A Comprehensive Review of Passive Water and Thermal Management of Air-Breathing Proton Exchange Membrane Fuel Cell

Abstract

Air-breathing proton exchange membrane fuel cells (AB-PEMFCs) utilize ambient air for oxygen and cooling, making them suitable for small-scale applications. However, the absence of auxiliary systems presents considerable challenges in water and thermal management, which are crucial for ensuring optimal performance and durability. Poor management can lead to issues like membrane dehydration or cathode flooding. This deficiency subsequently impacts the affordability and longevity of AB-PEMFCs, both of which are critical considerations in the commercialization process. This review highlights the importance of water-thermal transport processes in enhancing efficiency and durability. While much research has focused on airflow’s role in thermal regulation, internal factors such as current density have received less attention. It is recommended to prioritize the coupling of water and thermal management in future studies, employing strategies like AI-driven optimization to accelerate the commercialization of AB-PEMFCs.

1. Introduction

Hydrogen fuel cells have always been a core element of the “hydrogen economy,” where hydrogen is produced through zero-carbon or low-carbon technologies, such as electrolyzers powered by renewable energy, primarily aiming to address the adverse consequences of global warming and energy depletion. Under these circumstances, proton exchange membrane fuel cell (PEMFC), a type of fuel cell that generates electricity through the electrochemical reaction of hydrogen and oxygen using a proton-conducting polymer membrane as the electrolyte, is gaining significant scholarly attention these days. The notable advantages of it are low operating temperature, high efficiency, quick startup, and long endurance [1–4]. At the same time, portable electronic devices are increasingly sophisticated as technology advances. This progress demands higher performance, lifetime, and safety from power sources while maintaining a compact and lightweight design. Examples like commercial devices require short charging times and long battery life, whereas military devices must perform in extreme environmental conditions [5]. Given these circumstances, PEMFCs are increasingly demonstrating significant potential as power sources for portable applications. These applications can be categorized by output power into battery substitutes and portable generators, with the former typically having an output power of less than 100 W, while the latter can reach up to 1 kW [6].

The demand for portable energy storage solutions has been steadily increasing, highlighting the challenges associated with integrating PEMFCs into portable devices due to their current limitations in portability. This requires the PEMFCs to undergo substantial reductions in size and weight but maintain high efficiency and long endurance to compete with continuously improving battery technologies.

To improve the competitiveness of PEMFCs in portable devices, it is essential to simplify the balance of plant (BOP) by removing most components. Such a fuel cell typically has the front of the cathode directly exposed to the atmosphere without the bipolar plate, or it is in a bipolar configuration, where the cathode flow field has openings to the air. In either case, an oxygen concentration gradient is formed between the open cathode (OC) and the catalyst layer (CL) to promote the occurrence of electrochemical reactions. The initial humidification of the membrane can be achieved by extracting the necessary water vapor directly from ambient air, which eliminates the requirement for an anode humidifier [6]. The above arrangement greatly simplifies the structure of PEMFC systems, making them more competitive in portable devices. The simplified fuel cell uses natural convection to draw air into the cathode channel for the electrochemical reaction, which is known as “Air-breathing PEMFC (AB-PEMFC).” Kurnia et al. [7] regard AB-PEMFC as a form of OC-PEMFC, which falls under the category of air-cooled PEMFCs [8]. Based on different ways of cathode air intake, another type of OC-PEMFC, which requires external forces provided by fans or blowers to pressurize ambient air into the cathode channel, is called forced-convection open cathode PEMFC (FCOC-PEMFC) [7, 9]. The research object of this review is AB-PEMFC.

However, the absence of BOP and the operation in harsh environments pose significant challenges for the performance of AB-PEMFCs. For the water and thermal transport within the stack entirely depends on the external environment and the internal structure, which leads to inconsistent performance. In contrast, PEMFCs can actively manage water and heat. External humidifiers prevent membrane drying or flooding, while water pumps and capillary systems recover liquid water to maintain humidity. For thermal management, liquid cooling systems control internal temperature, and recently, waste heat recovery methods like elastocaloric coolers and isopropanol-acetone-hydrogen chemical heat pumps have gained attention [10, 11]. A comparative study [12] shows that AB-PEMFCs, relying on natural convection, suffer from poor heat dissipation, causing cell temperatures to exceed 80°C at high current densities. This not only reduces membrane hydration but also increases ohmic losses by around 20%. Additionally, the increased gas diffusion layer (GDL) porosity (from 0.4 to 0.8) further accelerates water transport away from the CL, worsening membrane dehydration and raising ohmic losses by 15%–25%. In contrast, PEMFCs, with higher heat transfer coefficients, maintain better membrane hydration and improve performance under the same conditions. Consequently, the operational efficiency of AB-PEMFCs is generally lower than PEMFCs.

To effectively address these challenges in AB-PEMFCs, focusing on water and thermal transport management is crucial. Water management ensures optimal membrane hydration and prevents dehydration, reducing membrane resistance and improving performance. Thermal management facilitates an optimal temperature gradient, significantly enhancing reaction rates and efficiency. Due to their passive configuration, long (hydrogen) charging intervals, and lightweight nature [13], AB-PEMFCs are ideal for low-power, portable applications needing reliable performance in varying conditions. Table 1 presents small electronic devices that could potentially utilize AB-PEMFCs and their corresponding power requirements.

| Electronic devices | Power requirements |

|---|---|

| Cellular phone | 1 W |

| Smartphone | 2 W |

| iPhone | 2 W |

| Video camera | 1–10 W |

| Laptop | 20–40 W |

| Tablet personal computer | 10 W |

| Robot | 10–15 W |

| Toy car | 5–15 W |

| Toy airplane | 110 W/kg |

| PlayStation portable | 2 W |

| Flashlights | 1–10 W |

| Insulin pump | 10 mW |

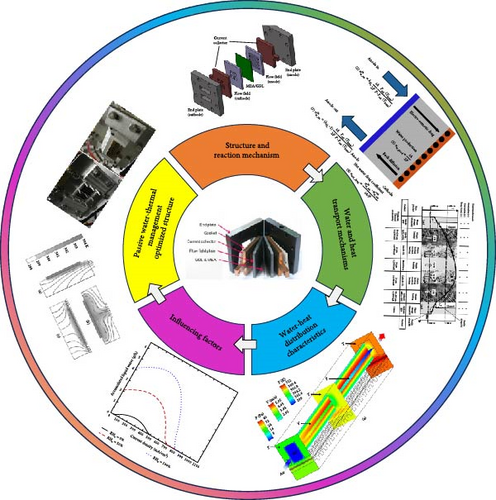

While PEMFCs have been extensively reviewed, only one comprehensive review paper exists for AB-PEMFCs [6]. However, it primarily focuses on optimizing various components in the stack, neglecting the critical area: water and thermal management. Given the unique challenges above of AB-PEMFCs, particularly regarding hydration and thermal stability, there is a notable lack of literature systematically addressing these crucial aspects, namely the water-thermal management issue. Xing et al. [9] only provided a systematic discussion on FCOC-PEMFCs, further highlighting the gap in research for AB-PEMFCs. Therefore, the main contribution of this review emphasizes the significance of water-thermal management in AB-PEMFCs, guided by operational principles and structural design. The framework of this review paper is shown in Figure 1. Section 2 briefly outlines the structure and reaction mechanism of AB-PEMFCs, while Section 3 introduces the water and heat transport mechanisms. These mechanisms underpin the water-thermal distribution characteristics discussed in Section 4. Section 5 examines factors influencing water-thermal performance, followed by Section 6, which discusses optimization methods for passive water-thermal management structures of AB-PEMFCs. Finally, the current research status and potential future directions are summarized based on the aforementioned analysis.

2. Structure and Reaction Mechanism

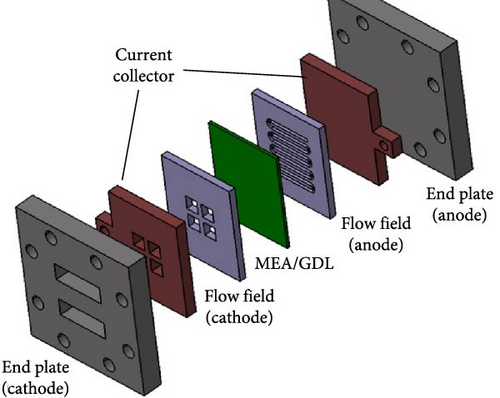

AB-PEMFCs are portable electrochemical energy sources. Oxygen is naturally drawn from the air at the cathode, while hydrogen from a storage unit is oxidized at the anode. Key components (Figure 2) include flow field plates at the anode and cathode, and a membrane electrode assembly (MEA) consisting of GDLs, CLs, and polymer electrolyte membrane (PEM). The functions and materials of each component are detailed in Table 2.

| Component | Main functions | Materials |

|---|---|---|

| Open cathode current collector/flow field plate |

|

A variety of metallic (e.g., stainless steel) and nonmetallic materials (e.g., silicon wafers and printed circuit boards (PCBs) coated with metals) |

| Anode current collector/flow field plate |

|

Graphite, carbon compositor metallic sheets |

| GDLs |

|

Carbon fiber-based paper or cloth coated with a microporous layer (a mixture of PTFE and carbon black) |

| Catalyst layers | • Facilitating electrochemical reactions | Platinum nanoparticles supported on carbon black particles |

| Polymer electrolyte | • Conduction of protonic (or ionic)charge | Perfluorosulfonic acid |

- Abbreviations: AB-PEMFC, air-breathing proton exchange membrane fuel cell; GDL, gas diffusion layer; PTFE, polytetrafluoroethylene.

In the MEA, the PEM facilitates the transport of protons from the anode to the cathode due to its ion conductivity. The CL, where electrochemical reactions occur, requires specific porosity, conductive solid phase, and membrane electrolyte phase to establish efficient triple phase boundary (TPB) conditions for gas, electron, and proton transfer. GDL is crucial for evenly distributing reactant gases to the CL. GDLs must also have good conductivity, effective water removal, and heat dissipation. They are often coated with microporous layers (MPL) to enhance electrical contact with the CL and improve water management [17, 18]. The specific reaction process and the principles of microscopic particle transport are essentially the same as those in PEMFCs and can be found in other references [6, 19].

3. Water–Heat Transport Mechanisms

Efficient water and heat management are crucial for optimizing AB-PEMFC performance. Poor water control, a byproduct of electrochemical reactions, can degrade both performance and durability, while proper heat management is essential to maintain optimal temperatures and prevent damage. Understanding key water transport mechanisms, like electro-migration and diffusion, enables the design of effective drainage systems [20, 21]. Similarly, grasping heat conduction principles supports the development of efficient thermal management, ensuring even temperature distribution [22, 23]. A solid understanding of these processes is vital for improving water-thermal characteristics and advancing AB-PEMFC technology.

3.1. Water Transport Mechanism

AB-PEMFCs keep only the essential functions, such as air supply and cooling, while maintaining core functionality akin to PEMFCs. Consequently, in investigating the water transport mechanism of this fuel cell, researchers often leverage insights gleaned from PEMFC studies.

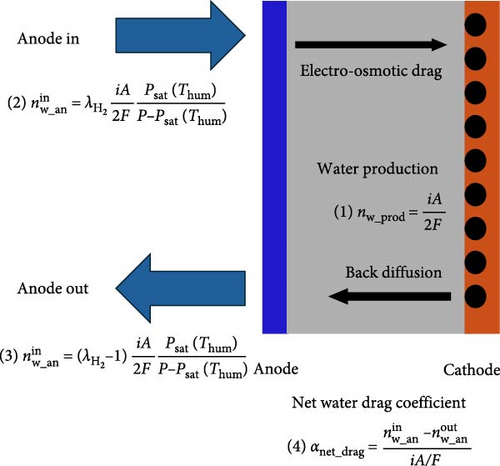

The performance of PEMFCs is intricately linked to the water content within the membrane [24, 25]. In the absence of active humidification systems, researchers typically attribute internal water supply to that generated by cathodic electrochemical reactions [26]. Figure 3 presents a schematic diagram illustrating the water transport dynamics in AB-PEMFCs, accompanied by relevant reaction equations. In Figure 3, Equation (1) represents the electrochemical water production rate, assuming negligible water content at the anode inlet, while Equation (3) describes the anode water content in PEMFCs, which is approximated to zero in AB-PEMFCs. During transport, protons become enveloped by water molecules, and their movement is influenced by “electro-osmotic drag” [27–29]. This drag, combined with electrochemical water production, leads to accumulation at the cathode. Simultaneously, the water concentration gradient between the anode and cathode drives back diffusion, which helps mitigate membrane dehydration at the anode. Factors such as membrane thickness, water content, and the humidity of reaction gases dictate this gradient, with the latter often deemed negligible in AB-PEMFCs. Given that AB-PEMFCs typically operate at low current densities [30], back diffusion prevails over electro-osmotic drag, facilitating water transport from the anode to the cathode, which can lead to cathode flooding and membrane dehydration. This analysis indicates that limitations in the water transport mechanism stem primarily from the concentration difference between the dry anode and wet cathode, driving a back diffusion-dominated conduction phenomenon.

In AB-PEMFCs, back diffusion predominates over electro-osmotic drag, resulting in a negative net water drag coefficient. As shown in Equation (4) of Figure 3, this coefficient is influenced by current density; as current density increases, the absolute value of the net water drag coefficient decreases. Higher current densities produce more water and humidity at the anode, accelerating back diffusion; however, the change in the concentration gradient between the electrodes remains minimal, leading to only slight increases in back diffusion. Conversely, electro-osmotic drag experiences a significant increase with higher current density due to its dependence on the electric field. Additionally, the net water drag coefficient is affected by temperature, hydrogen stoichiometry, and humidity [26].

3.2. Heat Transfer Mechanism

The heat dissipation principles in AB-PEMFCs mirror those of conventional PEMFCs. Given the early stage of AB-PEMFC research, investigating their thermal conduction mechanisms would likely benefit from leveraging well-established principles of PEMFC heat transfer.

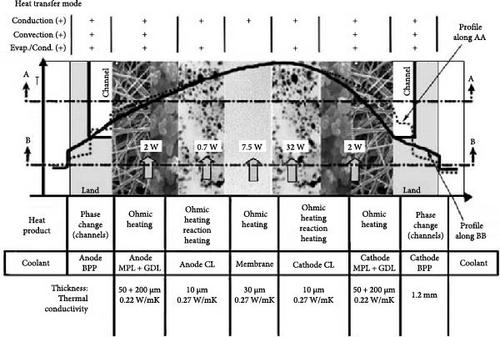

Heat in AB-PEMFCs primarily originates from the cathode CL (CCL), with additional contributions from ohmic losses in the membrane and other conductive components. Figure 4 illustrates the heat production across different MEA components and the resulting temperature gradients in a single cell. The main sources of heat include entropic changes, electrochemical reaction irreversibilities, ohmic resistance, and water condensation [32–34].

Uneven heat distribution is a common challenge in all types of PEMFCs, arising from asymmetrical entropy variation and losses within the electrodes. In AB-PEMFCs, heat generation is linked to exothermic electrochemical reactions at the cathodic interface [36]. The primary heat transfer mechanism is thermal conduction, though radiation and convection also play significant roles within the CL and GDL [37]. Convective heat flux aligns with the flow direction, while temperature gradients govern conductive heat flux [37–39]. The heat generation rate critically impacts fuel cell performance and durability, yet precise quantification remains a challenge.

4. Water–Heat Distribution Characteristics

Understanding the microscopic water-thermal transport in AB-PEMFCs is essential for comprehending its macroscopic distribution. Research on water-thermal distribution is categorized into experimental and numerical methods. However, experimental studies are constrained by high costs and the difficulties associated with passive internal management.

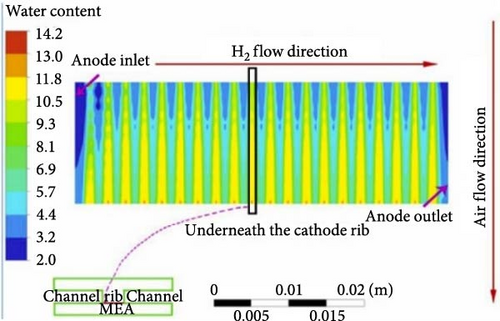

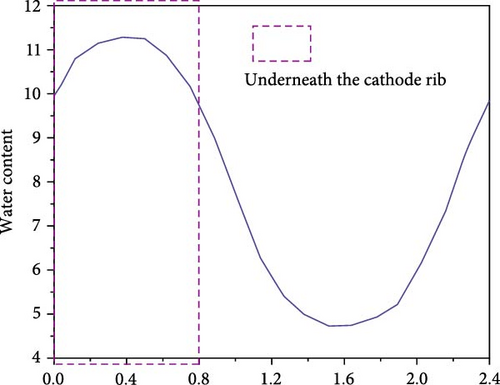

Water transport in AB-PEMFCs is influenced by key factors such as electrochemical reaction rates, water concentration gradients, and capillary pressure, all of which impact electroosmotic resistance and shape water distribution at a macroscopic scale. Current research on AB-PEMFC water distribution can draw valuable insights from FCOC-PEMFC studies. As shown in Figure 5a [40], water content peaks near the cathode outlet and is lowest at the junction of the anode and cathode inlets, increasing periodically along the gas flow direction. Figure 5b [40] highlights significant water gradients beneath the ribs and channels, with higher airflow velocities promoting moisture removal and reducing water content in the PEM region.

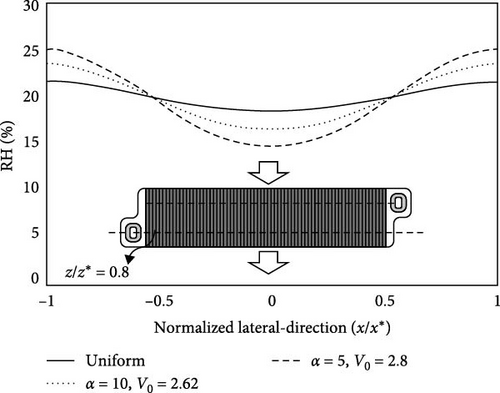

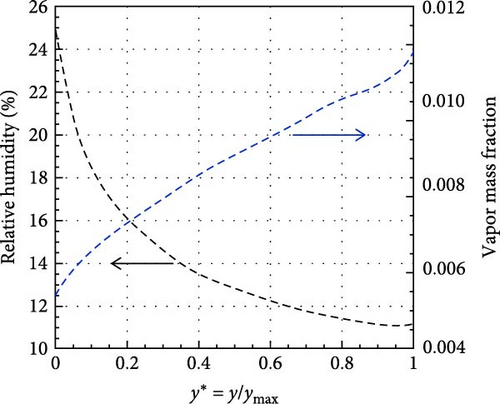

Uneven humidity in the airflow through the stack significantly impacts water distribution. As shown in Figure 6 [41], both airflow direction and perpendicular flow (y-axis and x-axis) exhibit nonuniform. Higher temperatures from CCL electrochemical reactions reduce relative humidity (RH) along the flow direction, increasing saturated vapor pressure and driving more water into PEM channels. As a result, gas humidity decreases progressively. The strong interaction between temperature and water content is critical for maintaining high-performance stability in AB-PEMFCs.

While understanding water distribution characteristics is key to managing PEMFCs hydration, thermal distribution is just as critical for overall system stability. In AB-PEMFCs, passive cooling introduces additional challenges to thermal management, highlighting the need for a deeper understanding of heat distribution within the cell.

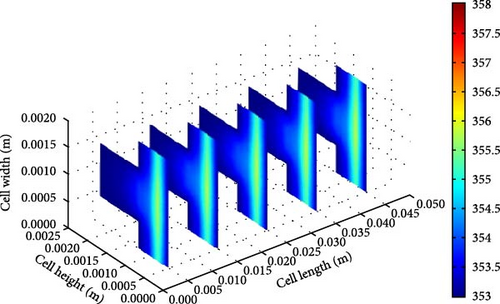

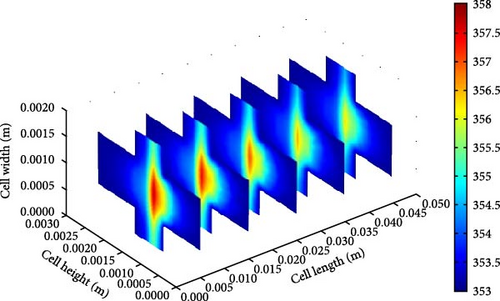

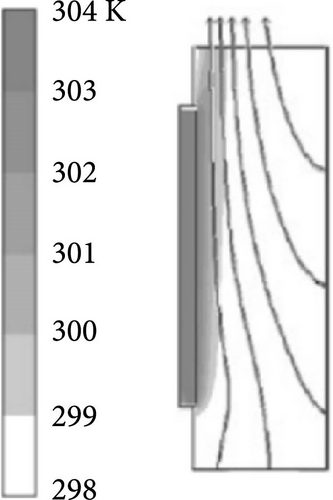

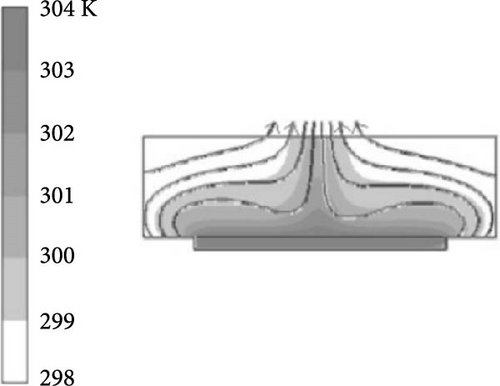

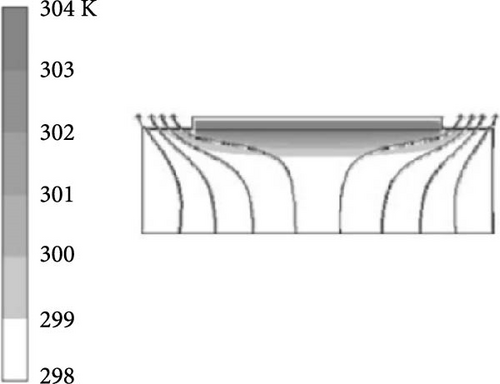

Analogizing AB-PEMFCs with PEMFCs provides a straightforward method for examining thermal distribution. Numerous studies have developed comprehensive CFD models for both types of cells, addressing convective and diffusive heat transfer. Figure 7 [42] illustrates the internal temperature distribution (in Kelvin) for each cell type, showing that the highest temperatures are found in the CL. Research indicates that AB-PEMFCs, with their relatively uniform and lower current density, display lower and more evenly distributed temperatures. Consequently, elevated temperatures from electrochemical reactions pose a more significant challenge in the temperature distribution of AB-PEMFCs.

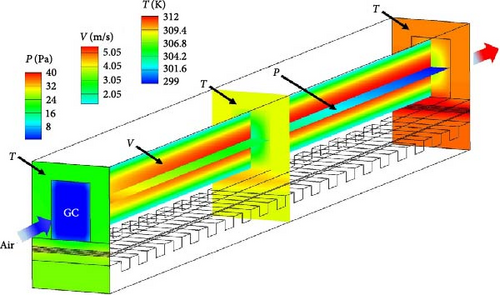

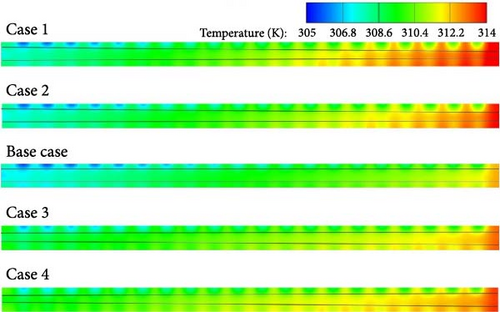

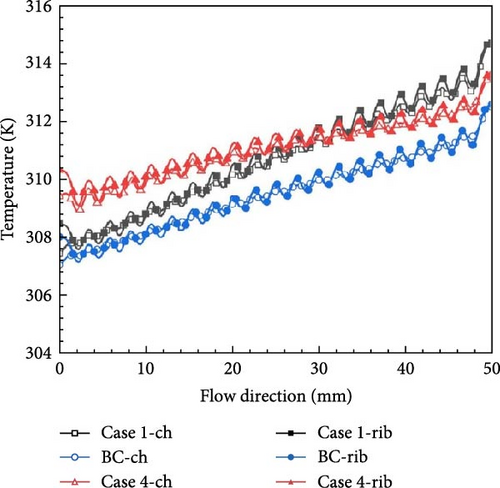

Several studies have focused on thermal distribution within the cathode gas channel (CGC). For instance, Peng [43] developed a nonisothermal model to analyze how CGC structures affect fuel cell performance. Figure 8a displays the temperature distribution in the CGC, indicating an increase along the flow direction due to heat generated by electrochemical reactions, leading to higher temperatures in the MEA. Figure 8b,c illustrates temperature variations in the CCL. Different channel structures yield distinct temperature profiles (Cases 1 and 2 for convergent channels, Cases 3 and 4 for divergent channels), with higher temperatures at the intersections of anode and cathode ribs and lower temperatures at channel junctions. Internal temperatures gradually rise along the airflow direction, demonstrating that the structural design of AB-PEMFCs significantly impacts thermal distribution, particularly in the high-temperature regions of the CCL, where further research is essential.

5. Influencing Factors

The water-thermal distribution in AB-PEMFCs offers valuable insights into the key factors governing its management. These factors can be broadly divided into external and internal categories. External factors, such as ambient temperature and humidity, influence water-thermal performance from outside the system, while internal factors, including operational parameters (e.g., current density) and structural components (e.g., current collector, GDL), affect it from within. A deeper quantitative understanding of these influences will be crucial for optimizing AB-PEMFC performance.

5.1. External Factors

External factors such as temperature and humidity play a critical role in water management by affecting generation, distribution, and discharge. High temperatures and low humidity accelerate evaporation, drying the membrane, while low temperatures and high humidity lead to water buildup and flooding. Techniques like reactant humidification or purging, though effective, require additional components that are unsuitable for AB-PEMFCs.

Beyond water management, external factors also influence heat conduction, though research in this area is limited. Studies have primarily focused on airflow velocity, as passive thermal management in AB-PEMFCs relies on adjusting internal parameters. Temperature has a fixed effect on heat transfer, while humidity and pressure impact it indirectly through airflow velocity. Therefore, airflow velocity’s effect on heat conduction warrants further investigation.

5.1.1. Ambient Temperature

Research on liquid water nucleation and accumulation in AB-PEMFCs shows a strong correlation with operating temperature. Ous and Acroumanis [44] observed water droplet formation in cathode channels using a charge-coupled device camera, identifying temperature as the key factor influencing droplet behavior. Similarly, Obeisun et al. [45] emphasized the critical role of temperature in determining water dynamics in OC-PEMFCs. Building on these insights, Paquin and Frechette [46] analyzed cathode flooding and drying in small-scale AB-PEMFCs, demonstrating that the ratio of thermal-to-mass transfer resistance is crucial for water management. A high resistance ratio leads to membrane drying, while a low ratio causes flooding. They underscored the need to balance maximum current density and cell stability, with temperature being central to addressing membrane drying issues.

5.1.2. Humidity

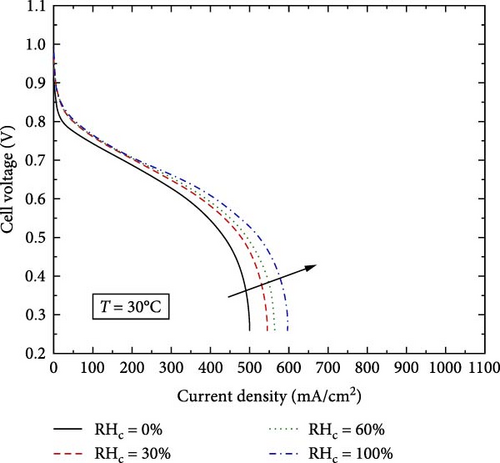

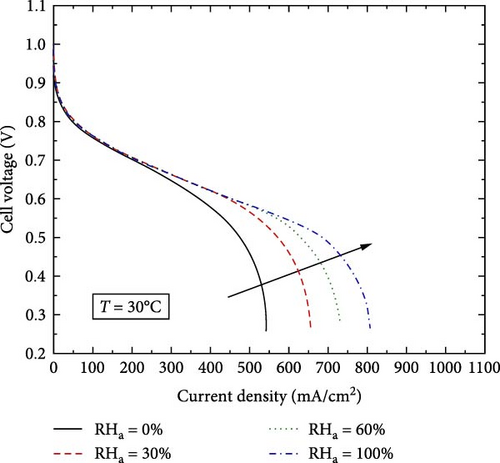

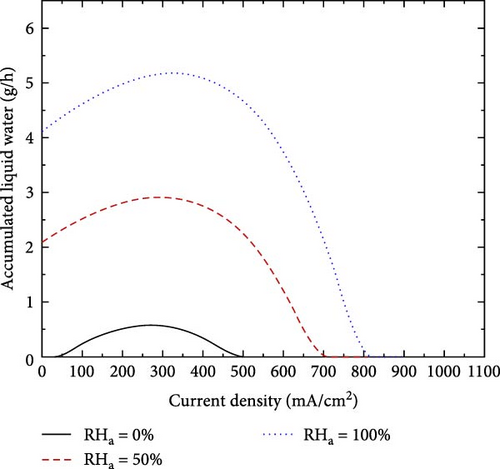

Ismail et al. [47] suggest that specific environmental conditions are required for optimal performance of AB-PEMFCs at different operating potentials. Moderate temperature and low humidity enhance membrane conductivity and mitigate flooding, while low temperature and high humidity help prevent membrane dehydration. Building on this, Chen et al. [48] developed a MATLAB model to explore the influence of hydrogen humidity and heat transfer coefficients on performance at various temperatures (10, 20, and 30°C). The findings indicate that hydrogen humidity dictates the performance-limiting mode, and increased anode humidity significantly boosts cell performance, particularly at high current densities, effectively addressing membrane dehydration. Figures 9 and 10 illustrate that the improvement in cell performance with increased anode RH is notably greater than that with ambient RH, especially at higher ambient levels. Higher hydrogen RH promotes water accumulation in the CCL, resulting in increased maximum current density.

5.1.3. Air Flow Rate

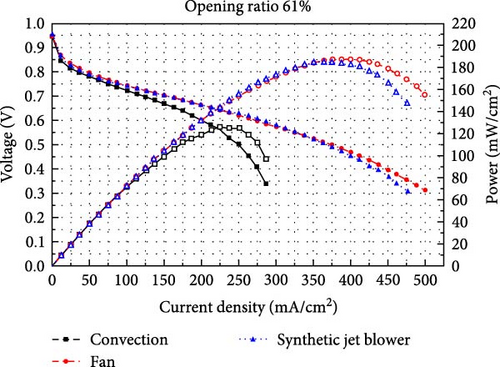

Song et al. [49] demonstrated that air-cooled PEMFCs can effectively self-regulate with appropriate airflow rates, ensuring stable operation without additional temperature control strategies. Their findings indicate that varying airflow rates impact stack performance through changes in temperature and membrane hydration, although this effect is minimal at low current densities. Building on this, Choi et al. [50] developed a synthetic jet blower to enhance airflow in AB-PEMFCs, focusing on parameters such as airflow rates and the cathode side opening ratio. Figure 11 compares the performance of cells with three supply methods at selected cathode slot opening ratios. The implementation of synthetic jet blowers and fans yielded a 40% performance improvement over naturally convected AB-PEMFCs by ensuring adequate air supply to the cathode, thereby facilitating efficient water removal from the GDL.

5.2. Internal Factors

Internal operational and structural parameters significantly influence both water and thermal management in AB-PEMFCs. Factors like current density and pressure directly affect water generation and discharge rates; for instance, higher current densities can lead to increased water generation and potential flooding, while inappropriate pressures hinder water evaporation and diffusion. These dynamics are also influenced by airflow rates and the internal structure of the fuel cell, making isolated studies on these aspects less necessary. The design of internal structures, such as the opening ratios of current collector plates and the GDL, impacts water channels and diffusion pathways. Well-designed structures facilitate efficient water transport, enhancing the distribution of water molecules within the fuel cell. Moreover, internal structural and operational parameters can be controlled to study their effects on thermal management, providing insights through adjustments in aspects like the number of single cells and the ratios or shapes of cathode openings.

5.2.1. Current Density

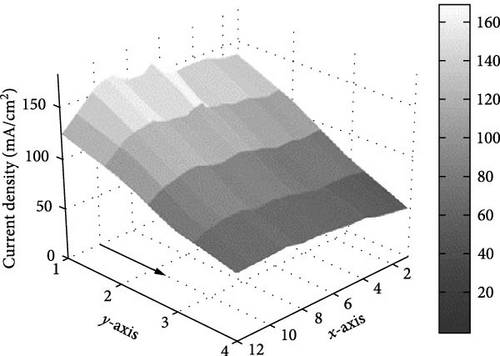

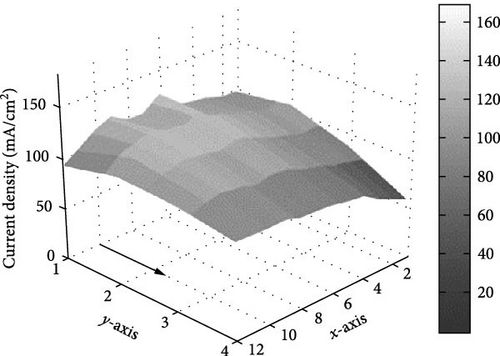

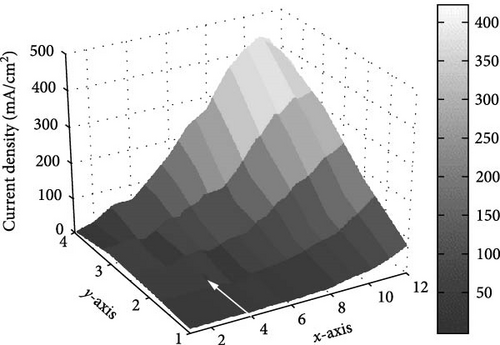

Noponen et al. [51] developed a measurement system to map the current distribution in AB-PEMFCs and its relationship with temperature. Their research indicates an optimal operating temperature of ~60°C without external humidification, where current density is more uniform. In contrast, lower temperatures favor molecular diffusion, leading to heterogeneous current density. Figure 12a shows that at ambient temperature, molecular diffusion dominates oxygen transport. At 60°C (Figure 12b), airflow enhances oxygen concentration uniformity, while at 75°C (Figure 12c), water vaporization and dry hydrogen intake result in uneven current distribution.

Coz et al. [52] employed neutron imaging to examine water management in planar AB-PEMFCs, revealing its critical impact on performance. They identified dehydration at high current densities and flooding at low densities, emphasizing the need for effective water management to optimize fuel cell operation.

5.2.2. Cathode Current Collector

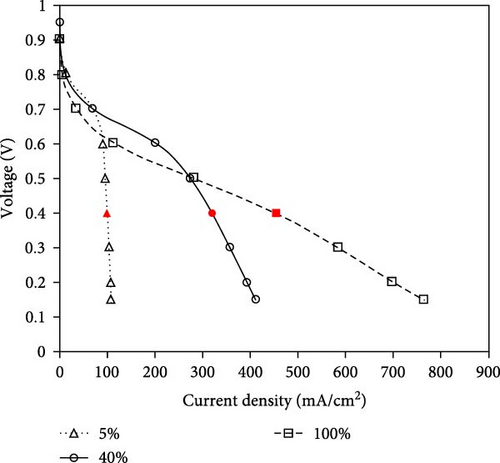

Karst et al. [53] assessed the effect of cathode cover opening ratios on water management and performance in AB-PEMFCs, finding that a 40% opening ratio was optimal at 10% RH, while a 100% opening ratio performed best at 70% humidity (Figure 13). Jang et al. [54] further investigated how cathode opening geometry and ratio impact performance under no-convection conditions. They observed that increasing the opening ratio generally improved cell performance, although a high ratio of 72% resulted in lower performance compared to lower ratios due to oxygen depletion.

Yan et al. [55] introduced a novel cathode channel configuration with varying opening ratios by adjusting channel height and rib dimensions. They found that a combination of 50% for the upper and lower blocks and 58.3% for the middle block improved temperature uniformity, enhancing stability and performance.

Jeong et al. [56] examined the effects of cathode opening area, discovering that increasing the opening area from 52% to 92% at low current densities decreased performance due to faster water evaporation, while at high current densities, an increase from 52% to 77% improved performance through enhanced oxygen mass transfer.

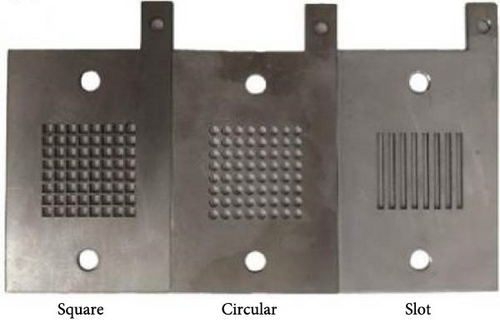

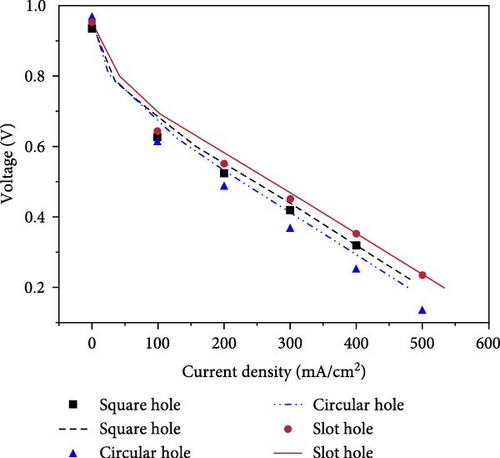

Xu et al. [30] analyzed various factors, including cathode flow field opening shape and opening rate. They concluded that while endplate thickness and direction had minimal impact, opening shape, and rate significantly influenced performance, with slot-shaped openings performing best, followed by square and circular shapes. A 75% cathode opening rate yielded the highest maximum power density (Figure 14).

5.2.3. GDL

Schmitz et al. [57] evaluated the impact of wettability on the performance of AB-PEMFCs. In line with previous research, they found that untreated GDLs outperformed both hydrophilic and hydrophobic GDLs. Hydrophilic GDLs absorb excessive condensate, hindering oxygen supply, while hydrophobic GDLs form a water layer, also impeding oxygen diffusion.

Ferreira Aparicio and Chaparro [58] explored the effect of gas diffusion cathode structure on AB-PEMFC performance, focusing on CL thickness and GDL macroporous substrate. They found that GDL’s macroporous structure, rather than its permeability and hydrophobicity, played a crucial role in enhancing oxygen diffusion into the CL, thus improving fuel cell performance by expelling water from the cathode.

5.2.4. Cell Number and Orientation

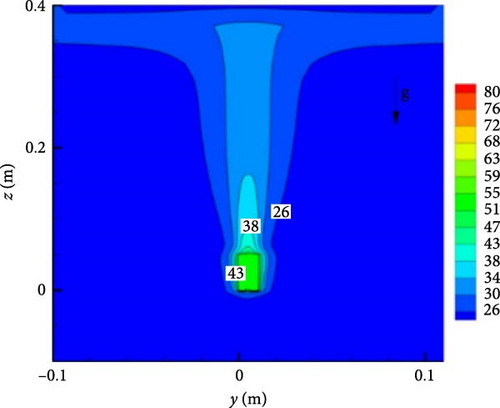

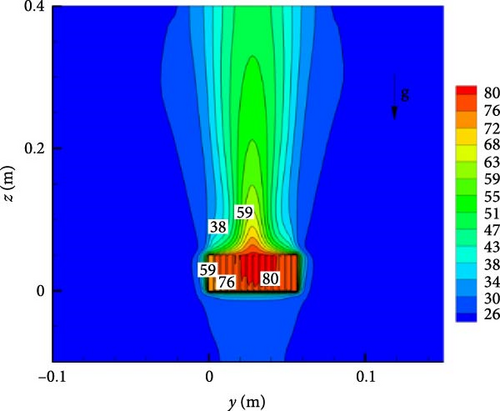

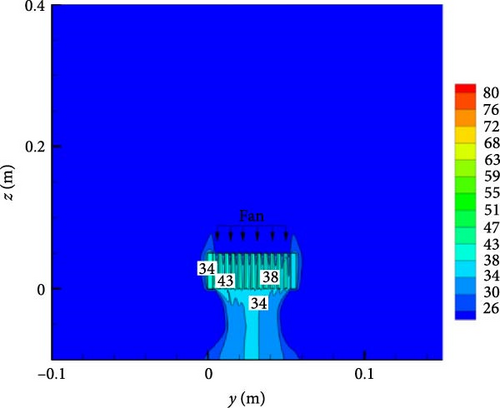

The heat dissipation rate of AB-PEMFCs is constrained by natural convection, limiting the number of cells in the stack. Sasmito, Birgersson, and Mujumdar [59] compared various cooling strategies to determine optimal conditions. As illustrated in Figure 15, stack temperatures can reach ~80°C with natural convection, while individual cells rise by about 40°C. In contrast, forced convection cooling yields the lowest stack temperatures, highlighting the need to consider cell numbers during design to prevent overheating.

Cell orientation also significantly affects heat dissipation efficiency. Ismail et al. [60] developed a 2D thermal model for single cells, revealing that vertical or upward-horizontal orientations enhance heat dissipation compared to downward horizontal orientations. This finding emphasizes the critical role of both cooling strategies and cell orientation in optimizing AB-PEMFC performance.

5.3. Assessment of Influencing Factors and Research Priorities

This section highlights the influence of ambient working factors and internal cell structure on water-thermal management in AB-PEMFCs. Key ambient factors, such as temperature, humidity, and airflow velocity, are well-established considerations that significantly impact both water and thermal management. Notably, the effectiveness of water management in AB-PEMFCs is closely tied to environmental temperature, underscoring the significant coupling with thermal management. Therefore, researchers are encouraged to adopt a comprehensive perspective on this relationship to enhance research rigor and fuel cell performance.

Moreover, there is a limited focus on the operational parameters of AB-PEMFCs due to challenges in controlling and measuring factors like current density and voltage, which are primarily passively regulated by the fuel cell. This limitation has led to a predominant focus on structural parameters, as adjusting these is often more manageable and has a direct impact on performance.

Among structural parameters, the openings in the cathode current collector merit particular attention due to their direct influence on gas distribution, reactant acquisition, and heat dissipation in AB-PEMFCs. Studying these openings is advantageous because of their relatively simple structure and the ease of observing variations. Adjusting parameters such as opening shape and size is straightforward, making research on the cathode current collector more accessible compared to micro-scale components like GDL. Thus, it has become a mainstream focus of research, which could yield significant insights into optimizing AB-PEMFC performance.

6. Optimal Design in Cell Level

Effective water-thermal management in AB-PEMFCs depends heavily on structural design and cell configuration. The main focus is maintaining a balance between water and heat within the cell. Key structural factors include the cathode current collector and GDL. The current collector impacts air intake and distribution due to its direct contact with air, while the GDL facilitates gas and water exchange with the CL. Cell orientation also plays a crucial role, as it influences natural convection airflow. Important design parameters include the current collector’s opening ratio and shape, as well as the GDL’s thickness and wettability.

6.1. Cathode Current Collector

The cathode current collector, located at the outermost layer, plays a pivotal role in AB-PEMFC performance by directly interacting with oxygen and water vapor in the surrounding air. Optimizing its structural design is, therefore, crucial. Currently, two primary types are employed: channel-type and window-type. Channel-type designs often suffer from uneven oxygen distribution due to the vertical flow of air, which can lead to non-uniform current density. In contrast, window-type designs allow for more uniform oxygen and current distribution by exposing the entire cathode to air, making them more widely adopted in AB-PEMFCs.

Optimization efforts have mainly focused on the size and shape of the openings in the current collector. Larger openings enhance oxygen flow and water removal but can reduce contact with the MEA, thereby decreasing the electrochemical performance due to reduced active area. Striking a balance between mass transfer efficiency and maintaining sufficient contact area remains a challenge in optimizing cathode current collector design.

Ying et al. [61] developed a 3D model to assess the impact of cathode current collector opening size on temperature distribution, gas pressure, and fluid flow. They found that larger openings improve water-thermal management, but beyond a certain size, performance gains diminish.

Similarly, Schmitz et al. [62] investigated the influence of rectangular openings in the cathode flow field plate. They found that at low current densities, cell performance was unaffected by the opening ratio. However, at higher current densities, larger opening ratios improved performance due to enhanced oxygen and liquid water transport. Their experiments also showed that higher opening ratios reduced liquid water accumulation on the anode side, improving drainage efficiency. Subsequent studies [57] confirmed that this effect persisted regardless of the GDL’s hydrophobicity.

Bussayajarn et al. [63] examined different opening shapes, including parallel slots, slanted slots, and circular openings, at a fixed opening ratio of 47%. Their findings showed that circular openings yielded the best fuel cell performance, likely due to their shorter rib width and smaller hydraulic diameter. Kim et al. [64] further demonstrated that each opening shape has an optimal opening ratio, with rectangular openings requiring a sufficiently large ratio for effective water removal.

Kumar and Kolar [65] developed a 3D, steady-state, nonisothermal single-phase model to compare channel-type and window-type cathode current collectors. Their results showed that window-type designs enhanced heat and water transport, resulting in superior performance. However, Tabe et al. [66] found that channel-type designs offered better performance due to lower contact resistance in window-type structures. Despite this, the optimal opening ratio for window-type collectors remains undetermined.

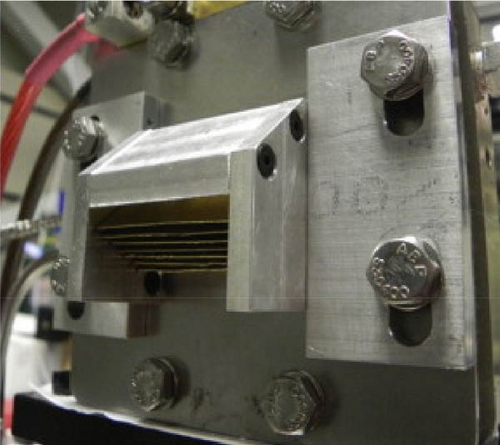

Chun et al. [67] introduced fin-shaped and tubular-shaped top covers on the outer side of the window-type flow field plate (Figure 16). Their research revealed that fin-shaped covers improved heat dissipation, preventing overheating. In further studies [68], they tested various fin-shaped structures at different external temperatures (room temperature, 30, 40, and 50°C), finding that the fin-shaped plates enhanced heat dissipation and performance at 50°C through improved convective heat transfer, though their effect was minimal at lower temperatures.

In summary, optimizing the design of cathode current collectors is crucial for passive water-thermal management in AB-PEMFCs. Window-type collectors generally outperform channel-type ones due to more uniform oxygen distribution and enhanced water removal. Opening size and shape, along with other structural parameters, play a significant role in determining performance, with different operating conditions requiring different optimal values. Additionally, innovative design modifications, such as flow field plate extensions, could further improve the water-thermal management capabilities of AB-PEMFCs by enhancing heat dissipation and water transport efficiency.

6.2. GDL

The GDL plays a crucial role in water-thermal management in AB-PEMFCs by facilitating the exchange of air and water between the environment and the CL. It typically includes an MPL, which aids in water management within the MEA and enhances electrical contact with the CL. Key GDL characteristics, such as thickness, wettability, and material composition, significantly affect AB-PEMFC performance.

Hottinen, Mikkola, and Lund [69] compared two GDLs with varying thicknesses and porosities. One GDL, with higher porosity (78%), exhibited better mass transport at higher current densities, while the lower-resistance GDL performed better at lower current densities due to reduced cell resistance. In a follow-up study [70], three GDL materials—thick carbon paper, carbon cloth, and titanium sinter—were evaluated. Thinner and more compressible carbon paper GDLs showed superior performance at high opening ratios, suggesting that GDL thickness plays a key role in managing oxygen transport and water removal.

Optimizing GDL thickness is essential for balancing water and thermal management. A thinner GDL can lead to membrane drying due to high water discharge rates, while a thicker GDL may cause oxygen depletion and increased thermal resistance, resulting in water flooding. Jeong et al. [26] found that increasing GDL thickness from 100 to 280 μm improved performance, but further increases led to performance declines, likely due to hindered oxygen transport in thicker GDLs.

The influence of GDL thickness was further explored by Schmitz et al. [62] and Tabe et al. [66]. Both studies indicated that thicker GDLs reduce limiting current due to longer oxygen diffusion paths, especially in fuel cells with window-type current collectors, where thicker GDLs can mitigate pressure distribution issues and lower cell resistance. However, for channel-type collectors, GDL thickness had a minimal effect on cell resistance due to more uniform contact pressure distribution.

Calili et al. [71] used a dynamic model to study the impact of GDL thickness and thermal conductivity on both dynamic response and steady-state performance. Their findings emphasized the importance of an optimal GDL thickness to improve the cell’s load-following ability and reduce dehydration-related losses, enhancing membrane humidification and dynamic performance.

In addition to thickness, GDL material properties such as porosity and wettability also influence fuel cell performance. Studies show that GDLs with lower porosity improve both steady-state and dynamic performance by enhancing membrane humidification and reducing ohmic losses. Wettability, often improved by treating GDLs with polytetrafluoroethylene (PTFE), aids in water removal and prevents cathode flooding. Xiong et al. [72] showed that increasing PTFE content to 15−25 wt% significantly improves GDL gas transport and hydrophobicity.

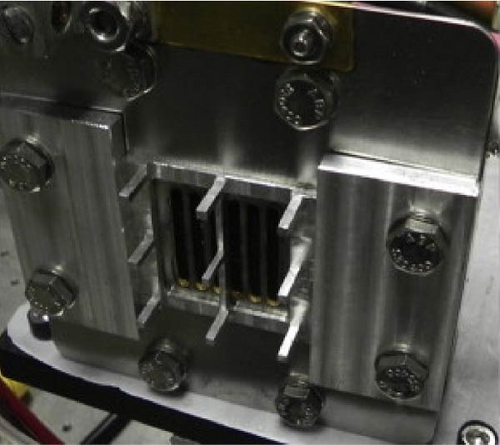

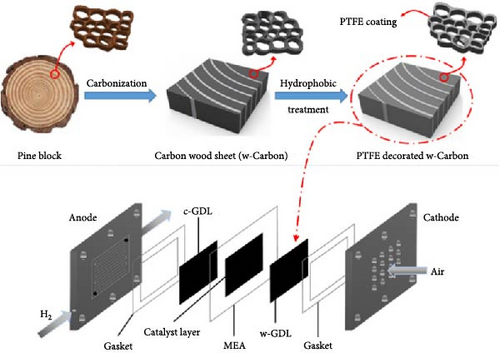

Innovative approaches to GDL design continue to emerge. Dang et al. [73] developed a wood-based GDL treated with PTFE (Figure 17), achieving a peak power density of 102 mW/cm2 at 318 mA/cm2 under 20 wt% PTFE conditions. This highlights the potential for new materials to enhance GDL performance while maintaining effective water-thermal management.

In summary, the design of the GDL, particularly its thickness and wettability, is crucial to optimizing AB-PEMFC performance. A balance can be found between facilitating mass transport, maintaining thermal management, and avoiding membrane drying or flooding. Further optimization of GDL parameters, such as porosity and material composition, will continue to enhance the effectiveness of water-thermal management in AB-PEMFCs.

6.3. Design of Cell Orientation

The orientation of AB-PEMFCs plays a critical role in optimizing performance, as it directly affects heat and mass transfer due to natural convection airflow. Three common orientations are typically considered: vertical (Figure 18a), horizontal facing upward (Figure 18b), and horizontal facing downward (Figure 18c).

Li et al. [75] found that both vertical and horizontally upward-facing orientations improve oxygen concentration on the cathode surface, with experimental results favoring the latter due to enhanced natural convection-driven mass transfer. Similarly, Obeisun et al. [45] observed reduced liquid water accumulation in channels when the cell was horizontally oriented upward. However, most studies indicate that vertical orientation consistently provides the best overall performance [70, 76]. For example, Zhang and Pitchumani [74] demonstrated that vertical orientation optimizes oxygen supply and water removal through buoyancy effects, while Vijay Babu et al. [77] confirmed that vertical orientation offers superior performance for both window-type and channel-type AB-PEMFCs, owing to improved heat transfer and gravity-assisted water removal.

Further studies by Hottinen et al. [69] compared vertically and upward-horizontally oriented single cells, finding comparable performance between the two but with longer stable operation in the vertical configuration. Similarly, Kim et al. [64] suggested that water removal is more efficient in either vertical or upward-horizontal orientations, further supporting the vertical arrangement.

In terms of thermal management, Ismail et al. [60] developed a 2D thermal model to examine how orientation affects heat dissipation. Their findings confirmed that vertical and upward-horizontal orientations provide better heat dissipation compared to downward-horizontal orientations. This was consistent with the results of Kumar and Kolar [65], who conducted a numerical investigation on the impact of orientation for both window-type and channel-type cells. Their results showed a significant performance reduction for channel-type cells when deviating from the vertical orientation. For window-type cells, performance decreased notably when the cathode faced upward but remained close to optimal when facing downward.

In summary, cell orientation in AB-PEMFCs significantly affects performance through its influence on heat and mass transfer. Vertical and upward-horizontal orientations consistently deliver better results, with the vertical orientation typically being the most effective. Nonetheless, the difference in performance between these two orientations is often minimal, particularly in specific operational conditions, where either could be adopted depending on design preferences or constraints [69].

7. Discussion and Recommendations for Future Work

Water-thermal management in AB-PEMFCs can be addressed through two key areas: the factors affecting water and thermal distribution and the latest optimization approaches. These factors provide insight into the water-thermal characteristics, helping to define optimal operating conditions. Building on this, optimization methods aim to passively manage water and heat by controlling structural elements. Given the early stage of AB-PEMFC development, current research has limitations, offering opportunities for further advancements.

7.1. Limitations and Directions for Water-Thermal Distribution Factors

Research on water-thermal management in AB-PEMFCs is limited due to their early-stage development and lack of auxiliary systems. Most studies focus on internal structures, often overlooking the critical operational parameters necessary for effective management. To optimize AB-PEMFCs for commercial use in portable devices and harsh environments, greater emphasis could be placed on stack-level optimization strategies.

One key theme in the literature is the interdependence of water and thermal management, which underscores the close relationship between passive water management and temperature dynamics. A comprehensive understanding of how temperature variations affect water management strategies is essential. Future studies are encouraged to consider this relationship, as neglecting either factor could diminish the practical value of the findings.

Furthermore, research on water-thermal management primarily emphasizes external factors, such as temperature, humidity, and air flow rate. Among these, air flow velocity has been shown to significantly impact water and thermal management, suggesting a promising avenue for future exploration. However, there is still limited research on internal operational parameters, such as current, voltage, and internal pressure, and their effects on water-thermal management. Therefore, enhancing our understanding of both external and operational factors is crucial for optimizing management strategies.

Environmental humidity significantly affects the performance of AB-PEMFCs by playing a dual role in both mitigating flooding and preventing membrane dehydration. This duality illustrates the complex relationship between humidity and fuel cell performance. While some studies advocate for active water management techniques to control these effects, such approaches often introduce additional complexity that may undermine the competitiveness of AB-PEMFCs. Therefore, it is crucial to develop flexible water management strategies that can effectively adapt to fluctuating environmental conditions.

Additionally, while AB-PEMFCs share similarities with traditional PEMFCs, differences in their operational parameters can lead to contrasting performance outcomes. For instance, findings indicate that the porosity of the GDL affects AB-PEMFC performance differently than it does in PEMFCs. This divergence highlights the necessity for caution when extrapolating data from PEMFC research to AB-PEMFC contexts, as understanding these component-specific differences is crucial for optimizing AB-PEMFC performance.

7.2. Limitations and Directions of Water-Thermal Management Optimization Design

The design of the MPL on the cathode side is critical, as an inadequately designed MPL can exacerbate water accumulation issues. While current research primarily focuses on optimizing MPL thickness, exploring additional parameters such as porosity and contact angle could yield further improvements in water-thermal management. These micro-level optimizations are essential as they directly influence the overall performance of the AB-PEMFCs.

Moreover, the orientation of AB-PEMFCs significantly influences their performance. Configurations such as vertical or upward-horizontal enhance water drainage and heat dissipation. This practical insight suggests that, in addition to MPL design, the physical configuration of the fuel cell could also be taken into account to optimize performance.

Given the inherent challenges of passive water-thermal management in AB-PEMFCs, establishing an ideal distribution of water and heat at the macroscopic level remains problematic. Additionally, controlling the micro-level processes such as electro-osmotic drag, back diffusion, and thermal buoyancy is complex. Understanding both micro and macro aspects is crucial, as it provides a comprehensive view of the challenges faced in effective water-thermal management. Nonetheless, the potential of AB-PEMFCs in portable applications necessitates a deeper understanding of stack-level water-thermal management. Leveraging extensive experimental data alongside advanced artificial intelligence methodologies presents a promising direction for future research, which could facilitate breakthroughs in optimizing AB-PEMFC performance and expanding their application range in larger power systems.

Nomenclature

-

- AB-PEMFC:

-

- Air-breathing proton exchange membrane fuel cell

-

- BOP:

-

- Balance of plant

-

- CCL:

-

- Cathode catalyst layer

-

- CGC:

-

- Cathode gas channel

-

- CL:

-

- Catalyst layer

-

- FCOC-PEMFC:

-

- Forced-convection open cathode proton exchange membrane fuel cell

-

- GDL:

-

- Gas diffusion layer

-

- MEA:

-

- Membrane electrode assembly

-

- MPL:

-

- Microporous layers

-

- OC-PEMFC:

-

- Open-cathode proton exchange membrane fuel cell

-

- PEM:

-

- Polymer electrolyte membrane

-

- PEMFC:

-

- Proton exchange membrane fuel cell

-

- PTFE:

-

- Polytetrafluoroethylene

-

- TPB:

-

- Triple phase boundary.

Ethics Statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Disclosure

The authors confirm that there are no financial or personal relationships with other people or organizations that could inappropriately influence (bias) this work.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Siqi Huang: conceptualization, methodology, investigation, validation, writing–original draft, writing–review and editing. Yinghua Zhao: software, formal analysis, resources. Xiaoyu Wang: formal analysis, investigation, data curation. Jingwu Shi: resources, visualization. Shouwen Yao: methodology, validation, writing–review and editing, supervision, project administration, funding acquisition. All authors have approved the manuscript and agree with its submission to International Journal of Energy Research.

Funding

The authors declare that no specific grant from any funding agency in the public, commercial, or not-for-profit sectors was received for the preparation of this manuscript. The research, data collection, and manuscript writing were conducted independently by the authors without financial support from any external organization or institution.

Acknowledgments

The authors have nothing to report.

Open Research

Data Availability Statement

All data supporting the findings of this study are publicly available and have been properly cited in the manuscript. The data were obtained from previously published studies and can be accessed through the references provided. Any additional information regarding the data can be requested from the corresponding author.