 100 | 100 | 100 | 100 |

| W/B ratio | 0.48 | 0.38 | 0.45 | 0.27 | 0.22 |

| Superplasticizer (kg/m3) | — | 13 | — | 13 | 13 |

| Foam (L/m3) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

- Note: FC is a foamed concrete, f is a fly ash, p is a superplasticizer, g is a glass powder, s is a silica sand, and n is a normal sand.

2.3. Experimental Tests

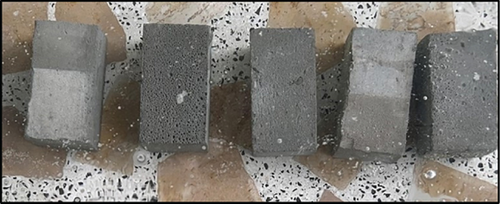

The properties of the hardened concrete mixes were assessed by means of compressive, tensile, flexural, sorptivity, porosity, and water absorption tests. BS.1881 Part 116 [24] was followed for the compressive strength tests. Three samples of cubes with dimensions of 150 × 150 × 150 mm were tested at 7 and 28 days of age for all of the FC mixes. Splitting tensile strength testing was conducted as per ASTM C496/C496M-17 [25] using three cylindrical samples with dimensions of 100 × 200 mm at 7 and 28 days of age. Three prism samples with dimensions of 100 × 100 × 400 mm were used to measure the modulus of rupture according to ASTM C78/02 [26] at 7 and 28 days of age. The sorptivity test procedure involved preparing concrete cubes, typically 40 × 40 × 100 mm, cured for 28 days. The sorptivity testing followed ASTM C1585-4 [27]. Porosity measurements were conducted using 40 × 40 × 100 mm samples. The porosity testing was conducted in accordance with ASTM C642-13 [28]. A water absorption test was conducted in accordance with ASTM C642-13 [28] using 40 × 40 × 100 mm samples. Figure 5 illustrates the hardened concrete tests conducted.

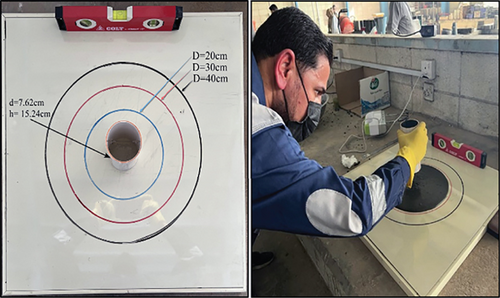

Two tests, fresh density and spread tests, were carried out to evaluate fresh concrete properties. Containers of predetermined mass and volume were used to determine the fresh density of each of the FC mixes. The FC fresh density was evaluated according to Brewer [29]. FC is a free-flowing, self-levelling material and should be expected to exhibit a collapse slump. Therefore, measurement of the “spreadability” of foamed mixtures is required, as described by Mehta and Siddique [30]. A test developed for low-strength materials can be used to assess the workability of the base mix Brewer [29]. Workability can be quantified by the “spreadability” of a cylinder 76.2 mm (3 in.) in diameter and 152.4 mm (6 in.) in length. This test was used to assess the workability of the FC mixes developed for the current study. Figure 6 illustrates the tests of the fresh mixtures conducted.

SEM is essential for analysing FC’s microstructure, providing detailed images that reveal the pore structure, pore size distribution, and bonding between the cement matrix and the foam. Preparing samples involves drying, cutting, polishing, and coating with a conductive material to prevent charging under the electron beam. During SEM analysis, images were captured at various magnifications, allowing examination of features such as porosity and microcracks.

3. Test Results and Discussion

3.1. Fresh Properties

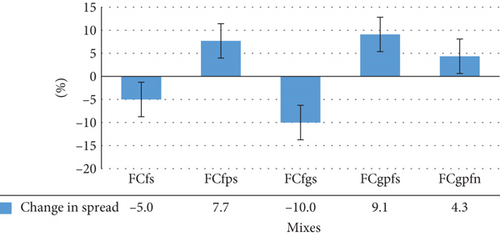

The foaming agent yielded different results depending on the mix to which it was added. For the mixes without a superplasticizer added, the foaming agent reduced the spread by approximately 5% and 10% relative to those of the control mix and the mix with WGP, respectively. Foaming agents often increase a mixture’s viscosity. A more viscous mixture spreads more slowly than a less viscous one because it resists flow. A foaming agent works by trapping air within the liquid, forming bubbles. The presence of these bubbles changes the physical characteristics of the mixture, often making it more stable and less prone to spreading. The bubbles can also act as physical barriers, limiting the movement of the liquid phase and, therefore, reducing its spread. Consequently, these factors combine to decrease the spreadability of mixtures containing foaming agents.

All remaining mixes that contained a superplasticizer alone or with WGP exhibited an increase in the spread because the influence of the superplasticizer dominated. A slight increase in the spread was observed after the foaming agent was incorporated, with a maximum increase of 9.1% in the mixture with superplasticizer, WGP, and SiO₂ sand. The fresh densities of all mixes were within the lightweight range. Table 4 summarizes the findings concerning the fresh characteristics of the tested mixes, and Figure 7 illustrates the influence of the foaming agent after its addition to mixes.

| Mixes | Spread/before foam add (cm) | Spread/after foam add (cm) | Fresh density (kg/m 3) |

|---|---|---|---|

| FCfs | 20 | 19 | 1716 |

| FCfps | 26 | 28 | 1708 |

| FCfgs | 20 | 18 | 1718 |

| FCgpfs | 22 | 24 | 1716 |

| FCgpfn | 23 | 24 | 1720 |

3.2. Permeation Properties

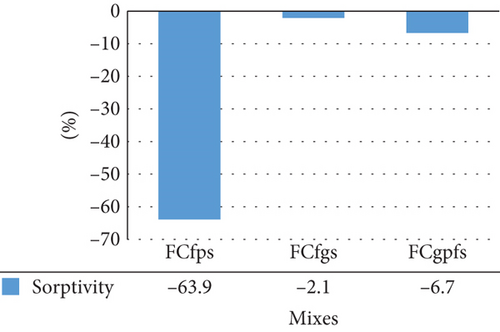

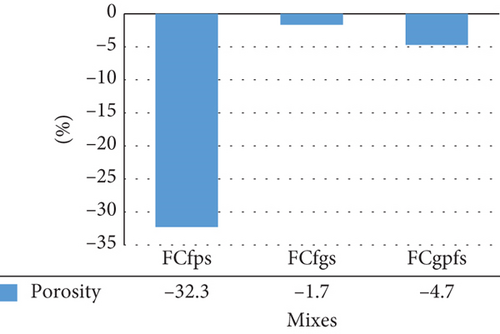

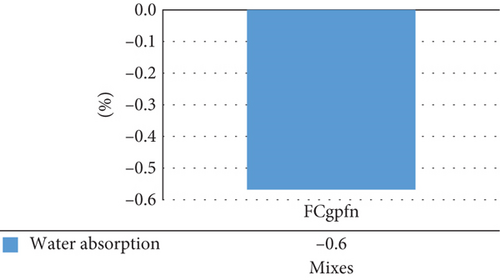

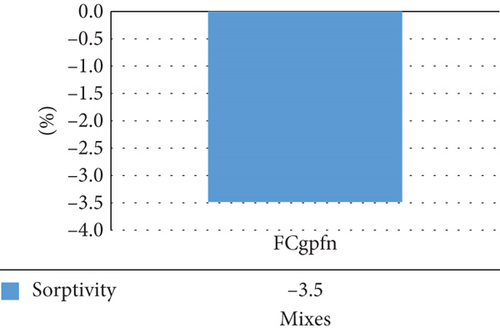

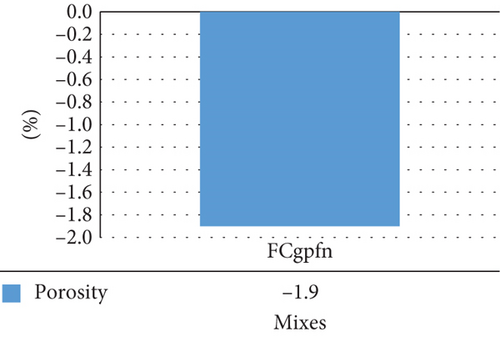

The addition of a superplasticizer permits a reduction in the water–cement ratio, which contributes to reducing voids and, consequently, porosity and sorptivity. The porosity and sorptivity were lowered by approximately 32.3% and 63.9%, respectively, compared to the control mix when the superplasticizer was added alone, indicating a more significant effect. In contrast, the mixes with WGP added alone or in conjunction with the superplasticizer exhibited very slight reductions in porosity and sorptivity relative to those of the control mix, as shown in Figure 8. This can be attributed to the physical and chemical properties of WGP. The smooth surfaces and angular shapes of WGP particles can lead to poor packing density within the concrete mix, creating more voids and increasing porosity. Moreover, a less dense cement paste microstructure can occur when glass powder interferes with cement’s hydration, increasing porosity. Furthermore, WGP is composed primarily of SiO₂, which can react with the calcium hydroxide (Ca(OH)₂) produced during cement hydration to form additional calcium–silicate–hydrate (C-S-H) [31]. However, this reaction, known as the pozzolanic reaction, may not be as efficient or complete as the hydration reactions of traditional cement particles, potentially leaving some unreacted glass particles and increasing the porosity. Figure 9 illustrates the extraordinary effect of the superplasticizer in reducing water absorption by approximately 35.9% relative to the control mix and the marginal reduction in water absorption achieved by WGP alone or together with the superplasticizer. Because of the high specific surface area of glass powder, it can attract and hold water molecules through surface tension and capillary action. Glass particles can also have hydrophilic properties that cause them to attract and hold water molecules more readily.

Replacing the SiO₂ sand with normal sand resulted in only minor reductions in water absorption, porosity, and sorptivity. SiO₂ sand, however, often has rounder and more uniform particles, which can reduce the packing density and lead to less interlocking, thus not significantly enhancing compressive strength. Overall, while SiO₂ sand has benefits in certain uses, its uniformity and specific properties do not necessarily increase concrete’s compressive strength or other properties significantly, as shown in Figure 10.

3.3. Hardening Properties

Table 5 lists data collected for hardening properties tests, which comprise compressive, tensile, and flexural strength.

| Mixes | Compression strength (MPa) | Tensile strength (MPa) | Flexural strength (MPa) | |||

|---|---|---|---|---|---|---|

| 7 days | 28 days | 7 days | 28 days | 7 days | 28 days | |

| FCfs (control) | 13.9 | 18.6 | 1.4 | 1.9 | 1.35 | 1.31 |

| FCfps | 24.5 | 25.3 | 2.01 | 2.67 | 1.62 | 1.73 |

| FCfgs | 14.8 | 19.6 | 1.36 | 1.92 | 1.2 | 1.62 |

| FCgpfs | 19.2 | 25.6 | 2.3 | 2.4 | 1.57 | 1.83 |

| FCgpfn | 20.6 | 23.3 | 2.15 | 2.26 | 1.7 | 1.9 |

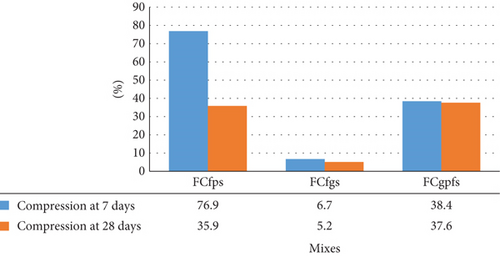

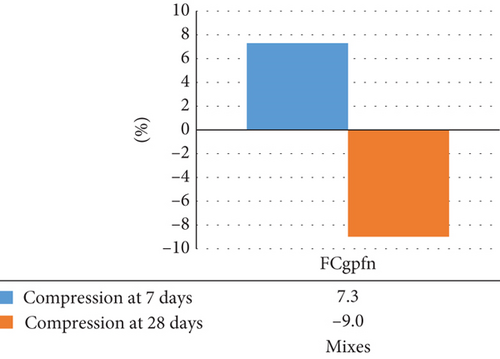

The compressive strength tests revealed considerable increases in compressive strength at 7 and 28 days for FC mixtures to which the superplasticizer was added. In contrast, the addition of WGP did not result in any notable increase in compressive strength. The mix with both the superplasticizer and WGP exhibited moderate and almost equal increases in compressive strength at 7 and 28 days (38.4% and 37.6%, respectively), relative to the control mix. Figure 11 illustrates the effect of the superplasticizer and glass powder on compressive strength.

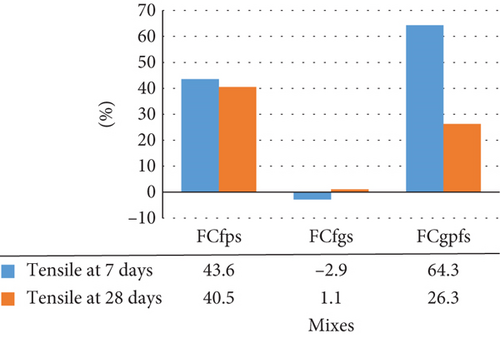

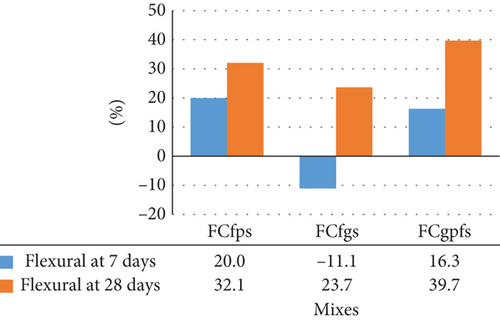

The superplasticizer increased the tensile and flexural strengths of foamed mixes at 7 days by approximately 43.6% and 20%, respectively, relative to the control mixture. The increases were greater (40.5% and 32.1%, respectively) at 28 days, as shown in Figure 12. Superplasticizers improve the distribution of foam and improve the uniformity of concrete mixes, leading to denser and more robust concrete. They contribute to a more refined microstructure by reducing the size and number of capillary pores, leading to densification and a stronger concrete matrix, which results in better tensile and flexural strength.

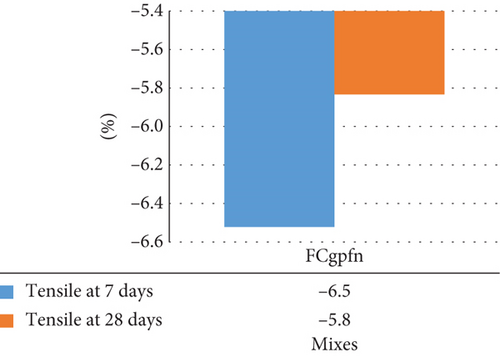

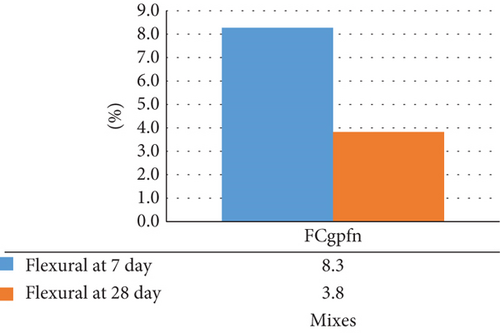

Replacing the SiO₂ sand with normal sand resulted in only minor reductions in compressive, tensile, and flexural strength, as shown in Figure 13, compared to the FCgpfs mix with SiO₂ sand.

3.4. SEM

A SEM produces high-definition images of a sample’s surface using a concentrated beam of electrons. In this study, all SEM images were taken at 70× magnification, permitting observation of surface textures and structures at a moderate scale. The SEM images of the FC mixes revealed distinct differences, as illustrated in Figure 14. In the image of the FCfs sample, the surface appears porous, with various pore sizes. The pores are relatively uniformly distributed, which is typical for FC. The addition of FA likely contributed to the uniformity and strength of the concrete. FA can fill voids and reduce permeability, which might be reflected in the relatively smoother areas in the image. In the image of the FCfps sample, the surface appears more textured, with smaller pores and possibly some fibrous structures. Using a superplasticizer can lead to a more uniform pore distribution. The enhanced dispersion of FA particles by the superplasticizer can result in improved mechanical properties and reduced pore sizes and quantities. In the image of the FCfgs sample, the surface appears highly porous, with irregularly shaped pores and rough textures. The angular particles of the glass powder might explain the irregular shapes of the pores.

A close-up view of the FCgpfs sample image shows a highly porous surface with a different texture than the others, probably because of the combination of additives. Adding SiO₂ sand results in a denser matrix and could enhance the concrete’s mechanical properties. The superplasticizer aided in the even distribution of these particles, leading to a more consistent pore structure. The image of the FCgpfn sample displays a mixture of small and large pores with a somewhat smoother texture in some areas compared to the other samples. Using normal sand, as opposed to SiO₂ sand, resulted in different pore structures and surface textures. Normal sand typically has a broader range of particle sizes, which might explain the varied pore sizes observed in the image.

The reaction between SiO2 from WGP and alkaline solutions produces calcium silicate hydrate (C-S-H) or C-A-S-H gel, which increases the compressive strength of FC. According to Provis et al., the development of N-A-S-H gel results in decreased bound water in FA-enriched mixes [32].

Because the glass powder-enriched mixes primarily produced C-A-S-H gel, which included a higher amount of bound water, the water absorption in FA-based mixes was higher than that of the mix containing glass powder; in general, the material that has a pozzolanic nature helps increase compressive strength [33, 34].

Compressive strength is subsequently increased as a result of the development of a densified three-dimensional network of silico-aluminate structure [35]. According to Mehta and Siddique [30], a compact and dense microstructure is produced when calcium hydration products are present.

4. Conclusion

- 1.

Several positive outcomes were related to the addition of the superplasticizer, the most important being a moderate increase in the FC compressive strength at both 7 and 28 days. The use of the superplasticizer alone resulted in FC with a compressive strength of approximately 25.3 MPa at 28 days, which is suitable for structural applications.

- 2.

The addition of the superplasticizer substantially reduced the water absorption, sorptivity, and porosity of FC by up to 35.9%, 63.9%, and 32.3%, respectively, compared to those of the control mix without any additives.

- 3.

The addition of WGP had marginal effects on the compressive strength, water absorption, sorptivity, and porosity of FC. The presence of WGP in an FC mixture without replacing cement, as in the current study, points to the role of glass powder as a filler material. In addition, the SEM imagery indicates that glass powder can reduce the size of pores but produces irregular pore shapes. Increasing the fineness of WGP through additional grinding might result in more responsiveness to filling action and more regularity that approaches microscales.

- 4.

The combined effects of adding the superplasticizer and WGP together yielded results close to those achieved using the superplasticizer alone, such as a compressive strength of 25.6 MPa. Slightly greater reductions were achieved in water absorption, sorptivity, and porosity (up to 5.9%, 6.7%, and 4.7%, respectively), relative to the control mix.

- 5.

Adding the superplasticizer alone or with glass powder also improved the tensile and flexural strengths of the FC. Using superplasticizer and WGP together resulted in higher tensile and flexural strengths (64.3% and 16.3%, respectively, at 7 days and 26.3% and 39.7%, respectively, at 28 days), compared to the control mix.

- 6.

WGP on its own did not yield any significant improvements except for a 23.7% increase in flexural strength at 28 days, relative to the control mix.

- 7.

There was little to no difference in the foamed mixes’ mechanical properties using SiO₂ versus normal sand as the fine aggregate. Therefore, if SiO₂ sand is more accessible than the normal one, it can be considered a good alternative with comparable effects on FC properties.

- 8.

All mixes exhibit a foamed structure with numerous pores, which is characteristic of FC. The differences observed in pore size and distribution can be attributed to the specific additives used in each mix.

- 9.

Foaming agents increase the viscosity of foamed mixes. The foaming agent reduced spread by 5% and 10% in the control and WGP mixes without the addition of a superplasticizer. The foaming agent’s effect on viscosity disappeared in mixes with a superplasticizer because of the dominance of the effect of the superplasticizer on viscosity.

- 10.

The fresh densities of all the mixes evaluated in this study fell within the lightweight range, according to Neville [36].

This work provides knowledge about the use of local WGP in FC, in the opinion to facilitate the adoption of the concept of recycling waste into sustainable concrete products and improve the compressive strength of this type of concrete to advance to structural use while it is commonly used for nonstructural units due to its low strength. Foam concrete with a compressive strength of 23 MPa was obtained. To further verify its structural efficiency, more future investigations into the behavior of this type of concrete are required by using it in beams, slabs, and other structural members as part of proposed future work to expand the use of this promising material in the field of construction. It is possible to make a number of mixtures with different proportions of glass powder and different proportions of FA to determine the optimal proportion of both materials for part of future investigations.

Consent

I am the first author (Husam Khalaf Khudhair Al-Ani). I confirm and agree to include my images in the manuscript and consent to publish them.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

The first author was responsible for the experimental work part and writing the initial version of the manuscript. The second author developed the work plan in addition to reviewing the manuscript, and the third author also contributed by revising the manuscript and responding to reviewers’ comments.

Funding

No funding was received for this manuscript.

Acknowledgments

The authors acknowledge the University of Anbar Civil Engineering Department and the technicians working in the material and structure laboratory of the faculty of engineering.

General Statement

Identifiable Images. The person who appears in Figures 2 and 6 is the corresponding author (Husam Khalaf Khudhair Al-Ani) during the experimental work of this research.

Open Research

Data Availability Statement

Research data are not shared.