Metal Hydrides for Sustainable Hydrogen Storage: A Review

Abstract

Storing hydrogen in metals has received much attention due to the advantages of this approach for safely storing. It is a promising method of storing hydrogen and eliminates the challenges associated with storing hydrogen gas at high pressure, which includes material durability, tank safety, and overall weight. Much work has been done for the past decade to bring this approach closer to wide-scale application. However, much experimental research is needed to improve the volumetric and gravimetric capacity, hydrogen adsorption/desorption kinetics, material life cycle, and reaction thermodynamics of potential materials for hydrogen storage. Other important properties to consider are transient performance, the regeneration process of spent storage materials, effective adsorption temperature associated with activation energy, induced pore sizes in materials, increasing pore volume and surface area, and materials densification. In recent years, this solid-state storage has progressed at conditions close to normal atmospheric pressure and temperature, with metal hydrides (MHs) emerging as a promising option. Their high storage density per unit volume, volume storage capabilities, and their ability to reverse the process while maintaining stability have qualified the MHs for low-pressure storage and fulfilling the hydrogen storing requirements. However, understanding the principles of kinetics and thermodynamics is crucial for understanding the reactions of MHs as they absorb and release hydrogen. This review evaluates the current hydrogen storage methods, the different types of MHs, their thermodynamics and kinetics, as well as their applications and challenges. For the advancement of further research in this field of study, suggestions for future work and studies are also provided.

1. Introduction

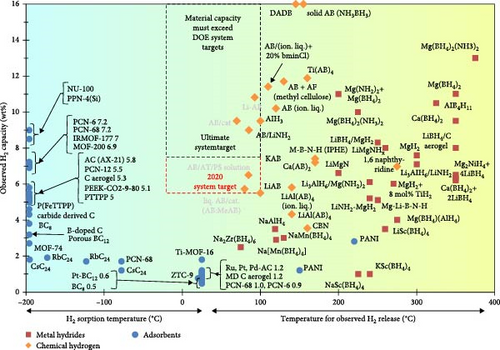

Metal hydrides (MHs) are chemical compounds that form when hydrogen reacts with metals or alloys. The formation of these compounds offers an opportunity to utilize them for hydrogen storage if the process can be easily achieved at ambient conditions. There are various forms of these MHs produced and operated under various conditions. Normally, they differ based on their capability to take in and release hydrogen electrochemically, which makes them safer and more efficient than gaseous or liquid hydrogen storage systems [1]. Mostly, the MH formation is an exothermic process, whereas decomposition is an endothermic process, which emphasizes their thermodynamic characteristics [2]. The volumetric and gravimetric capacity properties of a particularly formed MH describe the capability of its potential application as a hydrogen storing system. It should be noted that the volumetric energy density of hydrogen, which is the amount of energy stored per unit volume of hydrogen, is low at ambient conditions. Therefore, the choice of the metal to be reacted with hydrogen is of paramount importance [3]. The gravimetric energy density of hydrogen, which refers to the amount of energy stored per unit mass, is ~33.3 kWh/kg (120 MJ/kg). This value is significantly higher than that of most conventional fuels and batteries. As a result, hydrogen is an attractive option for applications where weight is a critical factor, such as in aviation, aerospace, and long-range transportation [4]. This also makes the choice of the metal to be reacted with hydrogen to be of paramount importance. For example, lighter energy storage systems can reduce the overall weight of vehicles or equipment, potentially increasing their range and performance in applications where weight is critical. However, focusing solely on gravimetric energy density does not fully capture the practicality of hydrogen storage, as it overlooks challenges related to volume. Some other challenges remain in finding MHs with optimal properties, such as low cost and fast kinetics [5]. Volumetric and gravimetric hydrogen storage densities of different hydrogen storage methods that have been studied are presented in Figure 1. Table 1 also presents some systems that have been studied and their storing capacity.

| Examples | Storage capacity |

|---|---|

| Metal–organic frameworks (MOFs) | 0.7–2.5 wt% @ ambient conditions [7] |

| LaNi5 | 1.6 wt% @ low operating temperature and pressure [8] |

| LiH | 12.6 wt% @ extremely high hydrogen release temperature (720°C) [9] |

| BeH2 and AlH3 | 18.2 wt% [10] and 10 wt% [11]. BeH2 is highly toxic and AlH3 is not reversible |

| NaH | 4.2 wt% with high decomposition temperatures required for hydrogen release [12] |

| 14.9 wt% but poor reversibility [13]. | |

| MgH2 | 7.6 wt% and 110g/L. Good reversibility as a strong candidate for high-capacity hydrogen storage [14]. |

Several studies have reported increased and advanced applications of MHs as hydrogen storage materials, but several critical issues are yet to be addressed. These include but are not limited to a deeper understanding of their thermodynamic stability, gravimetric optimization, improved hydrogen storage, and volumetric capacity. A major study gap in the application of MHs for hydrogen storage includes the regeneration of the materials spent, the durability of the materials in the long term, and their lifecycle performance. To enhance the efficiency of the materials’ storage and their microstructural factors such as the surface area, densification, the pore size, further studies are necessary. Additionally, there exists a gap between scalable real-world applications and laboratory-scale research, which requires to be addressed. Therefore, there is a need to address these gaps to realize the full potential of hydrogen as a clean energy carrier.

- a.

Incorporating elements that produce fewer stable hydrides significantly enhances the stability of the hydrogenated state. This approach allows us to reach thermodynamically favorable conditions, specifically achieving a ΔHΘ of 20−50 kJ/mol H2 within magnesium (Mg) systems [15].

- b.

A significant reduction in particle sizes dramatically enhances surface energy. This phenomenon allows a portion of formation heat to be retained as excess surface energy, ultimately lowering enthalpy. Moreover, the stabilization of Mg particles through nanoconfinement encourages the creation of nanosized grains, resulting in numerous grain boundaries. This increase in grain boundaries creates an abundance of excess enthalpy, which can be harnessed for various applications [16].

- c.

The establishment of metastable phases that increase the distance between metal and hydrogen can significantly diminish Coulombic attraction. This reduction not only lowers the formation energy but also enhances the mobility of hydrogen atoms, promoting more efficient interactions [17, 18]

- d.

The reactivity of surfaces through catalysis plays a crucial role in the effective chemisorption of hydrogen molecules on metal surfaces. To dissociate hydrogen molecules, an energy of 36,118.069 62 (37)/cm≈432 kJ/mol is required [19, 20]. Following Sabatier’s principle, it is essential for effective catalysts to achieve optimal adsorption energy for hydrogen—not too high and not too low. High adsorption energy can slow down the attachment process at the catalyst surface, limiting the overall reaction rate. Conversely, if the energy is too low, hydrogen bonds too strongly, hindering desorption and impeding its movement into the Mg subsurface. This careful balance is key to optimizing catalytic performance.

These approaches are further discussed later in this paper, expanding their impact on the hydrogen-storing capability of various MHs, such as that mentioned in Figure 1 and Table 1.

In general, MHs have advantageous properties that render them ideal for hydrogen storage owing to their ability to readily form complexes with hydrogen, facilitating the controlled storage and eventual release of hydrogen. Different compounds display a wide range of desired characteristics, with some materials showing exceptional promise for hydrogen storage. Three main categories of MHs exist: interstitial, complex, and nanostructured. Moreover, MHs are a very efficient and dependable method for storing hydrogen, offering several benefits. They store significant amounts of hydrogen in a condensed form, minimizing the probability of unfavorable occurrences. MHs exhibit inertness towards chemical reactions with other substances, rendering them dependable and environmentally benign. This makes them perfect for situations where the amount of weight is significant. These hydrides surpass traditional hydrogen storage methods and propel the advancement of hydrogen storage technology [21].

In this study, clarity and conciseness are sought in the exploration of hydrogen storage materials, as well as the relevant fundamental thermodynamic and kinetic principles necessary to understand the strengths and weaknesses of such materials. Brief discussions will also present some effects of various factors, such as microstructural properties and material composition, on hydrogen storage performance, i.e., adsorption/desorption kinetics and storage capacity. This study also attempts to provide practical examples and insights on how hydrogen storage solutions exist in real-world applications while looking at the challenges and advancements that are imperative for scalable and efficient hydrogen storage solutions.

2. Types of MHs

2.1. Classical/Interstitial Hydrides

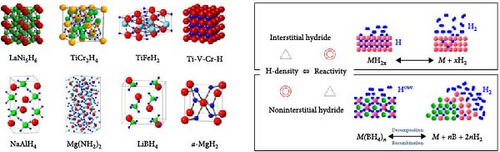

Interstitial hydrides, also known as metallic hydrides, involve hydrogen bonding with transition metals. These hydrides are nonstoichiometric, meaning the ratio of hydrogen atoms to metals is not fixed. They are produced by heating the metal with hydrogen under high pressure. Several intermetallic compounds of the types AB2, AB5, A2B, and AB are always used. The most commonly used hydrides are AB5 materials in which “A” refers to lanthanide (atomic number 57–71), calcium, or mixed metal (a combination of rare earth elements), while nickel (Ni), cobalt (Co), aluminum (Al), manganese (Mn), iron (Fe), sodium (Na), copper (Cu), titanium (Ti), etc., are represented by “B,” as depicted in Figure 2. In these hydrides, hydrogen atoms are trapped within the lattice structure of the matrix composed of heavier atoms, specifically at an interstitial location. By adding small amounts of elements “A” or “B” with the prescribed elements, the hydriding characteristics of these classic hydrides can be finely tuned [23]. Interstitial hydrides are commonly formed by intermetallic alloys, including rare earth elements (Ln) or yttrium (Y). Repulsive H ⋯ H interactions determine the atomic spacing of atoms inside the interstices of an MH. In practical applications, it is generally considered that this spacing does not exceed 2.0 Å [24]. Intermetallic hydrides demonstrate a strong connection between the arrangement of their crystals and their ability to absorb and release hydrogen. This relationship enables the modification and enhancement of their hydrogen storage capabilities. When the metal lattice absorbs hydrogen, there are usually a few alterations in the spacing between the metal atoms. As a result, hydrogen atoms occupy the gaps that were initially present in the unaltered intermetallic [25]. The term used to refer to these MHs is interstitial MHs, which may be conveniently denoted as ABx. The variable A denotes the metals responsible for the formation of hydrides, whereas the variable B represents the metals that do not exhibit hydride production. The variable x indicates the atomic ratio between B and A. The intermetallic compounds known as ABx have the AB, AB2, and AB5 systems and have been widely researched due to their exceptional hydrogen uptake capability, ease of synthesis, adaptability to thermodynamic parameters, efficient absorption/desorption kinetics, and long life cycles. Distinctive types of intermetallic compounds may be categorized according to their crystal structures, for instance, the AB2 type (known as Laves phase) and AB5 type phases [26] and the AB types.

AB-type intermetallic hydrides—the initial identification and evaluation of AB compounds for hydrogen storage dates back to 1958 [27]. Predominantly, alloys are composed of Ti, Zr (A), Fe, Co, and Ni (B) elements, as seen in Figure 2, with some examples of the structures of the hydride forming intermetallic compounds. AB-type MHs are appealing for practical use due to their cost-effectiveness (excluding Co) and the restricted availability of essential raw materials. Hydrogen has the potential to be kept in conditions that closely approximate ambient temperature while also guaranteeing optimal reaction rates and storage capacities. The primary limitations are stringent activation requirements, susceptibility to poisoning, and the potential for various hydriding mechanisms that might restrict their efficacy within a specific pressure range [28].

A category of intermetallic hydrides with the AB2 type is made up of those compounds with elements like Zr, Ti, Y, and La for A, and V, Cr, Mn, Fe, and Ni for B. AB2 have high volumetric hydrogen capacities, rapid formation and breakdown rates, and simple activation processes. Due to the costly principal components used in their formulation, they have substantial production expenses. They exhibit reduced contaminant resistance and decreased structural stability compared to AB5 compounds [28].

AB5 type intermetallic hydrides—A study conducted by van Vucht, Kuijpers, and Bruning [29] found that certain intermetallic compounds, classified as AB5, can react quickly and reversibly with hydrogen. These compounds consist of a rare earth metal (represented by A) and either Ni or Co (represented by B). When they react with hydrogen, they form a ternary MH. Since the AB5 phase may accept a wide range of substitutional alloys, this class of hydrides is well-suited for numerous applications. Therefore, it is feasible to create a hydride that is ideally suited for a specific purpose [30]. An intriguing application includes the combination of AB5-type MH tanks with proton-exchange membrane hydrogen fuel cells (PEMFCs). This integrated system is designed to offer both hydrogen storage and a reliable power supply. An illustration of an AB5-type compound is (LaCe)Ni5, which includes three MH tanks. These tanks are designed to manage the release of hydrogen during discharge, carefully minimizing the potential for accidents. AB5 alloys, which have a CCaCu5-type structure and are composed of rare earth and d-metal elements, are widely recognized for their exceptional capacity to absorb hydrogen, withstand cycles, and resist impurities. As a result, they are well-suited for a wide range of applications. AB5 alloys are made up of rare earth and d-metal elements and have a CaCu5-type structure. They are known for their outstanding ability to absorb hydrogen, withstand cycles, and resist impurities, making them ideal for various applications [31]. One disadvantage of these alloys is that the AB5 alloy is vulnerable to several forms of contamination. To improve the toxicity resistance, several surface modification techniques should be employed. The research on hydride-forming intermetallic compounds is summarized in Table 2.

| Intermetallic compound | Prototype | Hydrides | Structure |

|---|---|---|---|

| AB5 | LaNi5 | LaNiH6 |

|

| AB2 | ZrV2, ZrMn2, TiMn2 | ZrV2H5.5 | Laves phase, hexagonal, or cubic |

| AB3 | CeNi3, YFe3 | CeNi3H4 | Hexagonal, PuNi3 − type |

| A2B7 | Y6Ni7, Th2Fe7 | Y2Ni7H3 | Hexagonal, Ce2Ni7 − type |

| A6B23 | Y6Fe23 | Ho6Fe23H12 | Cubic, Th6Mn23 − type |

| AB | TiFe, ZrNi | TiFeH2 | Cubic, CsCl − or CrB − type |

| A2B | Mg2Ni, Ti2Ni | Mg2NiH4 | Cubic, MoSi2 − or Ti2Ni − type |

2.2. Complex Hydrides

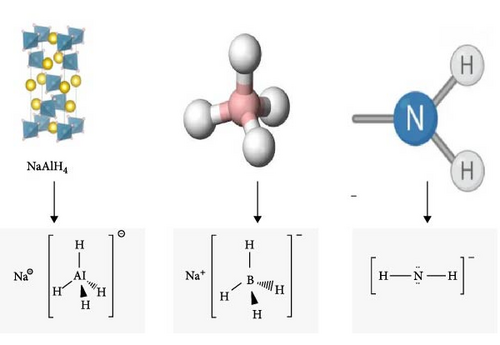

Complex hydrides are metal salts where hydrogen and a core atom create a complex anion through directional covalent bonding. Complex hydrides have excellent hydrogen storage capacity [33]. A crystal structure comprising complex anions occurs in complex hydrides, crystalline compounds in which hydrogen is covalently bound to the core atoms. Complex hydrides often follow the formula AxMeyHz [34], where A denotes elements from the first and second groups of the periodic table, Me represents either boron or Al, and H represents hydrogen. The numbers x, y, and z are non-zero. Within complex MHs, hydrogen exists as a constituent of a complex anion, which is subsequently linked to a metallic cation [35]. The main groups of complex hydrides considered of interest for hydrogen storage are the alanates (based on the anion), the borohydrides (based on the anion), and the amides (based on the anion) [36]. The structural representation of these main groups of complex hydrides is shown in Figure 3.

Complex MHs are made up of lighter elements, which distinguishes them from intermetallic hydrides [35]. Complex MHs possess significant gravimetric hydrogen storage capabilities [39]. Hydrogen is typically discharged in complex hydrides at temperatures higher than 200°C, while hydrogen absorption happens at pressures higher than 50 bar. In most circumstances, these processes exhibit slow kinetics [40]. Due to weak thermodynamics and sluggish kinetics, complex hydrides are not suitable for hydrogen storage. The three primary categories of complex hydrides are as follows: (1) alanates, which are Al-containing complex hydrides, (2) borohydrides, as well as (3) amides-imides, which contain a nitrogen atom within them [41]. The alanates and borates can hold many hydrogen atoms per metal atom because of their low mass [34].

Alanates—The name “alanate,” which is also identical to “alumino-hydride,” describes a class of complex hydrides in which four hydrogen atoms are covalently bound by a metallic cation coordinating with an anion that has Al in the center through an ionic connection [42]. Alanates are Al-containing complex hydrides [41]. Their coordination by hydrogen atoms is either octahedral or tetrahedral [43, 44]. Alanates encompass a variety of compounds, such as Na alanates, lithium alanates, Mg alanates, potassium alanates, calcium alanates, and mixed metal alanates. Na Al hydride (NaAlH4) is a complex hydride that has been the subject of much investigation. The substance has a total amount of hydrogen (H2) equal to 7.4 wt% [45]. However, only 5.6 wt% (H2) [46, 47] can be released. For most alanates, the dehydrogenated compounds cannot be rehydrogenated under conditions suitable for practical applications. Additionally, the last desorption step for certain products occurs at excessively high temperatures for practical uses. The storage capacity experiences a notable decrease while focusing on the initial two steps. Nevertheless, this decrease has potential for stationary applications, contingent upon the resolution of any limitations in kinetics [42]

Borohydrides—Out of all the complex hydrides, borohydrides have the highest theoretical gravimetric capacity for storing hydrogen. Lithium borohydride (LiBH4) attains a maximum value of 18.5 wt% [48]. Borates exhibit stability and undergo decomposition exclusively at high temperatures [34]. Na borohydrides, LiBH4, Mg borohydrides, and calcium borohydrides are among the several examples of borohydrides. A borohydride undergoes hydrogen release through either hydrolysis or breakdown processes [45, 49, 50] shown below.

Intermediate products may also be observed in specific borohydrides, such as LiBH4 breakdown [51]. Borohydrides exhibit a more considerable affinity for hydrogen binding compared to alanates. LiBH4 illustrates this phenomenon, with an average dehydrogenation enthalpy of around 75 kJ/mol. High temperatures, often over 300°C, are necessary to liberate hydrogen [52]. Boron hydrides have more stability compared to alanates, albeit with slower kinetics [14, 34, 53–55]. Alkali borohydrides’ dehydrogenation enthalpy and H2 release temperature are high [56]. The dehydrogenation reaction produces tiny amounts of hazardous boron hydrides [14, 55]. The resulting boranes have the potential to pollute hydrogen, degrade the fuel cell system, and gradually reduce the capacity for hydride storage [45, 55]. Boranes are hygroscopic and challenging to manage and store [14, 34], although they do not explode with water [14].

3. Thermodynamics and Kinetics of MH Formation

3.1. Thermodynamics of Hydrogen Storage

3.2. Kinetics of Hydrogen Absorption and Desorption

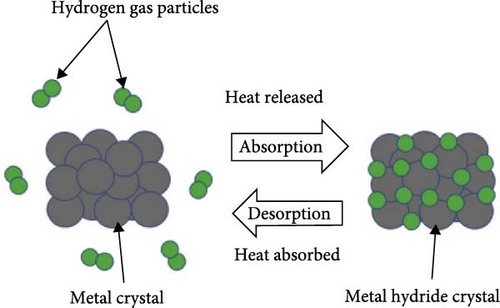

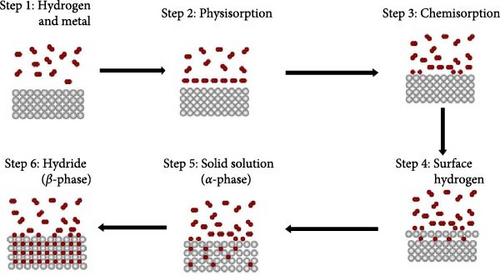

The formation of MHs results from the combination of hydrogen and metals, as shown in Figure 4. Upon absorption, hydrogen dissociates and diffuses through the metal lattice [61], as shown in Figure 5. The reaction generates thermal energy, producing an MH. The hydrogen atom binds to the material and is retained at room temperature. The reaction can exhibit significant variations in pressure and temperature settings and the physical features of different MHs. This phenomenon gives rise to a diverse array of possible uses for MHs as a viable method for hydrogen storage [63].

Metals, as well as intermetallic compounds and alloys, can react with hydrogen to form MHs (MHx) through an exothermic reaction, as shown by Equation (4) [59].

The measurement of reaction enthalpy ΔHR using the calorimetric technique is dependent on the physical characteristics of the hydride. The energy content of known hydrides varies between 16 and 200 kJ/mol H2 [64]. Forming an MH involves several steps, as shown in Figure 6. Step 1: The metal and hydrogen gas exist in distinct phases. Step 2: Since Van der Waals forces are present, Hydrogen molecules are confined in a small region near the surface of a metal in physisorption. Step 3: When hydrogen molecules are adsorbed on the metal surface during chemisorption, they dissociate and bond with the metal. Step 4: Typically, metal surfaces absorb the hydrogen. Step 5: The α structure is formed by the metal, which the hydrogen enters randomly occupying interstitial positions. Step 6: When the concentration of hydrogen atoms residing in the crystal structure reaches a critical level, a new phase is formed, known as the β-phase. This new phase has unique physicochemical properties. The α-phase gradually disappears as the β-phase grows. [65]. The conditions of temperature and pressure required for the reaction and the physical characteristics of various MHs can vary significantly. MHs can be used for many different purposes when it comes to hydrogen storage [64].

In this context, the symbol k stands for the rate constant, while A represents the pre-exponential factor. Ea indicates the activation energy, R denotes the gas constant, and T stands for the temperature expressed in Kelvin. Increasing the temperature often results in a higher reaction rate. However, the activation energy represents the minimum energy required for the reaction to happen.

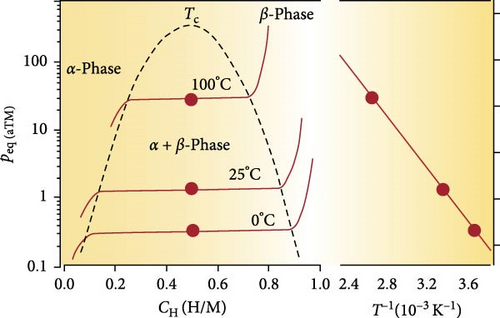

The kinetics of hydrogen absorption and desorption in MHs are often studied experimentally using temperature-programmed desorption (TPD) and pressure-composition isotherms (PCIs). These methodologies provide crucial insights into reaction mechanisms, rate laws, and kinetic variables. The Ti-H phase diagram was last updated in 2000 by Manchester and San-Martin [67]. They compiled all available data on the Ti-H system. The phase boundaries in the phase diagram were identified primarily through experimental data from PCI curves. These were supplemented with some microcalorimeter observations for specific segments of the phase boundaries. The thermodynamic calculations conducted at temperatures below 427°C did not confirm the presence of phase barriers characterized by high hydrogen concentrations in hypereutectoid Ti-H alloys [68]. In their 1976 study, Dantzer, Kleppa, and Melnichak [69] demonstrated that, within the complete PCI curves of the Ti-H system, the lowest temperature and hydrogen pressure plateau achieved were 441°C and 17 Pa, respectively.

4. Transient Performance of MHs

The transient performance of MHs is important for optimizing hydrogen storage systems. Factors such as temperature, pressure, and porosity significantly influence the absorption kinetics and thermal behavior of MHs. In their study, [1] investigated a LaNi5 shell-and-tube-based MH hydrogen storage reactor. They reported an increase in hydrogen absorption rates and heat transfer, which was limited by conduction, and developed a transient multifield coupling model to examine the effects of temperature, pressure, and porosity on hydrogen absorption reactions [1, 70]. They established that lower temperatures and higher pressures enhance hydrogen absorption capacity and rates, and large porosity improves reaction rates and reduces the reaction bed temperatures. According to [71], the reaction rates in the initial phases are primarily controlled by the intrinsic reaction kinetics and then later by the heat transfer process. They further reported that high temperatures and pressures also enhance the reaction rates. A sensitivity analysis of their study indicated that the activation energy, effective thermal conductivity, and heat of the reaction were the most important parameters influencing these rates. The transient phenomena in MH beds often lead to an increase in temperatures, leading to the need for an effective cooling mechanism [72], highlighting the importance of temperature management in optimizing MH systems.

5. Structural Modification

5.1. Induced Pore Sizes

Induced pores and their sizes in MHs significantly improve the hydrogen storage capabilities through various mechanisms. Hydrogen absorption kinetics and cycling stability have been demonstrated to be enhanced using nanoconfinement and nanosizing techniques. Ding et al. [73] proposed a unique carbon-induced porosity mechanism that enables a stable or even reduced length of MgH2 − Ni/C after cycling. This is because the high-quality particles, with their porous structure, effectively stabilize the rapid hydrogen absorption process. Xia [74] observed that improving the kinetics of hydrogenation and dehydrogenation can be expected when the particle size is reduced to the Nanometer range. This suggests that decreasing particle size is an effective way to enhance the overall hydrogen storage performance of metallic-N-H structures. This was further reported by Nielsen et al. [75], indicating that the kinetics of hydrogen desorption are significantly improved when Na Al hydride NaAlH4 is confined within a macroporous scaffold (with a maximum pore diameter greater than 100 nm), compared to its bulk form. The study found enhancements in both kinetics and reversibility due to the nanoconfinement of NaAlH4 in carbon aerogels. These improvements can be attributed to the catalytic properties of the scaffold surfaces, along with a smaller contribution stemming from the reduction of pore size, which ranges from 39 to 7 nm.

5.2. Increasing Pore Volumes and Surface Area

Increasing pore volumes and surfaces significantly enhances the hydrogen storage capacity of materials. This is associated with increased surface area for hydrogen adsorption and the ability to accommodate more hydrogen molecules within the pores. The hydrogen storage capacity of nanoporous carbon (NPC) was found to be contingent upon the presence of micropores with diameters less than 2 nm [76]. The specific surface area of the NPC increased from 220 to 2770 m2/g as the potassium hydroxide (KOH)/rice husk ash weight ratio was raised from 1:1 to 7:1. Thus, the increase in surface area provided more sites for hydrogen adsorption. The hydrogen storage capacity was influenced by the specific surface area of the materials, achieving 0.6 wt% at a specific surface area of 2070 m2/g [77]. Firuznia et al. [78] investigated modified zeolite (Z3) and found that it facilitates hydrogen storage in hydrate form at pressures of 8–10 bar. This significantly reduces the required storage pressure by two orders of magnitude compared to current leading materials, effectively addressing persistent challenges related to high operating pressure and slow formation kinetics of hydrogen hydrates, thus presenting a promising solution for hydrogen storage [78]. Generally, a balanced distribution between the micropores and mesopores optimizes hydrogen uptake [76].

5.3. Material Densification

MH densification for MHs in hydrogen storage applications is important for enhancing their efficiency and performance. The densification techniques, such as nanostructuring and catalyst addition, improve the gravimetric and volumetric capacities of MHs, making them more viable for both stationary and transportation.

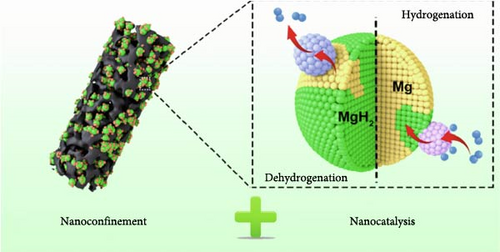

Alloying-hydrogen storage alloys have been extensively studied for many years, and they are materials that can store and release hydrogen through absorption and desorption. These alloys are usually made of Ti, zirconium (Zr), Mg, and some rare earth metals. These alloys are produced using different methods, which include solid-state alloying, mechanical alloying (ball milling), thermal evaporation, and chemical vapor deposition. The choice of method used for alloying has an impact on the resulting structure and the hydrogen storage capacity/hydrogen storage properties of the material. Solid-state alloying allows for the formation of intermetallic compounds with improved thermodynamic stability and hydrogen kinetics but, in most cases, requires elevated temperatures. Their [79] observations revealed that multi-site alloys added to MgH2 are the most prevalent. The most cost-effective mechanochemical method for producing nanosized metallic particles is ball milling, which utilizes hard balls made from materials such as stainless steel, tungsten, and ceramics. Specifically, ball milling involves mechanically grinding solid substances using these hard balls, including stainless steel and tungsten carbide. It reduces particle size, creates structural defects, and allows for homogeneous mixing to occur, which in turn enhances hydrogen diffusion and lower reaction temperatures. The green electricity switch and uniform mixing capabilities promote the homogenization and nanostructuring of MgH2, significantly improving the cloth’s hydrogen absorption and desorption performance, as well as its response rates. By optimizing the milling parameters, mechanical ball milling can effectively lower the reaction temperature of MgH2 and enhance its hydrogen storage capacity [80]. Additionally, [81] found that ball milling can act as a barrier to the dehydrogenation reaction and introduce nanocrystalline grain structures, which provide enhanced pathways for hydrogen diffusion. This, in turn, improves the kinetics of hydrogen storage. In their study, Panwar and Srivastava [82] discovered that employing a catalyst during the ball milling process enhances the hydrogenation properties of MHs and lowers the activation energy of the material. The alloying process using the warm vanishing technique allows for precise control of the thickness and composition of the alloy, resulting in improved hydrogen retention and desorption energy due to the increased surface area. Additionally, compound vapor deposition enables accurate control over the material’s composition and layer thickness. This method facilitates the creation of nanoscale alloy structures that exhibit enhanced surface activity for hydrogen retention. Nanostructuring increases the surface area and reduces diffusion distances for hydrogen atoms. Surface modification (catalysis) is used to lower the energy required for the hydrogenation/dehydrogenation process, as depicted in Figure 7. In nanostructured MHs, the α-phase to β-phase transitions occur more uniformly, as shown in Figure 8, as shorter diffusion paths in nanoparticles enhance hydrogen uptake and release rates. This uniform transition contrasts with larger particles, where distinct phase boundaries form and diffusion limits the kinetics. MHs are often produced as nanoparticles. Their extensive surface areas lead to reduced hydrogen diffusion distances, accelerated reaction kinetics, and decreased activation energy due to surface phenomena [85]. Additionally, nanostructured particles exhibit reduced hysteresis between hydrogen absorption and desorption and higher resistance to degradation over multiple cycles, enhancing their reversibility and long-term stability. The integration of nanomaterials to enhance hydrogen storage in nanostructured MHs depends on internal composition, particle size, morphology, and material interactions. [81]. Enhanced surface area and porosity in nanostructures will provide supplementary binding sites on the surface and within the pores, potentially augmenting storage mostly through physisorption.

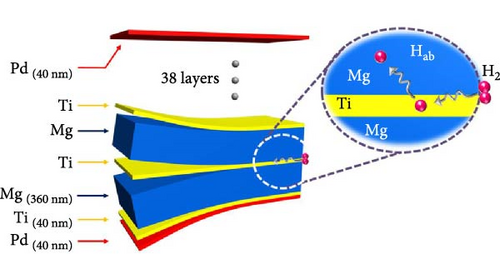

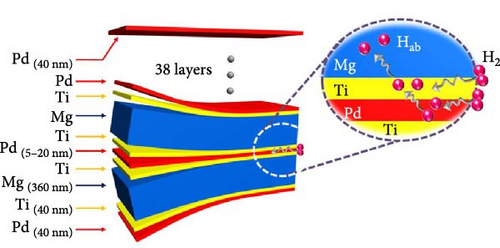

Multilayer thin films to enhance hydrogen diffusion and storage kinetics have also been studied, such as the one shown in Figure 8. The key structural factor that affects the effectiveness of hydrogen storage in multilayered materials is the spacing between the layers. The amount of hydrogen that can be adsorbed is influenced by the elemental compositions of each layer and the functional groups present on them [86]. The multilayer configuration, as depicted in Figure 9, demonstrates how alternating layers of materials like Pd, Ti, and Mg can be engineered to optimize hydrogen storage. The Pd layers are particularly effective in dissociating hydrogen molecules, while the Mg layers provide a medium for hydrogen absorption. Furthermore, adjusting the interlayer spacing, as shown in Figure 9b, can enhance hydrogen diffusion by reducing the distance over which hydrogen atoms must travel. The hydrogen storage characteristics of as-deposited Mg/Pd multilayer films were examined, revealing that the films absorbed and desorbed ~2.6 wt% hydrogen at a low temperature of 373 K. This value is close to the theoretical hydrogen absorption capacity of 2.8 wt% for Mg6Pd. At a lower temperature of 323 K, the films were still able to absorb and desorb around 2.5 wt% hydrogen.

6. MHs Systems and Applications

Efficient and sustainable storage methods are considered essential for energy. MHs are prioritized among these solutions because of their characteristics, which offer significant potential for storing and releasing hydrogen. This work provides a comprehensive overview of hydrogen storage utilizing MHs, including basic principles, synthesis methodologies, and many applications. MH technology is touted as a revolutionary method for hydrogen storage and quickly transitioning to a hydrogen economy. It offers solutions that can be integrated with renewable energy for stationary storage. These may be utilized in various applications, from portable fuel cell cars to MH systems.

6.1. Onboard Mobile Storage

MH-based hydrogen storage devices must satisfy many crucial criteria to be suitable for use in onboard vehicles. The characteristics above cover a notable capacity for storing hydrogen, quick hydrogen absorption and release, a compact and lightweight design, seamless interaction with vehicles, and strict adherence to safety rules. To achieve a driving range comparable to existing automobiles, it is essential to possess solid-state storage materials with elevated gas density and volumetric hydrogen densities. These materials must have fast reaction kinetics for easy sorption, even under mild conditions [88]. For hydrogen to be widely used as a fuel for vehicles, it needs to be stored onboard at high densities and be able to enter or leave quickly. To achieve this, researchers around the world are currently working on developing chemical methods to store hydrogen in condensed forms. This is because current storage technologies, which rely on physical processes such as high-pressure gas or cryogenic liquefaction, are insufficient in meeting performance and cost objectives. More materials must exhibit the requisite combination of attributes suitable for high-volume automotive applications [89]. Applications for mobile devices have unique requirements compared to desktop applications. The importance of weight varies depending on the mode of transportation. Human-made waterborne vessels and railway rolling stock are widely considered some of the largest vehicles [90]. The study conducted by Danebergs and Deledda [91] in 2024 evaluated the competitiveness of MH hydrogen storage tanks for onboard hydrogen storage in the marine sector. By using MH-based tanks, which have simple refueling requirements, the expenses associated with hydrogen handling equipment are considerably decreased when compared to the costs of storing hydrogen as a compressed gas or in liquid form. Nevertheless, MH tanks’ low gravimetric energy density, especially in automobile contexts, is a notable drawback [92].

6.2. Stationary Storage

The affordability of hydrides is the key factor for stationary hydrogen storage, as weight and volume restrictions are not critical factors [93]. Stationary applications of metal hydrogen storage certainly offer great potential in the future to satisfy energy demands held by many sectors. Principally, they are essential backup power sources for such critical infrastructure; they guarantee continuous operation during grid outages at facilities like hospitals, data centers, and telecommunication networks. It may serve a meaningful purpose to integrate renewable sources, like wind and sun power, onto the grid by the needful storage of excess energy during low demand or peak supply periods generated from renewable sources and their release back during peak demand to retain grid stability. MH-based hydrogen storage is a promising method that offers a sustainable option for energy generation. Mostly, it is advised for relatively remote or off-grid locations where these existing or old-type sources are incredibly scarce. Industries that use hydrogen, such as petroleum refineries and ammonia production, utilize on-site MH storage systems to present safe and compact methods for delivering and storing hydrogen. Stationary MH storage is also available at hydrogen fueling stations to foster development in the hydrogen infrastructure relating to fuel cell vehicles and other transport requirements. These further stationary uses are linked to the flexibility and sustainability behind the potential of MHs in their services to meet energy needs within different categories or industries. The inspiring work motivates people to engage in more economical and effective research and development projects, thereby promoting a better and more sustainable energy future.

6.3. Portable Storage

MH tanks have been effectively utilized in various fuel cell-powered systems, including portable devices, light cars, forklifts, and mining vehicles. Furthermore, the use of hydrogen storage solutions has shown advantageous for stationary systems that utilize solid oxide fuel cells and proton exchange membrane fuel cells at both high and low temperatures [94]. In 2014, Song et al. [95] conducted a study to explore the practical advantages of using interstitial MH hydrogen storage in the production of fuel cell systems and aircraft ground support equipment (GSE). The research demonstrated the technological feasibility and benefits of implementing MH hydrogen storage in portable fuel cell lighting systems intended for use in remote locations [95]. MHs are a highly effective way to store hydrogen for off-grid and mobile energy applications. They have exceptional volumetric and gravimetric energy density capabilities, making them a clean alternative to nonrenewable fossil fuels. MHs enable the creation of portable power-generating devices for activities like emergency response, off-grid living, and wilderness expeditions. The production of hydrogen is a clean and renewable energy source that is ideally suited for MH-based hydrogen storage. This further allows the generation of power for portable electronic devices like laptops, smartphones, and wearable gadgets. With fast-charging capacitors, these devices can run for a longer period than today’s conventional batteries. Portable lighting, heating, and cooking appliances: Such systems also find application in the catalytic burner of portable light, heat, and cooking devices, such as camping lanterns, backpacking stoves, and portable heaters, to allow them to be considerably used before refueling. The hydride storage system also provides a reliable means of energy for a typical primary power source to most remote sensors, data loggers, and communication devices while working in ecosystem monitoring, agriculture, and infrastructure management. Moreover, wearable supplies of the same technology will apply to military and defense operations, unscrewed vehicles, and remote surveillance equipment. Furthermore, advancements in materials design, system integration, and processing will be made to enhance the effectiveness of these solutions for portable energy storage. This will help with the continuous development of a robust and ecologically responsible energy future.

7. Challenges and Future Perspectives

Multiple barriers obstruct the commercialization of MHs as a means for hydrogen storage. The study addresses several problems, including the exorbitant expense of green hydrogen, safety considerations, infrastructural obstacles, equipment expenses, storage density and reversibility, and energy dissipation during storage and retrieval.

Thermodynamics and kinetics—A primary obstacle lies in the thermodynamics and kinetics involved in the process of hydrogen absorption and desorption in MHs. Most MHs necessitate elevated temperatures to liberate hydrogen, which is not feasible for most applications, especially in the portable and automobile industries. An optimal hydrogen storage material should have the ability to absorb and release hydrogen under conditions that are close to room temperature and pressure. Nevertheless, attaining this equilibrium is intricate because of the sluggish kinetics of hydrogen assimilation and release. The sluggish reaction rate of this mechanism renders it inefficient and impractical for real-world applications that require quick absorption and release of hydrogen.

Safety concerns—The primary issues related to hydrogen storage are safety concerns. Hydrogen is a combustible and volatile gas that presents substantial safety hazards if mishandled or stored incorrectly [96]. One potential initial manifestation of the hydrogen economy is the extensive adoption of hydrogen for powering vehicles. Compared to traditional fuel-powered vehicles, hydrogen-powered cars carry a higher risk of fires and explosions due to the potential for hydrogen leaks during traffic accidents or vehicle malfunctions [97, 98]. Table 3 summarizes the hydrogen storage methods and their operation principle, as well as the safety concerns associated with each respective storage method.

| Storage/transport method | Operation principle | Safety concerns |

|---|---|---|

| Compressed hydrogen | Compression up to 80–100 (gas pipelines), 150–200 (steel cylinders), or 350–700 (composite cylinders) atm | The issue is the safety and dependability of hydrogen compressors at high-pressure conditions. The potential for an explosion exists in the event of cylinder or gas pipeline damage—structural materials experiencing hydrogen embrittlement. |

| Liquid hydrogen | Liquefaction of hydrogen by cooling to T = 20 K (−253°C) | The potential for unregulated hydrogen gas emission in thermal insulation failure. The potential for the solidification of oxygen in liquid hydrogen (H2). The storage system experiences a continuous process of hydrogen evaporation. Materials undergo embrittlement when exposed to low temperatures. |

| Hydrogen in metal hydrides | The reversible interaction between hydrogen and metals and alloys that generate hydrides. | It is conceivable that finely split metal powder (hydride) may be carried across—the potential for self-ignition of finely dispersed metal powder (hydride) upon exposure to atmospheric conditions. |

Hydrogen capacity—Hydrogen capacity is an important measure for evaluating the feasibility of hydrogen storage materials. MHs typically have a high hydrogen storage potential in terms of volume, but they have a very low capacity when measured by weight. This means that while they can store a significant amount of hydrogen within a given volume, the amount of hydrogen stored per unit weight is relatively small. The low gravimetric density of these materials results in a high weight, which is a major disadvantage in weight-sensitive applications like transportation.

Cost—For a metal or metal alloy to be considered for hydrogen storage, it must be affordable, as the economic feasibility of the technology is also essential. However, the materials with high hydrogen content are costly, so even their alloys will be expensive. Researchers are trying to find a material that is affordable and performs well [89].

Reversibility—An additional crucial concern pertains to the reversibility of the process of hydrogen absorption and desorption. MHs may experience irreversible degradation during repeated cycles of hydrogen charging and discharging, resulting in a decrease in their hydrogen storage capacity. This deterioration might arise from alterations in the material’s structure or the creation of byproducts that obstruct the diffusion of hydrogen.

Surface poisoning—One significant disadvantage of MH is the potential for surface poisoning during gas purification [100]. This is primarily due to the occurrence of contaminations during the manufacture, processing, and storage of alloys, which can result in the creation of surface passivation layers due to air contact. These layers can obstruct hydrogen diffusion and occupy places where hydrogen can be adsorbed or dissociated, potentially hindering or blocking hydrogen absorption [101]. The MHs may get contaminated by impurities in the hydrogen gas that are absorbed during many absorption cycles. A concern arises when impurities, such as oxygen, segregate from the MH structure upon heating or when alloy constituents accumulate on the surface [102]. Research has shown that for LaNi5, the rate at which it absorbs hydrogen significantly diminishes when the time allocated for removing moisture under a low vacuum condition of 102 mbar is extended during cycling processes. This reduction in the hydrogen absorption rate is closely associated with alterations in the material’s surface caused by contamination, which also impacts the characteristic curve of the hydrogen absorption process [103].

System integrations—Incorporating MH storage systems into practical applications, such as automobiles or portable electronics, requires addressing obstacles relating to weight, volume, and compatibility with current infrastructure. MH structures can be bulky and heavy, complicating their integration into small or lightweight designs. In addition, the existing hydrogen infrastructure may not be efficiently designed for MH systems, necessitating additional investment and modification.

8. Conclusion

This work on MHs for sustainable hydrogen storage shows a possible method for addressing future energy issues. This assessment evaluated basic strategies for hydrogen storage, focusing on advancements in modern storage systems, different types of MHs, and the complexities of thermodynamics and kinetics. MHs are used in various industries, including transportation and stationary power storage, showcasing their versatility in meeting a range of energy needs.

Despite advancements, several obstacles persist, such as slow kinetics, limited reversibility, and material durability. Presently, several study endeavors are concentrated on augmenting the efficacy of MHs by utilizing nanostructuration, alloying, and their amalgamation with a catalyst. There is still the possibility of effectively resolving these problems. Therefore, incorporating solar or wind power can promote a sustainable hydrogen economy. Cooperation among academia, business, and government will be essential in overcoming the remaining challenges and advancing the development and implementation of MH-based hydrogen storage systems. By coordinating efforts to address technological hurdles, improve system design efficiencies, and streamline manufacturing processes, we can effectively harness the potential of MHs to achieve a more environmentally sustainable energy landscape.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

No funding was received to conduct this research and prepare this manuscript.

Open Research

Data Availability Statement

Data sharing is not applicable to this article as no new data were created or analyzed in this study.