Bearing Performance Analysis of the Thermal and Surface Roughness Effects by Finite Element Method on Slider Bearings Through Non-Newtonian Fluid-Type Lubricant

Abstract

The finite element method was used in this study to explore the impact of surface roughness and thermal characteristics on slider bearings with non-Newtonian power-law fluid flow lubricant. One-dimensional transverse and longitudinal surface roughness models were considered under the stochastic assumption that roughness has a Gaussian random distribution. For improved computing efficiency, the surface’s uneven texture is transformed into a regular domain. For non-Newtonian power-law lubrication, a modified Reynolds equation was developed. The pressure distribution of the combined effect is less than that of the surface roughness and thermal effect in longitudinal surface roughness for all non-Newtonian parameters n and M⊛ values. As a result, there is an 1.6% reduction in load-carrying capacity performance and negligible friction force for nonparallel w = 0.4 between the thermal effect and surface roughness. Nevertheless, for all non-Newtonian parameters n and M⊛ values, the pressure distribution of the thermal effect in the transverse roughness model is smaller than that of the combined and surface roughness effects. Consequently, there is an 8.9% reduction in load-carrying capacity performance and a negligible friction force for nonparallel w = 0.4 between the surface roughness effect and the thermal effect condition, respectively. Additionally, the combined impacts at different temperatures were examined. As a result, in longitudinal models, the load-carrying capacity performance is better when the slider temperature is higher than the pad temperature, and vice versa for transverse models. Surface roughness and non-Newtonian power-law fluid characteristics generally enhance the performance of a slider bearing. Tables and graphs were employed to present the results.

1. Introduction

One of the most popular features of some types of machinery components is the slider bearing, which reduces friction between any two moving parts. The performance of plane slider bearings is largely dependent on the properties of the fluid, particularly if the fluid is non-Newtonian. The complex fluid viscosity of non-Newtonian fluids is dependent on factors such as temperature and shear rate; however, surface roughness can have a significant effect on the bearing’s performance as well as the flow of fluid; furthermore, the friction and wear of a bearing can be greatly influenced by its surface roughness, which may have an effect on the bearing’s overall performance and lifespan.

Special difficulties occur in non-Newtonian fluid flow applications with plane slider bearing. By aiding in the design of the bearings and optimizing these fluid-using devices, these findings may enhance the functionality and efficiency of machinery and equipment utilized in the biomedical engineering, materials processing, and oil and gas sectors.

In order to construct the Reynolds equation for the general lubrication problem of the non-Newtonian fluid, Yang et al. [1] treat the lubricant flow as the superposition of the Poiseuille flow and the Couette flow. Lin [2] conducted a theoretical investigation to examine the non-Newtonian effects of an isothermal, incompressible laminar-flow lubricant on the damping properties and dynamic stiffness of one-dimensional (1D) slider bearings. The modified Reynolds equation for bearing-squeeze action is derived from the Rabinowitsch fluid (cubic equation) model in order to take into consideration the non-Newtonian characteristics of lubricants as well as the slider’s transient motion. The effect of partial and full texturing on a hybrid thrust pad bearing with a non-Newtonian lubricant is theoretically examined by Yadav and Sharama [3]. The finite element method (FEM) with Reynolds boundary conditions was used to complete the task by Rao and Agarwal [4] which looked at the modified Reynold equation model that was lubricated with micropolar fluid. The modified Reynolds equation, applicable to power-law lubricants, was derived using an analytical approach for the analysis of slider bearings with non-Newtonian lubricants [5].

The static and dynamic performance of an orifice-compensated hole-entry hybrid journal bearing system taking into account the combined influence of surface roughness and non-Newtonian behavior of the lubricant is described in Nagaraju et al. [6]. The lubricant flow field in the clearance space of a rough journal bearing system has been solved using the modified form of the average Reynolds equation. The power-law model has been expected to be followed by non-Newtonian lubricants [7]. The treatment of a non-Newtonian lubricant’s flow in a slider bearing is dealt with analytically. Oladeinde et al. [8] investigated numerically the performance of a fixed inclined slider bearing whose surfaces are lubricated by a non-Newtonian power-law lubricant. Walters et al. [9] discuss the importance of non-Newtonian effects in journal bearing lubrication using a numerical approach. The modified Reynolds equation for non-Newtonian fluid with the rheological model in the frequency domain for journal bearing was derived by Haosheng and Darong [10].

Among the studies on the impact of surface roughness on various bearing types are those on hydrostatic bearings by Lin [11], journal bearings by Guha [12], and slider bearings by Christensen and Tonder [13]. Alternatively, Kumar [14] examined a segregated FEM of the Petrov–Galerkin framework with appropriate weight functions for a nonisothermal flow in the model’s high-speed slider bearings that has temperature-dependent viscosity and density. In Rathish Kumar and Srinivasa Rao [15], the load-carrying support’s slider bearing was numerically simulated using the FEM. Sinha and Adamu [16] conducted a thermohydrodynamic analysis of an infinitely many long tilted pad slider bearings with roughness using the finite difference method (FDM). In Adamu and Sinha [17], surface roughness is taken to be Gaussian randomly distributed and stochastic characteristic and heat conduction through both the pad and slider is taken into consideration for both of the two models of 1D transverse and longitudinal roughness.

Using the FEM, the authors of [18–20] recently examined the performance of the slider bearings in relation to surface roughness and temperature on 1D transverse and longitudinal roughness types. The static and dynamic properties of a few rough, porous Rayleigh step bearings lubricated with stress fluid were investigated by Naduvinamani and Angadi [21]. Nb and Angadi [22] examined how roughness and micropolar fluid affected the dynamic properties of inclined porous slider bearings. Gu et al. [23] investigated the static properties of aerostatics porous journal bearings using theoretical and numerical analysis. Transient elastohydrodynamic lubrication under line contact stiffness and damping behaviors were covered by Fang et al. [24]. Jamshed et al. [25] demonstrated how unsteady hybrid nanofluids can increase thermal efficiency in solar-powered aircraft using a single-phase optimized entropy analysis. Raees et al. [26] studied the energy transfer in a power-law nanofluid driven by magnetization to flow along a horizontal wall. Overall, our review of the literature and our knowledge gaps show that, when it comes to the derivation of the modified Reynold equation, FEM has not been shown to be able to solve the performance of the slider bearings over combined surface roughness and thermal effects with non-Newtonian fluid type. It is this that spurs us on to this study.

However, the derivation of the modified Reynolds equation for surface roughness (for 1D longitudinal and transverse) with thermal effect for slider bearing for non-Newtonian fluid flow type and solved by FEM has received little attention. Thus, the combined effect of temperature and surface roughness on a slider bearing with a non-Newtonian fluid film type by considering the local power-law exponent and consistency factor effect will be numerically analyzed using FEM in this paper.

2. Basic Equations

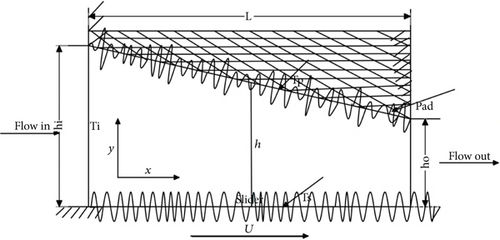

Figure 1 depicts the geometry and configuration of a rough, long slider bearing with a bearing length that is infinitely long compared to the fluid film’s thickness.

The developed equations to express the flow of lubricants in bearings result from simplifications of the governing equations of fluid flow. Dien and Elrod [27] adopted perturbation procedure to develop a generalized Reynolds equation for power-law fluids. With the usual assumptions made for the derivation of the Reynolds equation, the simplified momentum equations are written as given in Desu Tessema et al. [18].

- *

The fluid is a non-Newtonian lubricant.

- *

The fluid film thickness is significantly less than other bearing dimensions.

- *

The inertia and body force of the fluid are negligible.

- *

The lubricant is laminar and incompressible.

- *

There is no slip at the bearing surfaces of fluid flow.

- 1.

Conduction terms are negligible other than those across the fluid film.

- 2.

Specific heat and thermal conductivity are constant.

Based on the above assumptions, ρ0 and ρav are the density at temperature T and ambient temperature Ta, respectively, λ is the coefficient of thermal expansion, the subscript a denotes an ambient condition, and Tav is the average temperature on the slider.

2.1. Basic Assumptions

- a.

It will be assumed that the stochastic variable ∂P/∂k has zero variance or that the deterministic variable, the pressure gradient in the roughness direction (∂p/∂k), exists.

- b.

We will assume that the variable qs, which represents the unit flow perpendicular to the direction of surface roughness, is deterministic, meaning that the variance of the stochastic variable qs is zero.

- c.

By Sinha and Adamu [16], the velocity and temperature assumptions were refined. The temperature and velocity magnitudes related to roughness are negligible when compared to the corresponding general bearing magnitudes. The gradients of temperature ∂T/∂y, velocity ∂u/∂y, and variances of ρ are therefore negligible in the direction of roughness.

3. Transformation of the Problem

The detail has been given in Sinha and Adamu [16].

4. Finite Element Formulation

Using bilinear rectangular elements which are provided in a similar manner in Desu Tessema et al. [18], one must first form the weighted integral Equations (21)–(25) and then apply integration by parts to the terms with second derivatives to derive the above equations’ weak form.

4.1. Treatment of the Solution

FEM was developed and used to solve the system of equations with a finite number of unknowns. There are nonlinear terms in the formulated equations. Owing to this nonlinearity, a directive iterative approach is used to solve the algebraic system of equations, based on the general steps of solving the systems of equations which is given in the general algorithm (Section 4.2).

The iteration was carried out with (Tol) = 10−3, 10−4, and 10−5. However, there is no significant difference in the approximation. The outcome was accomplished by developing MATLAB code for MATLAB Software Version 2021.

4.2. General Algorithm

The following algorithm is used to approximate the solution of all field variables.

- i.

Input the constant data value: λ⊛, β⊛, σ⊛, Pr, E, Pe, n, m⊛.

- ii.

Set boundary conditions for u⊛, v⊛, T⊛, P⊛.

- iii.

Set fictitious values for u⊛, v⊛, T⊛, P⊛ over the entire grid points.

Step 2. Evaluate p⊛new using Equation (34) or (35).

Step 3. Evaluate u⊛new using p⊛new, u⊛old, v⊛old, and T⊛old and Equation (36).

Step 4. Evaluate v⊛new using u⊛new, v⊛old, and T⊛old and Equation (37).

Step 5. Evaluate T⊛new using p⊛new, u⊛new, v⊛new, and T⊛old and Equation (38).

Step 6. Test for convergence.

Step 7. Repeat steps 2–6 till convergence is obtained on all field variables.

Step 8. Calculate load-carrying capacity W⊛ and friction force F⊛ using Equation (27).

5. Results and Discussion

The parameters of bearing in this article for non-Newtonian fluid types seem to be functions of w, n, m⊛, and σ⊛, in addition to the dimensionless parameters Pe and E. The parameter values chosen by the Lebeck consideration, as reported in Schumack [31], are as follows: μa = 0.0174 Pas, β = 0.035 K, λ = 0.0012 K, k = 0.132 W/(mK), U = 20 m/s, hi = 0.00005 m, B = 0.1 m, c = 1,926 J/kgK, Ta = 310 K, ρa = 897.1 kg/m3. With fixed values for Pe, Pr, and Ec, the simulations took place for a variety of values for the parameters w, λ⊛, β⊛, σ⊛, n, and m⊛. The effects of texture can only be felt via ho/3σ⊛, where ho is the minimum film thickness as established by Gururajan and Prakash [32]. When ho ≫ 3σ⊛, roughness has negligible impact. On the other hand, bearing performance may be significantly affected if ho ≈ 3σ⊛ (within the HD limit, that is, ho > 3σ⊛). The parameter roughness of σ⊛ is taken to be fixed at 0.1 for comparison’s sake. For w = 0.4 and w = 1.0, respectively, this translates to 25% and 10% of the minimum film thickness. Moreover, it is assumed that the constants λ⊛ = 0.4 and β⊛ = 10 are fixed for the same.

The results of the temperature performance, drag force, load-bearing capacity, and pressure distribution have been studied. The solutions are shown using tables and graphs. To guarantee the grid independence of the results, the numerical simulations were performed using 10 by 10, 20 by 20, and 25 by 25 grid points on a variety of grid systems. The load-carrying capacity performance (LCCP) for different grids has been compared and shown in Table 1. This ultimately leads to the view that a grid-independent solution is produced by the 25 by 25 grid scheme.

| w | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | |

|---|---|---|---|---|---|---|---|---|

| 25 | W⊛ | 0.2951 | 0.2071 | 0.1412 | 0.0907 | 0.0513 | 0.0202 | 0.0045 |

| 20 | W⊛ | 0.2947 | 0.2069 | 0.1412 | 0.0907 | 0.0513 | 0.0202 | 0.0045 |

| 10 | W⊛ | 0.2914 | 0.2054 | 0.1406 | 0.0906 | 0.0513 | 0.0202 | 0.0045 |

- a.

The combined effect of thermal and surface roughness

- b.

Thermal effect on the smooth surface

- c.

Pure surface roughness effect (with constant viscosity and density)

5.1. 1D Longitudinal Roughness

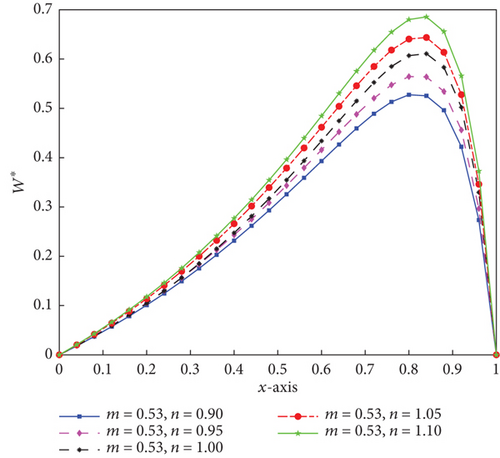

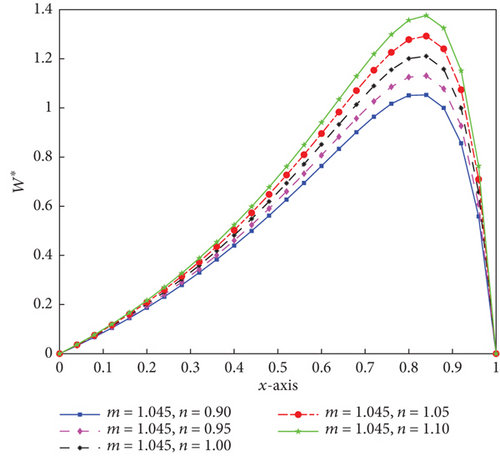

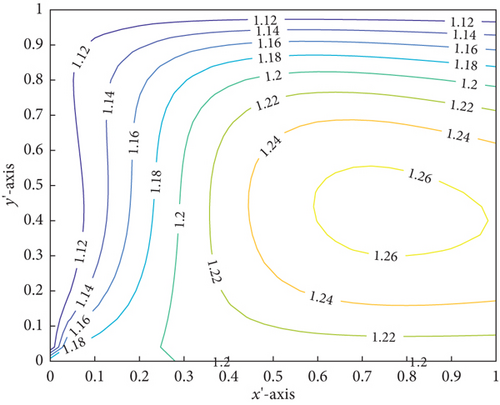

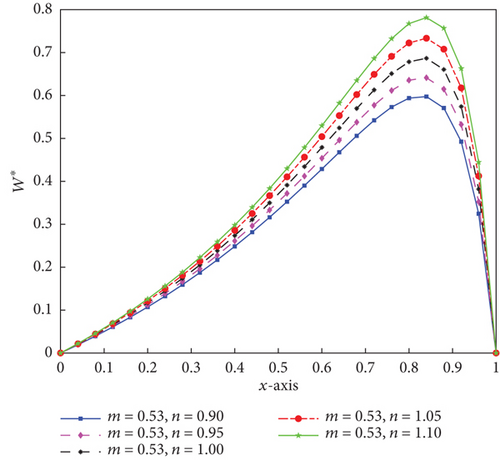

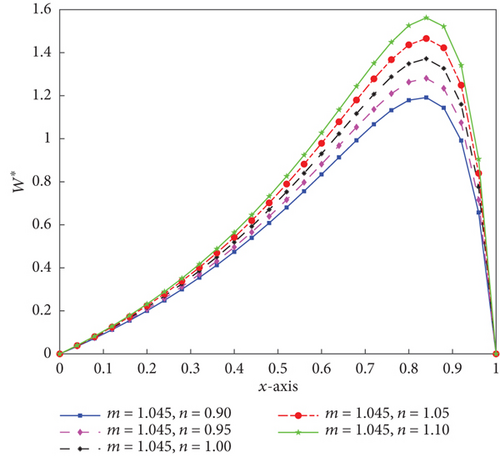

Figures 2, 3, and 4 show the 1D longitudinal distribution of pressure performance caused by surface roughness and the combined influence of temperature for non-Newtonian fluid flow for various values of local power-law exponent (n) and consistency factor (M⊛). The LCCP is in increasing order of rising n value for any constant value of x† and M⊛. Similarly, LCCP is increasing as M⊛ increases for the same value of n as we observe in the aforementioned figure. This demonstrates that, for a range of M⊛ values, the bearing design will get better as n increases, taking into account the effects of thermal and surface roughness on LCCP. In addition, the consistency factor is also a critical parameter in the performance of slider bearings over non-Newtonian power-law fluids.

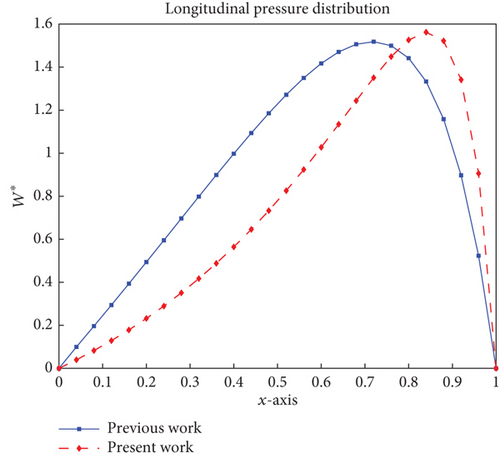

The pressure distributions for non-Newtonian fluid type of power-law for a plane slider bearing are in good agreement with Sinha and Adamu [16], Kumar [14], Rathish Kumar and Srinivasa Rao [15], and Desu Tessema et al. [18], which can be used as a cross-check to verify validity of the numerical method result. Furthermore, the pressure distribution peak can be seen nearer the outlet. Distribution of the pressure for non-Newtonian fluid type lubricant of power-law constant of a slider bearing for n = 1.1 and M⊛ = 1.045, along with the pressure distribution for laminar Newtonian fluid type, performed in Desu Tessema et al. [18], is shown in Figure 5, demonstrating the superiority of the current work over previous work.

For the inclination parameter w = 0.4, the bearing performance of LCCP and drag force of 1D longitudinal roughness corresponding to the ahead of illnesses are shown in Table 2. It is clear that between conditions b and a, there is a decrement of nearly 1.6% in LCCP for all values of n and M⊛ = 0.530. The drag frictional force between conditions a and b is also negligible for all values of n and M⊛ = 0.530. Furthermore, as this table illustrates, under all conditions, the LCCP and drag force increase as the values of n and M⊛ rise.

| Condition | M⊛ | W⊛ | n | ||||

|---|---|---|---|---|---|---|---|

| F⊛ | 0.9000 | 0.9500 | 1.0000 | 1.0500 | 1.1000 | ||

| a | 0.530 | W⊛ | 0.2776 | 0.2951 | 0.3127 | 0.3306 | 0.3487 |

| F⊛ | 1.5507 | 1.5510 | 1.5512 | 1.5514 | 1.5515 | ||

| 1.000 | W⊛ | 0.5201 | 0.5528 | 0.5858 | 0.6193 | 0.6534 | |

| F⊛ | 1.5834 | 1.5842 | 1.5845 | 1.5846 | 1.5846 | ||

| 1.045 | W⊛ | 0.5432 | 0.5772 | 0.6117 | 0.6467 | 0.6821 | |

| F⊛ | 1.5874 | 1.5881 | 1.5884 | 1.5884 | 1.5879 | ||

| b | 0.530 | W⊛ | 0.2820 | 0.2999 | 0.3179 | 0.3362 | 0.3549 |

| F⊛ | 1.5502 | 1.5505 | 1.5506 | 1.5507 | 1.5507 | ||

| 1.000 | W⊛ | 0.5285 | 0.5618 | 0.5956 | 0.6299 | 0.6646 | |

| F⊛ | 1.5818 | 1.5821 | 1.5822 | 1.5819 | 1.5813 | ||

| 1.045 | W⊛ | 0.5519 | 0.5866 | 0.6220 | 0.6578 | 0.6938 | |

| F⊛ | 1.5853 | 1.5858 | 1.5858 | 1.5855 | 1.5846 | ||

| c | 0.530 | W⊛ | 0.2796 | 0.2971 | 0.3149 | 0.3329 | 0.3511 |

| F⊛ | 1.5520 | 1.5525 | 1.5528 | 1.5532 | 1.5534 | ||

| 1.000 | W⊛ | 0.5276 | 0.5607 | 0.5941 | 0.6281 | 0.6624 | |

| F⊛ | 1.5928 | 1.5943 | 1.5957 | 1.5968 | 1.5977 | ||

| 1.045 | W⊛ | 0.5514 | 0.5859 | 0.6209 | 0.6563 | 0.6923 | |

| F⊛ | 1.5980 | 1.5997 | 1.6011 | 1.6024 | 1.6033 | ||

This is because, in this instance for the combined condition effect, the density of the fluid lubricant is decreased. As a result, the equivalent LCCP is reduced. Additionally, for all values of n and M⊛ = 0.530, the LCCP between conditions b and c differs by 0.9%, and the change in drag force for the nonparallel (w = 0.4) is decreased by 0.14%. The surface roughness of plane slider bearing is assumed to have the characteristics of furrows, ridges of long narrow, and valleys in the flow direction (x-axis) for the 1D longitudinal surface texture model type in particular. This facilitates quick lubricant flow and lowers pressure distribution, which suggests a lower LCCP in comparison to other circumstances.

The drag force and LCCP performance of 1D longitudinal roughness corresponding to the above conditions are shown in Table 3 for various fluid gap parameters of non-Newtonian power-law fluid flow. The values of the pressure developed for each fixed n and M⊛ are in the order of LCCP due to condition (a)< condition (c)< condition (b) for all circumstances, indicating that LCCP is in the same order as the corresponding condition of pressure. Condition (b)< condition (a)< condition (c) for all values n and M⊛ over the whole inclination represent the order of the frictional force. This table shows that, under all conditions, the LCCP and drag force increase as n and M⊛ rise and fall as the fluid gap decreases.

| M⊛ | n | Ci | W⊛ | w | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F⊛ | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | |||

| 0.53 | 0.95 | a | W⊛ | 0.2951 | 0.2071 | 0.1412 | 0.0907 | 0.0513 | 0.0202 | 0.0045 |

| F⊛ | 1.5510 | 1.3959 | 1.2791 | 1.1873 | 1.1130 | 1.0515 | 0.9997 | |||

| b | W⊛ | 0.2999 | 0.2098 | 0.1429 | 0.0917 | 0.0518 | 0.0203 | 0.0045 | ||

| F⊛ | 1.5505 | 1.3957 | 1.2789 | 1.1872 | 1.1130 | 1.0515 | 0.9997 | |||

| c | W⊛ | 0.2971 | 0.2099 | 0.1447 | 0.0946 | 0.0555 | 0.0246 | 0.0000 | ||

| F⊛ | 1.5525 | 1.3973 | 1.2803 | 1.1883 | 1.1138 | 1.0520 | 1.0000 | |||

| 1.05 | a | W⊛ | 0.3306 | 0.2307 | 0.1566 | 0.1002 | 0.0564 | 0.0221 | 0.0050 | |

| F⊛ | 1.5514 | 1.3957 | 1.2786 | 1.1867 | 1.1126 | 1.0513 | 0.9997 | |||

| b | W⊛ | 0.3362 | 0.2339 | 0.1585 | 0.1013 | 0.0570 | 0.0223 | 0.0050 | ||

| F⊛ | 1.5507 | 1.3953 | 1.2784 | 1.1866 | 1.1125 | 1.0512 | 0.9997 | |||

| c | W⊛ | 0.3329 | 0.2338 | 0.1605 | 0.1046 | 0.0612 | 0.0270 | 0.0000 | ||

| F⊛ | 1.5532 | 1.3973 | 1.2799 | 1.1878 | 1.1134 | 1.0518 | 1.0000 | |||

| 1.0 | 0.95 | a | W⊛ | 0.5528 | 0.3855 | 0.2603 | 0.1642 | 0.0892 | 0.0302 | 0.0165 |

| F⊛ | 1.5842 | 1.4045 | 1.2747 | 1.1774 | 1.1027 | 1.0443 | 0.9979 | |||

| b | W⊛ | 0.5618 | 0.3907 | 0.2633 | 0.1659 | 0.0900 | 0.0304 | 0.0166 | ||

| F⊛ | 1.5821 | 1.4034 | 1.2740 | 1.1770 | 1.1025 | 1.0442 | 0.9979 | |||

| c | W⊛ | 0.5607 | 0.3960 | 0.2729 | 0.1785 | 0.1047 | 0.0464 | 0.0000 | ||

| F⊛ | 1.5943 | 1.4137 | 1.2827 | 1.1840 | 1.1078 | 1.0479 | 1.0000 | |||

| 1.05 | a | W⊛ | 0.6160 | 0.4271 | 0.2871 | 0.1803 | 0.0976 | 0.0328 | 0.0182 | |

| F⊛ | 1.5846 | 1.4029 | 1.2723 | 1.1751 | 1.1009 | 1.0433 | 0.9978 | |||

| b | W⊛ | 0.6265 | 0.4331 | 0.2906 | 0.1823 | 0.0985 | 0.0331 | 0.0184 | ||

| F⊛ | 1.5820 | 1.4015 | 1.2715 | 1.1746 | 1.1006 | 1.0431 | 0.9977 | |||

| c | W⊛ | 0.6246 | 0.4389 | 0.3013 | 0.1964 | 0.1149 | 0.0508 | 0.0000 | ||

| F⊛ | 1.5967 | 1.4137 | 1.2815 | 1.1825 | 1.1066 | 1.0472 | 1.0000 | |||

| 1.045 | 0.95 | a | W⊛ | 0.5772 | 0.4023 | 0.2714 | 0.1708 | 0.0924 | 0.0308 | 0.0180 |

| F⊛ | 1.5881 | 1.4053 | 1.2738 | 1.1759 | 1.1012 | 1.0433 | 0.9976 | |||

| b | W⊛ | 0.5866 | 0.4077 | 0.2745 | 0.1726 | 0.0933 | 0.0310 | 0.0182 | ||

| F⊛ | 1.5858 | 1.4041 | 1.2731 | 1.1754 | 1.1010 | 1.0431 | 0.9976 | |||

| c | W⊛ | 0.5859 | 0.4138 | 0.2852 | 0.1865 | 0.1094 | 0.0485 | 0.0000 | ||

| F⊛ | 1.5997 | 1.4158 | 1.2830 | 1.1834 | 1.1070 | 1.0473 | 1.0000 | |||

| 1.05 | a | W⊛ | 0.6467 | 0.4481 | 0.3008 | 0.1885 | 0.1016 | 0.0335 | 0.0200 | |

| F⊛ | 1.5884 | 1.4033 | 1.2710 | 1.1732 | 1.0991 | 1.0420 | 0.9974 | |||

| b | W⊛ | 0.6578 | 0.4544 | 0.3044 | 0.1905 | 0.1025 | 0.0338 | 0.0202 | ||

| F⊛ | 1.5855 | 1.4017 | 1.2701 | 1.1726 | 1.0988 | 1.0419 | 0.9974 | |||

| c | W⊛ | 0.6563 | 0.4610 | 0.3164 | 0.2062 | 0.1206 | 0.0533 | 0.0000 | ||

| F⊛ | 1.6024 | 1.4157 | 1.2816 | 1.1818 | 1.1056 | 1.0465 | 1.0000 | |||

The LCCP that developed in the bearings in a and b relative to c when the bearing inclination parameter of w = 1 is caused by fluid expansion for varying values of n and M⊛ as the lubricant temperature rises. The temperatures in Figures 6 and 7 do not significantly differ between a and b.

A suction action may happen in parallel plane slider bearings when the surface boundary temperature of the slider bearing is lower than the pad temperature, according to Zienkiewicz [33], which investigated pads and sliders of a plane slider bearing at different boundary temperatures. As a consequence, the LCCP can drastically drop.

Considering the boundary temperature of the slider and pad over the effect of thermal (Tp > Ts or Tp < Ts) on the LCCP and drag frictional force of a slider bearing is of enormously realistic relevance, according to Pinkus and Sternlicht [34]. He claims that based on his finding, in reality, the stationary surface of the slider is usually warmer than the moving part of slider surface. Another very important condition in a slider bearing application is taking into account the inlet lubricant boundary temperature being lower than the pad and slider boundary temperatures of the bearing. Based on different cases of temperature boundary conditions given, the combined effects have been considered for the non-Newtonian power-law fluid flow lubricant at the following temperature boundary conditions:

Case i: Ti = Tp = 1.1 and Ts = 1.2.

Case ii: Ti = Ts = 1.1 and Tp = 1.2.

Case iii: Ti = 1.0, Ts = 1.1, and Tp = 1.2.

Case iv: Ti = 1.0, Ts = 1.2, and Tp = 1.1.

Table 4 displays the drag force and LCCP of non-Newtonian fluid film lubricant of 1D longitudinal roughness for various n and M⊛ power-law exponent effects corresponding to the aforementioned cases. The inflow inlet boundary temperature is lower than or equal to the other solid body of slider bearing. When the boundary temperature of the solid bodies are differs between Case i and Case ii for w = 0.4, the bearing performance of the pressure differs by 7%. For w = 1, however, Case ii performs somewhat better than Case i over all non-Newtonian constant consideration in terms of pressure and drag force. In the case of friction force, Cases ii and i are almost equal unless some differ from one another.

| Case | n/M | W⊛ | w | ||||||

|---|---|---|---|---|---|---|---|---|---|

| F⊛ | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | ||

| i | 0.95/0.53 | W⊛ | 0.3065 | 0.2179 | 0.1510 | 0.1002 | 0.0601 | 0.0284 | 0.0031 |

| F⊛ | 1.5516 | 1.3962 | 1.2790 | 1.1870 | 1.1125 | 1.0508 | 0.9989 | ||

| 1.05/1.045 | W⊛ | 0.6725 | 0.4721 | 0.3231 | 0.2092 | 0.1206 | 0.0510 | 0.0040 | |

| F⊛ | 1.5905 | 1.4038 | 1.2703 | 1.1714 | 1.0965 | 1.0387 | 0.9936 | ||

| ii | 0.95/0.53 | W⊛ | 0.2839 | 0.1968 | 0.1319 | 0.0823 | 0.0437 | 0.0135 | 0.0104 |

| F⊛ | 1.5509 | 1.3961 | 1.2795 | 1.1880 | 1.1138 | 1.0525 | 1.0007 | ||

| 1.05/1.045 | W⊛ | 0.6214 | 0.4248 | 0.1693 | 0.1693 | 0.0844 | 0.0182 | 0.0335 | |

| F⊛ | 1.5876 | 1.4039 | 1.1759 | 1.1759 | 1.1026 | 1.0460 | 1.0017 | ||

| iii | 0.95/0.53 | W⊛ | 0.2920 | 0.2046 | 0.1395 | 0.0896 | 0.0509 | 0.0204 | 0.0037 |

| F⊛ | 1.5513 | 1.3964 | 1.2796 | 1.1879 | 1.1136 | 1.0521 | 1.0002 | ||

| 1.05/1.045 | W⊛ | 0.6399 | 0.4426 | 0.2967 | 0.1860 | 0.1005 | 0.0338 | 0.0184 | |

| F⊛ | 1.5898 | 1.4052 | 1.2733 | 1.1757 | 1.1016 | 1.0444 | 0.9995 | ||

| iv | 0.95/0.53 | W⊛ | 0.3068 | 0.2184 | 0.1523 | 0.1014 | 0.0616 | 0.0302 | 0.0052 |

| F⊛ | 1.5522 | 1.3968 | 1.2796 | 1.1875 | 1.1130 | 1.0512 | 0.9992 | ||

| 1.05/1.045 | W⊛ | 0.6732 | 0.4736 | 0.3254 | 0.2122 | 0.1243 | 0.0553 | 0.0008 | |

| F⊛ | 1.5934 | 1.4066 | 1.2729 | 1.1738 | 1.0985 | 1.0404 | 0.9948 | ||

This mentioned table demonstrates that if the inflow inlet boundary temperature is lower than the other two solid bodies of slider bearing, Case iii’s friction force and LCCP show lower performance than Case iv’s for each fluid gap parameter value. Due to these many numerous factors and others, if the stationary part of slider bearing temperature rises above the other solid part of slider bearing temperature, the temperature may rise over all the slider bearing body that could affect the bearing’s ability to support pressure and its drag force.

Generally, we observed that in each case given above, when the values of the non-Newtonian parameters n and M⊛ increase, LCCP and drag force increase as well. In contrast to this, LCCP and frictional values decrease as the fluid gap parameter value decreases.

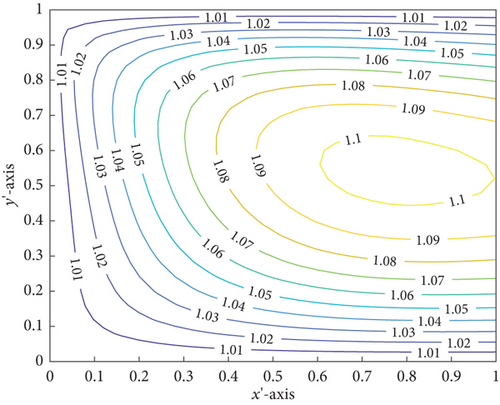

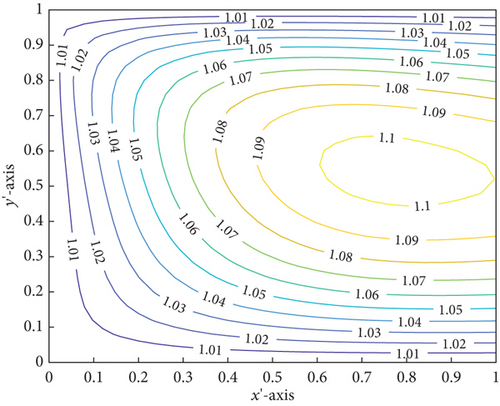

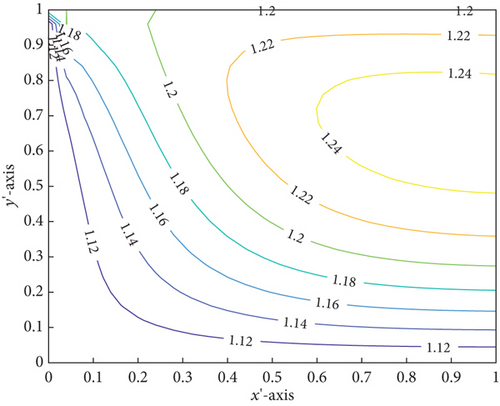

Figures 8 and 9 show the sliders over all temperature contours for Case i and Case ii for w = 0.4 to grasp more. Due to the fact that Case ii has more cumulative average temperature than Case i, Case ii’s LCCP for various values of n and M⊛ of non-Newtonian power-law fluid lubricant is lower than that of Case i.

In Table 5, assuming that inflow inlet boundary pressure is equal to zero, the LCCP of 1D transversal and longitudinal surface texture for different values of σ⊛, n = 0.95, and M⊛ = 0.53 is displayed. For 1D longitudinal surface roughness of slider bearing to support LCCP, it is evident that non-Newtonian fluid lubricants with less surface texture σ⊛ function show best results. For the 1D transverse surface texture model type, however, the opposite is true. Furthermore, as the surface texture value changes, there is a negligible variation in drag force for both types of models. As a consequence, a non-Newtonian fluid lubricant that has high surface texture values in the transverse model has greater effect thresholds, which is connected to its ability to hold more heavy loads.

| Type | σ⊛ | 0.0 | 0.02 | 0.04 | 0.06 | 0.08 | 0.10 |

|---|---|---|---|---|---|---|---|

| Longitudinal | w⊛ | 0.2999 | 0.2997 | 0.2991 | 0.2981 | 0.2968 | 0.2951 |

| F⊛ | 1.5505 | 1.5505 | 1.5505 | 1.5507 | 1.5508 | 1.5510 | |

| Transversal | w⊛ | 0.2999 | 0.3009 | 0.3042 | 0.3096 | 0.3172 | 0.3272 |

| F⊛ | 1.5505 | 1.5505 | 1.5504 | 1.5504 | 1.5503 | 1.5502 |

This is because the 1D longitudinal roughness model contains that the texture appears as furrows, long, narrow ridges, and valleys in the sliding direction (x-axis), allowing for the fast non-Newtonian fluid lubricant flow and resulting in a drop in pressure distribution, implying a reduction in LCCP. However, in the case of a transverse roughness pattern, which consists of valleys and ridges running in the direction perpendicular to sliding (x-direction), which obstruct the fluid flow lubricant, LCCP rises as a consequence.

5.2. Transverse 1D Roughness

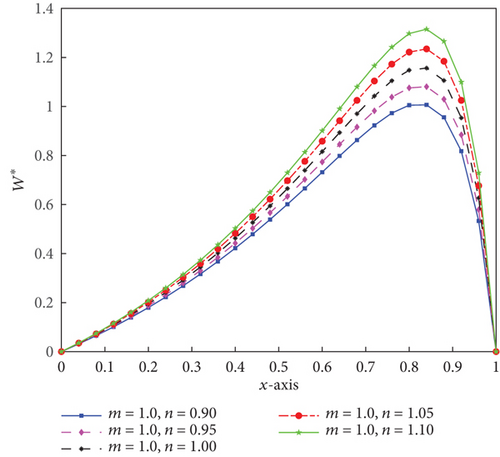

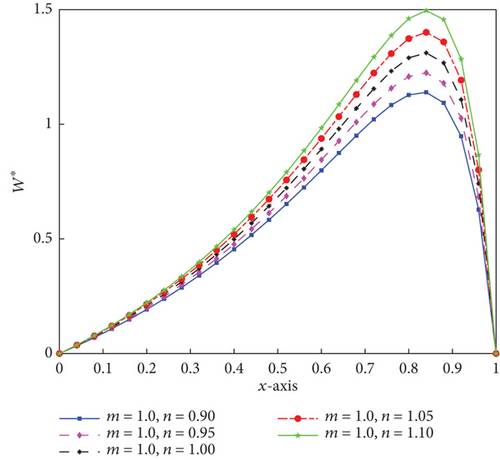

Figures 10, 11, and 12 illustrate the 1D transverse distribution of pressure performance caused by C1 for non-Newtonian fluid flow for different values of the local power-law exponent (n) and consistency factor (M⊛). For any constant value of n, M⊛, and x†, the LCCP is in ascending order of growing n value. Similar to what we see in the aforementioned graph, LCCP is rising as M⊛ rises for the same value of n. This demonstrates that as the value of n increases for various values of M⊛, the design of bearing will get better when taking both the effects of temperature and surface texture on LCCP. Additionally, a crucial component is the consistency factor.

For the fluid gap parameter w = 0.4, the LCCP and drag frictional force of transversal roughness are displayed in Table 6. It is obvious that the LCCP between b and c drops by about 8.9% for all values of n and M⊛ = 0.530. In the same fashion, for all given values of n and M⊛ = 0.530, the drag frictional force between c and b conditions almost goes to zero. The named table also indicates that the LCCP and drag force increase in each case as n and M⊛ increase in value.

| Condition | M⊛ | W⊛ | n | ||||

|---|---|---|---|---|---|---|---|

| F⊛ | 0.9 | 0.95 | 1.0 | 1.05 | 1.1 | ||

| a | 0.53 | W⊛ | 0.3076 | 0.3272 | 0.3470 | 0.3672 | 0.3876 |

| F⊛ | 1.5501 | 1.5502 | 1.5503 | 1.5502 | 1.5500 | ||

| 1.0 | W⊛ | 0.5762 | 0.6130 | 0.6502 | 0.6880 | 0.7264 | |

| F⊛ | 1.5813 | 1.5816 | 1.5812 | 1.5806 | 1.5793 | ||

| 1.045 | W⊛ | 0.6018 | 0.6401 | 0.6789 | 0.7184 | 0.7586 | |

| F⊛ | 1.5850 | 1.5852 | 1.5848 | 1.5840 | 1.5825 | ||

| b | 0.53 | W⊛ | 0.2820 | 0.2999 | 0.3179 | 0.3362 | 0.3549 |

| F⊛ | 1.5502 | 1.5505 | 1.5506 | 1.5507 | 1.5507 | ||

| 1.0 | W⊛ | 0.5284 | 0.5618 | 0.5956 | 0.6299 | 0.6649 | |

| F⊛ | 1.5817 | 1.5821 | 1.5822 | 1.5819 | 1.5816 | ||

| 1.045 | W⊛ | 0.5518 | 0.5866 | 0.6890 | 0.6578 | 0.6941 | |

| F⊛ | 1.5853 | 1.5858 | 1.5974 | 1.5855 | 1.5846 | ||

| c | 0.53 | W⊛ | 0.3098 | 0.3295 | 0.3495 | 0.3698 | 0.3905 |

| F⊛ | 1.5514 | 1.5517 | 1.5519 | 1.5520 | 1.5520 | ||

| 1.0 | W⊛ | 0.5846 | 0.6217 | 0.6594 | 0.6977 | 0.7367 | |

| F⊛ | 1.5906 | 1.5915 | 1.5922 | 1.5926 | 1.5926 | ||

| 1.045 | W⊛ | 0.6109 | 0.6496 | 0.6890 | 0.7291 | 0.7699 | |

| F⊛ | 1.5956 | 1.5966 | 1.5974 | 1.5978 | 1.5978 | ||

The values of the LCCP for each fixed n and M⊛ are in the sequence of pressure due to condition (b)< condition (a)< condition (c) for all parameters, indicating that the LCCP is in the same order as the corresponding condition of pressure for non-Newtonian power-law fluid. For all values of n and M⊛ throughout the entire fluid gap, condition (a)< condition (b)< condition (c) are in that order for frictional force. Additionally, for n = 0.90 and M⊛ = 0.530, the load-bearing capacity for non-Newtonian between b and c differs by 0.7%, and the change in friction force for w = 0.4 is reduced by 2%.

This could be as consequence of the transverse roughness pattern, which obstructs the non-Newtonian fluid flow lubricant and increases pressure.

The LCCP and drag force of transversal roughness are illustrated in Table 7 for various n and M⊛ effects corresponding to the aforementioned conditions and fluid flow gap. The sold body of slider bearing boundary temperatures is lower than or equal to the inflow intake temperature. When Cases i and ii for w = 0.4 have different sold body temperatures of bearing, the performance of the load changes by 6%. In terms of load and drag force, Case i performs a little bit better than Case ii for w = 1. When it comes to friction force, Cases i and ii just slightly differ from one another.

| Case | n/M | W⊛ | w | ||||||

|---|---|---|---|---|---|---|---|---|---|

| F⊛ | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | ||

| i | 0.95/0.53 | W⊛ | 0.3380 | 0.2357 | 0.1617 | 0.1061 | 0.0632 | 0.0296 | 0.0030 |

| F⊛ | 1.5508 | 1.3957 | 1.2787 | 1.1867 | 1.1123 | 1.0508 | 0.9989 | ||

| 1.05/1.045 | W⊛ | 0.7427 | 0.5117 | 0.3461 | 0.2222 | 0.1274 | 0.0537 | 0.0041 | |

| F⊛ | 1.5857 | 1.4011 | 1.2684 | 1.1701 | 1.0956 | 1.0384 | 0.9937 | ||

| ii | 0.95/0.53 | W⊛ | 0.3167 | 0.2155 | 0.1428 | 0.0886 | 0.0471 | 0.0149 | 0.0103 |

| F⊛ | 1.5502 | 1.3957 | 1.2792 | 1.1877 | 1.1136 | 1.0523 | 1.0007 | ||

| 1.05/1.045 | W⊛ | 0.6947 | 0.4664 | 0.3039 | 0.1834 | 0.0919 | 0.0215 | 0.0332 | |

| F⊛ | 1.5835 | 1.4016 | 1.2711 | 1.1747 | 1.1017 | 1.0455 | 1.0017 | ||

| iii | 0.95/0.53 | W⊛ | 0.3245 | 0.2231 | 0.1502 | 0.0958 | 0.0541 | 0.0217 | 0.0037 |

| F⊛ | 1.5506 | 1.3959 | 1.2793 | 1.1876 | 1.1134 | 1.0520 | 1.0002 | ||

| 1.05/1.045 | W⊛ | 0.7123 | 0.4836 | 0.3206 | 0.1997 | 0.1078 | 0.0369 | 0.0183 | |

| F⊛ | 1.5854 | 1.4027 | 1.2716 | 1.1744 | 1.1007 | 1.0439 | 0.9995 | ||

| iv | 0.95/0.53 | W⊛ | 0.3384 | 0.2363 | 0.1626 | 0.1073 | 0.0647 | 0.0314 | 0.0051 |

| F⊛ | 1.5514 | 1.3963 | 1.2792 | 1.1872 | 1.1128 | 1.0511 | 0.9992 | ||

| 1.05/1.045 | W⊛ | 0.7437 | 0.5133 | 0.3484 | 0.2253 | 0.1311 | 0.0580 | 0.0007 | |

| F⊛ | 1.5886 | 1.4039 | 1.2710 | 1.1724 | 1.0976 | 1.0400 | 0.9949 | ||

The named table indicates that for any fluid gap, Case iv’s friction force and LCCP are lower than Case iii’s if the inflow inlet boundary temperature is lower than that of the solid body of the bearing. The temperature may increase across all the bearings if the pad temperature exceeds the slider temperature, which would decrease the bearing’s capacity to withstand loads and frictional force. In each case, we observe that LCCP and frictional force rise as the non-Newtonian parameters n and M⊛ grow. In contrast, as the fluid gap rises, the LCCP and frictional values decrease.

For various inclination parameters of a power-law non-Newtonian fluid-type lubricant, Table 8 displays the LCCP and drag force of transversal roughness corresponding to the aforementioned conditions. The values of the LCCP and drag force for each fixed n and M⊛ are in the order of pressure due to condition (b)< condition (a)< condition (c), indicating that the LCCP is in the same order as the relating condition of pressure. This table shows that the bearing performance increases under each condition as the values of n and M⊛ increase and decreases under each condition when fluid film gap decreases.

| M⊛ | n | Ci | W⊛ | w | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.53 | F⊛ | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | ||

| 0.95 | a | W⊛ | 0.3252 | 0.2253 | 0.1519 | 0.0968 | 0.0545 | 0.0215 | 0.0045 | |

| F⊛ | 1.5502 | 1.3955 | 1.2787 | 1.1870 | 1.1128 | 1.0514 | 0.9997 | |||

| b | W⊛ | 0.2999 | 0.2098 | 0.1429 | 0.0917 | 0.0518 | 0.0203 | 0.0045 | ||

| F⊛ | 1.5505 | 1.3957 | 1.2789 | 1.1872 | 1.1130 | 1.0515 | 0.9997 | |||

| c | W⊛ | 0.3295 | 0.2281 | 0.1553 | 0.1006 | 0.0587 | 0.0259 | 0.0000 | ||

| F⊛ | 1.5517 | 1.3968 | 1.2799 | 1.1880 | 1.1135 | 1.0519 | 1.0000 | |||

| 1.05 | a | W⊛ | 0.3672 | 0.2513 | 0.1686 | 0.1070 | 0.0600 | 0.0236 | 0.0050 | |

| F⊛ | 1.5502 | 1.3950 | 1.2781 | 1.1864 | 1.1123 | 1.0511 | 0.9997 | |||

| b | W⊛ | 0.3362 | 0.2339 | 0.1585 | 0.1013 | 0.0570 | 0.0223 | 0.0050 | ||

| F⊛ | 1.5507 | 1.3953 | 1.2784 | 1.1866 | 1.1125 | 1.0512 | 0.9997 | |||

| c | W⊛ | 0.3698 | 0.2545 | 0.1724 | 0.1114 | 0.0647 | 0.0285 | 0.0000 | ||

| F⊛ | 1.5520 | 1.3966 | 1.2794 | 1.1875 | 1.1132 | 1.0517 | 1.0000 | |||

| 1.0 | 0.95 | a | W⊛ | 0.6130 | 0.4198 | 0.2804 | 0.1757 | 0.0954 | 0.0328 | 0.0163 |

| F⊛ | 1.5816 | 1.4029 | 1.2734 | 1.1764 | 1.1021 | 1.0440 | 0.9980 | |||

| b | W⊛ | 0.5618 | 0.3907 | 0.2633 | 0.1659 | 0.0900 | 0.0304 | 0.0166 | ||

| F⊛ | 1.5821 | 1.4034 | 1.2740 | 1.1770 | 1.1025 | 1.0442 | 0.9979 | |||

| c | W⊛ | 0.6217 | 0.4305 | 0.2929 | 0.1899 | 0.1107 | 0.0488 | 0.0000 | ||

| F⊛ | 1.5915 | 1.4120 | 1.2813 | 1.1829 | 1.1070 | 1.0475 | 1.0000 | |||

| 1.05 | a | W⊛ | 0.6880 | 0.4682 | 0.3111 | 0.1942 | 0.1049 | 0.0358 | 0.0181 | |

| F⊛ | 1.5806 | 1.4004 | 1.2705 | 1.1738 | 1.1000 | 1.0428 | 0.9978 | |||

| b | W⊛ | 0.6299 | 0.4354 | 0.2920 | 0.1831 | 0.0990 | 0.0332 | 0.0185 | ||

| F⊛ | 1.5819 | 1.4013 | 1.2713 | 1.1745 | 1.1005 | 1.0431 | 0.9977 | |||

| c | W⊛ | 0.6977 | 0.4802 | 0.3254 | 0.2101 | 0.1221 | 0.0537 | 0.0000 | ||

| F⊛ | 1.5926 | 1.4112 | 1.2797 | 1.1812 | 1.1057 | 1.0467 | 1.0000 | |||

| 1.045 | 0.95 | a | W⊛ | 0.6401 | 0.4382 | 0.2924 | 0.1829 | 0.0989 | 0.0335 | 0.0179 |

| F⊛ | 1.5852 | 1.4035 | 1.2725 | 1.1748 | 1.1005 | 1.0429 | 0.9977 | |||

| b | W⊛ | 0.5866 | 0.4077 | 0.2745 | 0.1726 | 0.0933 | 0.0310 | 0.0182 | ||

| F⊛ | 1.5858 | 1.4041 | 1.2731 | 1.1754 | 1.1010 | 1.0431 | 0.9976 | |||

| c | W⊛ | 0.6496 | 0.4498 | 0.3061 | 0.1984 | 0.1156 | 0.0510 | 0.0000 | ||

| F⊛ | 1.5966 | 1.4139 | 1.2815 | 1.1822 | 1.1062 | 1.0469 | 1.0000 | |||

| 1.05 | a | W⊛ | 0.7184 | 0.4886 | 0.3244 | 0.2021 | 0.1087 | 0.0365 | 0.0198 | |

| F⊛ | 1.5840 | 1.4008 | 1.2693 | 1.1719 | 1.0983 | 1.0416 | 0.9975 | |||

| b | W⊛ | 0.6578 | 0.4544 | 0.3044 | 0.1905 | 0.1025 | 0.0338 | 0.0202 | ||

| F⊛ | 1.5855 | 1.4017 | 1.2701 | 1.1726 | 1.0988 | 1.0419 | 0.9974 | |||

| c | W⊛ | 0.7291 | 0.5018 | 0.3400 | 0.2196 | 0.1276 | 0.0561 | 0.0000 | ||

| F⊛ | 1.5978 | 1.4130 | 1.2797 | 1.1804 | 1.1047 | 1.0461 | 1.0000 | |||

Even though it is slight, fluid film expansion as the temperature of the fluid lubricant rises for various values of n and M⊛ results in the generation of LCCP in conditions a and b relative to c at w = 1.

6. Conclusions

- •

The bearing performance (LCCP and drag force) for both types of nonparallel plane slider bearings improves. However, the LCCP and drag force are minimal when w = 1 (in parallel). In both model types, the opposite is true for drag force.

- •

When power-law non-Newtonian fluid type is combined with the assumption that the slider’s temperature is higher than the pad’s, LCCP is higher for nonparallel bearing while it decreases to zero for parallel bearing (w = 1).

- •

Under all of the aforementioned circumstances, as the non-Newtonian power-law constant parameters n and M⊛ increase, so do the LCCP and drag force. The significance of taking into account the effects of the non-Newtonian power-law parameters n, M⊛, and surface roughness is brought out by this.

- •

1D longitudinal roughness slider bearings often have a lower pressure distribution than 1D transversal models.

- •

This method’s drawback is that it is challenging to discretize the given irregular domain using a bilinear rectangular element, particularly in slider bearings with irregular upper and lower bounds.

Symbols

-

- 1D

-

- one dimensional

-

- δ

-

- random distribution of roughness

-

- μ

-

- viscosity of the lubricant

-

- μav

-

- average viscosity across the film

-

- ρ

-

- density of the lubricant

-

- ρav

-

- average density across the film

-

- σ2

-

- variation of roughness

-

- B

-

- bearing width

-

- pr

-

- Prandtl number

-

- T

-

- lubricant temperature

-

- Tav

-

- average temperature across the film

-

- U

-

- velocity of the moving surface

-

- E

-

- expected value operator

-

- Ec

-

- Eckert number

-

- h

-

- nominal film thickness

-

- h0

-

- nominal film thickness at outlet

-

- hi

-

- nominal film thickness at inlet

-

- Ht

-

- height of rough surface

-

- k

-

- thermal conductivity of lubricant

-

- P

-

- lubricant pressure

-

- pe

-

- Peclet number

-

- pi

-

- inlet pressure

-

- v

-

- velocity in the direction of the y-coordinate

-

- w

-

- h0/hi

-

- W⊛

-

- load-carrying capacity of the bearing

-

- x†, y†

-

- transformed coordinate system

-

- ⊛

-

- a superscript “⊛” indicates the nondimensional quantity

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

The authors declare that no funds, grants, or other support was received during the preparation of this manuscript.

Open Research

Data Availability Statement

The authors have nothing to report.