Innovative Design for Energy Storage Cold Chain Logistics Vehicles

Abstract

To meet the demand for cold chain logistics through green transportation, this study designed a solar-powered vehicle with energy storage ability for cold chain logistics operations. The designed vehicle has solar panels on its roof that power the refrigeration system of the vehicle during transportation. This use of solar energy enables the fuel and energy consumption of the vehicle to be reduced. Moreover, the energy storage ability of the designed vehicle enables its refrigeration system to continue running continuously even when the vehicle is switched off. The designed vehicle reduces carbon and CO2 emissions by at least 36.3%, thereby mitigating urban air pollution. This study develops a business model to help relevant companies reduce carbon credit costs, ensure compliance with regulations and standards, and enhance corporate image. Thus, the designed vehicle contributes to the achievement of the sustainable development goals (SDGs) of the United Nations and the global objective of realizing net-zero carbon emissions by 2050; particularly, SDG 9 relates to the industry, innovation, and infrastructure; SDG 12 relates to responsible production and consumption; and SDG 13 relates to climate action.

1. Introduction

Since the 19th century, the average global temperature has increased by approximately 1.1°C, primarily because of carbon emissions from fossil fuel use and other human activities. The European Union’s long-term goals for achieving climate neutrality mandate that renewable energy should account for at least 75% of the total energy mix by 2050 [1]. However, the COVID-19 pandemic and changes in consumer behavior have led to a rapid increase in the demand for home delivery services. For example, Sheth showed that consumer behaviors have changed during the COVID-19 pandemic, such as increased online shopping, preference for home delivery, and a heightened focus on health and safety [2]. Donthu and Gustafsson demonstrated that the pandemic dramatically altered consumer behavior, with a notable increase observed in online shopping and the demand for delivery services [3]. This shift has driven growth in e-commerce and logistics, and businesses have to adapt to this new market dynamic. This trend has fueled the growth of retailers and e-commerce businesses, and the increase in the number of delivery vehicles comes with larger carbon footprint.

Moreover, according to statistics released by the Bureau of Energy, Ministry of Economic Affairs (MOEA), Taiwan’s total greenhouse gas emissions amounted to 285.97 million metric tons of carbon dioxide equivalent in 2022. The energy sector accounts for 71% of direct CO2 emissions in Taiwan, followed by transportation (13%), manufacturing (12.96%), households (2%), service industries (1%), and agriculture (less than 1%) [4]. While the transportation sector is widely recognized as the largest fuel-consuming sector in many countries, some research showed that accurate estimation of CO2 emission factors is essential for monitoring and managing the environmental impact of electricity generation, especially in countries where fossil fuels dominate the energy mix [5, 6]. However, dependence on imported fuels exposes Taiwan to global oil price fluctuations, which can impact the national economy. Additionally, high emissions may lead to international trade challenges, especially with the implementation of carbon border adjustment mechanisms.

The energy sustainability and independence are strategic concerns. Based on national security considerations, Taiwan’s heavy reliance on imported energy sources makes it vulnerable to external supply disruptions [7]. In addition, the concentration of transportation infrastructure in certain areas may pose risks in the event of natural disasters or geopolitical tensions. Therefore, Taiwan is promoting electric vehicles (EVs) to reduce dependence on fossil fuels and lower emissions. Recent research shows that widespread EV adoption could reduce energy consumption in the transportation sector by up to 82% by 2040 [8].

Projections based on several illustrative scenarios indicate that the global stock of light-duty vehicles will expand from 1.1 billion in 2015 to 1.65∼1.75 billion by 2050, whereas the global EV stock is anticipated to increase from roughly one million to between 585 million and 825 million over the same period [9]. In 2022, global CO2 emissions from the transport sector increased by more than 250 MtCO2, reaching nearly 8 GtCO2, which represents a 3% rise compared to 2021 [10]. Since 2000, tailpipe CO2 emissions from heavy-duty vehicles have exhibited a significant upward trend, with trucks contributing to over 80% of this increase. According to the International Energy Agency (IEA), despite comprising less than 8% of the total vehicle population (excluding two- and three-wheeled vehicles), trucks and buses are responsible for more than 35% of direct carbon dioxide emissions originating from road transportation. These statistics underscore the significant impact of the transportation sector on global fuel consumption and greenhouse gas emissions. The continued growth in vehicle numbers and distances traveled emphasizes the need for sustainable transportation solutions to mitigate environmental impacts and enhance national energy security. To mitigate the ongoing rise in emissions, it is essential to implement stringent vehicle efficiency standards and promote enhancements in logistics and operational efficiency.

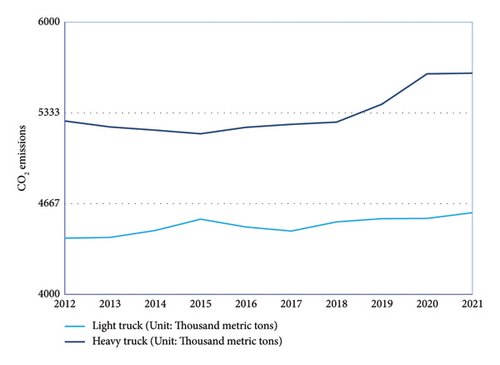

Delivery vehicles play a significant role in air pollution and energy consumption. In busy urban areas, delivery vehicles often idle while transporting goods. Over time, vehicle idling contributes notably to deteriorating air quality, energy wastage, and overall climate change. Therefore, an innovative solution is needed to reduce the negative environmental impact of delivery vehicles. During transportation, there are often issues related to energy consumption and environmental pollution, particularly greenhouse gas emissions. The total carbon dioxide emissions and energy consumption of light and heavy trucks in Taiwan are illustrated in Figure 1 [11]. This figure shows that the carbon emissions and energy consumption of trucks have increased over time in Taiwan. Therefore, we aim to achieve the goals of reducing greenhouse gas emissions, conserving energy, and transforming energy through this research.

Furthermore, Taiwan has three types of carbon taxes under the Climate Change Response Act of 2023. The vehicle designed in this study can help businesses to comply with these regulations and thus reduce their carbon taxes. In addition, several studies have explored the application of new energy technologies in light- and heavy-duty trucks [12–15]. For example, Breuer et al. indicated that electrification and hydrogen energy technologies can be used to reduce the environmental impact of truck transportation [12]. Moreover, Teixeira et al. analyzed various alternative fuel technologies, such as battery EVs, fuel cell EVs, compressed natural gas vehicles, liquefied natural gas vehicles, and biofuel vehicles, and compared their applications in heavy-duty trucks [13]. They evaluated the effectiveness of these technologies in reducing greenhouse gas emissions and air pollutants (such as nitrogen oxides and particulate matter) and explored the potential of using the technologies for reducing the environmental impact of heavy-duty trucks.

Studies have provided a comprehensive overview of the current and possible future applications of solar energy technology in vehicles [14, 15]. Wang et al. indicated that analyzing the optimal layout strategy for charging stations within the logistics network ensures the efficient operation of EV fleets. They also explored how renewable energy, such as solar and wind, can be integrated into charging infrastructure [16]. Such integration not only reduces the dependence on the traditional power grid but also decreases operational costs. The aforementioned authors also examined the role of energy storage technologies, such as battery energy storage systems, in achieving a balance between energy supply and demand. Moreover, recent studies have increasingly focused on the development of standalone or isolated hybrid renewable energy systems, integrating sources such as photovoltaic (PV) panels, wind turbines, diesel generators, and pumped hydroelectric storage [6, 17–20]. These systems are designed to enhance the reliability, economic viability, and environmental sustainability of power supply, particularly for remote regions, critical infrastructure, and areas facing electricity shortages. They also analyzed across different contexts and consistently demonstrated that hybrid energy systems can effectively mitigate energy deficits while facilitating the broader transition toward sustainable and resilient energy solutions.

Therefore, some enterprises have begun to manufacture solar-powered camper vans; however, solar-powered logistics vehicles have not yet been developed. Thus, we aimed to design a solar-powered vehicle capable of energy storage for cold chain logistics and build a sustainability business model in this study. Specifically, the designed vehicle can provide long-term sustainability of the proposed solution. It can reduce energy consumption and environmental pollution. In addition, utilizing solar energy to power compressors in cold chain logistics vehicles enables firms to align with carbon emission regulations and environmental standards, thereby reducing the risk of regulatory penalties and lowering carbon taxes. Furthermore, the proposed solution can help reduce carbon emissions in the delivery industry, thereby mitigating the impact of climate change.

2. Literature Review

2.1. Cold Chain Logistics and Solar Technology Applications

Recently, the American transportation company Thermo King operates electric refrigeration units on transport vehicles and is gradually improving on this technology [21]. This company has begun to develop solar-powered refrigeration units to reduce the charging time, energy consumption, and carbon emissions associated with cold-chain delivery.

Solar-powered refrigerated logistics vehicles are gradually becoming a viable alternative to traditional diesel refrigerated trucks. For example, Sono Motors developed a solar-powered refrigerated vehicle that can generate at least 50% of its energy requirements; this vehicle reduces operating costs and has high efficiency. The TIP Group’s “Endurance” transport refrigeration unit has demonstrated the feasibility and benefits of using solar energy and battery technology in cold chain transportation. Thermo King and- “Carrier Transicold” provide solar energy solutions where the solar panels are designed to keep the battery of the refrigeration unit charged, even under low light conditions and indirect sunlight. Additionally, many modern campers are equipped with solar panels on their roof, with these solar panels generating the electricity required by the vehicle. These systems use charging and energy storage technologies to supply power to a vehicle’s refrigeration, air conditioning, and water heating systems, thereby reducing the consumption of petroleum energy.

Previous studies have indicated that solar PV cell technology has become more diversified and is widely applied in energy, construction, transportation, and electronic devices [22, 23]. Some research has explored the key factors in the design and manufacturing of energy-efficient solar-powered transportation [24, 25]. Minak et al. mainly discusses how to improve the energy efficiency of solar-powered boat, including aerodynamic design, the application of lightweight materials, the optimization of solar cell performance, and smart energy management systems [24]. Their results emphasize the importance of these factors in reducing energy consumption, extending the driving range, and enhancing overall performance. In addition, Yamaguchi et al. focused on the development of high-efficiency and low-cost solar cells for PV-powered vehicles. They also explored the integration of these solar cells into vehicles, assessing their potential impact on energy consumption, driving range, and overall sustainability of PV-powered vehicles [25].

Moreover, the development of solar-powered EVs (SEVs) [26] is crucial for establishing a new clean energy society that achieves carbon neutrality. Several studies have illustrated the solar panel installation process and explored its implementation [27–31]. Major automakers have already implemented vehicle-integrated PV solutions in mass-market cars, such as Toyota Prius PHEV, Hyundai Ioniq 5, and Hyundai Sonata [27]. Katuri and Gorantla explored the optimal placement of solar panels in vehicles to maximize solar energy absorption efficiency and analyzed the impact of different types of PV battery technologies (such as monocrystalline silicon, polycrystalline silicon, and thin-film solar cells) on the performance of EVs [30]. Sankar and Seyezhai developed a solar EV prototype to verify the consistency of simulation results with actual applications, including solar power generation efficiency, battery performance, energy management strategies, and vehicle operating performance [31].

In addition, some research has extensively examined the integration of renewable energy sources with EV infrastructure and the advancement of EV charging technologies [32–39]. Mahmoud et al. provided a comprehensive review of charging systems and techniques for EVs, highlighting both conventional and emerging methods [32]. Integrating renewable energy with EV infrastructure to increase overall system renewability was explored by Ahmed et al. [34], while Khaleel et al. conducted a comparative analysis of EV market trends across China, Europe, and the United States [35]. Furthermore, Alsharif et al. [36] applied the whale optimization algorithm to optimize renewable energy integration with solar-to-vehicle technologies, emphasizing the importance of intelligent system design. Fast-charging solutions for lithium-ion batteries (LIBs) are critical for accelerating EV adoption [37]. Finally, Abodwair et al. assessed the techno-economic feasibility of a hybrid renewable energy-based EV charging station, underscoring the potential for sustainable EV infrastructure in emerging markets [39].

However, some companies have developed integrated charging and storage systems that use an energy management system to connect charging stations with energy storage systems. These systems can supply stored power to charging stations during periods of peak grid usage, thereby reducing the load on the power grid. Hence, this study designed a delivery vehicle in which solar panels convert solar energy into electricity to power refrigeration units with any excess electricity being stored in the vehicle’s energy storage system. Subsequently, the stored electricity can be transferred to charging stations installed at gas stations, convenience stores, or parking lots. The designed vehicle not only generates its own electricity but can also distribute power. This study also developed an accompanying mobile application to enable drivers to easily locate charging stations, thereby facilitating sustainable energy management.

2.2. Business Models

Research on business models has grown since 1990 [40–48]. Researchers often use the literature on transaction cost economics and capital budgeting as a theoretical basis for the development of business models. Foundational theories related to business models include Schumpeter’s innovation theory and the resource-based view of a firm [42–46]. Some studies have emphasized the connection between business models and managerial cognition [45], exploring the application of business model innovation in various industries and its effect on corporate competitive advantage [46].

According to Hatch [47], a business model should not be confined to only clients; it should also encompass suppliers, partners, competitors, and other stakeholders. Sustainable business model innovation refers to the process through which companies innovate and change their business models to achieve sustainable economic, social, and environmental development [48]. This approach not only focuses on corporate profitability but also emphasizes environmental and social responsibility. Companies must adopt more sustainable business models to address global environmental and social challenges, such as climate change, resource scarcity, and social inequality. Such models can not only benefit the long-term development of a company but also contributes to social and environmental development. Thus, this study developed a green business model: how a green business operates, what type of value it delivers, and how it manages this value and communicates the value to stakeholders.

3. Materials and Methods

3.1. Designed Vehicle

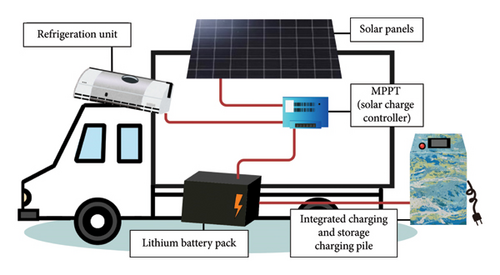

A schematic of the vehicle designed in this study for cold-chain logistics is displayed in Figure 2. By converting how many kilowatt-hours of electricity a square meter of solar panels can generate per hour on average, and if there is excess electricity, whether it can be stored in charging piles with minimal loss to supplement the electricity needed by refrigerated logistics vehicle.

This design concept illustrates the structure and function of a solar-powered refrigeration vehicle equipped with renewable energy and energy storage technologies. In this study, main components are described as follows. First, the solar panel module mounted on the roof captures solar energy and converts it into electricity, providing power for the vehicle’s refrigeration system. The raw material for monocrystalline silicon solar panels offers fast electron mobility and performs well under weak-light conditions, resulting in higher power generation efficiency [49, 50]. Second, the maximum power point tracking (MPPT) controller regulates the power flow from the solar panels to the lithium battery pack, ensuring maximum efficiency in charging. It plays a crucial role in optimizing the power output, especially under varying sunlight conditions. It is essential for PV systems to adjust their operating point effectively and precisely to optimize power generation by employing MPPT technology [51]. Third, the high-capacity LIBs store the energy generated by the solar panels. LIBs have been widely regarded as a highly efficient energy storage system due to their superior energy density, power density, reliability, and stability, securing an indispensable role in various fields of research over the past decades [52]. It provides a reliable power source for the refrigeration unit and other onboard electrical systems when solar power is insufficient, such as during cloudy weather or nighttime. Finally, the storage charging system and the storage charging pile act as a charging interface for the battery system, allowing for external charging when solar energy is not available. It ensures that the battery can be charged from an external power source if necessary.

3.2. Power Storage Devices

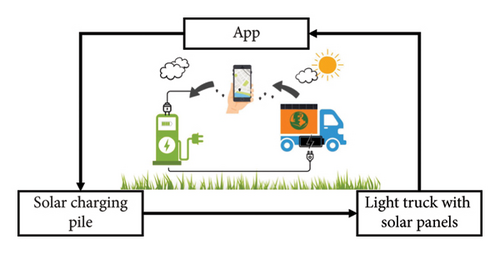

Solar panels are installed on the designed vehicle. These panels generate power for the operation of the vehicle, including its refrigeration system, with excess power being stored in an energy storage device. The excess power can then be transferred from this device to a charging station when the designed vehicle is refueling at a gas station or is parked at a location for an extended period. The overall design concept is illustrated in Figure 3. Additionally, solar panels will be added to the charging stations, and the energy source for the charging stations will rely solely on green energy, reducing dependence on traditional energy sources.

3.3. App for Optimizing Route Planning and Device Usage

Cold chain logistics involves the transportation of perishable goods that require special temperature control; thus, cold chain logistics has a high energy consumption and carbon footprint. The growing awareness regarding environmental protection has contributed to increased efforts to reducing carbon emissions in cold chain logistics. A prior study focuses on combining vehicle routing optimization and carbon trading mechanisms to provide an innovative solution for reducing carbon emissions and costs in cold chain logistics [53].

- •

Map interface: The designed app provides an interactive map interface that shows all nearby locations at which energy storage devices are installed. Drivers can easily find the nearest energy storage device by analyzing the map.

- •

Status of each energy storage device: The marker for each location displays the status of the energy storage device, including the available power and remaining capacity. Thus, drivers can select an appropriate charging location on the basis of their charging and power storage.

- •

Navigation function: The designed app offers a navigation function to guide drivers to the selected charging station. Drivers can select their preferred charging station through the app and then make their way to the station.

- •

Data collection: Because all vehicles use a global positioning system, the usage statuses of charging stations at various locations and the energy consumption of vehicles visiting these stations can be accurately tracked.

4. Results and Discussion

4.1. Energy Usage

In this study, the weight of the designed logistics vehicle was assumed to be less than 5 tons; the cargo box carried by the vehicle was assumed to have a length, width, and height of 4.3, 1.9, and 1.6 m, respectively; and the roof area of the vehicle was assumed to be 8.17 m2 (2.5 pings). This area can accommodate a solar power system with a peak power of approximately 1 kWp. The designed vehicle was assumed to use the V100 MAX compressor manufactured by Thermo King [21] for refrigeration. This compressor requires a power of approximately 1090 W (Pcompressor) to maintain a temperature of −20°C. Thus, this compressor would consume a power of 13,080 W if it was operated for an average of 12 h a day (time). In this study, the conversion efficiency was assumed to be 90% (ηinventer = 0.9). Under this assumption, the designed refrigerated logistics vehicle would require 14,533 W (≈14.5 kWh) of power per day. The relevant equations are as follows:

Equivalent sunlight hours are a crucial factor for evaluating solar power generation. A higher number of equivalent sunlight hours indicates the existence of stronger sunlight in an area, which can facilitate higher electricity generation. This parameter represents the effective exposure time under a standard energy density of 1000 W/m2; that is, it denotes the total number of hours in a day that solar panels can operate at their full power. In Taiwan, the number of equivalent sunlight hours ranges from approximately 900 to 1650 per year, with the daily average number of sunlight hours being approximately 2.5∼4.5 [54]. According to available data, most solar power stations in Taiwan generate power for an average of approximately 4∼5 h daily in the summer [55]. Therefore, the present study assumed the number of sunlight hours per day to be 4. In 4 equivalent sunlight hours, a solar panel system covering an area of 8.17 m2 can generate approximately 4 kWh of electricity, which is insufficient for meeting the daily requirement of the vehicle. The shortfall can be supplemented using the electricity stored in the energy storage devices of other logistics vehicles. In the designed vehicle, the refrigeration compressor is powered by solar energy and stored battery power rather than diesel; thus, the diesel consumption of the vehicle is reduced.

4.2. Cooling Load Estimation

4.2.1. Assumptions and Conditions

- -

Outdoor air temperature (Tout): 35°C (typical summer condition in Taiwan)

- -

Compartment internal temperature (Tin): −20°C for freezing

- -

Thermal conductivity of the insulation material (λ): 0.035 W/m·K (polyurethane foam)

- -

Insulation thickness (d): 80 mm (0.08 m)

- -

Compartment dimensions: 4.3 m length (L) × 1.9 m width (W) × 1.6 m height (H)

4.2.2. Surface Area Calculation

4.2.3. Overall Heat Transfer Coefficient

4.2.4. Wall Conduction Cooling Load

4.2.5. Total Cooling Load Estimation

4.3. Total Electricity Generated by Solar Panels

The Future Circulation Research Institute estimated that the number of logistics vehicles in Taiwan would be 81,000 in 2022 [57], with 9680 of these vehicles being cold chain logistics vehicles. The designed vehicle can generate 4 kWh of electricity per day in Taiwan; thus, if all logistics vehicles in Taiwan use the proposed design, they could generate a total of approximately 324,000 kWh of electricity per day. A cold chain logistics vehicle operating in Taiwan requires approximately 14.5 kWh of electricity per day; thus, the total electricity consumed by all cold-chain logistics vehicles in Taiwan is approximately 140,360 kWh per day. Therefore, if the power generated by all logistics vehicles in Taiwan is stored in power storage devices, then this power can be used to completely meet the electricity requirements of cold-chain logistics vehicles in Taiwan. The relevant equations are as follows:

The electricity generated by all logistics vehicles would be sufficient to fully cover the total electricity requirement of all cold-chain logistics vehicles in Taiwan, provided that effective energy storage systems are implemented.

4.4. Costs of the Installed Solar Panel and Charging Pile Setup

On the basis of a survey of various installation costs in Taiwan, this study estimated the cost of installing a 1 kWp solar panel on a logistics vehicle in Taiwan to be approximately US$2000 (including the cost of an MPPT controller). Thus, the cost of fitting 81,000 logistics vehicles with solar panels would be approximately US$162 million. Moreover, according to the PRO360 expert network in Taiwan, the average cost of installing a charging station in Taiwan was approximately US$3333 from 2022 to 2024.

According to statistics from AmpGo, as of the end of 2023, 1689 direct-current fast charging stations were in operation in Taiwan [58]. Because the use of charging stations is not yet widespread in Taiwan, 1000 charging stations can be initially established throughout Taiwan, on the basis of sunlight hours, resulting in a cost of approximately US$3.33 million. Considering the relatively long distances between counties and cities in Taiwan, solar installations on vehicles can be fully utilized on highways and store large amounts of energy. Thus, a dense distribution of charging stations is not necessary. The number of charging stations can be increased in areas with shorter equivalent sunlight hours to ensure that logistics vehicles can recharge at any time.

However, the cost of the proposed solution is considerably lower than that of replacing all delivery vehicles in Taiwan (approximately US$100,000 per vehicle; total cost of US$8100 million). The relevant cost data and expected product specifications associated with the proposed solution are presented in Tables 1 and 2, respectively.

| Item | Cost per unit (USD) | Quantity | Total cost (million USD) | Present value of total cost (million USD) |

|---|---|---|---|---|

| Solar panels (including MPPT) | 20001 | 81,000 | 162 | 300.30 |

| Energy storage batteries | 16662 | 81,000 | 134.94 | |

| Charging stations | 33333 | 1000 | 3.33 | |

| App development costs | 33,3334 | 1 | 0.033 | |

| Electric vehicles | 100,0005 | 81,000 | 8100 | 8100 |

- Note: The present value of the total cost is calculated, and the maximum value of the interval is determined.

- 1https://reurl.cc/eModnx.

- 2https://www.litime.com/collections/48v-batteries.

- 3https://www.pro360.com.tw/price/ev_charging_station.

- 4https://www.pro360.com.tw/price/app_design.

- 5https://www.cvn.com.tw/cgi-bin/news.cgi?c303000730001.

| Product name | Specifications | Quantity | Unit | Parameters |

|---|---|---|---|---|

| Solar panels | D1K330H3A1 (union renewable 330W/32V/10.12A) | 4 | pcs |

|

| MPPT solar charging controller | NEON 60 (HV)2 (suitable for 12, 24, 36, and 48 V battery charging) | 4 | pcs |

|

| Lithium battery | LiTime LiFePO43 (1 lithium ion) | 1 | pcs |

|

4.5. Reduction of Urban Air Pollution

Compared with traditional refrigeration vehicles with diesel compressors, refrigeration vehicles with electric compressors have lower diesel consumption and carbon emissions. Thus, refrigeration vehicles with electric compressors can reduce the urban air pollution caused by logistics vehicles during idling. In these vehicles, the compressor is separated from the engine, which allows the compressor to continue operating on electrical power even when the engine is turned off; thus, the required temperature can be maintained while reducing energy wastage.

According to the China carbon trading network, the carbon and CO2 emissions of diesel are 0.717 and 2.63 kg/L, respectively [59]. Moreover, research conducted by the Commercial Vehicle World in the cold chain transportation market indicated that using electric power for refrigeration can reduce diesel consumption by approximately 1∼1.5 L/h. Therefore, for an operation period of 12 h, the total carbon and CO2 emissions generated by a delivery logistics vehicle with an electric compressor would be approximately 8.6∼12.9 and 31.6∼47.3 kg lower, respectively, than those generated by a traditional logistics vehicle with a diesel generator. Traditional diesel cold-chain logistics vehicles consume approximately 33 L of diesel per day.

Compared with these vehicles, the designed vehicle reduces carbon and CO2 emissions by 36.3%, thus mitigating urban air pollution (Table 3).

| Item | Diesel (L) | Traditional cold chain logistics vehicle | The designed cold chain logistics vehicle | Reduction amount | Reduction percentage |

|---|---|---|---|---|---|

| Carbon emissions (kg) | 0.717 | 23.66 | 15.06 | 8.6 | 36.3% |

| Carbon dioxide (kg) | 2.63 | 86.79 | 55.23 | 31.56 |

- Note: (1) Each delivery logistics vehicle is assumed to operate for 12 h, and the calculation is based on a decrease of 1 L/h in the diesel consumption. (2) If the calculation assumes a reduction of up to 18 L of diesel, the reduction rate is even as high as 54.5%.

4.6. Sustainable Business Model

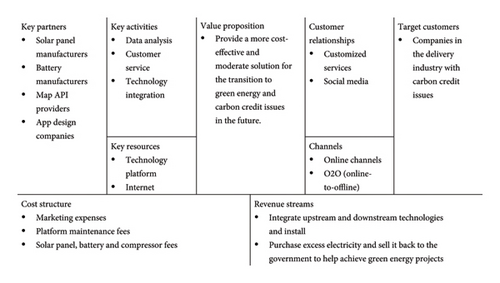

The market for solar-powered logistics vehicles is nascent, and business models for this industry have yet to be systematically explored. The present study used historical data to analyze the current development of business models in the market for solar-powered logistics vehicles. Drawing on previous studies [60, 61], this study used a business model canvas to develop a sustainable business model for cold chain logistics vehicles with energy storage ability (Figure 4).

5. Conclusion

This study proposed a solar-powered compressor refrigerated logistics vehicle to replace traditional diesel refrigerated trucks. It also established an innovative and sustainable business model for the designed vehicle. The designed vehicle can facilitate the achievement of the sustainable development goals (SDGs). This study can contribute to the achievement of the following SDGs and their targets.

To enhance the feasibility and sustainability of our solution and contribute to the SDG 9 industry, innovation, and infrastructure, we plan to install charging stations at gas stations or delivery vehicle stops to establish more convenient and stable charging facilities. Specifically, future work will focus on expanding charging infrastructure, prioritizing the installation of charging stations at locations where delivery vehicles stay for extended periods to meet the needs of the delivery industry. In addition, charging stations will be connected to a network to facilitate their remote monitoring and management, thereby improving their operational efficiency and stability.

With regard to SDG 12 responsible for consumption and production, the sustainability of the production process is a key consideration. The processes of producing solar panels and establishing charging stations should meet environmental standards to minimize their environmental impact. Renewable materials should be used, and measures for reducing energy consumption, waste generation, and pollution should be employed. Furthermore, renewable and recyclable products should be designed, such as detachable and recyclable charging stations and solar panels. During product use, the integration of solar power and charging technology can reduce dependence on traditional energy sources, thereby reducing greenhouse gas emissions and energy consumption in the logistics industry.

In addressing SDG 13 climate action, the proposed solution can help reduce carbon emissions in the delivery industry, thereby mitigating the impact of climate change. Moreover, the use of charging stations and solar panels can improve the energy efficiency of delivery vehicles and reduce energy wastage.

Finally, the solution also generates a positive impact on corporate carbon credits. The use of solar power and smart charging technology can reduce corporate carbon emissions, thereby decreasing carbon credit costs. Additionally, using solar energy to power compressors in cold chain logistics vehicles can help companies comply with carbon emission limits and environmental standards, allowing them to avoid penalties and minimize carbon taxes. Actively participating in carbon reduction initiatives and using green technology can enhance a company’s reputation, allowing it to attract more consumers and investors.

In addition to challenges related to technical specifications and product marketing, problems such as high costs, incomplete charging infrastructure, and underdeveloped regulations restrict the adoption of solar-powered vehicles in the cold chain logistics industry. For example, safety regulations related to vehicle components, chargers, and the entire vehicle are particularly crucial because they provide standardization in product development and foster innovation. Therefore, the aforementioned problems should be addressed to promote the widespread adoption of solar-powered vehicles in the cold chain logistics industry when promoting the expansion of the logistics vehicle industry.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

L. C. Shih: conceptualization, data curation, formal analysis, investigation, methodology, resources, validation, visualization, and writing – original draft. Y. J. Chiu: conceptualization, methodology, project administration, resources, and supervision. J. S. Huang: conceptualization, data curation, formal analysis, investigation, methodology, resources, validation, visualization, and writing – review and editing. All authors have worked equally and agreed to be accountable for the content and conclusions of the article.

Funding

No funding was received for this research.

Open Research

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.