Sustainable Energy Production From Waste: A Review of Hybrid Approaches Combining Anaerobic Digestion and Gasification

Abstract

This paper provides a comprehensive review of hybrid waste-to-energy (WTE) systems that integrate anaerobic digestion (AD) and biomass gasification, emphasizing their synergistic benefits in sustainable energy production and waste management. By combining biochemical and thermochemical processes, these hybrid systems maximize energy recovery, optimize resource utilization, and significantly mitigate environmental impacts. The study highlights the principles and operational dynamics of standalone AD and gasification technologies, showcasing how their integration addresses limitations such as incomplete biomass conversion and excessive digestate production. Hybrid systems demonstrate superior performance in converting diverse biomass feedstocks, including municipal solid waste (MSW), agricultural residues, and food waste, into renewable energy and valuable by-products. Advancements in reactor designs, pretreatment techniques, and system configurations are discussed, with a focus on enhancing energy efficiency and reducing greenhouse gas (GHG) emissions. Pretreatment methods such as AD pretreatment and advanced sorting mechanisms are explored to address feedstock variability and improve process stability. Key synergies, such as utilizing waste heat from gasification to dry AD residues, further boost overall system efficiency. The paper identifies critical operational parameters such as feedstock composition and reactor conditions that influence system performance and explores emerging solutions. Economic and environmental benefits, such as improved energy yields and cost efficiency, demonstrate the potential of hybrid AD–gasification systems. Despite the advantages, challenges persist, particularly in scaling hybrid systems and managing feedstock variability. Infrastructural limitations and the complexity of balancing AD and gasification processes remain significant barriers to widespread adoption. By reviewing existing research and case studies, this paper underscores the critical role of hybrid systems in achieving global renewable energy goals and sustainable waste management practices. Ultimately, hybrid AD–gasification systems offer a promising pathway for transitioning to cleaner energy systems, maximizing waste valorization, and supporting the global shift toward a circular economy.

1. Introduction

The use of nonrenewable resources has resulted in substantial carbon dioxide (CO2) emissions that contribute to the greenhouse effect, leading countries to investigate alternative energy sources [1]. Biomass plays a critical role in sustainable energy production, offering a renewable alternative to fossil fuels, while contributing to reductions in greenhouse gas (GHG) emissions. Biomass consumption has demonstrated the potential to mitigate CO2 emissions and boost economic growth, highlighting its value as a policy tool for environmentally sustainable development in the United States and beyond. By replacing fossil sources with biomass, it is possible to promote energy crops and encourage policymakers to support increased biomass production and consumption as a means to reduce emissions and improve welfare [2]. Biomass is increasingly valuable due to its diversity and availability in various forms, such as wood, sawdust, and agricultural residues. With major contributions from countries like the United States, China, and India, scientific research in biomass energy is expanding and prominent institutions are advancing technologies to harness its potential for renewable energy [3]. In addition, biomass production can help establish a sustainable bioeconomy by providing green biofuels and bioproducts that meet energy demands. Estimated to contribute 3000 terawatt hours (TWh) of electricity by 2050 and potentially save 1.3 billion tons of CO2 annually, biomass energy sources, including forest residues and agricultural biomass, are expected to fulfill a growing share of the global energy demand [4].

Biomass resources can be transformed into thermal energy, electricity, or biogas, proving essential to both centralized and decentralized utilities. This versatility shows the potential of biomass to play a significant role in the energy mix [5]. The effective choice of biomass feedstock and processes is critical to ensuring both the quality of energy output and economic viability, with innovations in densification techniques improving the long-term sustainability of biomass as an energy source [6]. Anaerobic digestion (AD) effectively transforms various biomass sources, such as energy crops and organic waste, into biogas with high energy content, providing resource savings across most lifecycle categories [7]. Meanwhile, gasification, as a thermal conversion process, enables the production of biofuels and energy by converting organic matter at high temperatures [8].

Waste-to-energy (WTE) technologies have emerged as an increasingly recognized option for ecologically friendly and economically feasible solid waste management and renewable energy. WTE technologies are essential for solving global waste problems, since they can obtain energy from waste materials and convert it into fuel, power, or heat. While traditional WTE plants primarily use incineration to convert waste into energy, other WTE methods include AD, gasification, pyrolysis, incineration, as well as the use of landfill gas. Among the available WTE, gasification efficiently handles plastic garbage, while AD is best suited for organic waste such as food scraps and yard debris [9, 10]. The organic fraction of municipal solid waste (MSW) can be converted into valuable energy such as electricity and heat, as well as gaseous and liquid fuels, using both thermochemical processes and biochemical conversion methods [5].

Integrating AD and gasification can offer several advantages compared to AD or gasification standalone systems. Such advantages include improved energy recovery, higher efficiency, and economic and environmental benefits. For instance, the excessive digestate production in AD systems poses a challenge. For instance, studies have investigated the utilization of excessive digestate from AD in the gasification process [11], which simultaneously addresses the issue of the cost of the feedstock pretreatment needed for the gasification process [12]. Different integrations of AD and gasification processes could lead to higher energy conversion and yields, as well as reduced sizes for treatment facilities [13]. This paper examines the integration of AD and biomass gasification as a hybrid WTE solution. The principles, limitations, and operational challenges of AD and gasification technologies are discussed in order to highlight the potential of hybrid systems in increasing energy recovery and optimizing processes. While there has been a considerable amount of research on AD and gasification as independent WTE phenomena, the integration of these processes has not been extensively reviewed. This paper reviews and discusses the synergy and challenges of hybrid AD–gasification systems, emphasizing their potential to optimize energy recovery, reduce GHG emissions, and support circular economy principles. According to our best knowledge, this is the first thorough review focusing particularly on the integration of AD with gasification, providing more insights into sustainable WTE approaches. This review presents a comprehensive analysis of the integration of AD with gasification, including recent advancements, technoeconomic feasibility, and environmental impact assessments.

2. AD for WTE

2.1. Principles of AD

AD is an increasingly prominent technology that efficiently converts organic waste, such as food scraps and plant materials with high moisture content, into renewable energy in the form of biogas through a series of biochemical reactions. This process, which unfolds in oxygen-depleted environments, involves several stages, including hydrolysis, acidogenesis, acetogenesis, and methanogenesis, wherein microorganisms break down organic matter into methane (CH4) and CO2 [14, 15]. In comparison to traditional disposal methods like landfilling and incineration, AD significantly mitigates GHG emissions, especially in regions with high food waste volumes such as China [16]. Research demonstrates that AD scenarios generally outperform incineration in environmental benefits, as shown in comparative studies involving centralized and decentralized AD setups with various biogas applications, such as electricity generation, cooking, and transportation fuel [17]. Additionally, AD technology is recognized for its flexibility and potential as an alternative to fossil-based energy, converting a wide variety of organic materials into biogas, which can be used for multiple applications and even as agricultural manure, thus, promoting sustainable biomass production [14, 18]. AD operates through a series of biochemical reactions, including hydrolysis, acidogenesis, acetogenesis, and methanogenesis, that break down organic materials in an oxygen-free environment to produce biogas, primarily CH4 and CO2, which is then stored and utilized for energy. Despite the process’s simplicity and low operational costs, AD systems still face efficiency, stability, and scalability challenges. Efforts to optimize factors such as temperature, pH, and nutrient balance are ongoing, as these conditions directly influence CH4 yield and energy performance, thus, underscoring AD’s potential as a sustainable solution within the bioeconomy and its critical role in achieving global renewable energy goals [19, 20].

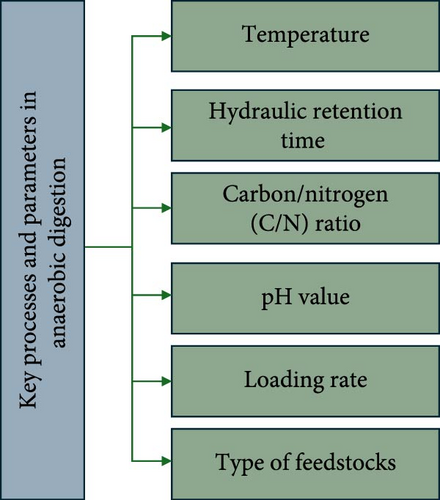

2.2. Key Processes and Parameters in AD

The efficiency of AD is highly dependent on several key operational parameters, as illustrated in Figure 1. These include temperature, pH value, hydraulic retention time (HRT), carbon/nitrogen (C/N) ratio, loading rate, and feedstock type. Research highlights that optimizing process parameters like temperature, pH, retention time, and organic loading rate (OLR) can significantly influence the production efficiency of these different outputs, each requiring tailored bioreactor configurations [21]. For effective process monitoring and control, online techniques involving electrochemical, chromatographic, and spectroscopic devices have been identified as essential tools, given AD’s sensitivity to disturbances [22, 23]. The relationship between kinetic parameters and AD process variables, including volatile fatty acids, total ammonia nitrogen, and C/N ratio, illustrates that initial pH and substrate properties like swine manure content can influence biogas production potential, hydrolysis rate, and lag phase. Consequently, factors such as C/N ratio and initial pH are crucial indicators of AD performance, impacting bacterial adaptation and biogas yield [24]. Studies underscore the necessity of understanding operational parameters like temperature, pH, and C/N ratios to maximize biogas yield, especially when processing MSW. Notably, parameters such as diameter-to-depth ratio, seeding, stirring rate, and feeding rate also impact production rates, but remain underexplored, suggesting a gap in optimizing AD for large-scale applications [25, 26]. The stability of microbial communities within AD systems is essential to maintain CH4 yield and disturbances in process conditions can reduce microbial efficacy, emphasizing the importance of regular process monitoring and optimized growth conditions [27]. Overall, the selection of reactor type and close monitoring of parameters like temperature, pH, HRT, and OLR are fundamental for enhancing CH4 production and ensuring process efficiency in AD systems [26]. With these considerations, AD can be adapted as a versatile technology for sustainable waste management and renewable energy production, underlining the need for further research into multi-stage digestion and parameter optimization to unlock its full potential.

2.3. Feedstock Challenges and Contaminant Impact

AD is a complex biochemical process that holds promise for renewable energy production and resource recovery, but achieving efficient operation requires sophisticated instrumentation, control tools, and an understanding of feedstock challenges. Over the years, research has evolved from focusing on municipal sewage sludge to various organic wastes, including industrial, municipal solid, and agricultural residues, with process time constants shifting from short durations (minutes or hours) to extended periods (weeks or months). This shift necessitates adaptive control approaches, wherein human operators are now integral to decision-making processes, especially for long retention-time substrates, to optimize AD performance through feed management [28–30]. Despite advancements in biodegradability assessment, bioaccessibility remains underexplored, even though detailed biochemical characterizations (e.g., proteins, lipids, and carbohydrates) are essential for accurately predicting CH4 yield and organic matter degradation [31, 32]. Lignocellulosic biomass represents a substantial feedstock for AD, yet its high C/N ratio limits biogas yield, necessitating synergistic codigestion with nitrogen-rich biomass. Hydrothermal pretreatment shows promise in enhancing CH4 yield by breaking down complex biomass structures, though it must be balanced with operational considerations like substrate C/N ratio and inhibitory by-products. Effective pretreatment and codigestion can mitigate challenges posed by high-lignin content, maximizing CH4 production, and creating a viable zero-waste model for GHG mitigation and energy production [33]. Furthermore, the integration of anaerobic biorefinery approaches can augment AD by producing multiple high-value products, increasing economic feasibility, and promoting sustainability. Such biorefineries, which combine AD with other biological and thermochemical processes, can enhance bioenergy yields from lignocellulosic biomass, although more research is needed on optimizing codigestion and enhancing bioavailability [34, 35].

In particular, integrating AD with microalgae cultivation presents a promising pathway for sustainable biogas and biofertilizer production, as microalgae can be grown locally without arable land use and contribute to an economically viable biorefinery. Research on reactor design and microbial community management is needed to improve hydrolysis rates and CH4 yield in microalgae-AD systems [36]. Additionally, agricultural biomass digestion faces specific hurdles, including the need for pretreatment tailored to lignocellulosic content and methods that balance energy efficiency with product quality. The prospect of a bioethanol–biogas combined process highlights the potential of lignocellulosic AD as a second-generation biofuel platform, though it requires continued innovation in pretreatment techniques [37]. Substrate-induced inhibition, particularly from high carbohydrate and acidic food wastes, poses risks for AD stability and CH4 yield. Variability in food waste composition based on geographic origin and seasonality further complicates AD performance, as high ammonia and sodium levels, especially in Asian food wastes, can cause instabilities. For effective AD operation, food waste with high cellulose content or low C/N ratios may benefit from aerobic or corrective treatments to prevent process disruption [38]. The integration of pyrolysis with AD represents an emerging strategy to increase bioproduct yields by combining the benefits of thermochemical and biological processes, although research on optimizing parameters for bioenergy recovery is still ongoing [39]. Pretreatment is especially crucial in hybrid systems, which integrate AD with other WTE technologies, to ensure feedstock uniformity and maximize energy recovery [40, 41]. Collectively, these insights underline the need for continuous advancements in feedstock characterization, process control, and pretreatment technologies to address the challenges and unlock the full potential of AD for sustainable energy and resource recovery.

3. Biomass Gasification Technology

3.1. Fundamentals of Biomass Gasification

Biomass gasification is a thermochemical conversion process that transforms solid biomass into a gaseous fuel mixture, primarily composed of carbon monoxide, hydrogen (H2), CH4, and CO2, through partial oxidation at high temperatures. This process has gained significant attention due to its ability to handle diverse feedstocks, including agricultural residues, wood waste, sewage sludge, and MSW, providing a sustainable pathway for bioenergy production [42, 43]. Gasification typically operates at temperatures ranging from 800 to 1300°C, with the choice of the gasifying agent such as air, oxygen, steam, or CO2 playing a crucial role in determining syngas composition and energy content [8, 44]. Among these, air gasification is the most common, but produces a lower heating value (LHV) syngas due to nitrogen dilution, whereas steam and oxygen gasification yield higher-quality syngas with enhanced H2 content [45]. However, challenges persist in optimizing gasifier performance, minimizing tar production, and enhancing economic viability through process integration and catalyst development [46].

Gasification technologies can be classified into fixed-bed, fluidized-bed, and entrained-flow gasifiers, each with distinct operational characteristics and efficiency levels. Fixed-bed gasifiers, including updraft and downdraft designs, are widely used in small-scale applications due to their simplicity and lower operational costs. Updraft gasifiers offer higher thermal efficiency and increased tar production, whereas downdraft gasifiers minimize tar formation, making them more suitable for engine applications [45]. Fluidized-bed gasifiers, such as bubbling fluidized bed (BFB) and circulating fluidized bed (CFB), provide improved feedstock flexibility, enhanced mixing, and better heat transfer, resulting in higher conversion efficiencies. However, they require advanced gas-cleaning technologies to mitigate tar and particulate emissions. Entrained-flow gasifiers, operating at temperatures above 1200°C, ensure near-complete feedstock conversion with minimal tar, but necessitate finely pulverized feedstock and higher capital investments [43]. The efficiency of these systems is influenced by several factors, including feedstock properties (moisture content and particle size), gasifier design, equivalence ratio, and catalyst utilization [8, 46].

3.2. Reactor Designs and Gasification Pathways

Gasifiers can be classified into fixed-bed, fluidized-bed reactors, and entrained flow reactors. The fixed bed gasifier forms a bed of gasification materials by filling the reactor with biomass through which the gasifying agent flows. These gasifiers can be further divided into three categories based on the direction in which the agent flows: updraft gasifiers, in which the agent and biomass feed flow in the reverse direction; downdraft gasifiers, in which the agent and biomass feed flow in the same direction; and cross-flow, in which the agent is injected laterally and the biomass moves downward [47]. Fixed-bed gasifiers are more cost-effective for small-scale applications and produce cleaner gas with lower dust and tar compared to fluidized bed gasifiers. However, drawbacks include poorer heat transfer, temperature inhomogeneity, and limited scalability. Additionally, fixed-bed gasifiers need more precise feed requirements, such as biomass with moisture content under 20% and a consistent particle size, to prevent issues like clogging [48].

In fluidized bed gasifiers, the bed is made up of materials like sand, limestone, and alumina, which are fluidized by air, oxygen, or steam. These reactors offer better mixing and higher heat transfer compared to fixed-bed gasifiers, leading to faster reaction rates and conversions. They also provide higher mass flow rates, flexibility in feedstock, scalability, and moderate tar production. Fluidized beds can process biomass with varying moisture content and particle sizes below 6 mm, but they are unsuitable for biomass high in ash or alkali metals, such as grasses and straws. The main types include bubbling, circulating, and dual-fluidized beds. BFB reactors produce a gas-particle combination that keeps the bed in a fluidized condition by operating at low gas velocities. These reactors have a larger section to lower gas velocity and return particles to the bed. BFBs can utilize a variety of fuels, including trash, biomass, and coals with a high ash percentage, however, they also create more tar and particulates, which means that cyclones are needed to collect the particles. On the other hand, CFB reactors run at significantly greater gas velocities, which produces turbulent flow and short residence durations. In CFB reactors, a cyclone recovers and recirculates solids, boosting mass flow, reaction rates, and carbon conversion while reducing tar formation. They handle diverse fuels and scale efficiently for high capacities, but are more expensive and complex to manage than BFBs. Finally, dual fluidized beds comprise two fluidized beds, offering various technical options by combining different types of fluidized bed systems [49, 50].

In entrained flow gasifiers, powdered fuel is injected into the reactor along with steam and oxygen to get entrained in the gasifying medium [51]. Entrained flow gasifiers use smaller particles and operate at a higher temperature than fixed-bed and fluidized-bed gasification. Entrained flow gasification frequently achieves a high carbon conversion and yields high-quality syngas with low levels of tar and CH4 [52].

3.3. Syngas Production and Applications

Biomass gasification results in the production of syngas from carbon-neutral feedstocks like biomass rather than natural gas or coal, which leads to lower GHG emissions. Syngas is an intermediate in the synthesis of several compounds like ammonia, H2, and methanol [53, 54]. It can serve as a feedstock for the production of industrial chemicals and can be utilized to produce biofuel and electricity since it can heat up to very high temperatures [55].

3.4. Challenges in Biomass Gasification

Biomass gasification has a number of syngas treatment issues due to the presence of contaminants such as tar, nitrogen compounds, halides, particulates, sulfur compounds, and alkali metals. These impurities must be eliminated before syngas can be utilized to produce chemicals, biofuels, or electricity, since they can deactivate catalysts, obstruct pipes, and cause metal corrosion in the system. Furthermore, contaminants like CO2 must be removed in order to increase the energy density of syngas and fulfill environmental criteria. Pollutant levels are heavily influenced by gasification conditions, feedstock type, and reactor design. Syngas cannot be used in applications such as chemicals synthesis or fuel cells unless it is properly treated [56]. For engine operations, producer petrol can be a viable transportation fuel that decreases the health risks associated with pollutants and protects air quality. However, specific engine modifications and conditions must be met in order to ensure that it has all of the properties of an ideal fuel, such as purity, heating value, and tar content, in order to run the engine properly. According to recent studies, the most significant problems include gas conditioning, government legislation, and the use of fuel gas for heat and power production. Despite the availability of many gasifier reactors, a highly efficient reactor design has to be developed for effective operation and commercialization. Furthermore, moisture content has an impact on gasification process performance as well as gaseous product quality. The moisture content of biomass and its composition can vary, necessitating pretreatment before feeding to the gasifier unit to provide process stability. The choice of drying process is critical in reaching the optimal moisture levels needed for the process [57].

4. Integration Strategies and Technological Innovations in Hybrid AD and Biomass Gasification Systems

The integration of biomass AD with gasification enables the utilization of different feedstock components and increases efficiency. Gasification has a large capacity for treatment and can reduce the volume. Gasification has a high treatment capacity, permits smaller equipment, and produces syngas for fuel and in-house heat that is easier to store and utilize. Using gasification heat to dry AD residues is an important synergy in AD–gasification integration since it improves the overall hybrid system efficiency [58]. Some of the studies that have investigated the integration of AD and gasification processes are summarized in Table 1 to examine the positive impacts and limitations.

| Hybrid system components | Feedstock | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| AD + hydrothermal gasification (HTG) | Wet biomass |

|

|

[59] |

| AD + supercritical water gasification (SCWG) | Wet biomass |

|

|

[60] |

| Anaerobic digestion (AD) vs. supercritical water gasification (SCWG) | Sewage sludge |

|

|

[61] |

| Anaerobic digester, gasifier, and an internal combustion engine | Maize grains |

|

- With complex integration with gasification and higher design intricacies, the system requires careful management to handle the tough-to-degrade stover efficiently | [62] |

| Anaerobic digestion, chemical looping gasification, and membrane separation technology | Liquid and solid biomass |

|

|

[12] |

| Anaerobic digestion and gasification | Sewage sludge |

|

|

[63] |

| Anaerobic digestion and gasification | Food waste |

|

- Limited methane production from certain types of vegetable waste and hydrogen content is dependent on precise control of moisture and equivalence ratio | [64] |

| Anaerobic digestion and gasification | Mixed agricultural waste |

|

- Generates large volumes of digestate needing further treatment and requires precise temperature and air ratio control for efficiency | [65] |

| Anaerobic digestion and gasification | Wood pellets |

|

- Separation reduces the energy potential of the syngas | [66] |

| Anaerobic digestion and gasification | Yard waste and woody biomass |

|

- High organic loading rate may inhibit the digestion process, while high AD residue mass ratio reduces syngas quality | [67] |

| Anaerobic digestion and gasification | Corn straw |

|

|

[68] |

| Anaerobic digestion and gasification | Mixed municipal solid waste |

|

|

[69] |

| Anaerobic digestion, gasification, and wastewater treatment | Organic MSW, sewage sludge, zoo-technical manure, combustible MSW, vegetables |

|

|

[70] |

| Anaerobic digestion and gasification | Plastic-containing food waste |

|

|

[71] |

| Anaerobic digestion and hydrothermal gasification | Wet biomass |

|

|

[72] |

| Anaerobic digestion, gasification, and power-to-gas system | — |

|

|

[73] |

| Anaerobic digestion and gasification | Kitchen waste |

|

|

[74] |

| Anaerobic digestion, gasification, and pressurized solid oxide electrolysis cells (SOEC) | Manure |

|

|

[75] |

Allesina et al. [62] explored the integration of AD and gasification processes to improve maize bioenergy conversion, proposing a hybrid power plant design where maize grains are processed in AD for biogas production, and the stover undergoes gasification to produce syngas. Utilizing a detailed mathematical model, the study compared the hybrid system’s performance with a conventional biogas plant relying solely on maize silage. Results indicated a 39% increase in overall energy yield for the hybrid system, attributed to the effective conversion of cellulose-rich stover, which standalone AD systems struggle to process. Additionally, the hybrid system demonstrated potential economic advantages, including reduced digester size due to enhanced conversion efficiency. The gasification process produced syngas with a heating value above 4 MJ/Nm3 and low tar content, though further filtration would be needed for direct application. The study highlighted key benefits of the hybrid system, such as a 26% increase in power output and improved resource efficiency, positioning it as a more productive and sustainable alternative. The authors concluded that hybrid AD–gasification systems could significantly advance maize-based bioenergy production. They recommend further research to validate and refine the model for practical implementation, emphasizing its transformative potential for sustainable agricultural residue utilization.

Antoniou et al. [65] investigated the integration of AD with gasification for managing mixed agricultural wastes, proposing a dual-system model to enhance energy recovery and material recycling. The study used digestate from a biogas plant processing diverse feedstocks, including animal manure and maize silage, which was gasified in a downdraft fixed-bed reactor under optimal conditions (850°C and equivalence ratio 0.24), yielding producer gas with a LHV of 2.88 MJ/Nm3. The system generated approximately 971 kWh of electricity daily and utilized waste heat for drying digestate, demonstrating economic viability. The resulting biochar, rich in nutrients, proved valuable for soil amendment and carbon sequestration. The study aligns with circular economy principles, emphasizing waste minimization, resource efficiency, and GHG reduction. While highlighting the system’s potential for sustainable agricultural waste management, the authors called for further research on scaling, energy optimization, and nutrient bioavailability in biochar.

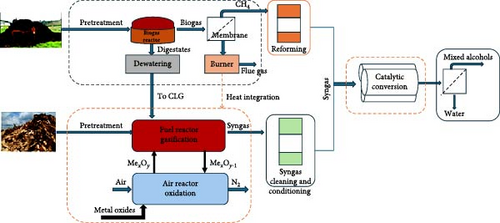

A study by He [12] investigated an innovative hybrid approach integrating AD, chemical looping gasification (CLG), and membrane technologies to convert biomass into high-purity bioalcohols, addressing the growing need for renewable energy solutions in the transportation sector. Figure 2 illustrates the integration of AD, CLG, and membrane technologies. The system combined biological and thermochemical processes to process forestry residues and organic waste into bioalcohols such as biobutanol, biomethanol, and bioethanol. AD facilitated biogas production, which was upgraded via membrane separation to achieve over 98% pure biomethane, while CLG converted solid biomass into syngas with enhanced carbon efficiency. The integration of membrane technologies significantly improved energy efficiency by minimizing separation losses. Coupling biogas upgrading with autothermal reforming and catalytic syngas conversion resulted in a theoretical biomass-to-liquid (BTL) efficiency of 44%, an 18.6% cost reduction in bioalcohol production, and over 75% CO2 emissions reduction, aligning with EU decarbonization goals. Key advancements included multifunctional catalysts and membrane materials, enabling high CO conversion rates and selective bioalcohol production. Despite its substantial environmental and economic benefits, including cost-effectiveness and reduced GHG emissions, the study identified challenges such as optimizing CLG efficiency and developing advanced oxygen carriers and catalysts.

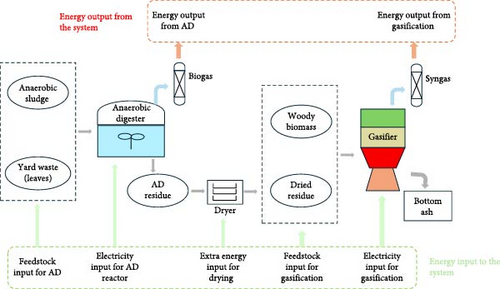

Li et al. [66] investigated the integration of AD and biomass gasification as an innovative approach to enhance biomethane production, particularly addressing the rising demand for renewable energy in sectors like transportation. Figure 3 shows the system configuration of the novel concept. The proposed system utilized H2-rich syngas generated from gasification to upgrade raw biogas from AD via the Sabatier reaction, converting CO2 into CH4 and achieving a 161% increase in biomethane yield compared to standalone systems. Based on full-scale operational data, the study demonstrated an overall system efficiency of 90.2%, with higher exergy efficiency due to the optimized use of energy outputs. Although syngas diversion for H2 separation reduced power and heat generation, the system’s economic performance showed a 5.3% increase in annual income, driven by the higher market value of biomethane and cost savings in biogas upgrading. Sensitivity analyses underscored the importance of biomethane pricing and energy market dynamics in influencing profitability. Despite challenges such as ensuring H2 purity and optimizing CO2 to CH4 conversion, the study highlighted this integrated system as a scalable and sustainable solution for renewable biomethane production, aligning with global energy transition and carbon neutrality goals.

Lacroix et al. [63] studied the integration of AD and gasification for wastewater sludge treatment, which presents a promising approach to enhance energy recovery and nutrient recycling, contributing to sustainable waste management. This study, conducted in Quebec, evaluates the mass and energy balances of a coupled AD–gasification system designed to process municipal wastewater sludge. The AD process effectively converted volatile solids in the sludge into biogas, achieving a CH4 yield of 0.45 Nm3 CH4 per kg volatile solids while reducing sludge volume by 50%. The residual dehydrated sludge was then subjected to gasification at low temperatures (400–500°C), maximizing energy recovery and preserving phosphorus content in the biochar by-product. The system demonstrated the capacity to recover over 90% of the sludge’s energy content, with outputs from biogas and thermal energy sufficient to meet the heating demands of the AD and sludge processing stages. Additionally, the resultant biochar, rich in phosphorus, offers potential applications as an agricultural fertilizer. The study highlighted the need for further optimization, particularly in heat recovery and large-scale implementation. This integrated approach underscores the environmental and economic benefits of coupling AD and gasification, but requires additional research to overcome logistical and technical challenges for widespread adoption.

Zhang et al. [64] conducted a comprehensive study on the integration of AD and gasification, enhanced by a food waste sorting mechanism, to optimize energy recovery and resource utilization. The approach involved separating food waste into pure organic fractions for AD and dry, nondigestible fractions for gasification. Under mesophilic and thermophilic conditions, the AD process achieved CH4 yields of 557 and 680 mL/g VS, respectively, while gasification produced H2-rich syngas with a peak H2 content of 28.91% at optimal moisture content (55%) and air equivalence ratio (0.35). The study employed a thermal equilibrium model validated by experimental data to refine parameters for efficiency maximization. This hybrid system demonstrated significant improvements in energy outputs, including enhanced electricity and heat generation. It produced by-products such as biochar, with potential applications in soil amendment and carbon sequestration. The research emphasized the system’s potential to reduce the environmental impact of food waste disposal while supporting renewable energy goals. However, the authors highlighted the need for further research into scaling the system to pilot or industrial levels and addressing challenges such as feedstock variability and system optimization. This innovative integration offers a sustainable solution for WTE conversion, contributing to circular economy principles and resource efficiency in urban and industrial settings.

Yao et al. [67] investigated the integration of AD and gasification to optimize energy recovery from yard waste and woody biomass, presenting a hybrid two-stage system validated through experimental, and numerical analyses. Figure 4 displays the process flowsheet of the hybrid system. In this system, yard waste was digested anaerobically to produce biogas with a high CH4 concentration, while the solid residue was subsequently cogasified with woody biomass. The integration achieved an overall energy efficiency of 70.8% under optimal conditions, particularly at a 20% AD residue to 30% moisture content ratio, which enhanced syngas quality with a LHV of 5.25 MJ/Nm3. The study demonstrated the complementary nature of the two processes, with gasification effectively utilizing lignin-rich residues that AD could not break down, ensuring nearly complete biomass conversion and minimal waste. Kinetic modeling, validated by experimental data, was employed to predict biogas and syngas outputs, providing a robust framework for system performance evaluation. Key parameters, including inoculum-to-substrate (I/S) ratios in AD and feedstock compositions during gasification, were optimized to maximize energy recovery. The study also highlighted the importance of maintaining appropriate moisture levels to avoid excessive drying energy losses. Comprehensive energy balance analyses confirmed the system’s potential for efficient biogas and syngas production. Despite its promising outcomes in sustainable waste management and energy generation, the authors noted that further optimization is needed to enhance energy recovery efficiency and cost-effectiveness for industrial-scale applications. This integrated system offers a sustainable solution for converting organic waste into valuable energy products while minimizing environmental impacts.

Chen et al. [68] investigated the integration of AD as a pretreatment step for biomass gasification to enhance the efficiency of lignocellulosic material conversion, focusing on corn straw (CS). The study aimed to address the limitations of conventional biomass gasification, such as low syngas heating value and high tar content, by evaluating the effects of AD pretreatment on the chemical, structural, and gasification properties of CS. The AD process, conducted for retention times of 7, 14, 21, and 28 days, enriched the lignin content, while reducing hemicellulose and cellulose, enhancing the structural characteristics of CS for improved gasification performance. Gasification experiments were carried out in a downdraft fixed-bed reactor at temperatures between 600 and 800°C. Key parameters were analyzed, such as syngas composition, LHV, cold gas efficiency (CGE), and tar content. The results demonstrated that a 14-day AD pretreatment followed by gasification at 800°C yielded optimal outcomes, achieving an LHV of 6.83 MJ/Nm3, a CGE of 73.62%, and a 56% reduction in tar content compared to untreated CS. Structural analyses using FTIR, XRD, and SEM revealed that AD pretreatment facilitated the breakdown of recalcitrant structures, increasing surface area and porosity, which improved mass and heat transfer during gasification. The authors emphasized the feasibility of implementing short AD retention times (7–14 days) for continuous biomass pretreatment in large-scale operations, while highlighting the need for further research to optimize system integration, scalability, and economic viability.

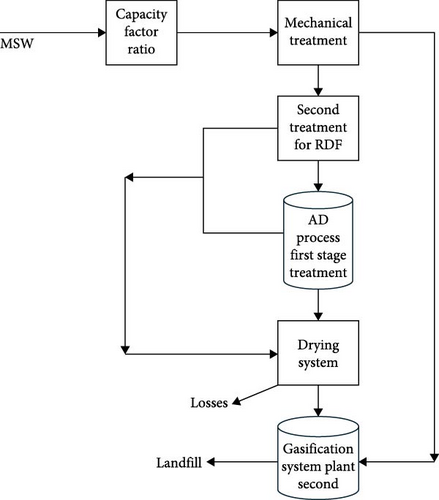

Mabalane et al. [69] conducted a technoeconomic analysis of a hybrid system in South Africa that used AD and gasification to recover energy from MSW. The aim of the hybrid integration strategy was to improve energy efficiency and economic viability by maximizing resource use. Figure 5 depicts the hybrid system used for energy recovery from MSW. AD was used for initial biogas production by processing organic waste. In the second step, gasification was used to produce syngas from waste materials such as plastics and paper, which are not appropriate for AD. During mechanical processing, about 0.3 tonnes of refuse-derived fuel (RDF) are produced per tonne of unsorted MSW, with the RDF being processed first in AD and the remaining 16.88% treated in gasification. The energy recovery was greatly improved by reducing waste transported to landfills and eliminating the inefficiency of AD in processing polymeric materials. The analysis demonstrated the economic viability of the integrated system, with positive outcomes for the net present value (NPV), internal rate of return (IRR), and levelized cost of energy (LCOEn). Sensitivity analysis found that energy prices and capital expenditure were the most important factors determining economic success. While the hybrid system had greater capital expenditures than standalone AD or gasification, its capacity to handle a wider spectrum of waste materials qualifies it as a sustainable WTE option. Furthermore, recycling revenue contributed significantly to the financial viability, particularly for the AD process. By removing garbage from landfills and converting MSW into electricity, the hybrid system helps to reduce GHG emissions significantly and increase resource utilization.

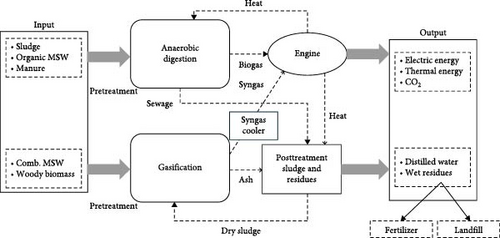

A study evaluated the performance of an integrated system combining AD, gasification, and water treatment for energy recovery from MSW, agricultural residues, and animal wastes. The system processes the organic fraction of waste in an anaerobic digester while subjecting the combustible portion to gasification, with pretreatment of sewage sludge, zoo-technical manure, and organic waste to optimize input quality. Figure 6 displays the process flowsheet of the system. Postdigestion, biological sludge is dehydrated, dried using recovered heat, and gasified to produce biogas and syngas, which are utilized to power a cogeneration system generating electricity and heat. Water recovery through forward and reverse osmosis produces distilled water and ammonia solutions, further enhancing resource utilization. The system outputs include syngas, biogas, electricity, heat, purified water, and fertilizer derived from the gasifier’s humid slag and treated digester sludge. Numerical simulations using a lumped parameter model demonstrated the plant’s capability to deliver substantial electric and thermal power, particularly in urban regions with populations between 300,000 and one million. For smaller towns, clustering neighboring areas was proposed to optimize scaling. The integrated system achieved an electric efficiency of approximately 35%, although thermal efficiency remained low. While the study highlighted significant advancements in biomass utilization, waste reduction, and energy recovery, it also identified barriers to commercial viability, including operational and logistical challenges. The authors emphasized the system’s potential to support district heating and industrial cogeneration in large cities, offering considerable environmental benefits and contributing to sustainable energy production. However, further development is necessary to overcome existing limitations and make these technologies practical for widespread implementation [70].

Zhang et al. [71] studied a hybrid system that combines AD and gasification to convert plastic-containing food waste (PCFW) into biogas, syngas, and biochar. In the study, AD converted the organic component to biogas and gasification treated plastic-containing digestate to produce syngas and biochar. The biochar was then employed as an additive in AD to increase CH4 production, therefore, completing the resource recovery cycle. The technology improved CH4 production in biochar-amended digesters by 6%–30%, while also increasing syngas yield from digestate, particularly for polystyrene-containing waste. The microbial community analysis indicated significant variations in bacterial and methanogenic communities between biochar-amended digesters and control digesters. The genus Methanosarcina increased in the biochar-amended digesters, resulting in more effective methanogenesis. Energy balance evaluations revealed that the system generates a net energy surplus, confirming its suitability for industrial-scale operations. The hybrid strategy tackles fundamental difficulties in mixed waste management by increasing resource recovery, lowering environmental impact, and providing economic opportunities through energy production and biochar commercialization.

In a study by Sharma et al. [72], AD with hydrothermal gasification (HTG) to convert wet biomass waste into sustainable CH4 and other energy products. Despite AD being an established method for recovering energy from industrial and municipal wastes, its efficiency in producing CH4 is limited due to inhibitory or poisonous chemicals such as ammonia, H2S, heavy metals, and microorganisms’ inability to break down lignin. Aside from CO2, the primary product of AD is vast amounts of very dilute digestate, which is extremely costly to manage both economically and environmentally. Therefore, the authors proposed HTG as an appropriate technique for processing aqueous streams with low carbon content. By operating at moderate temperatures, HTG can optimize CH4 synthesis relative to H2 yields. The study showed that AD effectively processed wet biomass to produce biogas, while HTG turned liquid digestate into renewable gases, specifically CH4, through high-temperature and high-pressure processing. This hybrid technique can overcome the constraints of stand-alone AD, such as incomplete biomass conversion and high digestate management costs, by achieving near-complete carbon conversion. The integration also generates coproducts such as biochar, which may be recycled to improve AD performance and nutrient-rich aqueous streams that could be utilized as fertilizers. The scalability and environmental benefits of this process were emphasized, including the ability of HTG to eliminate the requirement for predrying, making it a better option for processing wet biomass than conventional gasification. However, the researchers identified several obstacles, including high operational costs, reliance on costly construction materials, and the need for additional techno-economic assessments to support large-scale deployment.

Leonzio [73] reviewed the integration of power-to-gas (PtG) systems with AD and gasification to highlight the potential of water electrolysis and methanation for producing synthetic natural gas (SNG) from renewable electricity and biogas or syngas. Integrating these technologies enables the efficient use of biogas from AD and syngas from gasification in the manufacture of SNG and improves energy recovery from renewable resources by combining biological, thermal, and electrochemical processes. Surplus renewable electricity can be used for water electrolysis in the PtG system to produce H2. The H2 reacts with CO2 from AD and gasification during methanation to produce SNG, which can be stored, used in natural gas grids, or converted to energy. The review emphasized the scalability of PtG systems for energy storage, transportation, and grid integration, particularly in areas with renewable energy resources. Additionally, this approach maximizes resource utilization, reduces GHG emissions, and balances renewable energy supply and demand. Some of the challenges discussed included high energy demands for electrolysis and methanation, catalyst sensitivity to contaminants, and the requirement for extensive infrastructural development.

Ge et al. [74] developed an integrated model that consisted of AD coupled with gasification to maximize energy recovery and lower carbon emissions. The machine learning-enhanced models, M-AD Model No. 1 (ADM1) and T-artificial neural network (ANN), were used to simulate the integrated process. M-ADM1 is a modified version of the ADM1, optimized using support vector machine (SVM) to improve biogas production predictions by adjusting kinetic parameters for different feedstocks. T-ANN, on the other hand, combines thermodynamic equilibrium calculations with ANNs, improving the accuracy of syngas yield predictions and adapting to varying gasification conditions. The models simulated an AD–gasification process that can precisely forecast biogas and syngas generation, fertilizer efficiencies, and reduction in carbon emissions. AD converted the kitchen wastes into biogas and gasification converted solid digestate to syngas. Biogas slurry was processed to produce fertilizers, therefore, reducing carbon emissions and replacing chemical fertilizers. It was observed that the optimum integration point was on the 15th day of AD, where the carbon emission reduction peaked. Beyond this, the carbon emission reduction value stabilized, allowing for flexible modifications to the system’s output based on downstream requirements. This integration strategy can have positive environmental impacts by replacing fossil fuels and chemical fertilizers, decreasing waste, and contributing to carbon-neutral energy systems.

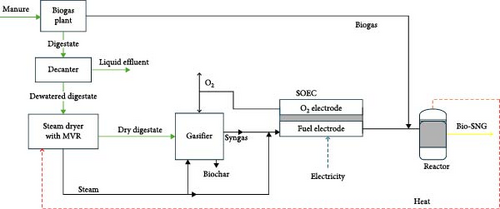

In another study, Clausen et al. [75] investigated an integrated system that combined AD, thermal gasification, and pressurized solid oxide electrolysis cells (SOEC) for bio-SNG generation with manure as the major feedstock. Figure 7 displays the process flowsheet of the proposed system. The system used digestate from AD for gasification, with syngas converted to CH4 by catalytic methanation and pressurized coelectrolysis. The coelectrolysis process transformed water and CO2 into syngas, which was then upgraded to high-purity CH4 by catalytic methanation, maximizing energy efficiency by using waste heat from CH4 synthesis. This approach produced a high energy output of 138% per manure input and an overall energy efficiency of 79%, exceeding both standalone AD (49% yield) and gasification-only systems (107% yield). Innovative SOEC features such as steam drying, mechanical vapor recompression, and internal methanation improved energy efficiency and lowered electricity use. The study emphasized the potential of integration potential for utilizing wet and ash-rich biomass, while attaining high conversion efficiency equivalent to wood gasification systems.

The integration of AD and gasification presents unique challenges due to their contrasting operational characteristics AD is a slow biochemical process, while gasification is a rapid thermochemical conversion. However, industrial and pilot-scale applications have demonstrated the feasibility of coupling these technologies to maximize energy recovery and waste valorization. Studies indicate that the combination of AD and gasification can enhance system efficiency by utilizing digestate as a feedstock for gasification, thereby reducing waste and increasing syngas production [11]. Pilot-scale implementations have successfully integrated AD–gasification systems for MSW and agricultural residues, optimizing the overall energy yield and lowering emissions [76]. Furthermore, research highlights that advanced process control mechanisms and modular system designs enable the synchronization of these processes, ensuring stable operation at large scales while maintaining economic feasibility [60].

5. Environmental and Economic Impact of Hybrid WTE Systems

5.1. Economic Viability

The integration of AD and gasification in hybrid WTE systems presents significant advantages in optimizing resource recovery and enhancing economic viability. Studies have demonstrated substantial improvements in energy yields. Allesina et al. [62] reported that hybrid configurations reduce the need for larger digester sizes, cutting down on capital expenditures, and improving the return on investment (ROI). From a technoeconomic perspective, hybrid systems have shown promising results across various metrics, including NPV, IRR, and levelized cost of electricity (LCOE). Research in South Africa and other regions indicates that these systems outperform standalone technologies due to improved energy recovery and cost efficiencies. Sensitivity analyses highlight the significance of market conditions, particularly energy prices and capital expenditures, in determining the financial performance of hybrid projects. Moreover, integrating AD and gasification can create a closed-loop system that minimizes waste disposal costs and generates valuable by-products like biochar, which can be used for soil enhancement. Studies have highlighted the environmental and economic benefits of this approach, noting reduced GHG emissions and lower energy production costs [65].

Mabalane et al. [69] studied the economic viability of the hybrid AD and gasification system, which is demonstrated through a NPV of $11,139,412 and a profit index of 1.197, indicating strong long-term profitability. The IRR of 18.49% suggests an attractive investment opportunity, while the low LCOE at $0.023/kWh highlights its cost-effectiveness in energy production. Shi et al. [77] highlighted the economic viability of integrating AD and gasification by optimizing cost reduction strategies, including subsidies, electricity sales, and carbon credits, making the system financially competitive. However, the research emphasizes that financial incentives and policy support are essential to enhance profitability and scalability, ensuring long-term sustainability in WTE applications. Tawo and Mbamalu [78] studied the economic analysis of the AD with gasification system, which leads to a profit index of 1.2, indicating financial feasibility. It also achieves cost savings through by-product valorization. Gholizadeh et al. [79] analysis reveals a payback period of 6.11 years and a levelized cost of biomethanol of €294.37 per ton, demonstrating strong economic feasibility. Armoo et al. [80] analysis reveals an IRR exceeding 18%, with a LCOE as low as 0.023 $/kWh. The hybrid system’s financial benefits stem from optimized feedstock utilization and increased energy efficiency.

Hybrid systems also offer unique opportunities for integration with other renewable energy sources, such as concentrated solar power (CSP) and PtG frameworks. For instance, Petrollese et al. [81] demonstrated that coupling biomass combustion and AD with CSP plants can reduce overall energy costs and enhance plant capacity factors. Additionally, the incorporation of biomethanation of CO2 from AD with digestate gasification has shown potential for biogas upgrading and grid balancing, with significant reductions in the minimum selling price of biomethane [82]. Moreover, AD produces digestate, a nutrient-rich by-product used as fertilizer, promoting circular economy principles and reducing the need for chemical fertilizers in agriculture [83, 84]. In regions with increasing waste generation and energy demands, such as Saudi Arabia, financial assessments have revealed the strong potential of integrated WTE plants to improve economic returns, contingent on strategic market analysis and facility optimization [85]. Investments in advanced feedstock pretreatment and energy recovery strategies lower total production costs, making these systems more competitive in WTE applications [86, 87]. The hybridization of AD and gasification processes presents a compelling pathway for maximizing energy recovery, reducing operational costs, and advancing sustainable waste management practices.

5.2. Environmental Benefits and Carbon Reduction

The application of hybrid AD and gasification systems in WTE processes offers substantial environmental benefits, particularly in reducing GHG emissions. These integrated technologies enhance the conversion rates of organic matter to energy, leading to improved energy efficiency and a lower carbon footprint. For instance, the combination of AD and pyrolysis has been shown to significantly enhance environmental performance compared to single pyrolysis pathways, as AD improves the breakdown of sludge organic matter, increasing the overall conversion rate to bioenergy [88]. Additionally, a life cycle assessment (LCA) conducted on hybrid systems for SNG production revealed a preference for biogas-based processes, primarily due to the emissions avoided by conventional waste management practices. The lowest carbon footprint was observed in biogas upgrading scenarios, with substantial environmental benefits when accounting for the credits from manure processing, showcasing a reduction of around 60 g CO2 per MJ of SNG produced [89].

The integration of AD and gasification systems in WTE processes has demonstrated significant potential in reducing GHG emissions, surpassing the environmental performance of conventional methods. AD primarily reduces CH4 emissions by converting organic waste into biogas, while gasification minimizes CO2 emissions through efficient energy conversion processes. For instance, the Göteborg biomass gasification project (GoBiGas) in Sweden, as the first large-scale demonstration plant for biomethane production via gasification of forest residues, highlights the effectiveness of this approach. Comparative studies on AD with biogas upgrading (AE) and gasification with methanation (GoBiGas) have shown similar efficiencies, approximately 62%–65%, indicating their comparable potential in emission reduction [90]. Furthermore, the implementation of AD in various regions has provided substantial GHG mitigation benefits. In China, using AD for food waste treatment is projected to cut up to 1.9 billion tonnes of CO2 equivalent by 2040, aligning with national climate targets. In Europe, AD’s application in MSW management has effectively reduced CH4 emissions from landfills while generating heat and electricity, contributing to energy recovery efforts [16]. Similarly, in Singapore, AD for cooking fuel has shown a lower global warming potential compared to traditional incineration, underlining its role in enhancing decentralized energy systems [17]. These examples underscore the critical role of hybrid AD–gasification systems in achieving substantial GHG emission reductions, optimizing resource recovery, and supporting sustainable waste management practices on a global scale.

The environmental impacts of these hybrid systems also extend to water and air quality improvements, alongside significant waste reduction. By converting waste into valuable by-products like biochar, hybrid AD–gasification systems contribute to achieving circular economy goals by minimizing landfill usage and promoting resource recovery. Table 2 shows some of the environmental benefits of hybrid systems. Furthermore, advancements in hybrid digestion–gasification processes have shown the potential for substantial CO2 emission reductions. For instance, integrating CLG with syngas conversion can enhance the overall efficiency of biofuel production, achieving a CO2 emission reduction of over 75% for road transport applications [12, 93]. This demonstrates the capacity of hybrid WTE systems not only to lower environmental pollutants, but also to provide sustainable energy solutions, thereby playing a critical role in reducing the carbon footprint and advancing renewable energy technologies for a cleaner future.

6. Challenges and Future Directions in Hybrid WTE Systems

Hybrid systems which combine AD and gasification present several technical and operational challenges. One significant issue lies in the scalability of these systems, influenced by the complexity of the integration between AD and gasification processes. Balancing the operational requirements of these two technologies is challenging, especially given the differing needs in terms of temperature and moisture control. For instance, the gasification process often requires a dry feedstock, while AD typically handles wet biomass, necessitating pre-treatment steps such as drying, which can be energy-intensive and reduce system efficiency [94]. Furthermore, issues related to regulatory frameworks and the lack of reliable infrastructure also pose substantial barriers. The difficulty in harmonizing various operational parameters, such as the moisture content and temperature requirements, as well as controlling the ash content during gasification, needs significant technological advancements and regulatory adjustments to achieve seamless integration [95].

Feedstock variability is another critical challenge in hybrid WTE systems. Variations in the composition and moisture content of biomass significantly impact the performance of AD and gasification processes. For instance, high moisture content in the feedstock can hinder the gasification efficiency by reducing the calorific value of the syngas produced. Advanced sorting and pretreatment techniques, such as feedstock drying and blending, are essential to ensure process stability and optimize energy recovery. Studies have shown that integrating a food waste sorting system with AD and gasification can enhance CH4 and H2 yield by separating pure food waste for AD and other discarded waste for gasification [64]. Similarly, the pretreatment of biomass, such as using anaerobically digested CS, has been demonstrated to enhance the quality of gasification by increasing the LHV and reducing tar formation [96]. These findings highlight the need for continuous optimization and standardization of feedstock handling procedures to enhance overall system performance.

Looking ahead, innovations such as digital twins and advanced process control systems are emerging as promising solutions to address the operational and feedstock challenges of hybrid WTE systems. Digital twins can provide real-time monitoring and predictive analysis, enabling better control over process parameters and enhancing system efficiency. Additionally, advanced control strategies can help manage the integration of AD and gasification processes, optimizing energy recovery and reducing costs [11]. Future research should focus on expanding feedstock flexibility, integrating advanced sensors for real-time monitoring, and exploring the economic feasibility of pilot-scale and large-scale hybrid systems. Continuous efforts to improve the process parameters and operational stability are crucial for enhancing the overall efficiency and sustainability of these hybrid WTE systems, making them viable solutions for large-scale waste management and renewable energy production.

7. Comparison of Hybrid AD and Gasification With Standalone Systems

Hybrid AD and gasification systems offer a synergistic approach to waste management, achieving higher process efficiency, energy yield, and often better economic and environmental outcomes than standalone AD or gasification. By sequentially extracting biogas from wet organic material and syngas from the remaining solids, these integrated systems can unlock more energy from industrial waste streams, agricultural residues, and MSW [67, 75]. This leads to improved energy recovery and a greater supply of renewable energy in the form of electricity, heat, or renewable gas. Cost-effectiveness is enhanced by multiple revenue sources and savings on waste disposal, with studies reporting favorable payback and viability for hybrid implementations in real-world scenarios. Carbon emissions are curbed to the maximum extent by capturing CH4 and shifting from fossil fuels, helping meet climate targets and waste diversion goals. Focusing on practical applications, industrial facilities can incorporate hybrid systems to treat production waste on-site and generate energy, turning liabilities into assets. In agriculture, hybrids address manure and crop waste sustainably while providing energy to farms and reducing pollution. For cities dealing with MSW, an integrated AD–gasification strategy can significantly reduce landfill reliance and produce green energy, contributing to a circular economy in waste management [72, 97]. To provide a comprehensive assessment of the advantages of hybrid AD and gasification systems, a comparative analysis is presented in Table 3 summarizes the key differences between hybrid and standalone processes.

| Criterion | Anaerobic digestion | Gasification | Hybrid AD + gasification |

|---|---|---|---|

| Process efficiency | Moderate, only converts the biodegradable materials, the residual is digestate | High for dry, uniform biomass, efficiency drops with wet feedstocks | High overall efficiency, utilizes both wet and dry components, achieves near-complete conversion of biomass |

| Energy yield | Yields biogas (CH4) from organic, the energy recovery is limited by the fraction of waste that digests | Yields syngas (CO/H2) from dry feed, captures most of the feedstock energy except losses in char/ash | Maximizes total energy output and more energy per ton of waste |

| Feedstock handling | Best for high-moisture, high-solids organic wastes (e.g., food waste, manure, sewage sludge) | Best for dry, low-moisture fuels (wood, RDF, crop residues). Requires preprocessing (drying, sizing) | Flexible, AD handles wet fraction, gasifier handles dry fraction. Can accommodate heterogeneous wastes by splitting them |

| Cost-effectiveness | Revenue from biogas (electricity/heat or biomethane) and possibly fertilizer. Lower capital cost, but high operating costs for digestate handling | Revenue from power or syngas products, high capital, and operating cost. Profitability depends on consistent high-energy feed and energy prices | Multiple revenue streams improve economics (biogas, syngas and waste treatment). Higher initial cost, but digestate conversion to energy reduces disposal costs, enhancing revenue |

| Carbon emissions | Significant GHG mitigation. Minimal residual emissions if digestate is managed well | Avoids landfill methane by immediate conversion to syngas. Net carbon-neutral if biomass is sourced sustainably. Some CO2 emissions from the process, but far lower GHG impact than open decay of waste | High GHG reduction, The hybrid system minimizes landfill volume, thereby preventing long-term methane leaks. Nearly all carbon in waste is converted to energy |

| Reference | [6, 20, 97–99] | [43, 100–102] | [67, 72, 75, 77] |

8. Conclusion

The integration of AD and gasification offers a novel and efficient WTE approach, addressing the limitations of standalone processes by enhancing energy recovery, reducing GHG emissions, and optimizing resource utilization. This review demonstrates that hybrid AD–gasification systems can achieve higher CH4 and syngas yields, minimize landfill dependency, and generate valuable by-products like biochar and digestate, which contribute to carbon sequestration and soil enrichment. Compared to numerous studies focusing on AD or gasification as standalone processes or their integration, this paper provides a comprehensive review consolidating existing knowledge from the integration studies, providing insights into comparative performance, challenges, and potential applications of hybrid AD–gasification systems based on literature has been notably absent. Key findings from this review show that hybrid AD–gasification systems can significantly enhance overall energy recovery and waste valorization compared to standalone systems and showcase the synergistic benefits of the hybrid systems, improvements in system efficiency, economic viability, and alignment with circular economy principles. For instance, nearly complete biomass utilization can be achieved by allowing for the conversion of wet organic fractions into biogas via AD and gasification of solid digestates and lignin-rich residues to produce H2-rich syngas and biochar. Studies demonstrated increase in energy yield as well as high CH4 and H2 production. Additional synergies, such as the use of gasification waste heat to dry AD residues, were found to improve system efficiency. The use of AD as a biological pretreatment enhances biomass. The review also focuses on new developments, including improved pretreatment technologies, innovative configurations, process optimization with digital twins, and innovative gas cleaning technologies, that enhance system reliability and efficiency.

Future research work should focus on refining integration strategies, optimizing process control mechanisms, and conducting large-scale technoeconomic analysis to determine commercial viability. In addition, the automation of processes by artificial intelligence and machine learning, as well as the establishment of a policy framework to ease the adoption of hybrid WTE, will be crucial for industrial uptake promotion. As sustainability goals at a global level continue to target carbon neutrality and an increase in the use of renewable energy, hybrid AD–gasification technology presents a sustainable pathway for WTE with high possibilities of revolutionizing the waste management process, increasing energy security, as well as mitigation of climate change. In the future, cross–disciplinary interaction between researchers, policymakers, and industry stakeholders will be essential to advancing integrated WTE solutions in line with climate and sustainability targets.

Disclosure

The funding body had no role in the design of the study, collection, analysis, and interpretation of data or in writing the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This research was financially supported by the University of Sharjah.

Open Research

Data Availability Statement

No data was used.