Effect of a Nonlinear Energy Sink on the Nonlinear Panel Flutter Suppression Under Variable Temperature Rise and Airflow Yawed Angle

Abstract

This study investigates the nonlinear aeroelastic response behaviors and robustness of a square isotropic panel with a nonlinear energy sink (NES) considering temperature rise and airflow yawed angle. Considering uniform temperature rise, the nonlinear aerothermoelastic equations for a three-dimensional (3D) isotropic panel with an NES were derived using the von Karman large deformation theory and the piston theoretical aerodynamic force with airflow yawed angle and then discretized using the Galerkin method. The fourth-order Runge–Kutta method was used to solve the aerothermoelastic equations for the panel response, and the effect of temperature rise and airflow yawed angle on the NES suppression ability was examined. The numerical results revealed the appearance of a buckling region due to the temperature rise; however, the NES had no impact on the boundary of this region. The suppression ability of the NES gradually weakened and disappeared completely as temperature increased. Furthermore, within a small angular range, the NES suppression ability increased with the increasing airflow yawed angle. For a large airflow yawed angle, the NES not only lost its suppression ability but also made the panel aeroelastic response worse.

1. Introduction

Panel flutter is an aeroelastically induced self-excited vibration of the flight vehicle skin exposed on one side to supersonic airflow [1]. Under supersonic airflow conditions, the panel experiences high-speed airflow effects with varying yawed angles [2], along with aerodynamic heating [3, 4]. Panel flutter usually appears as a limited amplitude oscillation due to the geometric nonlinearity of the panel. However, continuous large-amplitude oscillations can lead to panel fatigue and affect flight safety [5]. Therefore, panel flutter suppression is a crucial aspect when designing aerospace vehicles.

A significant amount of research on panel flutter control has been carried out. Scott and Weisshaar [6] and Sadri et al. [7] improved the panel flutter boundary using piezoceramic actuators. Moon and Hwang [8, 9] employed the LQR method to control the aeroelastic response for a composite flat panel and obtained the actuator and sensor locations using genetic algorithms for best control effects. Kim et al. [10] developed an active controller to control panel aeroelastic response by using aeroelastic modes. Hasheminejad and Motaaleghi [11] studied the flutter suppression of a sandwich cylindrical panel by using a tunable electrorheological fluid (ERF) mid-layer considering yawed supersonic airflow. Li [12] investigated the effect of active mass and stiffness on suppressing the panel aeroelastic response and revealed that increasing the feedback control gains can improve the active aeroelastic properties for the lower order modes. Chai et al. [13] utilized the MFC actuator and sensor to control panel flutter with time-dependent boundary conditions.

The abovementioned active control methods exhibit effective control of nonlinear aeroelastic panel response. However, these systems require additional sensors and actuators, and the stability of closed-loop systems is affected by the signal transmission delay. Passive control technology, by contrast, is simple in structure, robust, and consumes no energy, so it has been widely adopted as a means of suppressing panel flutter [14], especially in the form of dynamic vibration absorbers. However, traditional dynamic vibration absorbers are designed with linear stiffness. So, only when the frequency is equal to or close to the natural frequency of the main system does the vibration absorption effect become obvious. The vibration absorption frequency is also relatively narrow. This limits the scope of the development and application of this kind of solution. However, a dynamic vibration absorber called a nonlinear energy sink (NES), consisting of a small mass, a cubic stiffness, and a linear damping, has a wide frequency band and a highly efficient vibration absorption mechanism, displaying great potential for passive suppression [15–17].

NES have been widely studied for vibration suppression in beam structures under forced loads, such as harmonic/impact excitations [18–22]. NES can also suppress self-excited system responses. Lee et al. [23] suppressed the limit cycle oscillations of a van der Pol oscillator using an NES. They subsequently adopted an NES to suppress wing flutter and revealed the suppression mechanism using energy–frequency and time-frequency analyses [24, 25]. Yan et al. [26] studied transonic wing flutter suppression by using an NES. Zhang et al. [27] combined a piezoelectric energy harvester and an NES to suppress the aeroelastic response of an airfoil with two-degree-of-freedom. Guo et al. [28] introduced an NES to suppress the vibration of the airfoil with freeplay and enhance the reliability. NES has also been used to suppress other self-excited system vibrations, such as fluid-conveying pipes [29, 30], rotor blades [31], and a long-span bridges [32].

Relatively, fewer works exist on the panel flutter response suppressing using an NES. Zhang et al. [33] used an NES to rapidly restore the static state of the panel postperturbations in the supersonic airflow. Pacheco et al. [34] suppressed panel aeroelastic response using an NES and established the important suppression mechanism via the energy-based method. Zhou et al. [35, 36] studied the NES parameter effect on the suppression ability for the nonlinear aeroelastic response of a 2D panel and 3D panel. Wang et al. [37] designed an NES to suppress the nonlinear aeroelastic responses of graphene platelet–reinforced composite lattice sandwich plates. However, the temperature rise and airflow yawed angle, which will affect the NES suppression ability seriously, are not considered in the above studies.

In this study, we investigated the effect of the temperature rise and airflow yawed angle on the NES suppression ability of the panel aeroelastic response. The rest of the article is structured as follows: The nonlinear aerothermoelastic equations for a 3D isotropic panel with an NES under yawed supersonic flow are derived in Section 2; the validation and effectiveness analyses are demonstrated in Sections 3 and 4; and finally, Section 5 presents the primary conclusions of the study.

2. Nonlinear Aerothermoelastic Formulation

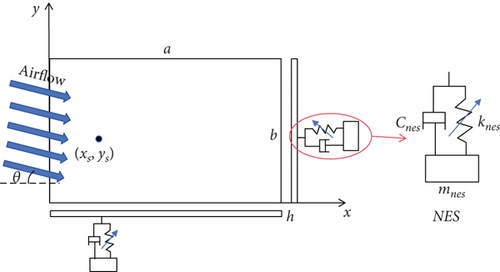

Figure 1 shows a 3D isotropic panel model with an NES under yawed supersonic flow, where a, b, and h are, respectively, the length, width, and thickness of the panel; mnes, knes, and cnes are, respectively, the mass, nonlinear stiffness, and damping of the NES. The NES is installed at (xs, ys) with θ being the airflow yawed angle with the x-axis.

2.1. Constitutive Equations

D = Eh3/12(1 − υ2) is the panel bending stiffness, NT = EhαΔT/(1 − υ), and E is elastic modulus.

2.2. Aerothermoelastic Equations

and , where Ma is the Mach number; ρ∞ and U∞ are the airflow density and velocity, respectively; ws is the panel displacement at (xs, ys); s is the NES displacement; and is the Dirac function.

2.3. Galerkin’s Discretization Method

is a homogeneous solution and is a particular solution.

3. Validations

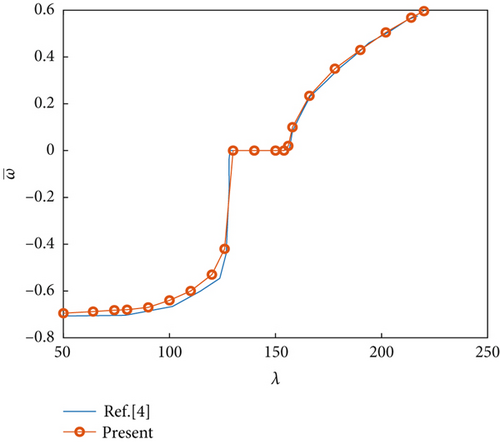

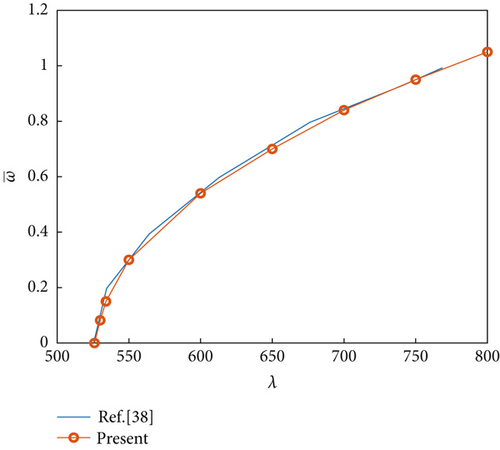

Following our previous work [36], we only needed to verify the introduction of the temperature rise and airflow yawed angle variables into the aeroelastic equations. The present panel aeroelastic response results were in good agreement with that of panels with a/b = 0.5, ΔT/Tcr = 3, and θ = 0 in [4] and a/b = 1, ΔT/Tcr = 0, and θ = 45° in [38] under temperature rise and airflow yawed angle conditions (Figure 2). This verified the validity of the proposed model, which can be used for further research on the effects of an NES on nonlinear panel aeroelastic response suppression.

4. Numerical Results and Discussions

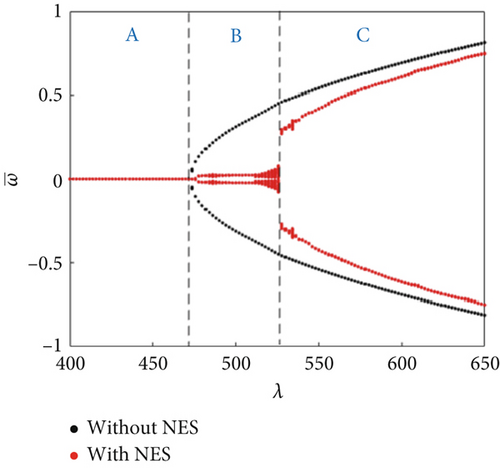

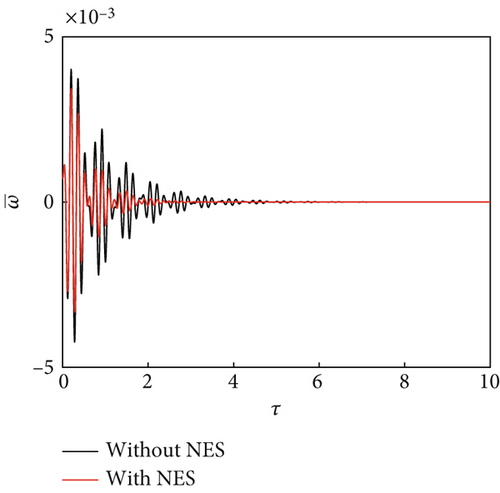

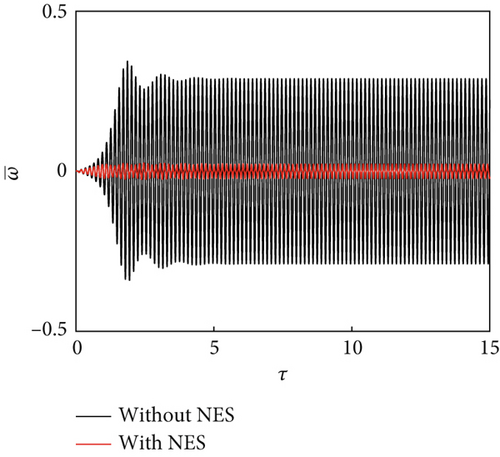

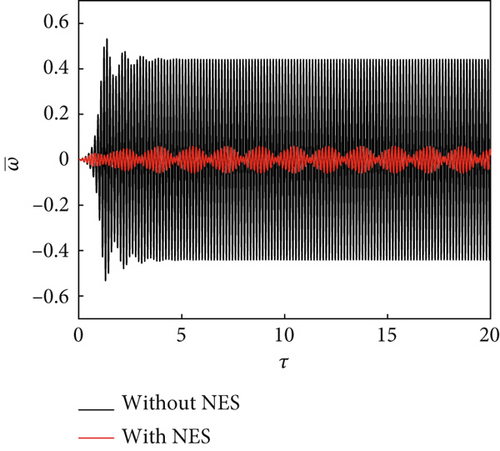

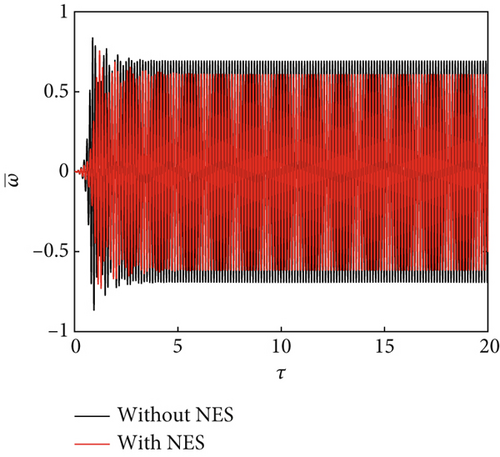

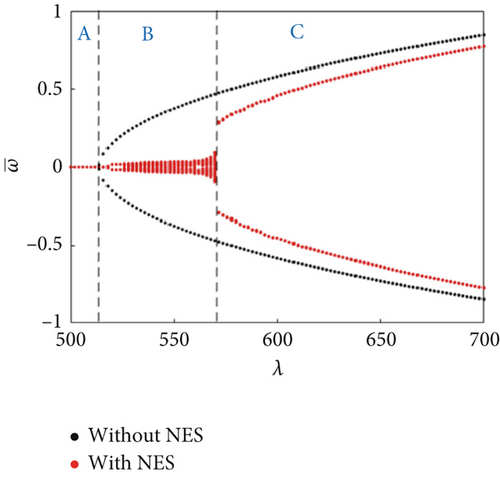

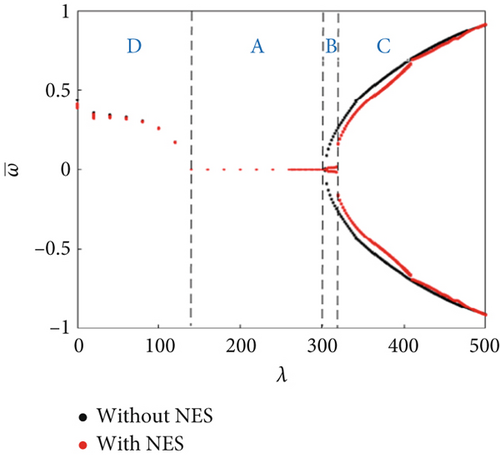

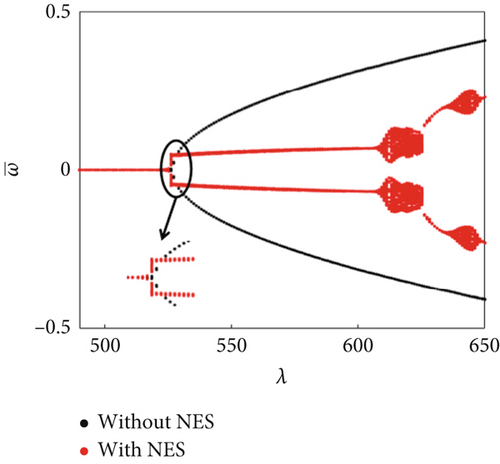

In this study, the NES parameters of the NES installed at and were set as , , and . The panel dimensions were a/b = 1 and h = 1/300a. The bifurcation diagrams were obtained using steady amplitude response data at and . For ΔT/Tcr = 0.5 and θ = 15°, the bifurcation characteristics were compared with and without the presence of an NES under changing dynamic pressure (Figure 3). The bifurcation characteristic diagram can be divided into three regions: (A) static equilibrium region: In this region, regardless of the presence/absence of the NES, the panel aeroelastic response eventually converges to the static equilibrium, with a faster convergence in the presence of an NES (Figure 4a). (B) NES suppression region: In this region, the aeroelastic response amplitudes of the panel with an NES are much smaller than those without an NES. The panel aeroelastic response is suppressed by the NES unique performance: permanent resonance capture (PRC) and recurrent transient resonance capture (TRC), as shown in Figure 4b,c. (C) Flutter response region: In this region, the NES performance deteriorates, and the panel exhibits a large amplitude vibration response (Figure 4d). The NES suppression region is not only affected by the NES parameters [36] but is also related to the temperature rise of the panel and the airflow yawed angle (discussed later).

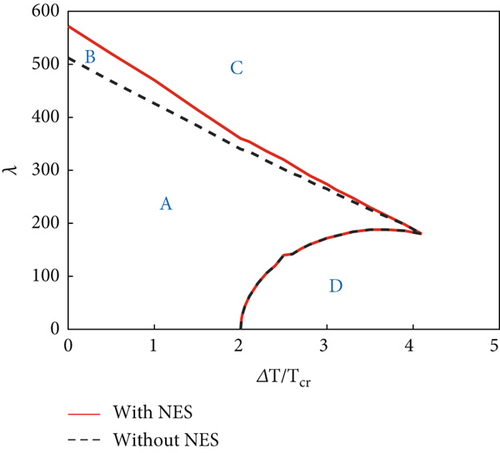

4.1. Effect of Temperature Rise

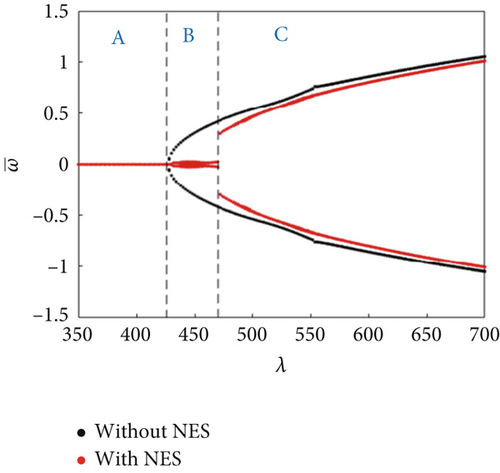

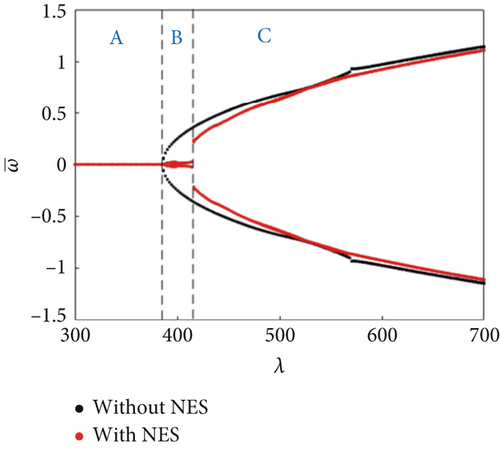

The bifurcation characteristics with/without an NES were further compared under dynamically varying pressure for ΔT/Tcr = 0.0, 1.0, 1.5, and 2.5 (Figure 5). The dynamic pressure ranges of the NES suppression region under the above four temperature rise values were obtained as 512 ≤ λ ≤ 570, 426 ≤ λ ≤ 470, 384 ≤ λ ≤ 414, and 302 ≤ λ ≤ 318, respectively. It shows that the static equilibrium region decreased with the increasing temperature rise, indicating that the flutter critical dynamic pressure decreased. The NES suppression region also decreased with increasing temperature rise, suggesting that the NES gradually loses performance under temperature rise conditions. Additionally, a buckling region (Region D) appeared for a high ΔT/Tcr (Figure 5d). In this region, the buckling response amplitude and boundary of the buckling region are basically the same, indicating that the NES did not affect the buckling region. Overall, the panel response suppression ability of the NES will gradually weakened with increasing temperature rise till it disappeared completely (Figure 6).

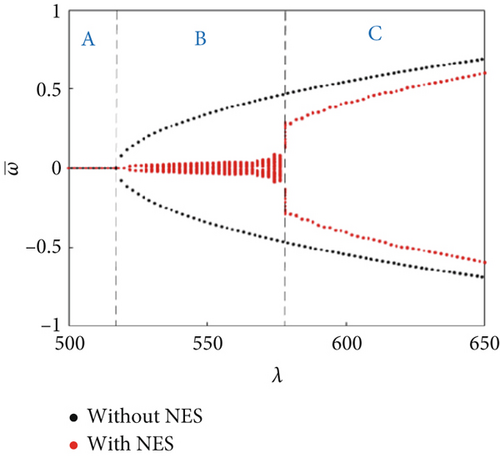

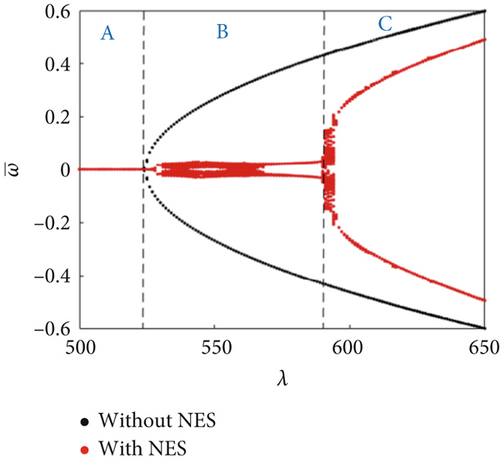

4.2. Effect of Airflow Yawed Angle

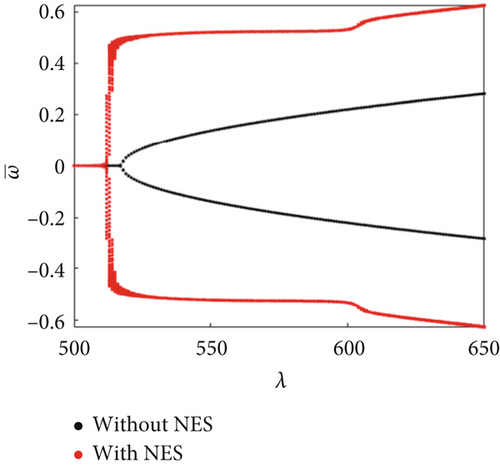

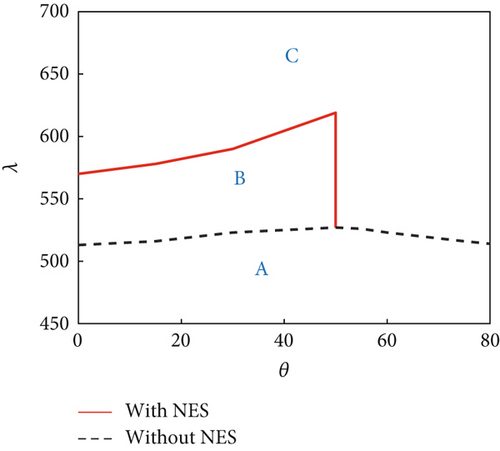

The bifurcation characteristics with/without an NES under changing dynamic pressure were further compared for θ = 15°, 30°, 55°, and 75° (Figure 7). For θ = 15° and θ = 30°, the dynamic pressure ranges of the NES suppression region were 513 ≤ λ ≤ 570 and 516 ≤ λ ≤ 578, respectively. The NES suppression region slightly increased with the increasing airflow yawed angle. However, when the airflow angle increases to θ = 55°, as shown in Figure 7c, although the NES has a good suppression effect in a large dynamic pressure range, the flutter critical dynamic pressure reduced unexpectedly, as shown in the enlarged part in Figure 7c. Therefore, the NES suppression performance lost its significance in this case. As θ was further increased, the flutter critical dynamic pressure of the panel reduced, while the aeroelastic response amplitude increased (Figure 7d), that is, the panel aeroelastic response deteriorated. We have plotted the effect of airflow yawed angle on the suppression region, as shown in Figure 8. From the figure, it revealed that the NES had good suppression ability for 0° ≤ θ ≤ 50°, and the NES suppression region also increases with the increase of the airflow yawed angle. If the airflow yawed angle is too large, the NES will not only lose its suppression ability but also make the panel aeroelastic response worse.

5. Conclusions

- 1.

The study reveals that temperature rise significantly diminishes the NES suppression ability. As the temperature increases, the NES suppression region shrinks, and the flutter critical dynamic pressure decreases. Notably, at high temperatures, a buckling region emerges where the NES has no effect on the buckling response amplitude.

- 2.

The airflow yawed angle exhibits a dual effect on NES performance. Within a moderate range (0° ≤ θ ≤ 50°), the NES suppression region expands slightly with increasing angle, suggesting enhanced performance. However, beyond this range, the flutter critical dynamic pressure drops abruptly, and the panel’s aeroelastic response deteriorates. Engineers should prioritize NES deployment in applications where the yawed angle remains within the effective range.

In summary, this work not only advances the theoretical understanding of NES-based flutter suppression but also delivers practical recommendations for aerospace engineers. By addressing the interplay between temperature, airflow angle, and NES dynamics, the study equips designers with the knowledge to enhance flight safety and structural reliability in supersonic applications.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This research was supported by the Natural Science Basic Research Program of Shaanxi (2023-JC-QN-0019).

Acknowledgments

This study was funded by the Natural Science Basic Research Program of Shaanxi (Program No. 2023-JC-QN-0019).

Appendix A

Appendix B

Appendix C

Open Research

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.